Enviro Solutions, a leading gas analyzer manufacturer, is at the forefront of environmental innovation.

Don't wanna be here? Send us removal request.

Text

Maximizing Industrial Combustion Efficiency and Safety with Zirconia Oxygen Analyzers

Why Oxygen Monitoring Matters in Industrial Combustion

In today’s industrial world, efficiency, safety, and environmental compliance are not just goals—they’re non-negotiable demands. Whether you're managing a power plant, refinery, or cement kiln, maintaining the right air-fuel ratio is the cornerstone of performance. This is where zirconia oxygen analyzers come in, offering real-time data that optimizes combustion and slashes emissions.

The Science Behind Zirconia Oxygen Analyzers

Zirconia oxygen analyzers use a ceramic sensor made from zirconium dioxide, which conducts oxygen ions at high temperatures. This enables the sensor to measure oxygen levels based on the difference in oxygen concentration between ambient air and flue gas. The result? A rapid, accurate voltage signal that represents real-time oxygen concentration.

This precision is critical for combustion control. Unlike traditional oxygen sensors, zirconia-based systems respond within seconds, allowing instant adjustments that save fuel, reduce emissions, and prevent dangerous operating conditions.

Improve Efficiency by Controlling Excess Air

Every industrial combustion system requires a bit of “excess air” to ensure complete fuel burn. However, too much excess air simply heats unused gases, wasting energy. Every 1% of excess oxygen can increase fuel usage by 0.5–1%. Zirconia oxygen analyzers allow you to operate much closer to the ideal combustion point. The result? More heat, less waste, and lower operational costs.

Reduce Emissions for Compliance and Sustainability

Incorrect oxygen levels lead to two major issues—CO formation from incomplete combustion and NOₓ formation from excess oxygen at high flame temperatures. By constantly monitoring and maintaining ideal oxygen levels, zirconia analyzers minimize both of these pollutants, helping your facility stay compliant with regulations like the EU’s Industrial Emissions Directive or the U.S. EPA standards.

Boost Safety in High-Temperature Systems

Safety is paramount. In furnaces and boilers, a sudden drop or spike in oxygen can indicate leaks, blockages, or incomplete combustion. With zirconia analyzers providing fast alerts, operators can take immediate action to avoid hazards like explosive gas buildup or overheating.

Reduce Maintenance and Extend Equipment Life

Poor combustion control can cause soot buildup, corrosion, and thermal stress. These problems reduce the lifespan of expensive equipment like heat exchangers and boilers. By maintaining stable combustion conditions, zirconia oxygen analyzers protect your system, lower maintenance needs, and reduce unplanned shutdowns.

Applications Across Key Industries

From coal-fired power plants to cement kilns, and from petrochemical heaters to waste incinerators, zirconia oxygen analyzers are the go-to choice for combustion optimization. Their durability, speed, and precision make them indispensable in:

Power generation

Oil and gas refining

Iron and steel manufacturing

Glass and ceramics

Pulp and paper mills

Cement and lime kilns

The Bottom Line: A Smart Investment in Performance

If your combustion process relies on guesswork or delayed sampling, you're leaving money and safety on the line. Zirconia oxygen analyzers deliver the real-time precision your process needs to thrive—maximizing efficiency, enhancing safety, and securing environmental compliance.

“In any industry where combustion drives productivity, real-time oxygen analysis isn’t just helpful—it’s essential.”

Looking to future-proof your operations? Start with smarter combustion monitoring. A zirconia oxygen analyzer is more than a sensor—it’s your combustion system’s brain.

0 notes

Text

Why Emission Gas Analyzers Are the Backbone of Industrial Air Quality Monitoring

If you're managing or operating in an industrial facility, you're likely no stranger to the pressure of environmental compliance. Regulatory bodies around the world are tightening the screws on emissions—making it more difficult to meet standards using outdated, manual, or limited monitoring systems. That’s where emission gas analyzers come in.

These advanced systems don't just check boxes for compliance—they give you the power to optimize your operation, reduce environmental impact, and stay ahead in an increasingly eco-conscious world.

