Don't wanna be here? Send us removal request.

Video

tumblr

They will deal with Wall Street and Main Street and wherever in the production network between. They will work in your home, drive your consideration, compose your messages, blog entries, and do your tweets, so you should become acclimated to setting off to the seashore.

0 notes

Text

AI Warehouse robots – An interesting invention of today

At this point, most of us understand that our present occupations will be supplanted by robots and additionally man-made brainpower. A portion of these frameworks will be preferable and progressively insightful over people, expecting obviously people are really savvy. These robots will work in our manufacturing plants, rural area, administration and retail. They will deal with Wall Street and Main Street and wherever in the production network between. They will work in your home, drive your consideration, compose your messages, blog entries, and do your tweets, so you should become acclimated to setting off to the seashore.

Little choices for supply chain autonomation company that robots make without anyone else can raise a ruckus since human developers may neglect to consider the entirety of a robot's potential decisions, and this isn't the robot end of the world. What we're seeing here are robots seeking after human-produced objectives in unconstrained manners. Having an essential comprehension of morals can assist technologists with bettering comprehend the potential repercussions of the AI-fuelled programming and apply autonomy they are making.

The teachers of fake wise mechanical technology noticed these difficulties yet didn't go into the potential issues, after all, many are not anticipated; anyway, let me take a fast cut at it. Over the top robots giving simply objectives to satisfy, for example, snatching something from the warehouse, and conveying it pre-bundled to the satisfaction focus' active, truckload region or even onto the truck could get very intriguing.

Consider the possibility that the warehouse robots begin battling once again employments, assaulting each other to be the robot that can convey the thing. Imagine a scenario in which the robots structure groups to monitor zones of the warehouse from different robots at that point do battle with one another to satisfy the requests gave. Imagine a scenario where they get the items or materials from different robots harming the items.

Imagine a scenario where autonomous mobile robots in a warehouse square columns causing different robots to go more distant around running down their batteries, and afterwards shut off the ability to different robots being charged. Consider the possibility that they keep robots from the docking station or force half charged robots away so their gatherings can charge. Imagine a scenario where robots break different robots at that point put their parts into boxes to be transported out - what befell half of the robots, did they get scaled back or right-sized.

Think this is simply too insane to be in any way convincing? Many may concur, even craftsmen figure they can't supplant, however one Google Search of creative robots will give you an enlivening. Obviously, as expressed above not all will be great, there will be an insane change period, one which will demonstrate pundits right and technologists right too.

0 notes

Text

An insight into warehouse control systems

Warehouse control frameworks (WCS) are a product application that coordinates the constant exercises inside distribution centres and appropriation focuses. As the "traffic cop" for the warehouse/appropriation focus, the WCS is answerable for keeping everything running easily, boosting the productivity of the material taking care of subsystems and frequently, the exercises of the distribution centre partners themselves. It gives a uniform interface to an expansive scope of material dealing with gear, for example, AS/RS, merry go rounds, transport frameworks, sorters, palletizers, and so forth. The essential elements of a WCS include:

Interfacing to an upper-level host framework/Warehouse framework (WMS) and trading data required along with warehouse execution software to deal with the everyday tasks of the appropriation focus.

Assigning work to the different material taking care of sub-frameworks to adjust framework movement to finish the mentioned remaining task at hand.

Giving continuous mandates to administrators and material dealing with hardware controllers to achieve the request satisfaction and item directing prerequisites.

Powerfully allocate containers to occupy areas dependent on characterized sortation calculations or dependent on steering/request data got from the Host (if relevant).

Each significant capacity of warehouse robots is intended to fill in as a component of a coordinated procedure to successfully connect the host frameworks with the lower-level control framework, while assuaging the Host from the on-going necessities, for example, administrator screens and lower level gear control interfaces

Key capacities of a WCS framework ought to incorporate diminishing a client have PC of dealing with a continuous material taking care of mechanization interface, augmenting framework throughput and execution while using the most productive techniques for bed, case and thing directing.

You may have perused an on-going story distributed by Modern Materials Handling Magazine that blueprints how one of the enterprises most exceptional Warehouse Control Systems helped Oriental Trading Company improve profitability, diminish work costs and augment request precision levels.

0 notes

Link

Make your warehouse more efficient by introducing an automation platform. Visit GreyOrange to introduce Autonomous Mobile Robots in a warehouse to become the leading company in the industry.

