Ever power transmission Pte.Ltd. is one of leading suppliers of power transmission products in Singapore, we offer a one-stop solution for your transmission requirement: chain sprocket, coupling, belt, pulley, gear, rack, Universal-joints, Shaft Collar, gearbox, motor, Brakes and clutch, torque limiter and many other power transmission products.

Don't wanna be here? Send us removal request.

Text

Thing to Learn About Transmission Products

The bevel gear has a conical form and through shafts that are typically at an angle of 90 degrees to each other, these can be used to transmit rotational power. In a wide range of applications starting from cordless hand-tools to automotive transmissions and outboard motors where the prime-mover location is not coaxial with the driven shaft, this functionality is very useful.

Bevel

For 90° drives, bevel gears are used most frequently, but other angles can also be used. Driving a vertical pump with a horizontal driver is the most typical application.

Between bevel gears and spur gears, the two major differences are their shape and the relation of the shafts on which they are mounted. In shape, a bevel gear is conical whereas a spur gear is essentially cylindrical. Between angular or intersecting shafts Bevel gears transmit motion whereas between parallel shafts spur gears transmit motion.

To connect shafts whose axes lie at an angle to each other bevel gears and transmission products China are used however in most applications the shafts are at right angles. The tooth profile is equally the same as used for spur gears except that the tooth gets smaller as it approaches the apex of the projected cone. Usually, the teeth are straight cut, and from the apex of the pitch cone they radiate, but in providing them curved, skew, or spiroid form it is possible.

The crown wheel will also have straight teeth when such a pinion has radial teeth but offset about the axis. The hypoid is a variation, where on the skew the teeth on both gears are cut and in such a situation with consequent smoother running, they will act similarly to helical gears. The spirit gear has curved teeth and, in many cases, to an offset worm drive, it can be likened. These systems cause higher tooth pressures and, as a result, efficient lubrication must be given.

The goal of this design is an increase of bearing capacity, especially in the case when the axes of rotation of gear and a mating pinion are not orthogonal to each other. You will find different transmission products supplier near you.

Original source:��https://gearreducers.seesaa.net/

#Transmission Products Manufacturer#Transmission Products Supplier#Bevel Gear#Transmission Products China

2 notes

·

View notes

Text

Everything You Need to Know about Tractor transmissions

Everything You Need to Know about Tractor transmissions

For many grounds, men and greenkeepers tractors and agricultural gearbox are a part of their daily life. There have been many changes to the size, power, and comfort of a tractor since the invention of the modern tractor. In this article, we will look at the current offerings and will try to establish the benefits of each transmission type. Manual Transmissions The original drive system was…

View On WordPress

#Agricultural Gearbox China#Agricultural Gearbox Manufacturer#Agricultural Gearbox Supplier#Agricultural Gearbox Wholesale

0 notes

Text

Power Transmission and the Products That Transmit Power to Create Motion

Power Transmission and the Products That Transmit Power to Create Motion

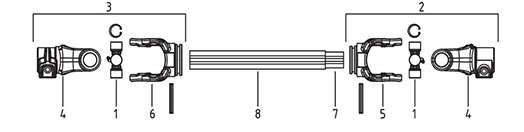

To create motion power transmission products transmit power. Motion is transmitted by the power transmission process from one shaft to another with a connection between them like a belt, chain, or gear. In industrial automation, construction machinery, and material handling system applications PTO shaft products are commonly used. The transmission method is a method that in terms of energy…

View On WordPress

0 notes

Text

Overview of Chains and its Uses

Overview of Chains and its Uses

A series of connected links or rings that are usually made of metal and can be connected or fitted into one another is what we call chains. Depending on its application each piece of the chain can have more than one link. Few uses of chains can be for supporting objects, fastening, or binding. The two most common styles of making chains are roller chains and those that are torus-shaped.…

