Text

Flashforge AD5X Multicolor CoreXY 3D Printer: A Deep Dive for the US Market

The 3D printing scene in the United States is evolving rapidly, with both hobbyists and professionals searching for affordable, reliable, and feature-rich printers. The Flashforge AD5X Multicolor CoreXY 3D printer, priced around $430, enters the market as a cost-effective multicolor solution. But how does it stack up against established competitors, and is it the right choice for US users? Here’s an in-depth look at its features, challenges, and how it compares to other popular options.

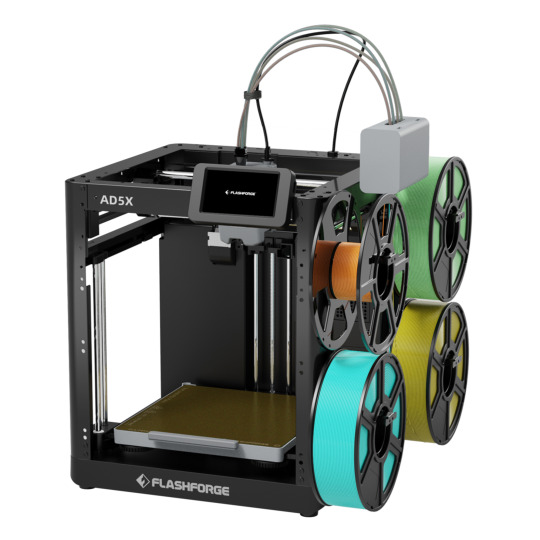

Product Overview and Setup

The Flashforge AD5X offers a build volume of 220 x 220 x 220 mm, making it suitable for a wide range of projects. Its standout feature is the integrated multicolor system, included at a price point lower than many rivals. Unlike some early-release models, the AD5X ships as a fully finished product, not a prototype.

What’s in the Box?

Generous accessory bundle, including specialized spool holders.

Open spool holder design (not an enclosed filament box), which may be less ideal for dusty environments.

Quick and straightforward final assembly—most users can get printing within minutes.

Technical Features

The AD5X is equipped with several modern 3D printing technologies:

Intelligent Multicolor Filament Switching (IFS) for automatic material changes, similar to other leading systems.

Auto bed leveling and Z-offset for easier setup and calibration.

Vibration compensation to improve print quality.

WiFi and LAN connectivity for remote monitoring and control.

A mobile app is available, though its features are currently limited.

Software Experience

One of the AD5X’s major pain points is its software. The included Orka Flashforge Slicer is plagued by installation bugs, a confusing interface, and frequent server disconnects. On-device controls also suffer from unclear icons and missing features. This can be frustrating, especially for beginners who expect a smooth, intuitive experience.

Print Quality and Technical Challenges

The AD5X delivers mixed results in terms of print quality:

Decent output thanks to features like auto-leveling and vibration compensation.

Lacks adaptive mesh leveling, making it less forgiving of bed imperfections.

Users report frequent layer shifts and nozzle clogs, often due to inadequate cooling (a problem known as “heat creep”).

Spool Holders and Filament Handling

The included spool holders only fit spools with an internal diameter of 52 mm or larger, which excludes many common brands in the US. The open, hanging design can also cause feeding issues and slower filament changes compared to competitors. Flashforge has announced improved spool holders for future batches, but current users may need to improvise or purchase third-party solutions.

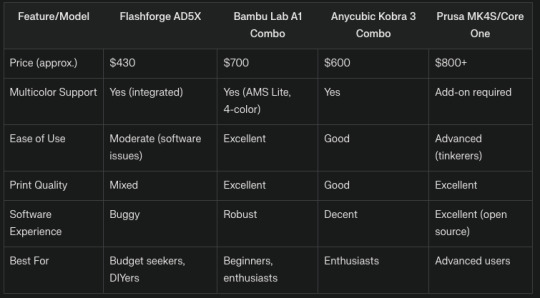

How Does It Compare? US Market Alternatives

The US 3D printing market is highly competitive, with several standout options for multicolor and CoreXY printing:

The Bambu Lab A1 Combo is widely praised for its ease of use, fast setup, and excellent print quality, especially for multicolor projects. It’s ideal for beginners and anyone wanting a hassle-free experience.

