Don't wanna be here? Send us removal request.

Text

CNC Router Machine Suppliers in Mumbai

In today’s fast-paced world of manufacturing, the demand for precision, efficiency, and advanced technology has skyrocketed. CNC (Computer Numerical Control) router machines are at the forefront of this technological evolution, playing a crucial role in industries like furniture manufacturing, signage, automotive, aerospace, and more. If you’re in Mumbai and looking for reliable CNC router machine suppliers, GK Laser Enterprises stands out as a trusted name in the industry.

Why Choose CNC Router Machines?

CNC router machines offer unmatched precision and automation, making them an essential tool for manufacturers. These machines are designed to cut, carve, and engrave a wide range of materials, including wood, acrylic, aluminum, plastic, and even composites. Their key benefits include:

High Precision: With computer-controlled operations, CNC routers deliver consistent, accurate cuts every time.

Cost Efficiency: Reduce material wastage and labor costs through automated processes.

Versatility: Handle various materials and projects, from intricate designs to large-scale productions.

Speed: High-speed operations ensure faster project completion, meeting tight deadlines.

Ease of Use: User-friendly interfaces make these machines accessible to operators of all skill levels.

About GK Laser Enterprises

Based in Mumbai, GK Laser Enterprises is a leading supplier of CNC router machines, offering high-quality products and exceptional customer service. With a strong commitment to innovation and client satisfaction, we cater to businesses of all sizes, from small workshops to large-scale manufacturing units.

Our portfolio includes a diverse range of CNC router machines tailored to meet specific industry needs. We focus on delivering cutting-edge technology that enhances productivity while maintaining cost-efficiency for our clients.

Key Features of Our CNC Router Machines

At GK Laser Enterprises, we pride ourselves on providing CNC router machines equipped with the latest advancements. Here are some key features that set our products apart:

Robust Build Quality: Built with durable materials to ensure longevity and performance.

Advanced Control Systems: User-friendly interfaces with high-performance controllers for precise operations.

Customizable Options: Machines can be tailored to meet specific operational requirements.

High-Speed Spindles: Capable of handling both soft and hard materials with ease.

Safety Features: Integrated systems for operator safety and machine reliability.

Low Maintenance: Designed for minimal downtime and easy maintenance.

Industries We Serve

CNC router machines from GK Laser Enterprises are versatile and can be applied across various industries, including:

Furniture Manufacturing: Create intricate woodwork designs with precision.

Signage and Advertising: Cut and engrave acrylics, plastics, and metals for high-quality signage.

Automotive: Design and fabricate parts with accuracy.

Aerospace: Ensure precision in manufacturing components for aircraft.

Education: Equip institutions with CNC routers for technical training and prototyping.

Why GK Laser Enterprises?

Choosing the right supplier is crucial when investing in CNC router machines. GK Laser Enterprises stands out for several reasons:

Quality Assurance: We offer only the best-in-class machines sourced from reputed manufacturers.

Expert Consultation: Our team of experts guides you in selecting the right machine based on your business needs.

Competitive Pricing: Get the best value for your investment with affordable pricing.

After-Sales Support: We provide comprehensive maintenance and support to ensure your machine operates seamlessly.

Training and Installation: We assist with on-site installation and operator training for a smooth transition.

Our Product Range

GK Laser Enterprises offers a wide range of CNC router machines to meet diverse manufacturing requirements:

3-Axis CNC Routers: Perfect for basic cutting and engraving tasks.

4-Axis CNC Routers: Ideal for intricate designs and complex shapes.

5-Axis CNC Routers: Best suited for advanced machining and multi-dimensional operations.

Custom CNC Routers: Tailored to your unique specifications for maximum efficiency.

Customer Success Stories

We have served numerous clients in Mumbai and beyond, helping them elevate their production capabilities. Here are a few success stories:

A leading signage company streamlined its production line using our high-speed CNC router, reducing turnaround time by 40%.

A furniture manufacturer in Mumbai leveraged our 4-axis CNC router to produce intricate designs, gaining a competitive edge in the market.

An educational institution integrated our CNC router into their curriculum, providing students hands-on experience with industry-grade machinery.

How to Choose the Right CNC Router Machine

When investing in a CNC router machine, consider the following factors:

Material Compatibility: Ensure the machine can handle the materials you work with.

Size and Work Area: Choose a machine with a work area suitable for your projects.

Power and Speed: Opt for a machine that balances power with efficiency.

Software Compatibility: Check for compatibility with your existing design software.

Budget: Consider the total cost, including installation, maintenance, and training.

Our Commitment to Sustainability

At GK Laser Enterprises, we are committed to sustainability. Our CNC router machines are designed to minimize material wastage, reduce energy consumption, and support eco-friendly manufacturing processes.

Contact GK Laser Enterprises Today!

If you’re looking for CNC router machine suppliers in Mumbai, look no further than GK Laser Enterprises. We are dedicated to providing top-quality machines, unmatched service, and ongoing support to help your business thrive.

Get in touch with us today to explore our range of CNC router machines and discover how we can transform your manufacturing process. Call us at [Your Contact Number] or email us at [Your Email Address]. Visit our website [Your Website URL] for more information.

Transform your business with cutting-edge CNC technology from GK Laser Enterprises!

1 note

·

View note

Text

Laser Cutting Machine in Thane

In today’s world, businesses across various industries require highly precise cutting tools to create products that meet exacting standards. From intricate designs to industrial-grade cuts, laser cutting technology has revolutionized the way we work with materials like metal, wood, plastic, and more. At GK Laser Enterprises, we are proud to be your go-to provider for laser cutting machines in Thane, catering to a wide range of industries and applications.

This article will guide you through the benefits, applications, and reasons why GK Laser Enterprises is the trusted name for laser cutting solutions in Thane.

What is Laser Cutting?

Laser cutting is a technology that uses a high-powered laser beam to cut or engrave materials with exceptional precision. The laser beam melts, burns, or vaporizes the material to create clean, accurate edges. With computer-controlled operations, this technology ensures repeatability and perfection in every cut.

The technique is widely used in industries such as automotive, aerospace, electronics, signage, jewelry, and construction, making it indispensable for modern manufacturing.

Why Choose Laser Cutting Machines?

1. High Precision and Accuracy

Laser cutting machines offer unparalleled precision, capable of creating intricate designs and cuts that would be impossible with traditional tools. The accuracy ensures minimal wastage, saving both material and cost.

2. Versatility

From metals like stainless steel and aluminum to non-metals like acrylic and wood, laser cutting machines handle a wide variety of materials with ease. This versatility makes them suitable for diverse industries.

3. Efficiency

Laser cutting machines are faster than conventional cutting methods, enabling high-speed production. Automation further enhances efficiency, reducing labor costs and improving turnaround time.

4. Minimal Material Wastage

Laser cutting ensures clean edges with minimal burrs or debris. This precision reduces material waste, making it an environmentally friendly option for businesses.

5. Customization

Whether you need unique patterns for jewelry or precise cuts for industrial components, laser cutting allows for endless customization, adapting to any design requirement.

Applications of Laser Cutting Machine in Thane

As a bustling industrial and commercial hub, Thane is home to businesses that demand cutting-edge technology. At GK Laser Enterprises, we cater to a variety of industries, including:

1. Automotive Industry

Laser cutting is ideal for creating precise automotive components, such as gears, brackets, and panels. Its high precision ensures that parts fit perfectly, enhancing vehicle performance.

2. Architectural and Interior Design

From intricate metal screens to wooden panels, laser cutting machines enable designers to create stunning architectural and interior elements. The technology also supports custom signage and decorative pieces.

3. Jewelry and Art

For artisans and jewelers in Thane, laser cutting is a game-changer. It allows for delicate cuts and engravings on precious metals, ensuring unique and intricate designs.