View On WordPress

0 notes

Text

Everything Explained about Bushings In Brief

A plain bearing also denoted as a bushing like the taper bush is a mechanical element. For minimizing friction between rotating shafts and stationary support members, it is used. Typically, to support the rotating shaft on the hardened shaft journal a bushing relies on soft metal or plastic and an oil film. Plain bearings are used in machinery that has a rotating or a sliding shaft component. These are also known as sliding bearings, sleeve bearings, or journal bearing, plain bearings have no rolling elements. To give protection to the shaft journals some are made of relatively soft metal. Depending on the application and load requirements they are made of other materials. In drilling operations, other bushings may be used for alignment jigs.

Applications of Bushings and Bearings

Unlike rolling element bearings which are designed with having finite lives in mind, plain bearings rely on full fluid lubrication that is theoretically capable of running indefinitely and are widely used in very critical applications where a failure in bearings can result in having severe consequences. In low-speed shafting applications such as ship propeller shafts, plain bearings are quite frequently used. It has been stated that taper bush China is almost exclusively used in engines.

Due to the low costs and simplicity plain bearings excel at the other end of the spectrum and to intermittent motion applications and linear motion they are very well suited. Materials play a wide role in these bearings. In food processing where lubricants must be kept out of foods, the latter are frequently applied. In bronze or pressed in powdered metal the casting of a plain bearing is done and is impregnated with oil that provides film lubrication.

There are plain bearings that are very specific to the applications. One such example is engine bearings that are an intended application that can be a good attribute to find bearings that are well suited to a particular need. On the other side, you will find many plain bushings from taper bush manufacturer for general purposes that are very well suited to a variety of bearing applications, and in such cases, searching by geometry, and material, etc. can give you better results.

2 notes

·

View notes

Text

Everything Explained about Bushings In Brief

Everything Explained about Bushings In Brief

A plain bearing also denoted as a bushing like the taper bush is a mechanical element. For minimizing friction between rotating shafts and stationary support members, it is used. Typically, to support the rotating shaft on the hardened shaft journal a bushing relies on soft metal or plastic and an oil film. Plain bearings are used in machinery that has a rotating or a sliding shaft component.…

View On WordPress

3 notes

·

View notes

Text

Tips to Achieve Gear Coupling Reliability

For connecting process equipment gear coupling is among the most commonly used methods. They can provide long life and good reliability when properly selected, installed, and maintained.

Over other couplings, Gear Coupling offers several advantages, including very high torque density, moderate misalignment capacity, and exceptional tensional stiffness and.

However, you will find many areas where failures may be initiated when it comes to gear coupling reliability. Because of a lack of knowledge or a lack of execution of certain fundamentals generally, these failures begin, which are very much important for these couplings to run reliably.

Installation

Due to their installation few couplings don’t get much of a chance at a decent life. There are times these parts don’t die but are murdered just like other components that experience infant mortality. If optimum reliability is to be obtained then certain elements of gear coupling installation must be considered by gear coupling manufacturer, including:

Keys and Keyway Fits - To reduce the risk for fatigue cracking keyways should have a proper radius. To minimize the coupling imbalance key lengths should be measured.

Hub and Sleeve Fit – You need to determine the type of hub fit. To offset centrifugal force effects on shaft/hub contact pressures higher speed applications should have an adequate interference fit. Excessive hub interference fits can result in hub cracks and hub failure.

Fastener Assembly – Select the correct type of fasteners and the proper arrangement. They may put the threads in the shear plane so that standard bolts can work. Coupling bolts require correct preload, which can only be achieved by proper bolt torque methods.

Correct Coupling Gaps -The shafts may impact one another under misalignment if floating shafts have a small coupling gap.

Proper Sealing – You need to use proper gaskets and O-rings so the lubricant stays in the coupling.

Hub Installation - If you want that your hub material properties are not compromised then you need to choose proper heating methods from gear coupling supplier and for interference fit hubs you need to select the proper heating magnitude.