The Modern-Day Challenges in Emissions Monitoring

Let’s face it—monitoring emissions today is not what it used to be. Whether you're in power generation, cement production, refining, or waste management, you're likely facing:

Stricter emission limits for gases like NOx, SO₂, CO, and particulate matter

Highly variable gas compositions due to process changes

Harsh conditions that can damage traditional analyzers

Outdated systems with no digital integration

Increased pressure for transparency from regulators and the public

These challenges make it clear: monitoring emissions with precision is no longer optional—it’s essential.

How Emission Gas Analyzers Deliver Accurate Results

Emission gas analyzers are built for real-time, high-accuracy measurements. These systems operate continuously and automatically, giving you a detailed picture of what your facility is emitting—minute by minute. Whether it's NOx, SO₂, CO, CO₂, or even hazardous gases like HCl and NH₃, these analyzers detect and quantify them with precision.

And that’s not all—they also come with self-calibration features, diagnostic tools, and remote monitoring capabilities, so you can stay informed and take corrective action before it becomes a problem.

Why It Matters Across Industries

Different industries have different emissions profiles—but they all need reliable gas analyzers:

Power Plants: Optimize combustion and meet strict EPA regulations

Cement & Steel: Handle high-temperature and dust-heavy emissions

Chemical & Petrochemical: Monitor volatile and hazardous gases

Oil & Gas: Detect leaks and ensure community safety

Waste Incineration: Track complex gases from unpredictable waste streams

These analyzers provide the data you need to stay in control and compliant.

Emission Monitoring Meets Sustainability

Here’s the truth: compliance is just the beginning. Emission gas analyzers also support your sustainability goals. By optimizing combustion and reducing excess fuel use, you’re not just cutting costs—you’re cutting CO₂. Many systems can also help with greenhouse gas inventory reporting, supporting global ESG frameworks like CDP, ISO 14064, and GRI.

Plus, with real-time emissions visibility, you gain trust and transparency—something regulators, investors, and communities now expect from every modern industrial player.

The Bottom Line

Emission gas analyzers are no longer optional. They're essential tools for any industry that takes environmental responsibility seriously. They offer more than just compliance—they offer data-driven insight, efficiency gains, and a stronger path toward sustainability.

In a world that’s moving toward net-zero and carbon transparency, having the right emission monitoring system isn’t just smart—it’s strategic.

0 notes

Text

How Does a Flue Gas Analyzer for a Boiler Enhance Efficiency and Safety?

In today's industrial world, boiler systems are the heartbeat of many operations. Yet, without proper monitoring, they can waste energy, harm the environment, and even pose safety hazards. That’s where flue gas analyzers come in. These compact yet powerful tools offer real-time insight into boiler performance, helping industries achieve higher efficiency and safer operations.

Why Flue Gas Analysis Matters for Boilers

Boilers burn fuel—natural gas, oil, or coal—to generate heat. But the combustion process also produces flue gases like CO₂, CO, NOₓ, and SO₂. These aren’t just emissions; they’re indicators of how well your boiler is working.

A flue gas analyzer monitors these gases to:

Detect incomplete combustion (high CO levels)

Reduce excess air (monitored via O₂ levels)

Improve combustion efficiency (by analyzing CO₂)

Ensure safety (by warning about toxic gases)

Meet environmental regulations (through NOₓ and SO₂ tracking)

By interpreting flue gas data, operators can fine-tune combustion, save on fuel, and reduce emissions.

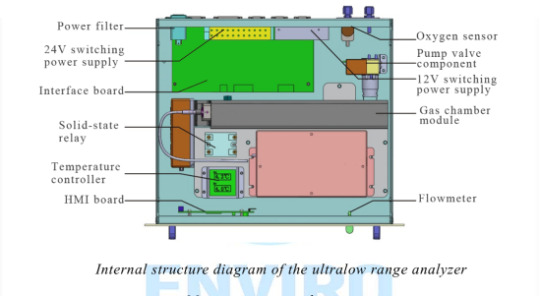

The Essential Components of a Flue Gas Analyzer

Modern flue gas analyzers, like those from ESEGAS, use advanced technologies to provide reliable, accurate readings. Their main components include:

Sampling Probe and Filters: To draw in gases while removing particulates and moisture.

Gas Chamber and Sensors: Using UV-DOAS or NDIR technology, these measure key gases with precision.