4. Electronics

The electronics industry relies on laser cutting for creating intricate circuits and components. Its precision ensures that even the smallest parts are manufactured flawlessly.

5. Manufacturing and Engineering

In industrial manufacturing, laser cutting machines are indispensable for creating machine parts, prototypes, and other components with exact specifications.

Why Choose GK Laser Enterprises in Thane?

At GK Laser Enterprises, we bring years of expertise and a commitment to delivering the best laser cutting machines to businesses in Thane. Here’s what sets us apart:

1. Wide Range of Machines

We offer a comprehensive range of laser cutting machines, including CO2 lasers, fiber lasers, and hybrid systems. Whether you need a compact machine for small-scale projects or a high-capacity system for industrial use, we have you covered.

2. Quality Assurance

Our laser cutting machines are sourced from leading manufacturers, ensuring durability, reliability, and top-notch performance. Each machine undergoes rigorous testing to meet global standards.

3. Customization and Support

We understand that every business has unique needs. That’s why we provide tailored solutions to match your specific requirements. Our team also offers installation, training, and ongoing technical support to ensure seamless operation.

4. Competitive Pricing

At GK Laser Enterprises, we believe that cutting-edge technology should be accessible to all businesses. Our laser cutting machines are competitively priced, offering excellent value for money.

5. Local Expertise

As a Thane-based business, we understand the local market and are committed to helping businesses in our community thrive. We’re just a call away for consultations, demonstrations, and support.

Advantages of Partnering with GK Laser Enterprises

Comprehensive Training We provide training to help your team maximize the potential of your laser cutting machine.

After-Sales Support Our dedicated customer service team ensures that your operations run smoothly with minimal downtime.

Upgrades and Maintenance Stay ahead with the latest technology. We offer upgrades and maintenance services to keep your machine in top condition.

Custom Solutions From bespoke machine configurations to specialized cutting needs, we deliver solutions tailored to your business.

Testimonials from Our Clients

“Our experience with GK Laser Enterprises has been exceptional. Their laser cutting machine has transformed our production process, saving us time and costs. The team’s support and expertise made the transition seamless.” – Ramesh Gupta, Automotive Parts Manufacturer

“Thanks to GK Laser Enterprises, we’ve been able to offer custom metal designs that have delighted our customers. Their machine’s precision is unmatched.” – Sneha Patel, Interior Designer

Contact GK Laser Enterprises Today

If you’re looking for laser cutting machines in Thane, look no further than GK Laser Enterprises. Our cutting-edge technology, exceptional customer service, and competitive pricing make us the ideal partner for your business.

Get in touch with us today to learn more about our laser cutting solutions and how they can benefit your business. Whether you’re starting a new venture or upgrading your existing setup, GK Laser Enterprises is here to support your growth.

0 notes

Text

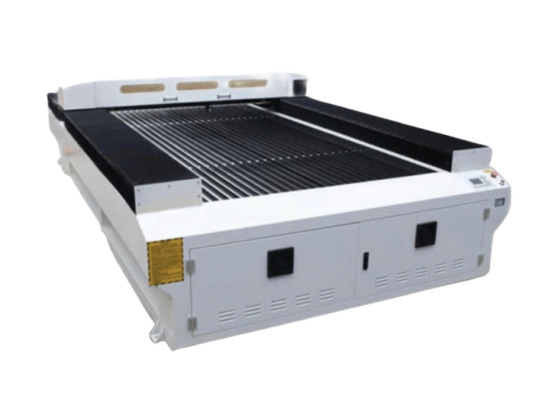

CO2 Laser Cutting and Engraving Machine

CO2 laser cutting and engraving machines have revolutionized industries by offering precision, speed, and versatility in material processing. For businesses like GK Laser Enterprises, located in Mira Bhayandar, CO2 laser machines are key assets that enhance manufacturing capabilities. Whether you're working with wood, acrylic, leather, or glass, these machines provide exceptional accuracy, making them indispensable for a variety of applications, from prototyping to mass production.

This article will explore the workings, benefits, and applications of CO2 laser cutting and engraving machines, and how they can transform your business at GK Laser Enterprises.

What is a CO2 Laser Cutting and Engraving Machine? A CO2 laser cutting and engraving machine is a type of laser that uses a carbon dioxide gas mixture to generate a powerful beam. This laser beam is highly concentrated, allowing it to cut or engrave through different materials with remarkable precision.

How It Works: Laser Generation: The CO2 laser is produced by electrically stimulating a gas-filled tube containing carbon dioxide. This produces infrared light, which is then directed towards a lens that focuses the beam onto the material. Cutting or Engraving: The focused laser beam either vaporizes or melts the material along the desired path, allowing for precise cuts or intricate engravings. Control System: Most CO2 laser machines are controlled via computer software, which allows for high levels of customization and accuracy. Designs are created digitally and then executed flawlessly by the machine. Key Benefits of CO2 Laser Machines for Businesses For companies like GK Laser Enterprises, CO2 laser cutting and engraving machines offer numerous advantages:

High Precision CO2 laser machines can cut intricate patterns and engrave fine details with extreme accuracy. The focused laser beam allows for minimal material waste and ensures consistent results, whether you're cutting through thin sheets of acrylic or engraving on glass. This level of precision makes these machines ideal for industries requiring detailed designs, such as jewelry making, signage, and custom crafts.

Versatility Across Multiple Materials One of the biggest strengths of CO2 laser machines is their ability to process a wide range of materials. From organic materials like wood and leather to synthetic ones like plastic and acrylic, the CO2 laser can handle them all. This makes it a versatile tool for a variety of industries, from furniture manufacturing to electronics.

Some common materials that CO2 laser machines can cut and engrave include:

Wood (hardwood, plywood, MDF) Acrylic and plastics Glass and crystal Leather and fabric Paper and cardboard Rubber and foam

Cost-Effective CO2 laser machines reduce costs by minimizing material waste and lowering labor expenses. The precision of the laser ensures fewer mistakes, which reduces the need for rework. Additionally, the machines operate quickly, allowing for higher production output without compromising on quality. This increased efficiency translates to savings in both time and money, providing a higher return on investment.

Automation and Easy Operation With modern CO2 laser machines, many tasks are automated. Operators only need to upload designs and input material specifications, and the machine handles the rest. This reduces the need for highly skilled labor, allowing businesses to streamline their workforce while maintaining high levels of production. Automation also reduces errors and ensures consistency across batches.

Environmentally Friendly CO2 laser cutting is a non-contact process, meaning it doesn’t require physical force to cut materials, which helps to reduce energy consumption. Since it produces less waste and fewer harmful emissions compared to traditional cutting methods, CO2 laser technology is a more eco-friendly option.

Applications of CO2 Laser Cutting and Engraving Machines CO2 laser cutting and engraving machines are used across a wide range of industries. Here are a few examples of how GK Laser Enterprises can utilize these machines:

Signage and Advertising Custom signs, banners, and display pieces are easily created with CO2 laser machines. The ability to cut and engrave materials like acrylic and wood allows for the creation of high-quality signage with a professional finish. This is ideal for retail stores, offices, and trade show displays.

Jewelry and Fashion Accessories For intricate designs, such as jewelry and fashion accessories, CO2 lasers offer unparalleled precision. Delicate cuts and engravings on metal, leather, or fabric allow designers to bring their unique creations to life with perfect accuracy. This application is especially valuable for small business owners looking to offer personalized items to their customers.

Custom Gifts and Awards Personalized engraving on items like trophies, plaques, and corporate gifts is a booming market. CO2 lasers can engrave intricate patterns, logos, and text onto glass, wood, or metal, adding a personal touch that clients love. Businesses can quickly customize products, adding names, dates, or company branding for unique gift options.

