Text

Should I buy a Hydraulic, Electric, or Hybrid Press Brake?

Found yourself in the market for a new press brake? The best (and easiest) first step is to contact your Sales Engineer. Set up a virtual or in-person appointment to review machine options and how they would fit into your production flow. Your Sales Engineer can walk you through options for controls, backgauges, material support, and automation; as well as brainstorm machine capabilities which would assist in growth and increased productivity.

In addition to reviewing options your Sales Engineer can help you decide what tonnage and bed length would suit your needs. They spend their days solving problems for metal fabricators and can offer helpful recommendations from past experiences.

Key factors when asking yourself – “should I buy a Hydraulic, Hybrid, or Electric Press Brake?”

Advantages of a Hydraulic Press Brake

When considering a new hydraulic brake look for a machine with a solid foundation, energy-saving technology, and options that automate the bending process. A well-built hydraulic press brake will have:

Widest variety of options and configurations

Configurations from a simple machine to a highly sophisticated machine, with a wide variety in between

Wide range of budget options

Potential for significantly higher tonnages and lengths

Wider variety of tooling options from planer tooling to precision

Heavy-Duty Options

Keep in mind, if you are bending BIG and need 650 to 3000+ ton capability to do it, the High-Tonnage Hydraulic Press Brakes are your answer. These machines are built with oversized components, powerful gauging devices, and increased open heights/stroke lengths. When considering high tonnage, you want a press brake that is tough, durable and will stand up to any forming challenge.

Advantages of an Electric Press Brake

These brakes run on electric motors that turn on during the bending sequence and shut off automatically when not in use. The ram descends quickly, stops at a preset position, creeps downward to make the bend, then moves quickly upward to start the process again. The short list of perks for electric brakes includes:

High speed and productivity

Designs (check out the SafanDarley models) require minimal crowning

Impressively high forming tolerances

Extremely quiet and clean – make for a nice working environment

Saving in electricity

Advantages of a Hybrid Press Brake

A hybrid press brake uses both hydraulic cylinder technology and a servo-drive motor – combining the best of both the hydraulic brake and electric brake. They are built with hydraulics to assist the bending process, but without gear pumps. Like an electric press brake, the hybrids shut off to conserve energy when not performing bending functions. A hybrid brake can be 20-30% more energy efficient than a hydraulic press brake.

Close to the productivity of electric with more size options

Less drive system maintenance then a hydraulic brake

Same high tolerances as an electric brake

Which Press Brake Machine Is Best?

Purchasing a new press brake should be like ordering at a restaurant: choosing options based on your preferences and needs, with the goal of ordering a machine built to help achieve your production goals.

Take advantage of your Sales Engineer’s expertise - call to discuss the best choice for your shop!

0 notes

Text

NORTH AMERICA’S LARGEST METAL FORMING, FABRICATING, WELDING AND FINISHING EVENT

Our team is your backstage pass to 30+ booths during four days of new technology, educational seminars, keynote presentations, panel discussions & networking events!

November 2019 in Chicago:

Mon., Nov. 11: 10am to 6pm

Tues., Nov. 12: 9am to 5pm

Weds., Nov. 13: 9am to 5pm

Thurs., Nov. 14: 9am to 3pm

In 2020 FabTech will be in Las Vegas.

REGISTER FOR FABTECH

2019 FABTECH SCHEDULE

FABTECH FAQ

We are representing 30+ different vendors who are showing at FabTech:

EXHIBITOR NAME BOOTH#

Accurpress A2980

Acrotech Inc A5081

Apex Machine Group A5308

Boschert Precision Machinery Inc A5723

Carell Corporation A5743

Cleveland Punch & Die Co A3326

Cleveland Steel Tool Co A3203

Euromac A3514 / A3714

DAVI Inc A4214

Ercolina – CML USA Inc A5355

Ficep Corporation A2961

FlexArm Inc A3254

Flow International Corp A4931

The Heim Group, The D45330

Mazak Optonics A4202

Messer Cutting Systems A4950

MetalForming Inc A2162

Midwest Automation A3179

Murata Machinery USA Inc A4901

Piranha \ MegaFab A4525 / A4924

RADAN I Hexagon Manufacturing Intelligence A3510

SafanDarley BV A2988

Scotchman Industries Inc A3532 / A3732

Timesavers LLC A3101

Universal Robots USA Inc B35083

Versatility Professional Tool Storage A5912

Wila USA A3140

We look forward to seeing you there!