Control Interface: Operators interact via touchscreens or digital systems, often integrated with DCS/BMS.

Flow and Temperature Control: Stability in gas flow and internal conditions ensures accurate measurements.

These instruments are designed for durability, ease of use, and minimal maintenance, making them ideal for industrial use.

What Gases Are Measured—and Why It Matters

Each measured gas tells a story:

Oxygen (O₂): Too much means wasted energy; too little signals inefficient burning.

Carbon Monoxide (CO): A red flag for incomplete combustion and a safety hazard.

Carbon Dioxide (CO₂): Higher levels usually indicate efficient combustion.

Nitrogen Oxides (NOₓ): Regulated pollutants formed at high temperatures.

Sulfur Dioxide (SO₂): Especially relevant for oil and coal-fired boilers.

Understanding these gases helps operators adjust air-to-fuel ratios, avoid equipment wear, and meet emissions regulations.

Choosing the Right Flue Gas Analyzer

Not all analyzers are built the same. When selecting one for your boiler, consider:

Type of boiler (residential, commercial, industrial)

Measurement range and sensitivity

Durability under harsh conditions

Ease of calibration and maintenance

Compliance with industry standards

A high-quality analyzer will adapt to your boiler’s specific needs and provide years of dependable service.

Looking Ahead: Smart Monitoring and Sustainability

Tomorrow’s boilers will be smarter, more connected, and greener. Integrating your flue gas analyzer with Building Management Systems (BMS) allows for:

Automated adjustments to combustion settings

Centralized monitoring across facilities

Cloud-based data analysis for predictive maintenance

AI-powered diagnostics for early fault detection

With tightening regulations and global calls for sustainability, investing in a robust flue gas analyzer is not just smart—it’s essential.

Final Thought: If your goal is to maximize efficiency, reduce emissions, and protect both workers and the environment, a flue gas analyzer isn’t optional—it’s a necessity. Start monitoring your boiler the smart way, and stay ahead of tomorrow’s energy and safety demands.

0 notes

Text

Why Portable Gas Analyzers Are a Must-Have for Industrial Safety

When lives, equipment, and entire facilities are on the line, fast gas detection isn’t a bonus—it’s critical. In high-risk environments like oil refineries, chemical plants, and wastewater treatment facilities, portable gas analyzers are becoming the go-to safety tools. Why? Because unlike fixed systems, they go where you go—and save lives doing it.

Fixed Detectors Can’t Cover Everything

Sure, fixed gas detectors are reliable, but they’re stuck in place. If a leak happens in a blind spot—or in a place people don’t normally access—you might not know until it’s too late.

That’s where portable gas analyzers come in. These handheld devices can detect multiple gases instantly, giving teams the ability to check for dangerous atmospheres wherever the job takes them—from pipelines and tunnels to storage tanks and confined spaces.

Real-Time Detection, Real-World Safety

Portable gas analyzers, especially those designed by ESEGAS, offer:

Real-time gas detection

Fast response (under 10 seconds)

Multi-gas monitoring (CH₄, H₂S, CO, O₂, SO₂, and more)

Data logging and wireless alerts

Rugged design for extreme industrial environments

They’re built for movement, built for emergencies, and built to keep workers safe.

Spot Checks Without Shutdowns

When maintenance teams need to inspect pipelines or equipment, they can’t afford to shut down the entire plant for a reading. ESEGAS portable analyzers let workers carry out spot checks instantly, without interrupting operations. That means less downtime, faster decisions, and safer results.

Where Are Portable Gas Analyzers Essential?

If your workplace includes any of the following environments, you need portable gas analyzers:

Oil & Gas: During pipeline inspections, tank cleaning, or leak detection.

Chemical Plants: When handling VOCs, ammonia, or chlorine.

Mines and Tunnels: For real-time methane and CO checks.

Wastewater Plants: Where H₂S and CH₄ are common.

Confined Spaces: Silo, tank, or ship entry where air quality can change instantly.

Power Generation Units: For boiler room entry and turbine inspection.

In each of these cases, mobility is key. If you can’t bring the danger to the detector, bring the detector to the danger.

