Text

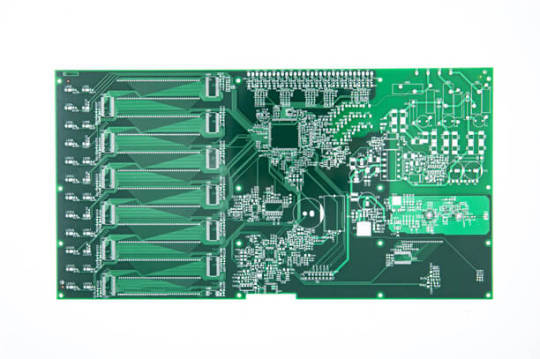

Rigid PCB

https://www.fastlink-electronics.com/products/rigid-pcb/

We can provide you with up to 64 layers, 12oz copper, HDI, high frequency, high TG, flex, MC pcb from prototype to mass production.

Fastlink Electronics offers the highest quality printed circuit boards at the most competitive pricing. Whether you need a few quick-turn PCB prototypes or mass production, our world-class manufacturing can meet your specialized PCB needs.

Combining years of experience with the latest in high-tech manufacturing efficiencies allow our pricing to be among the most competitive. Our boards are manufactured based on IPC guidelines and comply with ISO 9001:2015, UL, and RoHS standards.

What Are The Applications For Rigid PCBS

Rigid printed circuit boards are one of the most common circuit boards in electronic devices and have several typical applications. These include:

Use as motherboards for desktop and laptop computers

File servers and storage devices

It can be found on cell phones and other portable devices

Used in medical devices such as CT scans, x-rays, and pacemakers

Found in automobiles

Used as signal repeaters and GPS for mobile phones and other devices

0 notes

Text

Rigid-Flex PCB

https://www.fastlink-electronics.com/products/rigid-flex-pcb/

Fastlink helps customers finish a lot of projects including smart phone, smart TV, tablet pc, laptop, smart wearable devices, TWS etc. We can produce a maximum 24L rigid pcb plus 8 layer flex pcb.

Rigid-Flex PCB can safely bend into small and complicated electronics, making them suitable for modern devices like smartphones. Because of their good performance in absorbing shock and vibration in high stress environment, they are more and more widely used.

Fastlink Electronics' professional engineers combine standard circuit board construction with flexible design, which is suitable for situations requiring more durability. We have successfully provided our customers with tens of thousands of excellent manufacturing cases of Rigid-Flex PCB.

What Are The Applications Of Rigid-Flex PCBS

Rigid-Flex PCB not only maximizes space and weight but also greatly improves reliability, eliminating many of the needs for solder joints and fragile and fragile wiring prone to connection problems. So the Rigid-Flex PCB is more and more widely used in various fields, from smart devices to mobile phones and digital cameras. Because of its excellent weight reduction ability, the Rigid-Flex PCB is also increasingly used in medical devices such as pacemakers. There are also intelligent control systems and electrical applications, including test equipment, tools, cars, etc,

0 notes

Text

Quick Turn PCB

https://www.fastlink-electronics.com/products/quick-turn-pcb/

2-4 layers can be shipped within 48 hours 6-8 layers can be shipped within 96 hours 10-12 layers can be shipped within 4 working days.

Quick Turn PCB help reduce assembly time when projects need to be completed quickly. Quick Turn PCB services are best suited for low volume, prototype, or new product introduction volume projects.

Fastlink Electronics can make your project complete in a day. Our engineers oversee the design, equipment application and quality inspection process to ensure a streamlined manufacturing process.

What can you get from Fastlink Electronics with Quick turn PCB?

Do you have a lot of PCB requirements in a limited time? In this case, Fastlink Electronics will assist you, we provide high-quality fast transfer PCB at a reasonable price. Kmedic assures you that with us, you will never have to worry about missing deadlines or late deliveries. Our highly skilled engineering team communicates in detail with our customers to ensure that their requirements are met. We serve a wide range of industries and meet the requirements of our global customers. From us, you can get a turnaround time of 24 hours faster depending on your PCB requirements. Although the production time of PCB is very short, the quality of the product can be guaranteed without any problem.

Benefits of Quick Turn PCB

01.

Quick Turnaround Time

The goal of a fast turnaround PCB is to provide solutions in as little time as possible compared to traditional methods, regardless of the complexity of the board. Fastlink Electronics has been working hard to achieve this and prevent unnecessary delays for customers. This allows the client to focus on other important areas of work.

02.

Cost Effective

Another thing Fastlink Electronics can help you in fast PCB transfer with cost savings. In essence, using PCB technology helps reduce manufacturing time, which in turn helps you reduce production costs.