0 notes

Text

SafanDarley’s E-Bend L Blue

Optional Angle Measurement System for E-Brake Ultra & Duel Drive SafanDarley press brakes

System operates two (2) laser sensors that are CNC controlled

System continuously monitors & corrects the Y-axis position based on actual angle programmed – guaranteeing the end product has the highest degree of angle precision

System will automatically correct the crowning unit to account for spring-back

Equipped with a blue laser light so reflections and sunlight do not interfere with measurements

All details are stored in the database making the bending process faster and reducing production time

Systems can be used in three ways:

Angle measurement with measurement of spring back

Measures 1 or 3 positions during bending process

Corrects crowning and Y1/Y2 positions

Angle measurement with a database

Angle measurement with learned bending

youtube

0 notes

Text

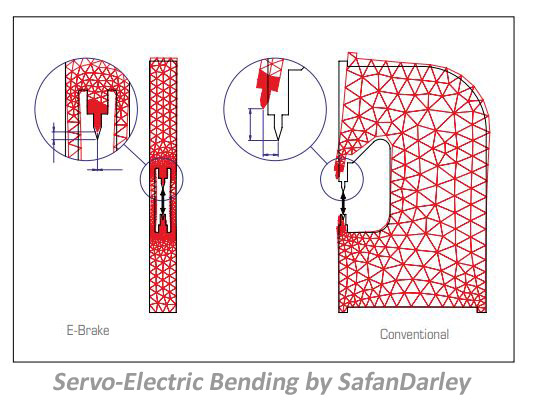

4 Things You Need to Know About Electric Brake Technology

Double your bending productivity,increase accuracy, and save money

1. Well-Vetted Technology

Electric brakes have come of age. Hesitations about moving from hydraulic brakes to electric are disappearing as e-brakes become the chosen technology to increase bending capacity in high mix, low-volume shops, as well as large run production.

Draw 50% less power during idle time than a hydraulic brake

Uses less power than hydraulics with energy-efficient servo drives

2. High Accuracy with Less Effort: belt and pulley system

When using hydraulic cylinders an operator must compensate for limited tonnage in the center and correct with crowning. The belt and pulley system virtually eliminates crowning and self- adjusts for tonnage. This is the #1 difference between electric and hydraulic brakes, saving power and time.

"The pulleys are spaced across the length of the beam, allowing an equal distribution of the bending force, which eliminates the need for a crowning table in 95 percent of jobs," said Mauricio Matta from SafanDarley. "The 5% exception is when a user wants to bend with an extreme load, for example, when V-width is less than eight times the sheet thickness."

3. 30% Faster

Cycle times of the SafanDarley E-Brake are far shorter than conventional press brakes due to the active integrated safety system and the acceleration of the servo motors. The SafanDarley E-Brake only uses energy when the top beam is actually moving. This equals an energy saving of up to 50% compared with conventional hydraulic press brakes.

4. More Than a Safety Tool: SafanDarley Integrated Safety System

The integrated safety system can be programmed to allow the upper beam to move within 1mm above the sheet in milliseconds prior to bending allowing the E-Brake to be automatically ready for the next step.

0 notes

Video

youtube

2019 FMA Open House Recap Video

#messercuttingsystems#accurpress#hydmech#flowinternational#waterjet#plasma#maxakoptonics#timesavers#safandarley

0 notes

Text

That’s a wrap, 2018!

It’s hard to believe that the end of 2018 is upon us. This year has been an exciting year for the Fox Machinery Team and we are glad to have shared many of those experiences with you. The Open House at our new showroom and offices here in Exton, PA was a huge success! We were glad to meet many of you in person, showcase some incredible machines with groundbreaking technology, provide informational classes - such as press brake bending science and more - and let’s be honest, that BBQ was amazing!

This was also the year that Fox Machinery celebrated it’s 50th anniversary! We are proud to have welcomed many new customers to the Fox Machinery Family in 2018, and honored by the continued relationships with our existing customers as well. It is because of you that we were able to celebrate these past 50 years and we look forward to serving you for 50 more. We eagerly await the new year and what it will bring. Thank you again for an amazing 2018! We wish you and your families a Joyous Holiday and a Happy, Healthy and Successful New Year!