Emergency Ready—When Seconds Count

In emergencies like leaks or chemical spills, you can’t rely on fixed systems alone. ESEGAS portable gas analyzers can be deployed in seconds to assess the scene. They provide fast, clear readings that guide emergency response—helping teams decide whether to evacuate, ventilate, or isolate a leak.

These devices also come with loud alarms, vibration alerts, and easy-to-read displays—so even in noisy, low-visibility situations, your team stays informed.

Why ESEGAS?

ESEGAS is trusted across multiple industries for their rugged, certified, and highly accurate portable analyzers. With ATEX and IECEx certifications, their devices are built for use in hazardous zones and critical moments.

Final Thoughts

In today’s fast-moving industrial world, fixed systems alone won’t cut it. Portable gas analyzers give you real-time insights, mobility, and peace of mind. When safety depends on speed and flexibility, trust devices that are built to go the distance.

0 notes

Text

Fermentation Control Unlocked: Real-Time CO₂ Monitoring for Next-Level Production

Why CO₂ Monitoring Matters in Fermentation

CO₂ isn’t just a byproduct—it’s your fermentation storyteller. Tracking carbon dioxide gives instant insight into microbial activity, allowing you to optimize timing, prevent overpressure, and catch bugs before they ruin a batch.

How NDIR CO₂ Analyzers Work Their Magic

Non-Dispersive Infrared (NDIR) is the gold standard for precise CO₂ measurement. A light beam travels through tank gas, CO₂ absorbs specific IR wavelengths, and a detector reads the change—translating it into accurate concentration data in seconds.

Benefits You Can Taste

Instant Feedback – CO₂ readings in <5 seconds mean smarter, quicker adjustments.

Built for Fermentation – Condensation-proof optics, corrosion-resistant enclosures, and heated sample paths keep things running smoothly.

Low Maintenance – With self-calibration and rugged design, it just works—even in humid, ethanol-rich tanks.

Smart Integration – Outputs like 4–20 mA and Modbus plug right into SCADA or PLC systems for automated control.

From Lab to Production Scale

Whether you're crafting craft beer or scaling biopharma, CO₂ control is essential. An inline probe gives real-time tank measurements, while an extractive setup works well for high-foam or sterile processes. Use the data to fine-tune temperature, nutrient feed, or aeration in real time.

Real-World Advantages

Consistent Batches: CO₂ curves become your SOP—predictable, repeatable outcomes.

Efficiency Gains: Early batch endpoints trim energy, time, and wasted ingredients.

Safety First: Overpressure alerts keep tanks safe and prevent costly accidents.

Traceability: Digital logs support audits and quality standards—ideal for GMP and food-grade systems ideal.

Ready to Boost Your Fermentation Game?

Stop guessing and start knowing. With ESEGAS CO₂ analyzers, fermentation becomes clearer, easier, and more consistent. Whether your production is small scale or industrial, this tech adapts to your needs.

0 notes

Text

How Infrared Gas Analyzers Transform Environmental Monitoring

Why Traditional Gas Detection Misses the Mark

Ever relied on spotty readings from old-school gas sensors? Chemical tests degrade, moisture sabotages them, and inaccuracies pile up. Traditional methods often fail to capture true pollutant levels over time, leading to delayed actions and compliance issues.

Enter Infrared Gas Analyzers: A Smarter Approach

Infrared gas analyzers use Non‑Dispersive Infrared (NDIR) technology—a fancy way of saying they shine an IR beam through air samples and measure what specific gases absorb. If CO₂ or CO is present, it'll soak up particular infrared wavelengths, allowing the analyzer to detect them precisely. Real‑time, reagent‑free, and non‑invasive—this is next‑gen monitoring in action

Six Advantages

Laser Precision & Selectivity Narrowband optical filters isolate exact gas signatures. No more false readings from humidity or other gases

Speed That Matters Get accurate CO₂ or pollutant levels in seconds—not minutes. Ideal for ever‑changing environments.

Built Tough Designed for harsh field conditions—heat, rain, dust—you name it. Reliable from city smog to landfill plumes.

Low‑Maintenance, High ROI With no chemicals or moving parts, downtime drops. Infrared analyzers deliver years of hands‑off service.

Eco‑Friendly & Safe No toxic reagents means zero hazardous waste. Plus, seamless integration with IoT and 4‑20 mA outputs makes these smart and sustainable.