Architectural Models and Prototypes CO2 laser cutting machines are also useful in the architectural industry, where precision is key. Architects can use the laser to cut out scale models of buildings and landscapes. Prototypes for new products or packaging designs can also be produced quickly and accurately.

Educational and Creative Projects Schools, universities, and makerspaces can benefit from CO2 laser machines for creating educational tools, models, and prototypes. Artists and creatives can explore their ideas by cutting or engraving intricate designs into various materials, bringing their visions to life.

Choosing the Right CO2 Laser Machine for Your Business At GK Laser Enterprises, selecting the right CO2 laser cutting and engraving machine is critical to meeting the diverse needs of your customers. When choosing a machine, consider the following factors:

Power Rating: CO2 laser machines come in different power ratings, typically ranging from 40 watts to 150 watts or more. Higher power allows for cutting through thicker materials or faster processing times. Bed Size: The size of the working area (bed size) determines how large a piece of material you can cut or engrave at once. Larger bed sizes are ideal for bigger projects. Cooling Systems: CO2 lasers generate a lot of heat, so effective cooling systems are necessary to prevent overheating. Water-cooled lasers tend to be more efficient and durable than air-cooled models. Software Compatibility: Ensure that the machine is compatible with the design software you use, such as CorelDRAW or Adobe Illustrator, for seamless operations.

Conclusion For businesses like GK Laser Enterprises, CO2 laser cutting and engraving machines represent a major advancement in material processing technology. With their precision, versatility, and efficiency, these machines can cater to a broad spectrum of industries, offering endless possibilities for creativity and productivity. Whether you’re looking to streamline production, create custom designs, or enter new markets, investing in a CO2 laser machine is a smart move toward growth and innovation.

At GK Laser Enterprises, we strive to bring you the best in cutting-edge laser technology, helping you stay ahead in an increasingly competitive market. Contact us today to learn more about how our CO2 laser machines can enhance your business operations.

0 notes

Text

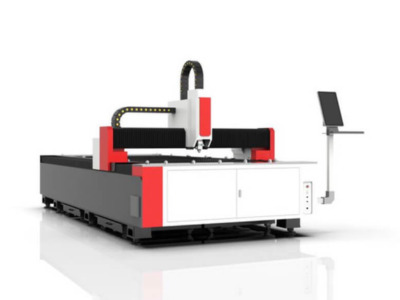

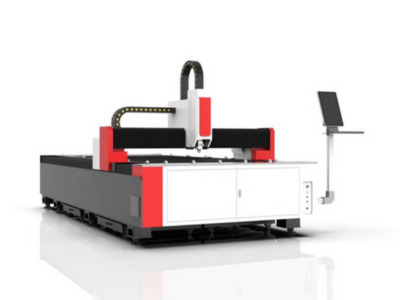

Fiber laser cutting machine dealer Mumbai

In today’s fast-paced manufacturing world, precision and efficiency are key. One technology that has significantly transformed the metalworking industry is fiber laser cutting machines. Whether it’s intricate designs, high-speed cuts, or unparalleled precision, fiber laser technology is revolutionizing industries across the board. If you're in Mumbai and looking for a reliable fiber laser cutting machine dealer, GK Laser Enterprises is your go-to destination for state-of-the-art machines and exceptional service.

Why Choose Fiber Laser Cutting Machines? Fiber laser cutting machines are considered a game-changer in industries ranging from automotive to aerospace, construction, and more. They offer unmatched versatility and quality in metal cutting, enabling businesses to take on complex projects with ease. Here’s why you should consider investing in a fiber laser cutting machine from GK Laser Enterprises:

Precision and Accuracy One of the standout features of fiber laser cutting machines is their precision. The lasers used in these machines produce a highly concentrated beam of light that can cut through metals with extreme accuracy. Whether you’re cutting stainless steel, aluminum, or even copper, fiber lasers ensure clean, burr-free edges. This precision is essential for industries where intricate designs and tight tolerances are required.

Speed and Efficiency When time is money, fiber laser cutting machines deliver unparalleled speed. Compared to traditional cutting methods like plasma or mechanical cutting, fiber lasers can work at faster speeds without compromising quality. The ability to cut through materials quickly helps in speeding up production, reducing lead times, and improving overall efficiency.

Low Operating Costs Another reason fiber laser cutting machines are gaining popularity is their low operational costs. Fiber lasers are more energy-efficient than CO2 lasers, reducing electricity consumption. Additionally, the lack of mirrors and other sensitive components in fiber lasers means fewer maintenance costs, translating into long-term savings for your business.

Versatility in Material Cutting Fiber lasers can handle a wide range of materials, from stainless steel and mild steel to brass, copper, and aluminum. Whether your project involves thick or thin materials, fiber laser technology provides excellent versatility, making it a preferred choice for various industries.

Why Buy from GK Laser Enterprises in Mumbai? GK Laser Enterprises is a leading name when it comes to providing high-quality fiber laser cutting machine dealer in Mumbai. We are known for our exceptional product range, reliable service, and commitment to helping businesses achieve the highest levels of precision in their cutting operations.

Extensive Product Range At GK Laser Enterprises, we offer an extensive range of fiber laser cutting machines to meet the needs of various industries. Whether you’re a small workshop or a large manufacturing plant, we have the perfect machine tailored to your specific requirements. Our machines are designed to offer high precision, reliability, and performance, helping your business stay ahead of the competition.

Top-Notch Customer Support At GK Laser Enterprises, customer satisfaction is our top priority. We understand that investing in a laser cutting machine is a significant decision for any business, which is why we offer personalized support and guidance to help you choose the right machine. From pre-purchase consultations to after-sales support, our team of experts is here to ensure that you have a seamless experience.

Installation and Training Services Buying a fiber laser cutting machine is just the beginning. To maximize the potential of your new machine, proper installation and training are essential. At GK Laser Enterprises, we offer comprehensive installation services to ensure that your machine is set up and running smoothly. Additionally, our training sessions are designed to equip your team with the skills needed to operate the machine efficiently, ensuring that you get the most out of your investment.

After-Sales Maintenance and Support Even the best machines require periodic maintenance and care to ensure they operate at peak performance. We offer regular maintenance services, troubleshooting, and repair support to ensure your machine stays in top working condition. Our goal is to minimize downtime and maximize productivity for your business.

Applications of Fiber Laser Cutting Machines Fiber laser cutting machines have wide applications across different industries. Here are some sectors where these machines play a crucial role:

Automotive Industry In the automotive sector, precision cutting of metal components is essential. Fiber lasers provide the ability to cut intricate parts for vehicles with extreme accuracy, ensuring that the components fit perfectly during assembly.

Aerospace Industry The aerospace industry requires cutting-edge technology for the production of parts that meet strict tolerances. Fiber lasers are used to cut components from materials like titanium, stainless steel, and aluminum, ensuring strength, durability, and lightweight properties in aircraft construction.

Construction and Architecture Fiber laser cutting is widely used in the construction industry to cut building materials like metal sheets and pipes. Architectural designs that require complex, customized metal patterns are made possible with the high precision of fiber lasers.

Medical Device Manufacturing In the medical field, precision is critical. Fiber laser cutting machines are used to manufacture medical instruments and devices, such as surgical tools and implants, where accuracy and cleanliness are paramount.

Electronics Industry The miniaturization of electronic components requires precise cutting of metals. Fiber lasers are used to cut thin sheets of metal with minimal heat damage, ensuring that sensitive electronic components are not compromised.

Why Fiber Laser Technology is the Future The future of manufacturing lies in precision, speed, and cost-effectiveness. Fiber laser cutting machines represent the perfect blend of these factors, making them a valuable asset for industries looking to scale their operations while maintaining high standards of quality.

