Evaporation concentrates solutions by vaporizing solvent, followed by filtration/drying or crystallization. Evaporators use heat exchangers and condensers.https://goldfinchevaporators.com/multi-effect-evaporator-manufacturer/

Don't wanna be here? Send us removal request.

Text

Water scarcity is a pressing global issue, exacerbated by increasing population, industrial demands, and climate change. As industries and municipalities strive to address this challenge, innovative technologies become vital for sustainable water management. One such technology is the Multiple Effect Evaporator (MEE). At Goldfinch Evaporation Systems, we specialize in designing and manufacturing cutting-edge MEE systems that significantly enhance water management processes.

#Multiple Effect Evaporator#mee 🌿#mvre 🌿#sustainability 🌿#zld 🌿#wastewatertreatment 🌿#goldfinchevaporationsystems#multiple effect evaporation#Goldfinch Evaporation#multi-effect-evaporator-manufacturer

0 notes

Text

Enhancing Water Management with Multiple Effect Evaporators (MEE)

Water scarcity is a pressing global issue, exacerbated by increasing population, industrial demands, and climate change. As industries and municipalities strive to address this challenge, innovative technologies become vital for sustainable water management. One such technology is the Multiple Effect Evaporator (MEE). At Goldfinch Evaporation Systems, we specialize in designing and manufacturing cutting-edge MEE systems that significantly enhance water management processes. In this blog, we will delve into how MEEs work, their benefits, and why they are a crucial component in addressing water scarcity.

What is a Multiple Effect Evaporator (MEE)?

A Multiple Effect Evaporator (MEE) is a sophisticated system used to concentrate solutions, typically by removing water through evaporation. It operates by utilizing steam or heat to evaporate water from a liquid, which then condenses and is collected. The key feature of an MEE system is its ability to perform this process in multiple stages or "effects," which improves efficiency and reduces energy consumption.

#🌿#MultiEffectEvaporatorManufacturer 🌿#WasteWaterTreatment 🌿#MVRE 🌿#MEE 🌿#ZLD 🌿#WaterScarcity 🌿#Sustainability 🌿#EnvironmentalImpact 🌿#GoldfinchEvaporationSystems

0 notes

Text

Enhancing Water Management with Multiple Effect Evaporators (MEE)

Water scarcity is a pressing global issue, exacerbated by increasing population, industrial demands, and climate change. As industries and municipalities strive to address this challenge, innovative technologies become vital for sustainable water management. One such technology is the Multiple Effect Evaporator (MEE). At Goldfinch Evaporation Systems, we specialize in designing and manufacturing cutting-edge MEE systems that significantly enhance water management processes. In this blog, we will delve into how MEEs work, their benefits, and why they are a crucial component in addressing water scarcity.

What is a Multiple Effect Evaporator (MEE)?

A Multiple Effect Evaporator (MEE) is a sophisticated system used to concentrate solutions, typically by removing water through evaporation. It operates by utilizing steam or heat to evaporate water from a liquid, which then condenses and is collected. The key feature of an MEE system is its ability to perform this process in multiple stages or "effects," which improves efficiency and reduces energy consumption.

How MEE Systems Work

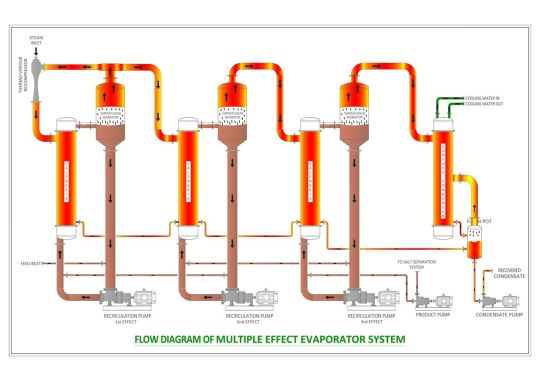

MEE systems consist of several evaporators arranged in a series. Each effect operates at progressively lower pressures, allowing steam from one effect to be used as the heat source for the next. Here’s a simplified overview of how an MEE system functions:

Feedwater Entry: The feedwater enters the first evaporator, where it is heated by steam or another heat source.