Fox’s Favorites from 2018

“Having the Mazak 6kw laser for the Open House was the highlight of my year. Logistically, there is a huge amount of planning to bring a machine of that size into a showroom for a three day event.” Mike Kistler, President

“While it isn’t exactly unique to 2018, I am continually impressed by our customer’s continued efforts to improve themselves. It is a lot of fun to work with companies that look to better themselves in the short, medium and long term. There is no “one size fits all” answer to this, and that uniqueness is very exciting.” Kyle Wenger, Vice-President

“Being new to the Metal Fabrication Industry, attending FabTech Atlanta this year was a real highlight for me. I was able to witness, firsthand, how well our vendors are represented and respected in the industry and got a “first glance” at the new and groundbreaking technology and innovations they are releasing. I have a real sense of pride in what we offer our customers.“

Zack Viscomi, General Manager

“As I think back on 2018, it was a notable year. For me, the biggest stand out had to be our Open House. Having the opportunity to help set up a Mazak OptiPlex 6Kw laser was a unique experience. Taking advantage of the opportunity the meet customers face-to-face was fantastic. I have worked with these folks over the phone for years. Shaking hands, sharing stories and laughing together brings a whole new dimension to our ongoing relationship.” Brian Gehman, Service Manager

“Probably setting up Accurpress Brakes with Wila Tooling and having the bends come out just about perfect on the first try. I’m in awe of the large Accurpress Accell U machines with Wila hemming die holders, as well as the shears with auto front gauging and Vision CNC. These are really cool systems and controls that are worth your attention!” Matt Doyle, Sales Engineer

“My favorite part of 2018 was the Open House. I not only enjoyed the opportunity to show off our new facility and showroom to our customers, but also the camaraderie that was built within Fox Machinery through preparation.” Alex Skypala, Sales Engineer

youtube

“My favorite from 2018 - the Mazak Optiplex 3015 Direct Diode Laser” (see video above!) Todd Lang, Sales Engineer

“Becca and I in our fleece jumpsuits on Halloween... which would have been great except for the heat wave of 80 degree weather that day!”

Olivia Whyte, AR

“One of my highlights this year was being a part of Fox Machinery’s 50th Anniversary and Open House. We had a great turnout at our new facility in Exton, and it was a special opportunity to be able to meet customers and factory reps I had talked to and worked with during the year. Happy holidays to everyone!” Jean Kistler, AP

“I’ve enjoyed watching videos on the latest and greatest technology in fiber lasers. Fiber lasers have numerous benefits to the end user, with less moving parts and no expensive optical mirrors to replace... in many cases they need less service then CO2 machines. With the added benefit of the ability to cut reflective material without fear of back reflection which could damage the machine.” Josh Proctor, Admin

“I have enjoyed CPD’s Instagram page. They get the chance to create some pretty crazy tooling and post great pictures and video of their work.” Becca Barker, Marketing Coordinator

0 notes

Text

WHAT IS Direct Diode Laser TECHNOLOGY? The buzz about DDL.

Article written by

Al Bohlen, President

Mazak Optonics Corp.

Better than fiber, DDL Lasers are:

1. More Efficient

2. Faster

3. Better Quality Cuts

Recently, Mazak Optonics Corp. introduced a first of its kind laser-cutting machine which utilized a direct diode laser (DDL), the Versatile Compact Laser - Tube 100 (VCL-T100). Now we have announced another direct diode laser, the OPTIPLEX 3015 DDL. This machine has changed the game for high power laser cutting. Direct diode laser technology has shaken the industrial laser cutting industry, but not everyone understands what it is, how it works or why it has gained such traction.

What is Direct Diode Laser (DDL) Technology?

The name explains the process. DDL technology utilizes diodes directly. This is managed through eliminating the doped fiber system used in fiber laser technology. Which in turn, makes the DDL course more efficient since the middle process is now eliminated. Direct diode lasers are also the smallest and most reliable laser source, all while having an exceptionally high quality beam.

Why is DDL now being introduced as a laser source?

Until recently, DDL has only been available in lower power levels less than 2,000 watts, which has limited its use in a wider range of industrial cutting applications. Today the platform has been developed and expanded to accommodate 8,000+ watts of power. These higher power levels combined with its very unique characteristics including reliability, efficiency and quality have now allowed DDL to be utilized in thicker material applications. While many laser users have embraced solid state laser technology and the benefits from higher cut speeds and lower costs of operation, these users have desired high edge quality that has not yet been possible with fiber and disc technology.

What are the benefits of DDL?

There are three key areas which DDL has made advancements over CO2, fiber and disc laser technology.

1. First is the overall efficiency of the laser. As you can see from below, Mazak's DDL has improved wall plug efficiency compared to any of the other laser sources. This is because the diodes can be used directly instead of having to

go through the doped fiber system.