At GK Laser Enterprises, we believe in staying ahead of the technological curve. Our commitment to offering cutting-edge fiber laser machines in Mumbai ensures that your business can take advantage of the latest advancements in laser cutting technology. Whether you are looking to upgrade your existing machinery or make a new investment, GK Laser Enterprises is your trusted partner.

Conclusion If you’re looking for a reliable and efficient fiber laser cutting machine dealer in Mumbai, GK Laser Enterprises is the perfect choice. We offer a wide range of machines tailored to different industrial needs, coupled with exceptional customer support and after-sales service. With the precision, speed, and efficiency of fiber laser technology, you can streamline your production process, reduce costs, and stay competitive in a rapidly evolving market.

Get in touch with us today to explore our product range and take your manufacturing capabilities to the next level!

0 notes

Text

Rotary CNC Router Machine

At GK Laser Enterprises, we pride ourselves on delivering cutting-edge solutions to meet the evolving needs of the manufacturing and fabrication industries. One such innovation that has gained popularity for its versatility and precision is the Rotary CNC Router Machine. As a leader in CNC technologies, we offer a range of advanced CNC machines, and today we dive deep into how a rotary CNC router machine can revolutionize your operations.

What is a Rotary CNC Router Machine? A Rotary CNC Router Machine is a computer-controlled cutting machine that uses rotary tools to carve, cut, or engrave materials in three dimensions. The term “rotary” refers to its ability to rotate the material around an axis while it works, providing access to all sides of the material. This capability enables intricate detailing, sculpting, and shaping of cylindrical or irregularly shaped materials.

Unlike traditional CNC routers that work on flat surfaces, rotary CNC routers can handle 3D shapes, making them ideal for creating complex, multi-faceted designs.

How Does a Rotary CNC Router Machine Work? The Rotary CNC Router works by rotating the material, typically using a rotary axis attachment, while the cutting tool precisely follows the programmed paths. Here’s a breakdown of the process:

Material Preparation: A workpiece, such as wood, metal, or plastic, is mounted on the rotary axis, which allows it to rotate. Programming: A computer-aided design (CAD) program creates a digital blueprint of the desired outcome. This is then converted into machine-readable code using computer-aided manufacturing (CAM) software. Cutting Process: The router uses its rotary axis to rotate the material while the cutting tool moves along the X, Y, and Z axes to carve, cut, or engrave the material into the desired shape. Finishing: Once the operation is complete, the workpiece is inspected and may require minimal finishing, thanks to the machine’s precision.

Key Features of a Rotary CNC Router Machine High Precision and Accuracy: Rotary CNC routers are known for their precision in handling complex designs, offering high accuracy even in detailed cuts and engravings. Versatility: Whether you’re working with wood, metal, plastic, or composites, the rotary CNC router can handle a wide range of materials. This versatility makes it invaluable for industries such as furniture design, sculpture, and sign-making. 3D Carving and Engraving: With the ability to rotate the material, rotary CNC routers are ideal for creating 3D objects like sculptures, chair legs, moldings, and even complex cylindrical designs. Automation and Efficiency: The CNC aspect automates the cutting process, ensuring uniformity in production and reducing the need for manual labor. This enhances efficiency and speeds up production time.

Why Choose a Rotary CNC Router Machine for Your Business? If your business requires precision, complexity, and scalability, a rotary CNC router is a wise investment. At GK Laser Enterprises, we emphasize the value it can bring to industries like:

Furniture Manufacturing: Intricate 3D carvings and details for chair legs, columns, and sculptures can be easily achieved using rotary CNC routers. Sign Making and Woodworking: From large signs to ornate wood designs, rotary CNC routers deliver exceptional precision that elevates your craftsmanship. Sculpture and Artwork Creation: Artists and designers benefit from the ability to craft complex shapes and details, providing unmatched creativity. Metal and Plastic Fabrication: Industrial manufacturers who work with metals and plastics can create custom parts, components, and molds with great precision.

Benefits of Using a Rotary CNC Router Machine Enhanced Productivity: With automated processes, your business can take on more projects with faster turnaround times, maximizing profitability. Cost Efficiency: Despite the upfront investment, the long-term savings on labor, material waste, and improved product quality make it a highly cost-effective solution. Precision and Consistency: The automation ensures that each piece you produce is identical in quality and detail, improving overall consistency. Flexibility: Whether you’re producing one-of-a-kind custom pieces or bulk products, the rotary CNC router offers the flexibility to handle both with ease. Lower Material Waste: Precision machining ensures that there is minimal waste, reducing the cost of raw materials and promoting sustainable practices.

Why Buy From GK Laser Enterprises? At GK Laser Enterprises, we provide high-quality rotary CNC router machines tailored to meet the unique needs of businesses across industries. With our deep industry expertise, we ensure that you get the most suitable machine for your applications, ensuring optimal performance and cost-efficiency.

We also offer:

Comprehensive Training and Support: Our team will provide full training on how to operate and maintain your CNC router machine. Maintenance Services: Regular servicing to keep your machine running smoothly, ensuring minimal downtime and maximum output. Custom Solutions: We understand that every business has different requirements, so we provide customized solutions that best fit your needs.

Conclusion The Rotary CNC Router Machine offers unparalleled precision and flexibility, making it an essential tool for businesses involved in woodworking, metalworking, and creative design. At GK Laser Enterprises, we’re committed to providing top-tier CNC solutions that enhance productivity and reduce costs. By investing in a rotary CNC router, your business can stay ahead of the competition while delivering superior quality products. Contact us today to learn more about our CNC machines and how they can benefit your operations!

2 notes

·

View notes

Text

Laser Cutting Machine Services in Mumbai

In the rapidly advancing world of precision engineering, laser cutting technology has emerged as a game-changer. It offers unparalleled accuracy, efficiency, and versatility, which is why industries across the globe are increasingly adopting laser cutting machines for a wide range of applications. GK Laser Enterprises, based in Thane, has been at the forefront of this revolution, providing cutting-edge laser cutting solutions that cater to various industries and their unique needs.

What is Laser Cutting? Laser cutting is a technology that uses a concentrated beam of light (laser) to cut or engrave materials with exceptional precision. The laser generates intense heat, which melts or vaporizes the material, creating clean, sharp edges. This technique is used to cut a wide array of materials, including metals, plastics, wood, glass, and even fabrics. Its ability to produce highly detailed and accurate cuts makes it a preferred method for industries like automotive, aerospace, electronics, construction, and more.

Why Choose Laser Cutting? Laser cutting machines are not only known for their precision but also for their efficiency. Unlike traditional cutting methods, laser cutting eliminates the need for physical contact with the material, reducing wear and tear on tools and ensuring a smooth, flawless finish. Here are some key advantages of using laser cutting technology:

Precision and Accuracy: Laser cutting machines offer unmatched precision, allowing for the creation of intricate designs and detailed cuts. Whether you need fine detailing for small components or larger cuts for industrial projects, laser cutting delivers consistent accuracy.

Versatility: Laser cutting is versatile enough to handle a variety of materials, including stainless steel, aluminum, copper, brass, acrylic, and more. This flexibility makes it an ideal choice for industries requiring diverse material handling.

Speed and Efficiency: Laser cutting machines work at high speeds, significantly reducing production time. This translates into faster project completion without compromising on quality. The speed and automation capabilities also lead to cost savings in labor and production processes.

Non-Contact Process: Since the laser cutting process is non-contact, there is minimal risk of material distortion, especially in delicate or thin materials. This also reduces the likelihood of damage to the machine parts, increasing the lifespan of the equipment.