Evaporation: The heat causes the water to evaporate, leaving behind concentrated solutes. The steam produced in this stage is collected and directed to the next effect.

Condensation: In the subsequent effects, the previously generated steam serves as the heating medium, evaporating additional water from the feedwater in each stage.

Final Concentration: The process continues through multiple stages until the desired concentration is achieved.

Condensate Recovery: The condensed steam from each effect is collected and often reused, enhancing energy efficiency.

Benefits of Multiple Effect Evaporators

1. Efficient Desalination

One of the primary applications of MEEs is in desalination, where they effectively remove salts and impurities from seawater or brackish water. By using MEEs, industries and municipalities can produce clean, potable water from non-potable sources. This is particularly beneficial in regions facing severe water shortages, as it enables the conversion of abundant saline water into valuable fresh water.

2. Energy Efficiency

Energy consumption is a significant concern in water treatment processes. Traditional evaporators often require substantial amounts of energy, leading to high operational costs. MEEs address this issue by reusing steam across multiple stages, which minimizes energy consumption. In each effect, the steam from the previous stage is utilized as the heat source, reducing the need for additional heating. This energy-efficient approach lowers operational costs and contributes to more sustainable practices.

3. High Water Recovery

Achieving high water recovery rates is crucial for effective water management. MEEs excel in this area by maximizing the amount of water recovered from the feed solution. This high recovery rate ensures that a significant portion of the water is recycled and reused, reducing the overall need for fresh water and supporting sustainable practices.

4. Scalability

MEEs are highly scalable, making them suitable for a range of applications from small-scale operations to large industrial facilities. Whether you're operating a small wastewater treatment plant or managing a large-scale industrial process, MEEs can be tailored to meet your specific needs. This scalability allows for flexibility in adapting to changing demands and expanding operations as required.

5. Reduced Environmental Impact

Environmental sustainability is a critical consideration in modern industrial processes. MEEs contribute to this by offering environmentally friendly wastewater treatment solutions. By reducing energy consumption and enhancing water recovery, MEEs help lower the overall environmental footprint of water management activities. Additionally, their ability to concentrate and recycle wastewater supports zero liquid discharge (ZLD) initiatives, where all wastewater is recovered and reused, minimizing environmental impact.

Applications of MEE Systems

MEEs are versatile and can be employed in various industries and applications:

Desalination Plants: MEEs are commonly used in desalination plants to convert seawater into fresh water, addressing water scarcity in arid regions.

Chemical and Pharmaceutical Industries: These industries use MEEs to concentrate solutions and recover solvents, ensuring efficient resource utilization.

Food and Beverage Industry: MEEs are employed to concentrate juices, syrups, and other liquid products, enhancing production efficiency.

Wastewater Treatment: In wastewater treatment facilities, MEEs are used to concentrate and recover valuable by-products while minimizing waste.

Goldfinch Evaporation Systems: Leading the Way in MEE Technology

At Goldfinch Evaporation Systems, we are committed to providing state-of-the-art MEE solutions that align with sustainability goals. Our expertise in designing and manufacturing MEEs ensures that you receive top-notch technology tailored to your specific needs. Here’s why you should consider our MEE systems:

1. Innovative Design

Our MEEs are designed with the latest technological advancements to offer superior performance and efficiency. We prioritize innovation to ensure that our systems meet the highest standards of quality and effectiveness.

2. Customized Solutions

We understand that each industry and application has unique requirements. That’s why we offer customized MEE solutions tailored to your specific needs. Whether you require a small-scale system or a large industrial setup, we can provide a solution that fits your requirements.

3. Expert Support

Our team of experts is dedicated to providing exceptional support throughout the entire process, from system design and installation to ongoing maintenance. We are here to ensure that your MEE system operates smoothly and efficiently.

