FIBER-MART based in Hong Kong & U.S., a worldwide leading supplier in a fiber-optic network, FTTx, fiber cabling & connectivity, fiber testing, fiber splicing, fiber polishing & integrated network solutions.

Don't wanna be here? Send us removal request.

Text

Benefits of Using Cat6 Ethernet Cables for Faster, Cleaner Connections

Ethernet cables serve as the foundation of our wired network connections, allowing for rapid and dependable data flow between devices. While there are numerous varieties of Ethernet cables available, such as Cat5, Cat5e, Cat7 and CAT6 Patch Cable, many people prefer the Cat6 variety. Let's look at the benefits of Cat6 Ethernet cables and how they compare to other cable kinds.

Increased Data Rate: Cat6 connections provide considerable increases in data transfer rates, reaching up to 10 Gbps. The performance gap is 10 times greater than that of Cat5e, which has a maximum speed of 1 Gbps. This makes Cat6 cables ideal for bandwidth-intensive applications such as streaming high-definition films or moving huge files over a network.

Higher Frequency: Cat6 cables may work at up to 250 MHz, but Cat5e cables are limited to 100 MHz Higher frequencies suggest that the cable can carry more data throughout the same period, resulting in quicker connections and more consistent performance.

Reduced crosstalk: Crosstalk is interference generated by signals from one cable impacting another neighboring cable. CAT6A Patch Cable has tighter twists and more insulation, which significantly reduces crosstalk. This guarantees a solid connection and minimizes data mistakes.

Future-Proofing: With the increasing need for faster internet and more data use, network infrastructure must keep up. By using Cat6 cables, you ensure that your network will be able to handle future technological breakthroughs for an extended period.

Better for Longer Distances: While both Cat5e and Cat6 can efficiently carry data over 100 meters, Cat6 maintains high-speed performance for a larger amount of that distance than Cat5e. This makes it especially handy in bigger settings or if devices are spread out.

Versatility: Despite its increased capabilities, Cat6 is backward compatible. This means it may be used with devices and configurations meant for earlier Ethernet cable types with no problems.

While CAT6 Patch Cable is slightly more expensive than its predecessors, the benefits they provide, particularly in terms of speed and dependability, make the investment worthwhile.

Next: How Polarization Maintaining Fiber Enables Coherent Optical Communications for 1.6T Ethernet

1 note

·

View note

Text

Understanding MTP Cables: The Backbone of High-Performance Fiber Networks

Multi-fiber push-on MTP Cable is required for fiber optic communication and is intended to facilitate and improve data transfer in high-performance networks. As technology advances, the demand for quicker, more dependable communication systems grows, necessitating experts’ complete understanding of MTP. This article will cover the technical specifications, installation procedures, and benefits of…

View On WordPress

0 notes

Text

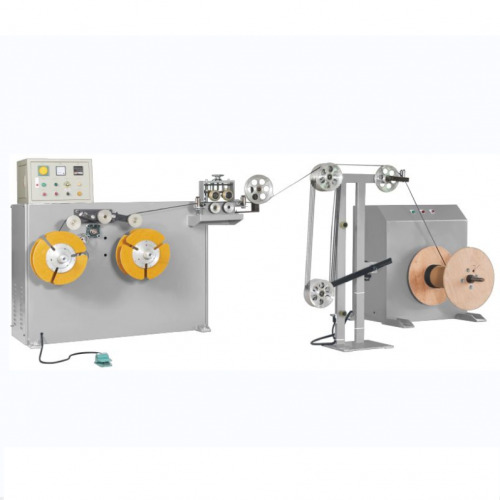

Fiber Jumper Production Line: Delivering Reliable Connections at the Core of Modern Networks

In the fast-evolving world of fiber optic communication, fiber jumpers—also known as patch cords—play a critical role. These essential components connect devices within data centers, telecom networks, and enterprise environments, ensuring efficient signal transmission with minimal loss. Behind each high-performance jumper is a carefully designed and controlled fiber jumper production line.

What is a Fiber Jumper?

A fiber jumper is a short fiber optic cable with pre-terminated connectors on both ends. It’s used to link optical equipment, patch panels, and transceivers. Jumpers vary by connector type (LC, SC, ST, FC, MPO), fiber mode (single-mode or multimode), and cable specifications, depending on application needs.

Stages of the Production Line

Cable Cutting and Preparation The process begins by cutting fiber cable to the desired length. Outer jackets are stripped, and internal strength members like Kevlar are exposed for reinforcement.