2. The second key benefit of DDL technology is the cut speeds. DDL has cut speed advantages typically about 15% faster in all material types and thickness, but it is most notable in aluminum. We are seeing, in come cases, 30% faster cut speeds in aluminum over fiber or disc.

3. However, what is most notable is the superior cut quality in all materials over the typical results seen in fiber or disc technology. Due to the DDL wavelength and beam shape characteristics are different than the other laser sources. The DDL characteristics are such that we can provide a more superior edge quality

not yet seen on fiber or disc laser all while running at speeds, which in many cases, are faster. DDL have the ability to cut a wide range of material types and thickness, which certainly include a variety of steel compositions, aluminum, stainless steel, etc.

In addition, DDL is very capable of cutting Titanium, Hastelloy, Inconel and other exotics quite well.

What does Mazak Optonics Corp offer?

Currently Mazak Optonics Corp. offers two different laser-cutting machines utilizing DDL technology. One is an affordable tube production laser and the other is a high power, high speed, flat sheet laser-cutting system. The VCL- T100 is an affordable tube production laser that is engineered and produced at our sister company's manufacturing campus in Florence, Kentucky. The VCL-T100 is a compact laser-cutting system that has high-end value and performance while maintaining an economical price point.

Yet the machine that we have seen the greatest impact with is the OPTIPLEX 3015 DDL. This laser-cutting system has changed the game with its impeccable finished parts' edge quality and extraordinary cutting speeds. This machine also

has our new cutting-edge PreviewG control and drive system which has integrated tech tables to simplify operation. The OPTIPLEX 3015 DDL incorporates our Intelligent Multi-Control Torch HP-D and Nozzle Changer technology to directly increase the productivity of the end user by allowing

the machine to optimize the torch setup automatically per program. This optimization can dramatically improve cut speeds, increase throughput and require less operator intervention, delivering more predictable processing day after day.

Mazak has made significant investments to develop proprietary DDL technology. We are excited to have this unique advantage exclusive to Mazak. We have established our self as the first to market with DDL and as the leader in DDL development. We will continue to expand its power levels and offering in all ranges of our products.

0 notes

Text

25 Types of Metal Forming KNOWLEDGE TEST

Listed are a wide variety of manufacturing methods - see how many you can match with the correct description below. Good luck!

[CLICK HERE FOR THE ANSWERS]

___ [A] Method using a _______ press to exert pressure so deformation obtains certain mechanical properties, shapes and sizes; it is one

of two components of stamping

___ [B] In this method the material makes contact with the punch tip and the side walls of the die but there is not enough tonnage to imprint or thin the material; spring back must also be accounted for

___ [C] In this method the material is conformed to the exact angle of the punch and die by using enough tonnage to do so; the material is thinned by the impact of the punch and die and compressed along the bending surfaces

___ [D] Very similar to using a cookie cutter; the process of cutting out and retaining a piece of metal

___ [E] A shearing process during which a metal scrap piece is removed from the outside edge of a metal workpiece; typically a manually operated, low-production process

___ [F] A blanking technology using a cutting die; the thin film panel is positioned on the base plate - the machine is used to control the blade to cut off the material

___ [G] Known as SLM, a computer controls a high-power carbon dioxide laser which scans the surface of the metal powder - where the laser goes, the surface of the metal is completely fused together

___ [H] Using a cutter with high speed to move the knife on the blank and cut out the shape/characteristics which are needed

___ [I] A form of metal separation accomplished partially by the slicing action of a dropping blade, followed by a clean fracture along the cut

___ [J] A variation of permanent mold casting; this casting method uses air pressure to force the metal through the gating system and the metal casting’s cavity

___ [K] Use a mold cavity to apply high pressure to molten metal; mold is usually made of stronger alloys, process is similar to injection molding

___ [L] In this method of bending the material only comes into contact with the tooling at 3 points; it requires the least amount of tonnage for a bend since the depth stroke, not the tooling, determines the angle; spring back must be accounted for

___ [M] In this method, a gas is employed to shield the material being welded in order to prevent it from being affected by oxygen and other natural elements

___ [N] Also called face milling; machining method of cutting the workpiece with the planer tool in the horizontal linear reciprocating motion; It is mainly used for the contour machining of parts

___ [O] Known as SLS, uses a laser as the power source to compact and form powdered material through heat

___ [P] The process of removing unwanted material from the block of metal to get the desired shape

___ [Q] Most commonly performed with a press brake, a set of dies are used to pinch the metal until it forms a desired crease