0 notes

Text

Prototype PCB Assembly

https://www.fastlink-electronics.com/products/prototype-pcb-assembly/

Prototype Assembly Specializing in small and medium runs with fast lead-times and no minimum quantity requirements.

Fast delivery time is critical for Prototype PCB Assembly. Fastlink Electronics has a professional team to manage the entire prototype PCB assembly process, including all component procurement, PCB assembly, quality control, functional testing, all the way to the product delivery to your hands.

Turnkey prototype PCB assembly is our specialty. We have professional soldering technicians, component sourcing experts and SMT process engineers, we can provide a reasonable price and highly flexible PCB assembly project, fast turnaround is also one of our big advantage.

What Are The Advantages Of Fastlink Electronics To Do The Prototype Pcb Assembly?

Fast turnaround time

For Prototype PCB Assembly, the most important thing customers need is to receive the perfect product in the shortest possible time. Fastlink Electronics is known for its fast delivery times.

No MOQ, according to your project requirements

We can provide automatic or semi-automatic through-hole assembly service, even if you only need 1pcs prototype PCB assembly, we are equally valued.

Technical Support

We are happy to provide initial consultation via phone or email to all customers who rely on Fastlink Electronics' fast turnaround time, superior customer service, and industry-leading engineering expertise.

Excellent Quality

Fastlink Electronics is fully qualified to manufacture PCB assemblies with lead and RoHS in accordance with IPC-A-610 specifications. We strive to comply with IPC quality standards every time because we know how important it is to keep electrical components as safe and efficient as possible. It is crucial to understand the common pitfalls of through-hole assembly PCBs, and how to avoid them and make durable products.

What Are The Precautions For Prototype Pcb Assembly When A New Product Is Released?

It is easy for changes in design. If you feel that the design doesn't seem right for you, you can easily change it.

It can easily troubleshoot problems. This means you don't have to deal with future errors at a high cost. With a prototype, you can test it over and over again to make sure it works the way you want it to.

It ensures quality, and with Prototype PCB Assembly you can make sure you're using the most efficient technology.

It allows new products to be tested and modified before production begins.

It allows for a shorter time. This is possible because it demonstrates the feasibility of the design and also reduces rework.

It provides the ability to test components individually. This is especially important for complex projects.

0 notes

Text

PCB Prototype

https://www.fastlink-electronics.com/products/pcb-prototype/

The minimum order quantity is 1pcs, protecting customer privacy and respecting product design. We can sign a confidentiality agreement with you.

By using decades of extensive experience, an efficient system, and cutting-edge technology, we are able to provide quick turn services for both simple and complex orders without sacrificing quality.

Fastlink Electronics has the experience and capabilities to create the exact prototype you need. Our experienced engineering staff knows when prototype is manufacturable which can help our clients determine the best materials and variations to hit budgets and manufacturing deadlines.

How Long Does It Take To Design And Customize The Pcb Prototype?

The time to customize a PCB prototype depends on the PCB material chosen and the complexity and number of PCB prototypes. A fast link circuit can help you to complete design and prototype production in the shortest time, we usually help customers save 1-2 weeks.

Benefits of PCB Prototype

01.

Avoid Failures

Prototypes can help analyze PCB design and functionality prior to production. Fastlink Electronics' engineers can anticipate the possibility of failure and help you avoid failure.

02.

Cost Savings

A PCB failure in the final stages of manufacturing can result in a loss of materials, costs, and effort. With us, Fastlink Electronics can analyze the function of the PCB at the beginning of the manufacturing process.

03.

Avoid Mistakes

Prototypes help manufacturers detect potential bugs in PCBS. They can simulate it to understand how it works in a real environment. In this way, PCB manufacturers can avoid the same mistakes and avoid potential bugs in final manufacturing.

0 notes

Text

PCB Layout/DFM

https://www.fastlink-electronics.com/products/pcb-layout-dfm/

Saving time and cost of research and development, helps product launch quickly. Considering also the possibility of mass production.

Helping our customers bring new products to market in a fast, efficient and highly strategic manner is what makes us stand out as an electronic contract manufacturer like Fastlink Electronics.

In the early stages of new design work, Fastlink Electronics strives to mitigate future production barriers and aims to optimize the production capacity of the product while keeping overhead costs low. Based on our actual manufacturing experience in past projects.

Design PCB products especially suitable for PCB assembly equipment and batch manufacturing process for customers.

What Electronics Products Fastlink Electronics has ever Designed For?