Connector Installation High-precision connectors are fixed to each end of the fiber. The bare fiber is carefully inserted into a ferrule, bonded with epoxy, and secured within the connector housing.

Curing and Polishing The connectors are cured in a temperature-controlled oven to set the epoxy. Next, the fiber end faces are polished using automatic polishing machines, ensuring a smooth, scratch-free surface for optimal signal transmission.

Endface Inspection and Optical Testing Every jumper is inspected under a microscope for surface defects. It then undergoes optical performance tests to measure insertion loss, return loss, and overall durability, ensuring compliance with industry standards (such as IEC or Telcordia).

Labeling and Packaging Each fiber jumper is labeled with key specifications—such as length, connector type, and performance—and packaged for safe transport.

Conclusion

A well-run fiber jumper production line ensures consistent quality, low signal loss, and high reliability—essential for modern high-speed networks. As demand for bandwidth continues to rise, precision-manufactured jumpers remain the backbone of fiber optic infrastructure worldwide.

1 note

·

View note

Text

Understanding DFB Laser Diodes: The Heart of Stable Optical Communication

In the realm of high-speed optical communication, the DFB laser diode is a core component that enables precise, stable, and high-performance light transmission. Widely used in fiber optic networks, data centers, and telecommunication systems, DFB laser diodes are critical for ensuring low-noise, narrow linewidth light sources essential for long-distance and high-data-rate applications. What is a…

View On WordPress

1 note

·

View note

Text

PM Fiber Patch Cords Basics You Must Know

Polarization Maintaining Patchcord is a type of specialised fibre patch cord. It has a wide range of applications. Here's all you need to know about PM fibre patch cords if your ideas call for them.

PM Fibre Patch Cord

A PM optical fiber is a single-mode optical fiber in which linearly polarised light when correctly launched into the fiber, maintains linear polarisation during propagation and exits the fiber in a specified linear polarisation state. PM fiber patch cord is a fiber optic cable constructed of PM fiber that is terminated at both ends with high-quality ceramic fiber connectors. The PM fiber patch cable is a basic optical passive component.

Features of PM Fibre Patch Cords

If the polarisation of the input light does not match the stress direction in the fiber, the output light will alternate between linear and circular polarisation. In addition, temperature and tension fluctuations in the fiber will affect the precise polarisation. When light is connected at the fiber entry parallel to the slow or fast axis, polarisation can be maintained. It is critical to ensure that the polarisation of the incoming light is maintained. PM fibre patch cords and Polarization Maintaining Optical Switch preserve the polarisation of linearly polarised light that is launched into the fibre with the proper orientation. PM fiber patch cords also have low insertion loss, a high extinction ratio, a high return loss, great changeability across a wide wavelength range, and exceptional environmental stability and durability.

Types of PM Fibre Patch Cords

Classification by connection type: PM fiber patch cords have fiber connectors on both ends. The most common connection types used for PM fiber termination are FC, SC, LC, and ST.

PM fiber patch cables are manufactured of polarization-maintaining fibers. To assure the polarisation of both the input and output light in a PM fibre, numerous rod forms are utilised, and the final fibre is sold.

PM fiber patch cables can be categorized based on cable type. There are three primary types of cables: 250um bare fiber, 900um loose tube jacket, and 3mm loose tube jacket. So, depending on the cable type, there are three varieties of PM fiber patch cables.

Fiber length classification: A standard length of 1 meter is used. It may be adjusted to meet specific needs. The length of Polarization Maintaining Patchcord may be adjusted.

Next: MTP MPO Fiber Patch Cables: Unraveling Their Technical Features and Superior Performance

#Polarization Maintaining Optical Switch#Polarization Maintaining Patchcord#Polarization Maintaining Patch Cable#Polarization Maintaining Fiber Cable