___ [R] A process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma

___ [S] A type of blanking technology, the preformed film is positioned on the punching male die and retains the 3D shape of the product and match the mold cavity

___ [T] Also called Cold Drawn, this method applies external force to the front end of the pulled metal; the metal billet is pulled from the die hole to obtain the corresponding shape and size of the product

___ [U] An arc welding process that uses a non-consumable tungsten electrode to produce the weld

___ [V] Uses a series of continuous frames to make the stainless steel into a complex shape; the roll type of each rack can deform the metal continuously until the desired final shape is obtained

___ [W] Refers to the process of removing excess material from the workpiece by abrasive materials and tools

___ [X] Method similar to punching, except the material is not cut; the die used creates a raised portion of material rather than penetrating entirely

___ [Y] The forming of workpiece with a desired shape and size by applying an external force on the plate, strip, pipe, and profile to produce plastic deformation (or separation) by pressing machine and die

MATCH these terms with the descriptions above:

1 Die-casting

2 Plamsa Cutting

3 Blanking

4 Air Bending

5 Forging

6 Stamping

7 Pressure Casting

8 Notching

9 TIG Welding

10 Bottoming

11 Folding

12 MIG Welding

13 Drawing

14 Punching

15 Coining

16 Shearing

17 Milling

18 Planning

19 Grinding

20 Selective Laser Melting

21 Selective Laser Sintering

22 Machining

23 Roll Forming

24 Die Cutting

25 Mold Cutting

0 notes

Text

PREVENTATIVE MAINTENANCE: Shear

Keeping a consistent eye on your machine is the easiest way to minimize downtime and maximize productivity. Manufacturers often recommend conducting preventative maintenance on shears by interval hours. Below is a

general outline. Fox Machinery and Welmaintained encourage our customers to use this as a starting point to develop a plan based on your machine’s usage.

Every 100 Hrs

_ Clean backgauge guideway

_ Lubricate lead screw

Adjust acme nut for backlash, if needed

Check ball transfers

Every 400 Hrs

Check hydraulic oil level

Check shadow light bulbs

Rear bearing greasing

Blade gap adjustments

Lubricate link bearings

Check lead screw endplay

Check backgauge bar height

Check drive gear belt tension

Check flip-up arms

Calibrate backgauge

Every 500 Hrs

Check ram thrust bearings

Check squaring arm

Check bolt tightness

Inspect blades

Every 1000 Hrs

Check fill cap

Adjust shadow line

Inspect backgauge drive belts (or chains)

Check backstop bar parallelism

Check for leaks

Check for loose fittings

Check cooling fan

Check heat exchanger

Every 9500 Hrs

Lubricate main motor

Check motor overloads

Inspect control console

Annually

Change hydraulic oil

Replace the return line filter

Check for user & maintenance manuals

Check suction strainer

Check limit switches

Clean the lenses on light curtain

Re-torque key bolts

Check relief valve

Inspect all wiring

Check valves

Inspect safety decals

Inspect safety guards

New Machine

2 weeks in use : Blade gap adjustments

6 months in use: Re-torque the key bolts

New Blades

2 weeks in use : Blade gap adjustments

DOWNLOAD this list to share with your maintenance team

0 notes

Text

Plasma Technology affects bottom line for structural market

Article Contributor: David Taylor, Messer Cutting Systems

With a recent influx in the structural market in New England, small iron

shops are turning to compact plasma machines to meet the increase in

demand. With a goal of versatility and minimizing production time, shops turn

to machines that minimize deburring, create weldable surfaces, have medium

heat input and can handle a wide range of material thickness. “...many are 10…15...25 man shops that need a small machine for burning clips and standard simple parts. Structural shopsare currently outsourcing to steel service centers,” says David Taylor, North East Regional Manager of Messer Cutting Systems, Inc. “The Messer 2.0 is built to be rugged, robust and a solid long term solution

for many structural shops, even in addition to their Peddinghaus machines,” he continued. Shops that have transitioned from having no burning equipment to plasma are enjoying shorter lead times and decreased outsourcing. “Eliminating

the need to outsource is a saving on time and money,” says Taylor, who

understands the value in going from nothing to a completed part in a short

amount of time.

Accommodating the influx doesn’t stop after production. Resetting for the next job needs to be just as streamlined to keep on schedule. Value is added for a machine that is fast turnaround.