Lubrication - For optimum gear coupling reliability get the right product in the right amount at the right time.

1 note

·

View note

Text

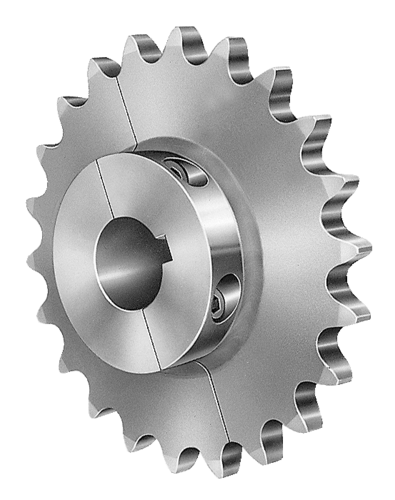

Get Acquainted with the Sprockets Chains in Details

Get Acquainted with the Sprockets Chains in Details

Used to convey materials or transmit power by engaging with conveyor or roller chains, chain sprocket is rotating toothed wheels. Key specifications are the pitch, material, intended application, and physical dimensions as well as several teeth as required. In chain-driven systems, Sprockets are used primarily to transmit rotation or power to other shafts. An example is transmitting rotation…

View On WordPress

1 note

·

View note

Text

Flow-Through the Details of a Conveyor System

Flow-Through the Details of a Conveyor System

Transporting material with minimal effort, conveyor chain is assemblies or mechanical devices. They usually consist of a frame supporting a belt, wheels, or rollers, upon which materials move from one place to another while there are various types of conveyor systems. By manually, by gravity, or motor, they may be powered. To suit the different materials or products that need to be transported,…

View On WordPress

1 note

·

View note

Text

Get Aware of the Applications and Types of Sprockets

The sprocket is also a useful part for power transmissions like some power transmission parts such as couplings, taper bush, shafts, and pulleys. Coming with metal teeth, it is a very common and popular wheel or gear that meshes perfectly with a track or chain. To refer to the distance between two sprockets, the term pitch is used. To slip away, they do not allow gears and in cases where chains get engaged by wheels or gears, they are applied specifically. Besides, producing rotational motions, they are also used in cases of motors. Essentially part of the chain drives is Industrial sprockets. In a chain drive, the type of chain used must match with the sprocket.

In a variety of types and styles, this kind of power transmission part is available. Some specific sprocket-making styles are adopted by some manufactures. For example, a sprocket having a hub extension on one side is one type.

Sprockets can be classified into various types based on the number of strands. Firstly, for solid type which allows quick installation, the split type sprocket is a good alternative without in any way hampering the alignment and shaft. Secondly, giving a positive grip on the drive shaft, taper bushed sprocket (TB) is an interchangeable bushed sprocket. Thirdly, a type of quick detachable (QD) sprocket is there. Machined in the sprocket is typically bolted into the bore in this type of tapered bushing from a taper bush manufacturer. Into the sprocket, A tight grip is offered as the bushing is inserted which compresses onto the shaft.

Wide use of applications is there in the Sprockets. In a seed-cum-fertilizer drill, they are used as farm implements. In the bicycle sector, they have a very popular application. In a bicycle, there are typically two sets of sprockets i.e. the rear and the front sprocket. Often they are also known as the driven sprocket and the driving sprocket. Commonly, automobile applications are there in the sprocket. A sprocket is typically a wheel that has metal teeth in two-wheeler scooters. Upon it, the chain rides. For smooth mobility of two-wheelers, they are imperative. Also, they are even used in the film transport mechanisms of movie cameras and movie projectors. In the film stock, the sprocket wheels engage film perforations In this case.

Without the need for special equipment or skills, mounting a tapered bushing can be performed and is very easy.

To tighten the component onto the shaft, Grub screws are used. As the downward pressure from the component clamps the bushing onto the shaft and the grub screws are tightened, the bushing is drawn into the component.