Eco-Friendly: Laser cutting is an environmentally friendly technology. It produces minimal waste and consumes less energy compared to traditional cutting methods. This makes it an eco-conscious choice for businesses looking to reduce their carbon footprint.

GK Laser Enterprises: Your Trusted Partner in Laser Cutting Solutions At GK Laser Enterprises, we pride ourselves on delivering top-tier laser cutting services to our clients in Thane and beyond. Our state-of-the-art laser cutting machines, coupled with a highly skilled team, ensure that every project is executed with precision, efficiency, and professionalism. Whether you’re a small business looking for custom components or a large enterprise in need of mass production, we have the expertise to meet your specific requirements.

Our services include:

Metal Cutting: From stainless steel to aluminum, we specialize in cutting various metals with pinpoint accuracy. This is essential for industries like automotive, machinery, and construction.

Acrylic Cutting: We offer specialized services in cutting acrylic sheets for applications in signage, displays, and decorative items. Our laser cutting machines produce smooth, polished edges, enhancing the aesthetic appeal of the finished product.

Customized Solutions: We understand that every business has unique needs. At GK Laser Enterprises, we work closely with our clients to provide tailored laser cutting solutions that align with their specific project requirements.

Why Choose GK Laser Enterprises? Advanced Technology: We utilize the latest laser cutting machines that are capable of handling complex designs and tight tolerances. Our equipment is regularly updated to ensure optimal performance.

Experienced Team: Our team of experts has years of experience in laser cutting, ensuring that every project is executed with the highest level of precision and care.

Customer-Centric Approach: At GK Laser Enterprises, we believe in building long-term relationships with our clients. We work collaboratively to understand your needs and deliver solutions that exceed expectations.

Quick Turnaround: Time is of the essence in any industry, and we prioritize delivering high-quality results within the shortest possible time frame. Our streamlined processes ensure efficiency without compromising on quality.

Applications of Laser Cutting Technology Laser cutting technology is used in a wide variety of industries, including:

Automotive: Manufacturing components for vehicles with high precision. Electronics: Cutting intricate parts for electronic devices. Construction: Customizing metal panels and architectural designs. Signage: Creating detailed and eye-catching signs. Jewelry: Designing intricate patterns for customized jewelry pieces.

Conclusion Laser cutting technology has transformed the way industries approach manufacturing, offering precision, efficiency, and versatility. As one of the leading providers of laser cutting solutions in Thane, GK Laser Enterprises is committed to delivering exceptional service and high-quality results for businesses across various sectors. Whether you need custom components or large-scale production, our expertise in laser cutting ensures that we meet and exceed your expectations.

For more information or to discuss your laser cutting needs, contact us GK Laser Enterprises today and let us help you take your business to the next level with precision engineering solutions.

0 notes

Text

CO2 Laser Cutting Machine in Mumbai

Mumbai, the bustling heart of India’s manufacturing sector, is home to numerous industries that rely on cutting-edge technology to maintain their competitive edge. Among these technologies, CO2 laser cutting machines have emerged as a vital tool for precision cutting and engraving across various materials. If you're in Mumbai and looking for top-quality CO2 laser cutting solutions, GK Laser Enterprises is your trusted partner.

What is a CO2 Laser Cutting Machine?

A CO2 laser cutting machine utilizes a carbon dioxide laser to cut through materials with high precision. This type of laser, known for its ability to generate intense light energy, is ideal for cutting, engraving, and etching on a wide variety of materials including metals, plastics, glass, wood, and more. The machine works by directing the laser beam through a series of mirrors and lenses to focus on the material's surface, vaporizing or burning away the targeted area to create the desired shape or design.

Why Choose a CO2 Laser Cutting Machine?

The popularity of CO2 laser cutting machines stems from their ability to deliver high precision and accuracy, making them an essential tool for industries requiring intricate designs and complex patterns. Here are some key advantages of using CO2 laser cutting machines:

Precision and Accuracy: CO2 lasers provide exceptional precision, with the ability to cut materials with intricate details. This makes them ideal for industries like electronics, automotive, and aerospace, where even the smallest error can lead to significant issues.

Versatility: CO2 laser cutting machines are highly versatile and can cut through a wide range of materials. Whether you need to cut metals, plastics, textiles, or organic materials like wood and leather, these machines can handle it all.

High-Speed Operation: With CO2 laser cutting, you can achieve high cutting speeds without compromising on quality. This efficiency makes it a cost-effective solution for large-scale production runs.

Minimal Material Waste: Laser cutting is a non-contact process, which means there is minimal material wastage. The precision of the laser ensures that only the required material is cut, leaving the rest intact.

Low Maintenance: CO2 laser cutting machines are known for their durability and require minimal maintenance. This ensures a long lifespan and reduces downtime, making them a reliable choice for businesses.

GK Laser Enterprises: Your Go-To Source for CO2 Laser Cutting Machines in Mumbai

At GK Laser Enterprises, we understand the unique needs of businesses in Mumbai's fast-paced industrial landscape. Our CO2 laser cutting machines are designed to offer the perfect blend of performance, reliability, and affordability. Here’s why you should choose GK Laser Enterprises:

Top-Quality Machines: We offer CO2 laser cutting machines that are built to last, ensuring that you get the best return on your investment. Our machines are sourced from reputable manufacturers and come equipped with the latest technology to ensure optimal performance.

Expert Support: Our team of experts is always on hand to provide you with the support you need. From helping you choose the right machine for your specific needs to providing installation and after-sales service, we are with you every step of the way.

Competitive Pricing: At GK Laser Enterprises, we believe in offering top-quality products at competitive prices. Our CO2 laser cutting machines provide excellent value for money, making them an ideal choice for businesses of all sizes.

Comprehensive Solutions: Beyond just providing machines, we offer complete solutions that include training, maintenance, and technical support. We ensure that you are fully equipped to make the most of your CO2 laser cutting machine.

Conclusion

CO2 laser cutting machines are revolutionizing the manufacturing industry in Mumbai, offering unparalleled precision, efficiency, and versatility. At GK Laser Enterprises, we are committed to providing you with the best CO2 laser cutting solutions to meet your specific needs. Whether you're a small business or a large-scale manufacturer, our machines will help you achieve superior results with minimal effort.

For more information or to inquire about our CO2 laser cutting machines, contact GK Laser Enterprises today. Let us help you take your business to the next level with the power of precision laser cutting technology.

0 notes

Text

Fiber Laser Cutting Machine in Thane

In today’s fast-paced manufacturing environment, precision, speed, and efficiency are paramount. Whether you're a small-scale business or a large industrial operation, having the right equipment can significantly impact your productivity and bottom line. If you're in Thane and looking for top-notch fiber laser cutting machines, look no further than GK Laser Enterprises.

Why Choose Fiber Laser Cutting Machines?

Fiber laser cutting machines are a revolutionary technology in the field of metal processing. These machines use a fiber laser to cut through a variety of materials with high precision. The laser beam is focused on a small spot, which allows for cutting with extreme accuracy, making it ideal for applications requiring intricate designs and fine details.

Here’s why fiber laser cutting machines are the preferred choice for many industries:

High Precision and Accuracy: One of the most significant advantages of fiber laser cutting machines is their precision. They can cut complex shapes and patterns with minimal deviation, ensuring that each piece meets the exact specifications.

Speed and Efficiency: Fiber lasers are known for their high cutting speeds, which can greatly reduce production time. This speed does not compromise the quality of the cut, making it possible to produce more in less time.

Low Maintenance: Fiber laser cutting machines require less maintenance compared to other cutting technologies. This is because they have fewer moving parts and use fiber optics to deliver the laser beam, which reduces wear and tear.