The Anycubic Kobra 3 Combo offers reliable performance and multicolor capabilities, though not as refined as the Bambu Lab A1 Combo.

The Prusa MK4S/Core One delivers top-tier print quality and open-source support, but at a higher price and with a steeper learning curve.

US Market Considerations

Many US filament brands use smaller spool diameters. The AD5X’s spool holders may require modification or replacement.

Flashforge has a presence in the US, but support and community resources are stronger for brands like Bambu Lab and Prusa.

US users expect polished, reliable software. The AD5X falls short here, making it less attractive for first-time buyers.

Final Verdict

The Flashforge AD5X Multicolor CoreXY 3D printer offers impressive features for the price, especially with its integrated multicolor system. However, software bugs, filament handling quirks, and print reliability issues currently hold it back. For US users—especially beginners or those seeking a plug-and-play experience—alternatives like the Bambu Lab A1 Combo or Prusa MK4S/Core One are more robust, even if they cost more upfront.

Recommendation:

Choose the Flashforge AD5X if you’re a budget-conscious DIYer comfortable with troubleshooting and eager to experiment with multicolor prints.

For a smoother, more reliable experience, especially for beginners or print farms, invest in the Bambu Lab A1 Combo or Prusa MK4S/Core One.

As the US 3D printing market continues to grow, user expectations for reliability, software quality, and support will only increase. Flashforge’s future updates may address current shortcomings, but for now, the AD5X is best suited for tinkerers willing to work around its limitations.

1 note

·

View note

Text

I really love this washing station. Every time I pass by, I wonder why not earlier created this.

Get it here:

How I Built a Game-Changing Motorized Washing and Color Mixer with a 3D Printer

If you’ve ever spent endless hours cleaning or mixing, you’ll appreciate the value of a device that automates these tedious tasks. For years, I believed it would be straightforward to create a motorized washing station and liquid mixer using a 3D printer. Finally, I took the plunge, and the results have revolutionized my workflow. And guess what? You can access the model for free!

The Big Idea

The idea came from a recurring need to degrease and clean various parts efficiently. The traditional manual process felt cumbersome, time-consuming, and often inconsistent. I also wanted to tackle color mixing, a task that was equally time-consuming when done by hand or with conventional mixers. Automating these would not only save time but enhance the quality of the results.

Building the Device

To bring this concept to life, I needed a few essential components:

A 3D Printer: For printing the parts that would house and support the mechanism.

A 12V Motor: This was the power behind the operation, providing the necessary torque to keep things moving.

A DC Motor Speed Controller: Essential for controlling the motor’s speed, ideally around 100 revolutions per minute.

Hardware: A collection of M3 screws and thread inserts to securely assemble the components.

With these tools, the assembly was straightforward. By printing the necessary components and integrating the electronic parts, I constructed a compact yet efficient machine.

How It Works

The operation of this device could not be more straightforward. Simply add some alcohol or your chosen liquid cleaner into a canister, place it within the machine, and let it do its work. By running the device for a few hours, you not only automate the cleaning process but often achieve superior results compared to manual methods.

For color mixing, the device's consistent motion ensures even distribution of colorants, reducing the occurrence of inconsistencies that are common with manual mixing.

User Experience

Having used this device for the past two months, I can’t imagine reverting to the old ways. The ease of use is phenomenal—fill it up, power it on, and leave it to handle the rest. The results? Most of the time, my parts come out pristine and sparkling clean, free of any rust or grime.

Why It's a Game Changer

This DIY project has saved me countless hours and immeasurable effort. By automating a labor-intensive process, I’ve been able to focus on more strategic aspects of my projects. Plus, the satisfaction of building a personal productivity tool fills me with pride and a sense of accomplishment.

Try It Yourself

Interested in building your own motorized washing station and color mixer? I invite you to download the 3D model for free and give it a try. It's a wonderful story of how creativity, technology, and practical application can combine to solve everyday problems.

By embracing the power of 3D printing and basic electronics, you too can revolutionize your workspace with customized tools precisely tailored to your needs. Happy building!

1 note

·

View note