Benefits and Features of a Taper Bushing

Components are secured onto a shaft.

Being used worldwide, a universal solution.

With a long service life, it is a high-quality component.

With no specialist equipment needed, it is easy to mount.

All in all, in many places, sprockets and taper bush play an important role. They also attract people's attention like some widely used power transmissions parts such as universal joints and gearboxes.

#gear reducers#gearboxes#mechanical products#PTO Shaft#Bevel Gear#Agricultural Gearbox#Jaw Coupling#Gear Coupling#Chain Sprocket#Dragging Chain#Conveyor Chain

1 note

·

View note

Text

Uses and Types of Gears According to Axle or Shaft Position

Depending on its purpose, there are several different kinds of gears manufactured according to sizes, shafts, material, and so on, all designed available in the market. According to the arrangement of the axle or PTO shaft, used to classify each type of gear, there are different criteria a popular method is categorizing them. 3 kinds of shaft arrangement are there, namely parallel shafts, non-parallel axis, and non-intersecting or intersecting shafts.

First, at the same surface level, parallel shaft gears are the type of gears that interlock. To transfer the power of rotational motion between the parallel shafts, they function as a mechanism. Designed for long-term efficiency, the advantages are these gears provide maximum horsepower. Also when it operates, it does not make much noise and can carry a high load. Production of these types of gear On the other hand creates axial thrust and is expensive. With manual transmissions like car steering and clock, these gears are used for machines generally.

Second, to allow smooth transfer of motion and power between axes that are angled to be perpendicular with each other, intersecting shaft gears from PTO shaft supplier are designed. Falling into this category, the following are types of gears: crown gear, coniflex, bevel, and angular. Requiring strength and speed, their purpose is to power machines that because it can handle high load capacity. Intersecting gears are more inexpensive as compared to the parallel shaft. These types of gears are typically used to power marine applications, locomotives, hand drills, and much more.

Lastly, while using gears with non-intersecting axes, used on applications, non-parallel or non-intersecting shaft gears are that require high-ratio speed reduction providing power transmission within a limited area. Because its production cost is also the lowest, it has a limited load capability although it is the most inexpensive type of gear from PTO shaft manufacturer. By lowering the ratios to increase efficiency, this setback can be solved easily.

Categorizing the use of gears, this is only one of many systems. Gears are categorized according to materials pitch diameter used to manufacturing precision, manufacture the gear, number of housing design and steps among others.

Follow our Facebook and Twitter for more information about our product.

2 notes

·

View notes

Text

The Benefits of the Various Systems with Tractor Transmissions

For many greenkeepers and groundsmen, Tractors are a part of daily life. They are the beasts of burden: powering attachments, towing trailers, loading trailers, towing mowers, and tipping loads like sprayers and aerators.

Available on agricultural gearbox of a modern tractor, one of the major changes has been to the transmission systems and when purchasing a new machine, the choice that the potential buyer faces. In this article, we try to establish the benefits of each transmission type and look at the current offerings.

Manual Transmissions

On operating a clutch to change range, gears, and to disengage or engage, the PTO drive by use of a 2 stage clutch, the original drive system relied where partial depression disengaged only the gearbox and full depression stopped all drives.

Removing the need for a two-stage clutch, Today's PTO drives are all independent.

Originally, between the driver's legs, the gear levers were situated on top of the gearbox. Allowing a wide spread of forwarding speeds and full engine power, one for the gears and a second lever which changed the ranges, There were two levers.

Shuttle shift: Today, there isn't a reverse gear separately. Instead of allowing a change of direction, we have a reverse and forward lever, without having to change the gear of the tractor. So, we have twelve reverse gears and twelve forward, if we have twelve gears from agricultural gearbox supplier!