Versatility: Fiber laser cutting machines are versatile and can cut a wide range of materials, including metals like steel, aluminum, brass, and copper. This versatility makes them suitable for various industries, from automotive to electronics.

Energy Efficiency: These machines are more energy-efficient than traditional cutting methods, which can lead to significant cost savings in the long run. Their lower energy consumption also makes them an environmentally friendly option.

GK Laser Enterprises - Your Trusted Partner in Thane

At GK Laser Enterprises, we understand the needs of businesses in Thane and beyond. Our fiber laser cutting machine in Thane are designed to deliver exceptional performance, reliability, and value. Here’s why GK Laser Enterprises is the best choice for your fiber laser cutting needs:

Advanced Technology: We offer the latest in fiber laser cutting technology. Our machines are equipped with advanced features that ensure precise cuts, high efficiency, and long-lasting performance.

Customization: We understand that every business has unique needs. That's why we offer customized solutions to meet your specific requirements. Whether you need a machine for high-volume production or specialized cutting tasks, we can tailor our products to suit your needs.

Expert Support: Our team of experts is always available to provide support and guidance. From helping you choose the right machine to providing after-sales service, we're here to ensure you get the most out of your investment.

Competitive Pricing: At GK Laser Enterprises, we believe in offering high-quality products at competitive prices. We work closely with our clients to provide cost-effective solutions without compromising on quality.

Training and Installation: We don't just sell machines; we also ensure that you know how to use them effectively. Our comprehensive training programs cover everything from basic operation to advanced techniques, ensuring that your team can operate the machine with confidence. Additionally, our skilled technicians handle the installation process, ensuring your machine is set up correctly and ready for immediate use.

Applications of Fiber Laser Cutting Machines

Fiber laser cutting machines from GK Laser Enterprises can be used in various applications, including:

Automotive Industry: For cutting parts and components with high precision.

Electronics Industry: For cutting thin sheets of metal used in electronic devices.

Jewelry Making: For creating intricate designs on metal.

Construction: For cutting structural materials and metal frameworks.

Conclusion

Investing in a fiber laser cutting machine from GK Laser Enterprises in Thane is a smart decision for businesses looking to enhance their production capabilities. With our advanced technology, customized solutions, and dedicated support, we ensure that you get the best value for your money.

Contact us at GK Laser Enterprises today to learn more about our fiber laser cutting machines and how they can benefit your business.

0 notes

Text

Laser Engraving Machine

At GK Laser Enterprises, we pride ourselves on offering the latest in laser engraving technology to meet the diverse needs of our clients. Laser engraving machines have revolutionized the way we approach detailed and intricate designs, providing unparalleled precision and efficiency. In this article, we'll delve into the various aspects of laser engraving machines, their benefits, applications, and why GK Laser Enterprises is your go-to provider for top-notch engraving solutions.

What is Laser Engraving? Laser engraving is a technique that uses a laser beam to etch designs, patterns, and text onto various materials. The laser beam's high intensity allows it to remove material from the surface, creating a precise and permanent mark. This process is controlled by computer software, which directs the laser to follow the desired pattern or design with incredible accuracy.

Benefits of Laser Engraving Machines

Precision and Accuracy One of the primary advantages of laser engraving machines is their precision. The laser beam can produce extremely fine details, making it ideal for intricate designs and small text. This precision ensures that every engraving is consistent and of the highest quality.

Versatility Laser engraving machines can work on a wide range of materials, including wood, metal, glass, acrylic, leather, and more. This versatility makes them suitable for various industries, from manufacturing to personalized gifts.

Efficiency and Speed Modern laser engraving machines are incredibly fast, allowing for high-volume production without compromising on quality. This efficiency translates to shorter turnaround times and increased productivity.

Non-Contact Process Since laser engraving is a non-contact process, it minimizes the risk of damaging the material being engraved. This is particularly important for delicate or valuable items that require careful handling.

Customization and Flexibility Laser engraving machines offer unparalleled customization options. Whether you need a single prototype or a large batch of identical items, laser engraving can accommodate your specific needs with ease.

Applications of Laser Engraving The applications of laser engraving machines are vast and varied, making them indispensable in numerous industries. Here are some common uses:

Manufacturing and Industrial Applications Laser engraving is widely used in the manufacturing sector for marking parts, tools, and equipment. It ensures traceability and compliance with industry standards, helping companies maintain quality control.

Personalized Gifts and Awards Laser engraving adds a personal touch to gifts and awards. From custom jewelry to engraved plaques, it creates memorable and unique items that stand out.

Signage and Branding Businesses use laser engraving to create professional signage and branding materials. Engraved logos and signs offer a sleek and sophisticated look that enhances brand image.

Electronics and Gadgets Laser engraving is essential in the electronics industry for marking components, circuit boards, and devices. It provides clear and durable markings that withstand wear and tear.

Medical Devices In the medical field, laser engraving is used for marking surgical instruments, implants, and other medical devices. It ensures proper identification and traceability, which is crucial for patient safety.

Why Choose GK Laser Enterprises? At GK Laser Enterprises, we are committed to providing the highest quality laser engraving solutions tailored to meet your specific needs. Here are a few reasons why we stand out:

State-of-the-Art Equipment We invest in the latest laser engraving technology to ensure our clients receive the best results. Our machines are equipped with advanced features that enhance precision, speed, and versatility.

Expertise and Experience Our team of skilled professionals has extensive experience in the field of laser engraving. We understand the nuances of different materials and applications, allowing us to deliver exceptional quality and service.

Custom Solutions We believe in offering customized solutions that align with our clients' unique requirements. Whether you need a one-off engraving or a large production run, we tailor our services to meet your goals.

Quality Assurance Quality is at the core of everything we do. We follow stringent quality control measures to ensure every engraving meets our high standards. Our commitment to excellence guarantees that you receive products that exceed your expectations.

Customer Satisfaction At GK Laser Enterprises, customer satisfaction is our top priority. We work closely with our clients to understand their needs and provide solutions that deliver value. Our responsive customer service team is always ready to assist you with any inquiries or concerns.

Conclusion Laser engraving machines have transformed the way we approach engraving, offering unmatched precision, efficiency, and versatility. At GK Laser Enterprises, we harness the power of this technology to deliver exceptional engraving solutions for a wide range of applications. Whether you're in manufacturing, electronics, or looking to personalize gifts, our state-of-the-art equipment and experienced team are here to meet your needs.

Choose GK Laser Enterprises for all your laser engraving requirements and experience the difference that precision and quality can make. Contact us today to learn more about our services and how we can help you achieve your engraving goals.

0 notes

Text

Stone CNC Router Machine

In the world of stone fabrication, precision, efficiency, and versatility are key. At GK Laser Enterprises, we understand that our clients need advanced technology to stay ahead in the competitive market. That's why we're proud to introduce our Stone CNC Router Machines – a game-changer in the stone-cutting industry.

What is a Stone CNC Router Machine? A Stone CNC (Computer Numerical Control) Router Machine is a state-of-the-art tool used for cutting, carving, engraving, and shaping stone materials. Unlike traditional methods, which rely heavily on manual labor and hand tools, CNC routers utilize computer-aided design (CAD) and computer-aided manufacturing (CAM) to perform intricate tasks with unmatched precision and efficiency.

How Does It Work? The magic of a Stone CNC Router Machine lies in its advanced software and robust hardware. Here's a step-by-step overview of how it operates:

Design Creation: The process begins with creating a digital design using CAD software. This design is a precise blueprint of the desired outcome, whether it's a detailed engraving or a complex cut.

Programming: The CAD design is then converted into a CAM file, which contains the instructions for the CNC machine. This file is uploaded to the CNC router's computer.

Setup: The stone material is securely placed on the machine's worktable. The CNC router is equipped with various cutting tools, which are selected based on the type of stone and the specific task.