1 note

·

View note

Text

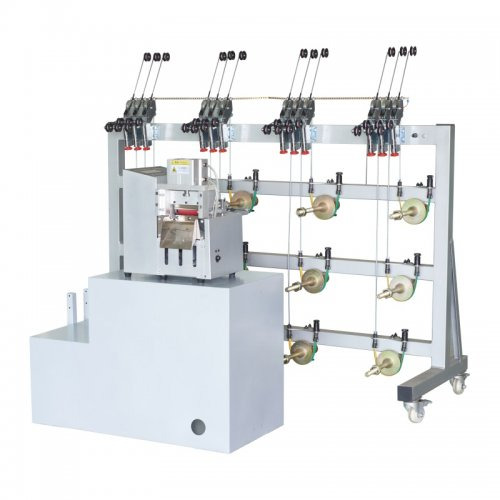

Choosing a Fiber Optic Connector Polisher

Fiber Polishing Machine has advanced significantly during the 1990s. The first connector termination jobs were done manually and labor-intensively, and one person did fiber connector polishing. With the growth of fiber optic networks, substantially better efficiency is required. Manufacturers of fiber optic patch cords attempted to compensate by adding additional operators, but they were still unable to meet demand. Until modern automatic polishing machines were introduced, fiber connection polishing met the requirements of large volume, high quality, and consistency.

Quality Fibre Connection Termination is critical for the fiber optic communication system. Fibre optic connection polishing is one of the most critical processes in the fiber connector termination process since poorly polished connectors increase insertion loss and back reflection, causing your system to malfunction.

Automatic fiber connection polishing machines are built to a set of industry standards and criteria. It can consistently produce high numbers of connections and is deemed cost effective due to the huge reduction in labour. This article is meant to assist you make an informed decision when selecting the best fibre polishing equipment for your individual needs. When choosing an automatic connector polishing equipment with Fiber Polisher, adhere to the following standards.

Polishing machines with adjustable pressure are preferred.

The completed end-face geometry of the fiber connection is determined by the loading pressure and hardness of the polishing surface. To optimize the connection end-face, adjust the polishing pressure with clearly specified divisions of measurement.

The four corner hold-downs are also necessary. Hold-down bolts on all four corners of the connection holder properly distribute film pressure, reducing off-center polishing. If you apply the center pressure from above, you will be able to wiggle or vibrate the connection holder. By using this approach, you increase the vertex offset, which results in irregular finishes.

You should also consider the polishing pad. The polishing pad, in conjunction with the four corner hold-downs, is used to uniformly apply pressure throughout the polishing area. The pads' resilience will aid in managing the radius of curvature when the ferrule is driven into the pad during the polishing process with the Fiber Polishing Machine. There are several pads for various sorts of connections; you should select the appropriate one based on your needs. Ensure that the holders may be readily changed for different types of connections.

Follow our Facebook and Twitter for more information about our product.

1 note

·

View note

Text

Optical Circulator: Enhancing Signal Direction in Fiber Optic Networks

As fiber optic networks become increasingly complex and high-performance, specialized components are essential to maintain speed, efficiency, and signal integrity. One such component is the Optical Circulator, a powerful three-port device that plays a critical role in managing the direction of light signals in a fiber optic system. What is an Optical Circulator? An Optical Circulator is a…

View On WordPress

0 notes

Text

PLC Fiber Splitter: A Critical Component in Fiber Optic Networks

In the rapidly expanding world of fiber optic communication, efficiency and scalability are crucial. One key device that plays a central role in optimizing the distribution of optical signals is the PLC Fiber Splitter (Planar Lightwave Circuit Fiber Splitter). This small yet powerful component is essential for signal distribution in various optical networks, ensuring that data can be transmitted…

View On WordPress

0 notes

Text

Unlocking Precision with Polarization Maintaining Fiber Splitters

In the world of advanced fiber optics, precision and stability are everything. One crucial component that plays a significant role in maintaining the integrity of light signals is the Polarization Maintaining Fiber Splitter. These specialized devices are essential in applications where preserving the polarization state of light is critical — such as in interferometry, fiber optic sensors, quantum communications, and coherent transmission systems.

A PM fiber splitter is designed to divide an optical signal into two or more outputs while maintaining the polarization of the input light. Unlike standard fiber splitters, PM splitters use polarization-maintained fibers, which are engineered with stress elements (like elliptical cores or panda-style structures) that keep the light's electric field aligned along a specific axis.

Why is this important? In systems where polarization impacts performance — like in coherent optical communication — any loss or shift in polarization can lead to significant signal degradation. PM fiber splitters ensure that the light's polarization remains stable, enabling higher accuracy and consistency in signal processing.

There are typically two main types of PM fiber splitters: 2x1 (combiner) and 1x2 (splitter) configurations. These can be customized for different split ratios, wavelengths, and connector types to fit various system requirements. High extinction ratios, low insertion loss, and minimal back reflection are critical specifications that define a high-quality PM splitter.