Intelligent Transmissions: to change gears, the latest manual transmissions now allow the driver and without using the clutch, to change direction. By pressing a down or up button on the gear stick, an electronic gear change is achieved, and by using a shuttle lever, a forward-reverse is selected. Making it easier for the driver to operate safely, the shuttle gives an additional neutral. Selecting the speed range the tractor is going to be working in the only time the clutch has to be used from agricultural gearbox manufacturer.

So, modern manual transmission has come a long way from an operational point of view. This is critical for accurate fertilizer and spraying, applications, the benefits of positive gears are a fixed forward speed, the essential turf maintenance task of aerating.

2 notes

·

View notes

Text

Benefits of Bevel Gears

One of the most important types of gear known is bevel gear. It takes the force from one direction and changes it to another direction. For example, the use of a bevel gear force from a drill that comes in horizontally can be changed to a vertical force. With most of its tip cut off, it is shaped like a right circular cone. They are highly used in the hafts from the main shaft to the back shaft.

In most of the commonly used machines, bevel gears are the driving force because of their flexible angles of operation and adjustable force levels. You will find them in several different machines such as watches, drills, and even some forms of can openers. Without them, we would be unable to operate printing presses, drive our cars, fly in helicopters, or do many other mechanical tasks.

This type of gear has many benefits that make them so popular in industries. At first, they have good flexibility. Bevel gears from bevel gear supplier have an adjustable angle of operation, unlike standard ones. By simply changing the number of teeth it’s easy to tweak their force output.

Secondly, the use of a variety of different materials can be made. In clocks as well as in hand tools such as the handheld drill drivers metal ones are quite common. However, by the use of plastic or nylon they can be made, and in electronic machines like toys as well as other components they are more common.

Thirdly, apart from just transferring force from one direction to another, they also increase the force generated after the transfer. By turning the bevel gears from bevel gear manufacturer, when the initial gear moves, the force goes up after the transfer process. Through the proper use of bevel gears in the power, the assembly can allow a relatively weak power source to generate a much stronger output of energy. The last thing is that they have practical uses.

2 notes

·

View notes

Text

All about Different Types of Couplings

There are two main categories of coupling: Material Flexing and Mechanical Flexing. From flexing of thin metallic discs or grid and from compressing or stretching a resilient material like rubber, their flexibility is obtained by the material flexible types. Except for grid couplings, material flexing jaw coupling does not require lubrication.

About the amount of downtime incurred for scheduled and unscheduled maintenance, the manufacturing sector has always been concerned. In unscheduled maintenance, the dollars lost can be quite substantial.

For conveyors pumps, compressors, and other machinery all industrial facilities use some type of flexible coupling. All these flexible couplings require some measure of maintenance.

From rocking, rolling, or sliding of metal surfaces the mechanical flexing couplings accept misalignment. Lubrication is necessary for all metal mechanical flexing couplings.

Material Flexing Couplings

Material flexing couplings operate in shear or compression and do not require lubrication. They can accept angular, parallel, and axial misalignment. Tire, jaw from jaw coupling supplier, diaphragm couplings sleeve, disc, and grid are the examples of material flexing couplings.

- Jaw Couplings

The jaw coupling is a material flexing coupling that transmits torque by the compression of an elastomeric spider insert that is placed between two intermeshing jaws. Jaw coupling from jaw coupling manufacturer is used for torsional dampening (vibration).

Transmission of torque

By NBR, polyurethane, Hytrel, or Bronze flex element is made.

It is used for Low torque, general-purpose applications

It Accommodates misalignment

Gear Couplings

In any flexible coupling, the highest amount of torque is transmitted by gear couplings in the smallest diameter.

Each coupling comprises two hubs with crowned external gear teeth. With two internally splined flanged sleeves, the hubs mesh that are bolted together. By having two adjacent hub or sleeve flex points, Parallel misalignment is accommodated. Depending on the application gear couplings require periodic lubrication. They are sensitive to lubrication failures, but these couplings have a service life of 3 to 5 years if properly installed and maintained and in some cases, they can last for decades.