Execution: Once everything is set, the machine executes the programmed instructions with high-speed precision. The router's spindle moves along the X, Y, and Z axes, following the design's path and performing cuts, carvings, or engravings.

Finishing: After the machining process is complete, the stone piece may require some finishing touches, such as polishing or additional detailing, to achieve the desired look.

Why Choose a Stone CNC Router Machine?

Unmatched Precision One of the most significant advantages of Stone CNC Router Machines is their ability to achieve unparalleled precision. Whether you're working on intricate patterns, detailed engravings, or complex shapes, the accuracy of CNC technology ensures that each piece is crafted to perfection. This level of precision is nearly impossible to achieve with manual methods.

Increased Efficiency Time is money in any industry, and stone fabrication is no exception. Stone CNC Router Machines significantly reduce the time required for cutting and shaping stone materials. Automated processes mean faster turnaround times, allowing you to complete projects more quickly and take on more clients.

Versatility Stone CNC Router Machines are incredibly versatile. They can work with a wide range of stone materials, including granite, marble, limestone, and more. This versatility opens up a world of possibilities for creating customized stone products, from countertops and flooring to intricate sculptures and architectural elements.

Cost-Effectiveness While the initial investment in a Stone CNC Router Machine may seem substantial, the long-term benefits far outweigh the costs. Reduced labor expenses, faster project completion, and minimal material wastage all contribute to significant cost savings over time. Additionally, the machine's precision minimizes the risk of errors, further reducing expenses.

Applications of Stone CNC Router Machines Stone CNC Router Machines have revolutionized various industries by offering precise and efficient solutions for stone fabrication. Some of the key applications include:

Countertops and Flooring The demand for customized stone countertops and flooring is on the rise. Stone CNC Router Machines allow for the creation of unique designs, precise cutouts for sinks and fixtures, and seamless edges, making them a favorite choice for kitchen and bathroom installations.

Architectural Elements From intricate moldings and columns to decorative facades and wall panels, Stone CNC Router Machines bring architectural visions to life. Their ability to produce detailed and complex designs makes them indispensable in the construction and interior design industries.

Sculptures and Artworks Artists and sculptors have embraced Stone CNC Router Machines for their ability to translate digital designs into tangible masterpieces. The precision and versatility of CNC technology enable the creation of detailed sculptures, engravings, and artistic installations.

Memorials and Gravestones The memorial industry relies on Stone CNC Router Machines to create personalized gravestones and monuments. The ability to engrave intricate designs, text, and images ensures that each memorial piece is a unique and lasting tribute.

Why Choose GK Laser Enterprises? At GK Laser Enterprises, we are committed to providing our clients with the best tools and technology for their stone fabrication needs. Our Stone CNC Router Machines are designed to deliver exceptional performance, reliability, and precision. Here are some reasons to choose us:

Cutting-Edge Technology: Our CNC routers are equipped with the latest advancements in CNC technology, ensuring top-notch performance and precision. Custom Solutions: We understand that every project is unique. That's why we offer customizable CNC router solutions to meet your specific requirements. Expert Support: Our team of experts is always ready to provide support, from installation and training to maintenance and troubleshooting. Quality Assurance: We stand behind the quality of our machines, offering warranties and comprehensive service packages for peace of mind.

Conclusion The Stone CNC Router Machine is a revolutionary tool that has transformed the stone fabrication industry. With its precision, efficiency, and versatility, it offers countless benefits for businesses in various sectors. At GK Laser Enterprises, we are proud to provide top-of-the-line Stone CNC Router Machines that empower our clients to achieve their creative and operational goals. Discover the power of precision with our CNC routers and take your stone fabrication projects to the next level. Contact us to learn more about how our advanced Stone CNC Router Machines can enhance your business and meet your specific needs.

0 notes

Text

Rotary CNC Router Machine

In the realm of precision engineering and manufacturing, CNC (Computer Numerical Control) machines have revolutionized the way intricate designs are crafted with efficiency and accuracy. Among these, the rotary CNC router machine stands out as a versatile tool that plays a crucial role in various industries, including woodworking, signage, aerospace, and beyond. At GK Laser Enterprises, we specialize in providing advanced CNC solutions, including rotary CNC routers, tailored to enhance productivity and craftsmanship across diverse applications.

Understanding Rotary CNC Router Machines A rotary CNC router machine is a specialized type of CNC router equipped with a rotary axis, allowing it to perform complex tasks such as 3D carving, engraving on cylindrical objects, and intricate relief work on curved surfaces. This capability makes it indispensable in industries where precision and versatility are paramount.

Key Features and Benefits

Enhanced Versatility: Rotary CNC routers excel in handling a wide range of materials, from wood and plastics to metals and composites. This versatility enables businesses to undertake diverse projects without the need for multiple specialized machines, thereby streamlining production processes and reducing operational costs.

3D Carving and Engraving: Unlike traditional flatbed CNC routers, rotary machines can carve intricate designs on cylindrical or irregularly shaped objects. This capability is invaluable in creating bespoke products such as custom furniture components, personalized gifts, and detailed architectural elements.

Precision and Efficiency: Leveraging advanced CNC technology, rotary routers ensure precise repeatability and consistency in manufacturing processes. This precision not only enhances product quality but also accelerates production timelines, allowing businesses to meet stringent deadlines and customer expectations effectively.

Scalability and Customization: Whether for prototyping or mass production, rotary CNC routers offer scalability to accommodate varying production volumes. They facilitate rapid tool changes and programming flexibility, enabling operators to quickly adapt to new designs or client specifications with minimal downtime.

Integration with CAD/CAM Software: Integration with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software enhances the efficiency of rotary CNC router machines. This synergy enables seamless design-to-production workflows, empowering designers and engineers to translate creative concepts into tangible products with ease.

Cost-Effective Manufacturing Solutions: By optimizing material usage and reducing manual labor requirements, rotary CNC routers contribute to cost savings over time. They minimize material wastage and error rates, thereby improving overall operational efficiency and profitability for businesses of all sizes.

Applications Across Industries The versatility of rotary CNC router machines extends their utility across various sectors: Woodworking: Crafting intricate furniture components, staircases, and decorative items. Signage and Advertising: Producing custom signage, 3D logos, and promotional displays. Aerospace and Automotive: Manufacturing complex parts, molds, and prototypes. Art and Design: Creating sculptures, jewelry, and artistic installations. Medical and Dental: Fabricating customized prosthetics and dental appliances.

Conclusion As technology continues to evolve, rotary CNC router machines remain at the forefront of innovation in manufacturing and design. At GK Laser Enterprises, we are committed to empowering businesses with cutting-edge CNC solutions that enhance productivity, precision, and creativity. Whether you're looking to expand your capabilities in woodworking, signage production, or industrial manufacturing, our rotary CNC routers offer the tools you need to achieve exceptional results. Contact us today to discover how our expertise and advanced machinery can elevate your production processes and propel your business forward in a competitive market landscape.

0 notes

Text

Second Hand Fiber Metal Cutting

As the owner of GK Laser Enterprises, exploring cost-effective solutions to enhance your business operations is paramount. Investing in second-hand fiber metal cutting machines can provide a strategic advantage, offering advanced technology at a fraction of the cost. This article delves into the benefits and considerations of incorporating second-hand fiber metal cutting technology into your business.

Advantages of Second-Hand Fiber Metal Cutting Machines Cost-Effectiveness One of the most significant advantages of purchasing second-hand fiber metal cutting machines is the cost savings. New fiber lasers can be prohibitively expensive, particularly for small to medium-sized enterprises. By opting for a pre-owned machine, you can access advanced cutting technology without the hefty price tag, freeing up capital for other investments within GK Laser Enterprises.