Another advantage is environmental stability. PM fiber splitters are designed to perform reliably under varying temperature and stress conditions, making them ideal for use in lab settings and field deployments alike.

As optical systems continue to evolve, the demand for components that support high-speed, high-fidelity transmission grows. PM fiber splitters are a cornerstone in achieving these goals — delivering reliable, stable performance where it matters most. If your project involves precision optical alignment or polarization-sensitive applications, investing in high-quality polarization maintaining fiber splitter is not just beneficial — it’s essential.

Next: How MTP Trunk Cables Simplify Large-Scale Fiber Optic Installations

1 note

·

View note

Text

Two Major Functions of Optical Splitters in a Fibre Optic Network

An optical splitter, also known as a beam splitter, is a device that separates a single fibre optics transmission into numerous signals. It serves as a power distribution device, able to divide an incident light beam into two or more beams and vice versa. The Fiber Splitter Production Line optimizes the functioning of optical network connections, guaranteeing signal distribution and effective network infrastructure utilization.

What Are the Crucial Functions of Optical Splitters in a Fibre Optic Network?

Increasing Network Capacity

An optical splitter may increase network capacity by dividing a single optical fibre into numerous fibres, which is especially useful in passive optical networks (PONs) and other fibre optic systems. Fibre splitters are widely used in telecommunications, data centers, and residential broadband networks to allow numerous users to share the same fibre infrastructure in a resource-efficient manner, reducing the need for additional connections. Fibre optic splitters meet the growing need for high-speed internet and data-intensive applications by allowing data to be sent to numerous destinations simultaneously. The Fiber Coupler Production Line is also vital.

Facilitating Shared Fibre across Multiple Locations.

The fibre splitter enables shared fibre across several sites by dividing an optical signal into multiple pathways. This invention enables numerous users or locations to easily use the same fibre optic line, enabling cost-effective fibre sharing while reducing the need for specialized cables and equipment. The benefits go beyond cost reductions since fibre optic splitters help to create passive optical networks (PONs), which allow many end users to connect to a central office or service provider. This results in a bandwidth distribution that is both efficient and cost-effective. Furthermore, fibre optic splitters are scalable and flexible, supporting a variety of network designs such as point-to-multipoint or point-to-point, allowing for easy extension to suit rising user bases. Fibre splitters are still necessary in today's environment to accommodate the growing need for high-speed internet and data transfer. As companies and individuals demand more dependable and fast connections, Fiber Splitter Production Line play an important role in expanding fibre optic networks to many locations while remaining efficient and cost-effective.

1 note

·

View note

Text

How a Fiber Patch Cable Production Line Powers the Digital World

One unsung hero that rarely receives recognition in a world where internet speed and data dependability are unavoidable is the Fiber Patch Cable Production Line. The unsung hero of our hyper-connected age is the modest fibre patchcord, which powers enormous data centers and ensures flawless video chats. Let’s go further into this intriguing realm and see how these essential connections are…

View On WordPress

0 notes

Text

Choosing the Right Optical Cable Production Line Supplier from China

Selecting the correct supplier is essential to long-term company success when purchasing goods like Optical Cable Production Line from China, particularly complex commodities like fibre optic cables. Despite the temptation to choose the lowest bidder, you shouldn’t base your choice just on price. Whether a supplier is genuinely dependable and able to satisfy your company’s demands depends on…

View On WordPress

#Fiber Cable Production Line#Fiber Optic Cable Production Line#Fiber Splitter Production Line#Optical Cable Production Line

0 notes

Text

Fiber Circulator: A Vital Component in Optical Communication

In modern fiber optic networks, managing the direction of light signals is essential for efficient data transmission. One key device that makes this possible is the fiber circulator. Though small in size, fiber circulators perform critical functions that improve the performance and flexibility of optical communication systems.

What is a Fiber Circulator?

A fiber circulator is a three-port optical device that directs light signals in a specific, one-way pattern. Unlike a simple splitter or coupler, a circulator routes signals from Port 1 to Port 2, Port 2 to Port 3, and sometimesPort 3 back to Port 1, without allowing signals to travel backward. This one-way flow makes circulators extremely useful in complex network setups where bidirectional signal management is required.

How Does a Fiber Circulator Work?

Fiber circulators operate based on polarization controlandmagneto-optic effects. Inside, they use Faraday rotators, polarizers, and other optical components to control the direction of light. This unique design allows circulators to separate forward and backward traveling light signals, guiding them along different paths without interference.