The trend sees small iron shops investing in plasma technology are currently relying on steel service centers to outsource a need which can easily be met in-house. There is a learning curve, investment and the need to make space, however, Taylor explains, these factors are diminished by a decrease in production time and an increase of in-house capability. “Today’s machinery is significantly more accurate, has way faster processing and is vastly more reliable, “ says Taylor, “these are the reasons you invest in newer technology.”

In addition to keeping up with consumer demand, small shops are challenged

to outperform - a task which may mean being versatile in manufacturing capability. An affordable plasma and oxyfuel cutting machine that provides outstanding productivity within a small footprint may be the answer. Fulfilling

manufacturers’ demands, Messer Cutting Systems now offers a low cost, compact, unitized cutting machine that precision cuts mild steel, stainless steel

and aluminum plate. The MetalMaster 2.0 is 5’ x 10’ featuring vertical plasma

and oxyfuel cutting up to 2”. It it not intended for a hobbiest, but for an industrial environment with proven training, warranty and service programs to back up

quality manufacturing. With quick and easy machine installation, let the MetalMaster 2.0 be your shops solution. For more information on this machine

CLICK HERE.

0 notes

Text

7 Tips to Extend the Life of Your Dependable “Dinosaur” Machine

Older machines, when taken care of, can be reliable, dependable work horses for your shop. Prolong the life of your older machine through early detection of inconsistent behavior.

1. Stay on top of operator training

Machinery wear and breakdown are often made worse by unskilled handling. Many machines have multiple operators, increasing the chances of “use & abuse”. Identify a list of best practices and reiterate it often to your team.

2. Add and test lubricants

Lubricants reduce friction around any moving part. A schedule of good lubrication maintenance extends the life of large machinery equipment and parts

Check the manufacturer’s recommendations for type of lubricant and consider purchasing onlyhigh-quality fluids to keep your older machine running smoothly

Consider having a fluid analysis completed - experts analyze particles in the used oil which canindicate parts that may be suffering from wear or breakdown

Lubrication prevents corrosion and water is a major course of corrosion. Maintaining seals andreplacing filters will help keep lubricants free of contaminants

Keep a close eye on oil usage

Sudden reduction in oil use can mean a clogged lubrication line

A sudden increase can indicate a leak somewhere

3. Check for signs of wear

Age affects many key components of your machine. Over time belts will warp, seals will dry/crack,bolts will loosen and stretch out of shape. Vibration, shock, high temperatures, friction and age allcontribute to the breakdown of parts in heavy machinery.

4. Maintain a clean environment

There are many seals and filters in place to keep working parts clean and free of contamination.Seals should be inspected regularly to make sure they’re in good condition. Filters should beinspected and changed regularly.

5. Plan, schedule, and keep good records

Know what needs to be inspected and when.

Components break down, and wear is inevitable. Establish forecasts for the expected life of all components and replace them on schedule.

A maintenance log should also be kept ensuring regular checks are not missed and compliance is measured.

Set aside an emergency fund. Even if you have insurance, it is ideal to set aside emergency funds to cover the cost of unexpected, urgent repair and maintenance work.

6. Get creative

Eventually your older machine will need a part replaced that is no longer available. Turn to yourservice technicians, local fab shops and the creative folks you employ as resources to get yourmachine up and running. This may be a better option then replacing your machine.

7. Keep an expert in the loop

Schedule a full service inspection on your older machine to get a base line and start the monitoring process. Schedule annual or biannual inspections to keep on top of fluids and signs of wear.

0 notes

Text

SafanDarley’s “Smart” Light Curtain

In most instances, light guarding on a press brake is associated with a simple safety function. If the light curtain sensors on either side of the bending window pick up anything other than the metal to be bent, the safety system shuts the machine down. The operator or interloper, whatever the case may be, is safe, but the bending process is stopped.

The light guard for the SafanDarley E-Brake, which is integrated into the press brake, provides the same safety function, but it also can be used to improve bending cycle times.

“Most people don’t want to invest in safety because they think it slows down productivity,” said Mauricio Gutierrez Matta, SafanDarley’s area export manager. “That’s why we invented something that would improve productivity and improve safety at the same time.”

The press brake has been engineered so that the operator can use the light guard as a means to direct operation of the ram. Different modes allow the operator to use the foot pedal or interruption of the light curtain or a combination of the two to run the machine.