Advanced Technology at Lower Costs Fiber laser technology has revolutionized the metal cutting industry with its precision, speed, and efficiency. By acquiring a second-hand machine, you can leverage these benefits without waiting for new technology to become affordable. Many pre-owned fiber lasers still possess cutting-edge capabilities that can enhance your production quality and efficiency.

Depreciation and Value Retention New machines depreciate rapidly in the first few years. By purchasing a second-hand fiber laser, you bypass the steepest part of the depreciation curve. This means the value of your investment will remain more stable over time, which is beneficial if you plan to upgrade again in the future.

Sustainability In today's environmentally conscious market, sustainability is a crucial consideration. Buying second-hand machinery is a form of recycling that reduces waste and the demand for new manufacturing. This not only lowers your carbon footprint but also aligns your business with eco-friendly practices, which can be attractive to environmentally-conscious customers.

Key Considerations When Buying Second-Hand Machine Condition and Maintenance History Before purchasing a second hand fiber metal cutting, it's essential to assess its condition thoroughly. Request detailed maintenance records and inspect the machine for any signs of wear and tear. A well-maintained machine can offer years of reliable service, but a poorly kept one can become a costly burden.

Source Reliability The source from which you purchase your second-hand machine is crucial. Opt for reputable dealers or certified pre-owned programs that offer warranties or service contracts. This ensures you are not only getting a quality machine but also have support in case any issues arise post-purchase.

Technological Compatibility Ensure that the second-hand machine you are considering is compatible with your current operations and software. Compatibility issues can lead to additional costs and downtime, negating the financial benefits of buying second-hand. It's advisable to consult with a technician or the machine's manufacturer regarding integration with your existing systems.

Upgradability The ability to upgrade the machine is another important factor. Technology is continuously advancing, and having a machine that can be upgraded with new software or hardware can extend its useful life and maintain its competitiveness.

Implementation Strategy for GK Laser Enterprises Needs Assessment Begin with a comprehensive assessment of your business needs. Identify the specific requirements of your production processes and how a second-hand fiber metal cutting machine can meet these needs. Consider factors such as cutting speed, precision, material types, and thicknesses you commonly work with.

Budget Planning Develop a detailed budget that includes the purchase price of the machine, transportation, installation, potential upgrades, and ongoing maintenance costs. Ensure that your budget aligns with your financial goals and does not compromise other critical areas of your business.

Vendor Research Conduct thorough research to find reputable vendors offering second-hand fiber metal cutting machines. Look for vendors with positive reviews, transparent pricing, and comprehensive service packages. Engage with multiple vendors to compare options and negotiate the best deal.

Inspection and Testing Arrange for a professional inspection and testing of the machine before finalizing the purchase. This can be done by a certified technician who can provide an unbiased evaluation of the machine's condition and performance.

Training and Integration Once the machine is acquired, invest in training for your staff to ensure they are proficient in operating the new equipment. Proper training minimizes the risk of errors and maximizes the efficiency of your new machine. Additionally, plan for a seamless integration of the machine into your existing production line to avoid disruptions.

Conclusion Investing in second-hand fiber metal cutting technology can be a game-changer for GK Laser Enterprises. It offers a cost-effective way to enhance your production capabilities while maintaining high standards of quality and efficiency. By carefully considering the machine's condition, source reliability, and compatibility with your operations, you can make a smart investment that drives your business forward. With a strategic approach to implementation, you can reap the benefits of advanced cutting technology and position GK Laser Enterprises for sustained growth and success. Contact us to learn more about how second-hand fiber metal cutting technology can transform your business.

0 notes

Text

Service Engineer for Laser Cutting Machine

At GK Laser Enterprises, we understand that the precision and efficiency of laser cutting machines are crucial to the success of your operations. To ensure your equipment operates at peak performance, we proudly offer the services of our highly skilled service engineers. These professionals are essential to maintaining, troubleshooting, and optimizing your laser cutting machinery, thereby maximizing productivity and minimizing downtime.

The Role of a Service Engineer A service engineer for laser cutting machines plays a multifaceted role that includes installation, maintenance, repair, and customer support. Their expertise ensures that your laser cutting equipment is always in optimal condition, which is vital for maintaining high-quality outputs and meeting production deadlines.

Installation The journey with a laser cutting machine begins with proper installation. Our service engineers at GK Laser Enterprises are trained to handle the intricate setup process of these advanced machines. They ensure that the machine is correctly integrated into your production line, calibrated accurately, and tested thoroughly before it starts operating. This meticulous approach helps prevent any initial hiccups and sets a solid foundation for the machine's performance.

Maintenance Regular maintenance is key to the longevity and efficiency of laser cutting machines. Our service engineers conduct routine check-ups and preventive maintenance to identify and resolve potential issues before they become major problems. This includes cleaning optical components, checking and adjusting laser alignment, and ensuring that all mechanical parts are in good working condition. Scheduled maintenance not only extends the lifespan of your equipment but also ensures consistent cutting quality.

Repair Even with regular maintenance, machines can encounter issues that require immediate attention. GK Laser Enterprises' service engineers are adept at diagnosing and repairing problems swiftly. Whether it's a malfunctioning laser source, a software glitch, or a mechanical failure, our engineers use their extensive knowledge and experience to get your machine back up and running as quickly as possible. Their ability to troubleshoot effectively reduces downtime, keeping your production schedule on track.

Customer Support and Training In addition to technical expertise, our service engineer for laser cutting machines provide invaluable support to your team. They offer training sessions to ensure your operators are proficient in using the laser cutting machines safely and efficiently. Understanding the nuances of machine operation can prevent operator errors that lead to machine damage or production delays. Moreover, our service engineers for laser cutting machines are always available to answer any questions and provide guidance on best practices for machine use and maintenance.

The Importance of Skilled Service Engineers Investing in skilled service engineers offers numerous benefits to your business:

Minimized Downtime: Quick and efficient troubleshooting and repairs ensure that production is not halted for long periods.

Enhanced Machine Performance: Regular maintenance and proper installation optimize machine performance, leading to better product quality and reduced waste.

Cost Savings: Preventive maintenance helps avoid costly major repairs and extends the lifespan of your equipment.

Increased Safety: Proper training and maintenance reduce the risk of accidents, ensuring a safer working environment.

Technical Expertise: With advanced knowledge of the latest technologies and industry standards, our engineers can provide insights and improvements that keep your operations at the cutting edge.

Why Choose GK Laser Enterprises? At GK Laser Enterprises, we pride ourselves on our commitment to excellence. Our service engineers are selected for their technical prowess, dedication to customer service, and ability to solve complex problems. Here are a few reasons why partnering with us is beneficial:

Certified Professionals: Our engineers are certified and regularly updated on the latest advancements in laser cutting technology. 24/7 Support: We offer round-the-clock support to address any issues that may arise, ensuring your operations run smoothly. Comprehensive Service Packages: We provide tailored service packages that include installation, maintenance, repair, and training, ensuring all your needs are covered. State-of-the-Art Tools: Equipped with the latest diagnostic and repair tools, our engineers can handle even the most sophisticated laser cutting machines.

Conclusion The role of a service engineer is indispensable in the realm of laser cutting. At GK Laser Enterprises, our engineers are the backbone of our commitment to ensuring that your machinery performs at its best. By offering expert installation, maintenance, repair, and support, we help you achieve superior production quality and operational efficiency. Trust GK Laser Enterprises to provide the exceptional service engineering support your business needs to thrive in the competitive world of laser cutting.

For more information or to schedule a service appointment, please contact us at GK Laser Enterprises today. Our team is ready to support your business and ensure your laser cutting machines operate flawlessly.

0 notes