Applications of Fiber Circulators

Bi-Directional Communication: Fiber circulators allow two-way communication over a single fiber strand, enabling efficient use of network infrastructure — commonly used in fiber-to-the-home (FTTH) systems.

Optical Sensing and Testing: In Optical Time-Domain Reflectometry (OTDR), circulators separate the outgoing test signal from the reflected signal, helping to locate faults or breaks in fiber optic cables.

Dense Wavelength Division Multiplexing (DWDM): Circulators are used to add or drop specific wavelength channels in DWDM systems, enhancing network capacity and flexibility.

Laser Protection: Circulators protect sensitive lasers by diverting any reflected light away from the laser source, preventing feedback that could damage equipment.

Conclusion

Fiber circulator is essential tools in fiber optic networks, enabling advanced routing, testing, and protection of optical signals. As demand for faster and more efficient communication grows, the role of fiber circulators continues to expand, supporting the backbone of modern telecommunications.

Follow our Facebook and Twitter for more information about our product.

2 notes

·

View notes

Text

Maximizing Network Efficiency with MPO Cables: Scalability, Flexibility, and Performance

MPO Cable is a fibre connector type, whereas MTP is a registered brand for an MPO connector made by US Conic. Although all MTPs are MPOs, not all MPOs are MTPs.

MPO connectors can be male or female. The two alignment pins protruding from the end of the ferrule indicate a male connector. MPO female connections will feature holes in their ferrules to take the male connector's alignment pins.

Advantages of MPO Fibre Optic Cables

High-density fibre connectivity

High-density fibre connection offers several advantages when space is limited.

It maximizes space utilization by lowering the footprint of cable infrastructure using MPO and other high-density connections that condense several fibres into a single interface. This is critical in data centers and telecom hubs that demand high bandwidths or rapid cable/fanout cable installations. It promotes scalability, allowing networks to be readily updated or expanded without having to rewire everything; it also aids in cooling by allowing more air to circulate network equipment, which must function under certain circumstances. High-density fibre connectivity maximizes performance while minimizing structured cabling environments to improve physical and logistical constraints.

Scalability and Flexibility

Scalability and flexibility are two important characteristics of MPO fibre optic cable systems that can support dynamic and expanding network designs. These systems permit growth by incorporating additional fibres into the system without requiring large infrastructure improvements. Organizations may simply alter their network capacity as data demand grows by adding more MPO or MTP Cable connections and adaptors with different fibre counts or configurations, such as those with 12-fiber cables for a reduced cost. Furthermore, the modular nature of these systems allows for quick changes in network design, allowing new technologies and equipment to be quickly integrated where they are required.

Reduction of Cable Clutter

High-density MPO Cable systems have the benefit of decreasing cable clutter. They do this by combining several fibres into a single connection, using fewer separate cables and resulting in a more organized network environment. This strategy not only improves the appearance of the workstation, but it also allows for easy maintenance and troubleshooting. Furthermore, organizations may reduce the chance of tangling or compromising the physical of the fibres by using fewer quantities.

1 note

·

View note

Text

Know About Choosing the Right MPO Cable

Data centers and other high-density cabling settings frequently employ MPO or MTP-terminated cables. Each fibre in a traditional, tight-buffered multi-fiber cable must be terminated separately by a qualified technician. Multiple fiber-carrying MPO cable like MPO 16 Cable is pre-terminated. Typically, factory-terminated MPO/MTP connections feature a 12 or 24 fibre array. Things to Take Into…

View On WordPress

0 notes

Text

SC vs. LC Fibre Optic Connectors: Key Differences, Applications, and Best Choices for Your Network

Fibre optic technology is important in contemporary telecommunications because it allows data to be sent at fast rates over great distances with minimal signal loss. Connectors are important in this type of technology because they help connect fibre optic cables to various networking devices seamlessly. When selecting a suitable fibre optic connector, professionals have two options: SC Cable and…

View On WordPress

0 notes

Text

What is a Network Patch Cable and Why is it Important?

In today’s highly connected world, network patch cable is essential components of any wired network setup. Whether you’re managing a home office, a small business, or a large enterprise, patch cables play a vital role in ensuring seamless data transmission between devices. What is a Network Patch Cable? A network patch cable is a type of Ethernet cable used to connect devices to a network. It…

View On WordPress

1 note

·

View note