2 notes

·

View notes

Text

Get a Brief Introduction to Sprockets

Power transmission has become vital for our day-to-day life, so other sources of transmission have also gained an important role.

Sprockets

But what's a chain sprocket to be exact? This is often a traditional and quite popular wheel or gear that features a row of teeth made up of metal that combine great with a track or a sequence. During this area, you would possibly have heard about the notion pitch, which refers to the length registered between 2 sprockets.

During this situation, the gears are prevented from slipping away and are normally applied when the chains are engaged by wheels or gears. Additionally to the present, sprockets also are utilized in the case of the motors that produce rotational motion.

The economic kind is a component of chain drives, but here is extremely important that the sprocket matches the type of chain used alternatively serious problems might appear.

Variety

The type of transmission mentioned above comes during a wide selection of types and designs. There are a couple of manufacturers that only take under consideration special sprocket making types. as an example, an excellent example of a sprocket is that the one that features a hub extension on one among its sides.

Another sort of sprocket from chain sprocket supplier features a detachable blot included on a hub. Further on, this is often united with a plate. But besides those mentioned above, there are other examples too.

Applications

As you've got probably expected, the sprockets have an outsized range of applications. They will be utilized as farm implements or within the bike sector. Within the latter case, there are normally 2 sorts of sprockets - the front and therefore the rear one.

Next to the present, a sprocket from a chain sprocket manufacturer also can have automobile applications. Within the case of the wheeler scooters, the sprocket maybe a wheel with metal teeth and a sequence that rides thereon. They’re necessary if you would like to get excellent mobility for the wheelers.

In a conclusion, we will say that sprockets are vital in many applications. a bit like in other power transmission sources, these also represent a hot spot for several people.

Follow our Facebook and Twitter for more information about our product.

2 notes

·

View notes

Text

Know about the Drag Chain

The conveyor consists of a sequence being drawn through a pipe. Units handling several tons per hour are often constructed using basic workshop facilities.

The operation was demonstrated with a typical mineral and typical grains, employing a chain with 25-mm links in pipes with diameters of 25, 38, or 50 mm. Angles ranged from horizontal to 60° and chain speeds from 0.2 to 4 m/s. Through-put varied linearly with chain speed from dragging chain supplier so that the device has potential also as a controlled solids feeder. The correlations presented to enable the essential design parameters of the conveyor to be estimated for materials resembling those tested.

The conveyor is meant for little through-puts over distances within 100 m, and when power consumption isn't a clincher. The speed of wear and tear will depend upon the character of the feed. The suitability of the conveyor for any specific application has got to be determined experimentally.

Chain/Tow/Drag Line Conveyor

Dragging chain uses mechanical devices attached to moving members, usually chains or cables, to tug or to products. Drag conveyors are used for moving bulk materials in bins, flights, or other attachments and may have multiple discharge or loading points. Tubular drag conveyors use an enclosed system of chains to convey product in any direction. Chain conveyors use a sequence, or multiple chains to maneuver pallets or other hard-to-convey products. Tow conveyors use a towline like cables or chains, usually within the floor or simply above it, to tow product directly or to tow wheeled carts or dollies.

Drag chain conveyors are used for special transportation of smaller capacities. Drag chain conveyors work on the principle of a chain-and-flight combination pulling a volume of fabric along. The chain is provided with different flights/paddles and drags the fabric from various charging points to a variety of discharge points.

The enclosed conveying device is employed mainly for dusty, abrasive, or hot material and, as such, has only a really limited application in coal. However, the facility plant industry and other industry players invite specialized conveying systems, that the very flexible drag chain conveyor from dragging chain manufacturer could be an answer.

Horizontal, vertical, or inclined solutions, with a possible explosion-proof and dust-tight design, could be necessary for a few special applications within the industry.

3 notes

·

View notes