Because so many industries use PCBs, they are almost everywhere, from small consumer equipment to large mechanical equipment. Fastlink Electronics has helped our customers from different industries with design work:

Medical Devices such as Medical imaging systems, Monitors, Infusion pumps, and Internal devices

LEDs such as Residential lighting, Storefront lighting, Automotive displays, Computer displays, Medical lighting

Consumer Electronics: Communications devices, Computers, Entertainment systems, Home appliances

Industrial Equipment: Manufacturing equipment, Power equipment, Measuring equipment

Automotive Components: Entertainment and navigation systems, Control systems, Sensors

Aerospace Components: Power supplies, Monitoring equipment, Communication equipment

Maritime Applications: Navigation systems, Communications systems, Control systems

Safety and Security Equipment: Security cameras, Smoke detectors, Electronic door locks, Motion sensors, and burglar alarms

Telecommunications Equipment: Telecom towers, Office communications equipment, LED displays, and indicators

Military and Defense Applications: Communications equipment, Control systems, Instrumentation

If DFM is Not Implemented Properly, These Unwanted Problems Can Potentially Arise During Volume Circuit Board Assembly and Manufacturing Operations:

Excessive production costs

Undesirable quality issues

Problems with functional test

Increased risk of inadequate quantity yields

0 notes

Text

PCB Box Build Assembly

https://www.fastlink-electronics.com/products/pcb-box-build-assembly/

Fastlink provides one-stop Box Build assembly including Product Assembly, Cable Assembly and System Assembly and various testings for customer final requirements.

PCB Box Build Assembly includes us assembling various PCBS, connecting them through various cabling and other cables. The process involves making the PCB, installing it, and then connecting all the components with various wires and cables to get a complete system. This system has many sub-components and many other electronic components installed in the components.

Fastlink Electronics has a professional customer service team, in the face of diverse needs of customers, we are always able to provide perfect solutions, we have rich experience in PCB box assembly, to meet the needs of customers, let the world redefine the made in China is our mission.

What does the Box Build Assembly Services Include?

At the core of any electronic manufacturing, service comes design, manufacturing, testing, and marketing. Fastlink Electronics will perform these functions, which may also include assembling complete systems for OEMs. Designed to provide complete solutions for our customers. In this respect, Fastlink Electronics is trusted by our customers, who always turn to us for help no matter what their needs are.

For example, by offering systems integration or "box build" services -- Fastlink Electronics can use a process to assemble printed circuit board components, wiring harnesses, package manufacturing, testing, and more.

0 notes

Text

Multilayer PCB

https://www.fastlink-electronics.com/products/multilayer-pcb/

Manufacturing multilayer PCB up to 64 layers, IPC III Standard, Multilayer Rigid PCB, Multilayer Flex PCB, Rigid-flex Board, hybrid PCB.

Over the past decade, the production of complex multi-layer PCB has been the cornerstone of The competitive advantage of FastLink electronics. We continue to invest in RESEARCH and development, equipment and engineering expertise to improve our technology and capabilities. Fastlink Electronics provides NPI with early prototypes of new products to help achieve high volume production. We do all the necessary operations in a production deployment environment to ensure you produce the quantity you need in the shortest possible time.

What Are The Applications Of Multilayer PCBs?

Multilayer printed circuit boards (PCBs) bring you greater flexibility, allow for greater circuit density, and reduce board size. They are widely used in various fields:

Computers and Laptops

Telecommunications Equipment – Mobile Phone, Tablets, and other Hand Help Devices

File server and Data storage

Signal transmission, mobile phone repeaters, GPS

Satellite

Medical Equipment: Testing, X-Ray, Heart Monitor, CAT Scan

Industrial Equipment

Atomic and Nuclear Systems

Military and Defense Equipment

Automotive

Aerospace

Anywhere, where complex Circuitry is needed.

Benefits of Multilayer PCB

01.

Increased Functionality And Capabilities

By compounding multilayer boards, you can effectively increase the functionality and capabilities of printed circuit boards. With more layers, you can fit more circuits and lines onto the board.

02.

More Flexible

Can be made rigid or flexible - These multi-layer PCB can be made rigid or flexible configurations, depending on your requirements. However, the more layers you add to the board, the less flexible it becomes.

03.

Smaller Sizes

This saves space when you stack layers on top of each other. Multiple layers allow you to have a higher capacity with a smaller footprint, which may benefit smaller devices.

04.

Lighter Weight

Due to the layered configuration of these PCB boards, it does not require a separate PCB connector. This simplifies the manufacturing process, which not only saves space, but also reduces the overall weight of the board.

1 note

·

View note