Real‑World Proven Whether it's urban air stations, incinerators, farmland, or tunnels—Infrared analyzers are already hard at work worldwide

Where They Shine

City Air Monitoring: Keep tabs on CO₂, NOx, SO₂—power your AQI and health alerts.

Industrial Emissions: Root out pollution at chimneys and stacks with CEMS-grade accuracy.

Greenhouse & Landfill Monitoring: Track methane and CO₂ to cut carbon footprints.

Remote or Harsh Sites: Arctic tundra? Urban canyons? These analyzers thrive there.

Tunnel & Underground Safety: Detect CO build-up where airflow is poor.

Ready to Upgrade Your Monitoring Game

Stop tolerating unreliable, slow gas detection. Infrared gas analyzers give you real‑time insights, fewer headaches, and cost savings—plus cleaner, safer operations.

If you’re interested in seeing one of these powerful tools in action or want help choosing the right model, I’d love to talk! Let’s make your air smarter and your impact cleaner.

0 notes

Text

ESEGas CO Gas Analyzer: Your Trusted Solution for Accurate Combustion Gas Monitoring

Why You Need a Reliable CO Gas Analyzer in Your Facility

Carbon monoxide (CO) is an invisible yet dangerous gas that can pose serious health and safety risks in industrial environments. That’s why having a reliable CO gas analyzer isn’t just a smart investment—it’s a necessity. Whether you're running a boiler, furnace, or chemical processing unit, accurate CO monitoring is vital to protect your team and meet environmental standards.

What Makes a Carbon Monoxide Gas Analyzer Essential?

A carbon monoxide gas analyzer helps detect and quantify CO levels in combustion systems and process gases. This not only enhances safety but also improves fuel efficiency, reduces emissions, and ensures regulatory compliance. With real-time monitoring, operators can quickly respond to irregularities and maintain optimal system performance.

ESEGas understands the critical nature of CO detection. That’s why we offer combustion gas monitoring solutions that are dependable, user-friendly, and built for demanding industrial applications.

ESEGas Industrial CO Gas Analyzer: Designed for Performance

When reliability matters, ESEGas delivers. Our industrial CO gas analyzer is engineered using advanced sensor technology to ensure precise and consistent readings, even in harsh operating conditions. With rugged construction and intelligent diagnostics, our analyzer supports continuous operation with minimal maintenance.

It’s ideal for use in:

Power plants

Petrochemical refineries

Cement kilns

Waste incineration facilities

Manufacturing and process industries

This carbon monoxide gas analyzer is not just a monitoring tool—it’s a critical safety asset that empowers operators with real-time data.

Combustion Gas Monitoring Solutions You Can Count On

Accurate combustion control starts with reliable data. ESEGas provides comprehensive combustion gas monitoring solutions that help you optimize air-to-fuel ratios, reduce operational costs, and minimize harmful emissions.

Our analyzers:

Deliver real-time CO readings

Integrate easily with control systems

Provide early warnings for unsafe conditions

Support energy-efficient combustion management

With ESEGas, you're not just buying a product—you're gaining a performance partner in gas safety and process optimization.

Why Choose ESEGas for Carbon Monoxide Industrial Gas Analysis?

Choosing the right carbon monoxide industrial gas analyzer means choosing peace of mind. ESEGas combines precision engineering with decades of industry expertise to offer gas analyzers trusted by professionals worldwide.

Here’s what sets us apart:

High sensitivity and accuracy

Rugged design for industrial use

Easy calibration and low maintenance

Reliable support and service

Our reliable CO gas analyzer helps industries reduce downtime, avoid fines, and create a safer working environment—all with confidence and clarity.

Conclusion: Make Safety and Efficiency Your Standard

Don’t take chances with CO detection. Invest in a reliable CO gas analyzer from ESEGas and ensure your facility meets the highest standards of safety, efficiency, and compliance. With powerful combustion gas monitoring solutions, our carbon monoxide gas analyzer empowers you to manage risk and drive performance.

Trust ESEGas—your partner in reliable, industrial-grade carbon monoxide industrial gas analyzer solutions.