For example, the machine’s “one break” mode can be set up for a rapid bending job. The operator’s simple interruption of the focus area in the bending tooling can trigger the ram to advance at 10 mm per second to produce the bend; the operator can then remove the bent part, put another blank in its place (which triggers the ram to advance), and continue the process. This type of option also is helpful when an operator is struggling with a large or awkward-shaped part and is unable to reach the foot pedal.

In many of the modes, the press brake is intelligent enough to advance to just millimeters above the actual pinch point to accelerate the bending process. Typically a press brake needs a couple of seconds to cycle from the top of the bending window to the actual bend for every step in a bending job. If the ram is situated to allow just enough room for a flat part to be inserted, the press brake does not require several seconds to complete the forming action. When the operator has to extract the bent part, the press brake knows that the ram has to fully rise to accommodate the removal of the part.

The light curtain is able to keep tabs on the bending area while also allowing other movement in the press brake window because the sensors focus on an area of about 30 mm, or a little over 1 inch, where the bending takes place.

These different modes are hard-wired into the machine. Any adjustment requires the operator to have a key and to walk to the side of the machine to select the appropriate bending mode.

youtube

0 notes

Text

Forming The Future: electric press brake technology

Wisconsin Metal Parts Inc. (WMP) in Waukesha, Wis. wanted to offer its customers cutting edge technology in the press brake department.

With the goal of jumping into an area where few other fabricators have ventured, and finding a machine robust in size and capability, they installed a 13.45-ft., 330-ton SafanDarley E-Brake.

WMP does not typically bend parts longer than 13 feet and found the longer machine bed of the new SafanDarley E-Brake is valuable when setting up multiple tool sets for complicated parts.

Joe Pease, WMP General Manager, mentioned quiet performance as an immediately noticeable feature - its servomotors provide near-silent operation. “If you had a 300-ton hydraulic brake, you know what the noise would be,” he said.

In addition, the E-Brake technology is consistently mentioned in discussions around short cycle times, as electric brakes move 10 to 20 percent faster than hydraulic brakes. “This really isn’t noticeable over a 10-part run, but over larger jobs the increased speed is quite evident,” said Pease.

In addition, the machine outperforms during larger job production where the operator can take advantage of the “smart” light guard and eliminate wasted press brake motion. We would normally wait while the ram retreated to the top of the operational window before cycling down for another hit. This machine is programmed to retract only as high as necessary to adjust for the next step. “The right combination of operator and new technology makes a big difference in efficient product flow” says Pease.

[Read more about SafanDarley Light Guarding]

The Safan electric press brakes produce more precise part quality thanks to the ram’s capability of stopping within milliseconds, thanks to control by the servo-electric drive and a double-pulley system. This technology eliminates the need for hydraulic oil to bring the ram to a complete stop - a process found in hydraulic press brakes.

In addition to the machine-standard gauge measurement tool and a 6-axis backgauge, the e-brake is designed to auto adjust to the ram’s bending target. If a material blank is used that is 0.005 in. thicker than the preceding blank the machine will adjust and bend based on the job’s specs.

For more information on SafanDarley E-Brakes: http://www.foxmachinery.com/safandarley/

0 notes

Text

OSHA reports “Top 10” Most Common Safety Violations in 2017

The Occupational Safety and Health Administration (OSHA) releases an

annual “Top 10” list of most frequent workplace safety violations, a compilation which sums up citations for close to 32,000 workplace inspections from that year. For the second year in a row “General Requirements for Fall Protection” sits at #1 and “Machine Guarding” at #8.

As the weather warms make time to double check your shop is a safe place for your team to do great work.

Click here to [READ UP ON NEW OSHA REGULATIONS]

1. Fall Protection; General Requirements (1926.501) – 6,072 citations

2. Hazard Communication (1910.1200) – 4,176 citations

3. Scaffolding (1926.451) – 3,288 citations

4. Respiratory Protection (1910.134) – 3,097 citations

5. Lockout/Tagout (1910.147) – 2,877 citations

6. Ladders (1926.1053) – 2,241 citations

7. Powered Industrial Trucks (1910.178) – 2,162 citations

8. Machine Guarding (1910.212) – 1,933 citations

9. Fall Protection – Training Requirements (1926.503) – 1,523 citations

10. Electrical – Wiring Methods (1910.305) – 1,405 citations

To read up on the topics above, and more, follow this LINK.

0 notes

Text

Trade Expansion Act of 1962

Quick Fact Sheet – get caught up on what everyone is talking about

What does the Act say?