4. Commitment to Sustainability

Goldfinch Evaporation Systems is committed to promoting sustainable water management practices. Our MEEs contribute to environmental conservation by reducing energy consumption, enhancing water recovery, and supporting zero liquid discharge initiatives.

Conclusion

In the face of global water scarcity, innovative technologies like Multiple Effect Evaporators (MEEs) play a crucial role in enhancing water management practices. At Goldfinch Evaporation Systems, we are proud to offer advanced MEE solutions that address the challenges of water treatment and conservation. Our systems provide efficient desalination, energy efficiency, high water recovery, scalability, and reduced environmental impact.By choosing Goldfinch Evaporation Systems, you are investing in cutting-edge technology that aligns with sustainability goals and supports effective water management. Join us in our mission to create a sustainable future with our innovative evaporation technologies. Connect with us today to learn more about how our MEE systems can benefit your industry and contribute to a greener planet.

#🌿#MultiEffectEvaporatorManufacturer 🌿#WasteWaterTreatment 🌿#MVRE 🌿#MEE 🌿#ZLD 🌿#WaterScarcity 🌿#Sustainability 🌿#EnvironmentalImpact 🌿#GoldfinchEvaporationSystems

0 notes

Text

Evaporation concentrates solutions by vaporizing solvent, followed by filtration/drying or crystallization. Multiple-effect evaporators use heat exchangers and condensers.

0 notes

Text

https://fortunetelleroracle.com/other/the-power-of-multiple-effect-evaporators--a-deep-dive-with-goldfinch-evaporators-company-862591

Evaporation concentrates solutions by vaporizing solvent, followed by filtration/drying or crystallization. Evaporators use heat exchangers and condensers. To Know More Visit This Link - https://goldfinchevaporators.com/multi-effect-evaporator-manufacturer/

0 notes

Text

Revolutionizing Industrial Water Treatment with Multiple-Effect Evaporation Systems

Industrial water treatment faces significant challenges, particularly when dealing with high Total Dissolved Solids (TDS) and Chemical Oxygen Demand (COD) in wastewater. Multiple-Effect Evaporation (MEE) systems have emerged as a game-changing solution, providing efficient and sustainable management of industrial wastewater.

MEE systems operate by using vapor from one stage to heat the next, significantly optimizing energy usage. This method drastically reduces steam consumption compared to traditional single-effect systems, making MEE systems exceptionally energy-efficient. The result is lower operational costs and a reduced environmental footprint, aligning with the industry's increasing focus on sustainable practices.

The versatility of MEE systems is another key advantage. They can be tailored to meet the specific needs of various industries, from pharmaceuticals to textiles. Their robust design allows them to handle challenging wastewater streams with high TDS and COD levels, making them a versatile solution for diverse industrial applications.

MEE systems are also integral to Zero Liquid Discharge (ZLD) systems, which aim to eliminate liquid waste by recovering and reusing all water within industrial processes. Companies like Goldfinch Evaporation Systems lead the field by utilizing MEE technology to create high-performance ZLD solutions. Goldfinch’s MEE evaporators ensure optimal resource utilization and compliance with stringent environmental regulations, providing a reliable and eco-friendly approach to wastewater treatment.

In conclusion, Multiple-Effect Evaporation systems are revolutionizing industrial water treatment. Their efficiency in managing high TDS and COD wastewater and their essential role in ZLD systems make them indispensable for sustainable industrial operations. As industries prioritize environmental responsibility and resource efficiency, the adoption of MEE systems will be a cornerstone of modern water treatment practices.

0 notes

Text

Evaporation concentrates solutions by vaporizing solvent, followed by filtration/drying or crystallization. Evaporators use heat exchangers and condensers and multiple effect evaporator.

0 notes

Text

Evaporation concentrates solutions by vaporizing solvent, followed by filtration/drying or crystallization. Evaporators use heat exchangers and condensers and multiple effect evaporation

1 note

·

View note