#gas analysis#gas analysis systems#co2 gas sensors#ndir technology#gas detection#gas analysis system

0 notes

Text

Industrial ultrasonic flow meter for stack emission control

Ese Gas brings you an industrial ultrasonic flow meter for stack emission control designed for accurate, non-intrusive gas flow measurement. Ideal for monitoring emissions in industrial exhaust systems, this high-performance device ensures compliance with environmental standards while maintaining long-term reliability in high-temperature and high-flow conditions.

#gas analysis system#gas sensors#gas detection#gas analysis systems#gasemissions#gas monitoring system

0 notes

Text

Portable Infrared Syngas Analyzer

If you are looking for a Portable Infrared Syngas Analyzer, ESEGas offers the ideal solution for accurate, on-site gas monitoring. Designed for efficiency, our analyzer delivers high stability and real-time results. Perfect for industrial applications, it ensures reliable detection of CO, CO₂, CH₄, and H₂ with advanced infrared technology.

0 notes

Text

Portable laser gas analyzer online

Experience unmatched precision with our Portable Laser Gas Analyzer Online. Designed for real-time, high-accuracy detection, it ensures industrial safety and efficiency. Ideal for emission monitoring and hazardous gas detection, it offers a lightweight, user-friendly design with cutting-edge laser technology. Get instant, reliable readings anytime, anywhere. Optimize your operations today!

0 notes

Text

Zirconia oxygen reliable gas monitoring system

Find a Zirconia oxygen reliable gas monitoring system designed for accurate and continuous oxygen measurement in industrial processes. Esegas offers advanced technology for enhanced efficiency, safety, and compliance. Ensure optimal combustion control and emission monitoring with our dependable gas analysis solution specific for demanding applications.

0 notes

Text

Flue gas emission analyzer for industrial gas monitoring

Get accurate emissions data with our flue gas emission analyzer for industrial gas monitoring. Designed for precision, it ensures regulatory compliance and optimal efficiency. Monitor CO, CO₂, NOx, and more in real time, reducing environmental impact and improving process control. Enhance safety and performance with advanced gas analysis technology.

0 notes

Text

NDIR Air Quality Monitoring Gas Sensors

NDIR air quality monitoring gas sensors provide accurate and reliable gas detection for industrial and environmental applications. Using advanced infrared technology, these sensors ensure precise process gas analysis, optimizing emissions control and air quality monitoring. With long lifespan and low maintenance, NDIR air quality gas sensors enhance safety and regulatory compliance.

0 notes

Text

Emissions NOx Gas Analyzer

We are bringing you the Emissions NOx Gas Analyzer, designed for precise and continuous monitoring of nitrogen oxides in industrial emissions. Ensure regulatory compliance, enhance environmental safety, and optimize combustion processes with our reliable, high-accuracy analyzer. Trust our advanced technology for efficient NOx gas detection and emissions control.

#gas analysis system#co2 gas sensors#co2 gas#gas monitoring system#oxygenmonitoring#gas analysis systems

0 notes

Text

Ceramic Sensing Zirconia Oxygen Humidity Analyzer

The Ceramic Sensing Zirconia Oxygen Humidity Analyzer provides precise oxygen and humidity measurements using advanced ceramic zirconia sensors. Designed for high-temperature environments, it ensures accurate monitoring, enhanced combustion efficiency, and regulatory compliance. Its durable construction and real-time data capabilities make it ideal for industrial applications requiring reliable gas analysis.

#gas analysis system#gas sensors#gas analysis systems#gas monitoring system#ndir technology#co2 gas sensors

0 notes

Text

Enhancing Industrial Efficiency with Zirconia Oxygen Analyzers

📌 Accurate oxygen measurement is essential for industrial efficiency, safety, and compliance. Zirconia oxygen analyzers offer high precision, durability, and real-time monitoring for industries such as power generation, metallurgy, and environmental control. Learn how this advanced technology optimizes industrial processes.

Read more for further information : Zirconia oxygen analyzers

0 notes

Text

Advanced SO₂ Gas Analyzer for Industrial Emission Control

The ESEGAS SO₂ Gas Analyzer delivers precise sulfur dioxide detection for various industrial applications. Designed for real-time monitoring, it ensures compliance with environmental standards while optimizing process efficiency. Its durable build, high sensitivity, and advanced data integration make it a reliable solution for emission control and workplace safety.

0 notes