As the world’s major economies worked to recover from WWII, 23 countries (the current World Trade Organization which includes 163 countries) signed the Trade Expansion Act of 1962. America’s participation was an act of generosity and of self-interest: we needed other countries to recover in order to trade. Included in the original Act was an escape clause: if at any point imports threaten a country’s national security, that country can charge super-high tariffs on those products. Flash forward 70 years - the troubled economies the Act once helped are now selling more stuff to the USA than we sell to them.

What does Section 232 of the Trade Expansion Act say?

Section 232 allows the President to initiate an investigation to determine whether the country’s security is indeed threatened by imports. Since the term “threat” is so broadly defined in the Act, there isn’t much that doesn’t qualify including “substantial unemployment … decrease in government revenue … displacement of any domestic products by excessive import” and the list goes on. One thing to note - since 1980 the Commerce Department has conducted fourteen Section 232 investigations.

Timetable on initiating an investigation:

Within 270 days of initiating any investigation, the US Commerce Department must produce the investigation’s findings, including whether certain imports threaten US national security. The President has 90 days to determine whether he concurs with the findings and, if so, to use his statutory authority (under Section 232) “to adjust the imports” through tariffs or quotas.

What happened this year?

In February 2018, the US Commerce Department publicly released Section 232 reports stating the quantities and circumstances of steel and aluminum imports “threaten to impair the national security” and recommended action be taken to protect the long-term viability of our nation’s steel and aluminum industries… that action is the tariffs. The answer to “Why now?” is worth a Google search where you will find varied opinions.

Why does it matter to me?

The metal industry has seen pricing changes filtering down from the cost of material into machine prices, part prices and the cost of shipping. Anyone who is working with the financials should be keeping a close eye on what’s going on… if you aren’t aware, it’s possible you end up under-quoting or undercharging.

0 notes

Text

This is the time of year businesses start exploring the advantages of Section 179 of the tax code and Bonus Depreciation. The interest gets more intense as the year comes to an end. It is best to start year end planning NOW to make year end deliveries on machine tools.

David Goose of Commercial Credit Group understands this process better than most and has provided Fox Machinery’s customers with guidance for the past 12 years. As a part of his whitepaper entitled “The New Tax Law & Its Impact On Equipment Financing,”

Goose reviews the new tax laws, laying out:

• Section 179 and Bonus Depreciation

• Corporations and Pass-through Entities

• Tax Deductible Business Expenses

• NOL, AMT and LKE

You are encouraged to DOWNLOAD and read the full whitepaper, however; we want to touch on one aspect in detail - Section 179.

What is Section 179?

Section 179 allows eligible small to mid-sized businesses to take additional tax deductions and depreciation, based on the purchase of qualifying equipment. These deductions effectively reduce the amount of a company’s taxable

income, thus reducing the overall tax burden. There are restrictions and limitations, so if your company is thinking about taking advantage of Section 179 there are some important considerations you should be aware of as you engage in year-end planning.

A Compelling Benefit

Because this write-off can have such a significant impact on a company’s taxes, lets review how Section 179 works and how it can benefit your company. Let’s

say your business has a taxable income of $250,000, and purchases a qualifying $250,000 machine.The purchase could effectively bring your taxable income to zero. If you’re in a normal or minimal tax environment this can mean an actual cash savings of around $50,000 or more.

Scheduled to expire in 2023, the change in Section 179 has already had economic impact. With the end goal to grow the US job market, taxpayers are encouraged to spend on equipment useful for manufacturing and building businesses. According to the Equipment

Leasing & Finance Association, investments in equipment/software are expected to double in 2018, landing somewhere around 9%. Reports predict a 2.7%

economic growth rate this year - powered by the financing and leasing of machinery and equipment.

The new tax plan contains several provisions that will impact equipment procurement – lower tax rates for businesses, non-deductibility of interest expense for C corporations, limiting like-kind exchanges to real property, and expensing of depreciable assets instead of writing them off over years. The key is to know how these changes may impact a company’s balance sheet, financial

plan, and tax strategy, and to adjust accordingly to help improve the company’s financial performance.

Consider having discussions with your accountant, operations team and Fox Sales Engineer before the third quarter. A clear understanding of what technology and machine functionality will have the greatest impact will keep your business in line with your competition.

Want to know more?

CLICK TO READ A FREE WHITE PAPER

published by the pros: “Tax Cuts and Jobs Act” - an interview conducted by Mark Lempko and Don Pokorny, both of Commercial Credit Group Inc. (CCG), with Dixon Hughes Goodman LLP (DHG).

0 notes