0 notes

Text

How Investing In Warehouse Management Robotic System Can Benefit You

The warehouse is the place where many tasks run to ensure order fulfillment with precise efficiency. With the advancement of technology, entrepreneurs are also taking a step forward to keep up with the latest market trends. They are showing more interest in implementing warehouse management robotic systems and other such solutions, applications, technology tools, and digital management systems where there is a need to increase productivity and reduce costs. These solutions are not only helping businesses deliver better results but reducing errors in production processes.

Warehouse management robotic system-Introduction:

Robots are now increasingly becoming an essential part of supply chain operations. And, speaking of the warehouse management robotic system, this is an environment where a robot automation system or robot with the power of AI thinks, works, acts, and processes situations like humans 50 * times faster than the human labor force. They are not only able to lift entire shelves of products and leave inventory at different packing stations, but also make decisions about picking/dropping, depending on the popularity of an item or nearest supply.

Organizing Processes:

The warehouse management robotic system is designed in such a way that it can handle all routine tasks while maintaining completeness for longer. They help increase the efficiency of operations without negatively affecting quality.

Less risks of injuries:

Bots are programmed with sensors and algorithms. They are capable of performing their tasks, along with avoiding other robots or objects. These robots reduce the likelihood of serious injuries, which can affect the health and safety of humans. Hence, supply chain companies are embedding them to increase robustness in operations as well as employees.

Warehouse Robots:

The industry of warehouse robots consists of multiple types of warehouse robots, serving a variety of purposes and functions such as order picking and moving inventory throughout the warehouse. Since these robots are relatively easy to install in a facility, you can use a modular deployment system, starting with a few units and adding more as your business increases and needs change. This allows you to avoid an incredibly high initial investment, as you can start with one or two and increase your floor over time rather than buy a large number of robots at once. They free you from the capital to pursue other initiatives, analyzing robots ‘ impact on your business, and taking the next steps.

About GreyOrange Pte Ltd.

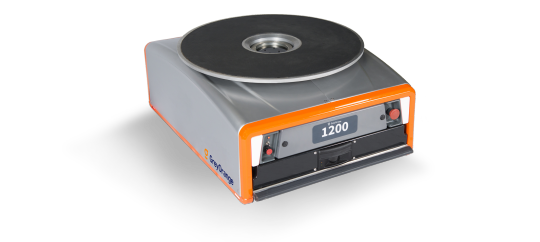

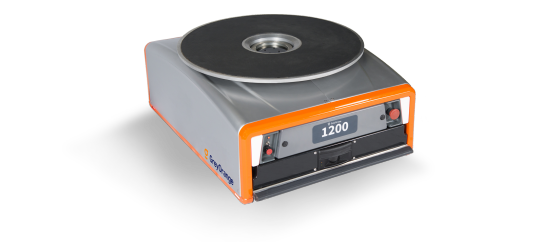

Being a reliable warehouse automation company, GreyOrange is offering a wide range of warehouse automation companies such as parcel sorter, linear sorter, butler, autonomous mobile robots in a warehouse, warehouse execution software, etc. The solution includes goods-to-man technology and advanced features and functionalities. Considering a team of experienced professionals, this major supply chain automation company is catering to the need of many customers related to various.

0 notes

Text

Introduction Of Warehouse Robots & Their Benefits

Many fulfillment centers struggle for fast and accurate service with rising expectations of e-commerce customers, as well as the labor challenges they face. Warehouse robots are said to be the ultimate solution for fulfilling today's increasing demands for same-day order delivery, real-time order tracking and such other customer requirements. A modern logistics operation will need to adopt robotics technologies to succeed in the future. Many types of warehouse robots provide a variety of functionality, allowing these robots to select solutions that assist in different processes. Store operators must understand the options available to implement the correct technologies to suit the needs of the warehouse. Let's take a look at the robotics market, knowing the types of these bots to invest in information technology, their functions, and other information store operators.

Warehouse Robots:

These fast-growing warehouse robots have reduced the time required to complete many tasks and have largely replaced human effort. The social labor force needs holidays, sick leaves, paid leaves, lunch breaks, health insurance, and many other benefits. However, all these requirements are eliminated when the robot comes into the picture. Professionals in multitasking, robots can pick up pallets of goods, move entire stacks of shelves to shipping stations, and accomplish tedious tasks better than humans. While some warehouses are purely pick-and-package systems, other warehouses are experimenting with robots explicitly designed for speed-sorting. Multi-robot fulfillment systems are some of the most expensive warehouse automatons that work in the transport of pallets, along with humans. Traveling as a group, these robots can navigate automatically, with guidance from a server. Some bots can also pick up racks and leave them in human-powered workstations.

Warehouse Management Robotic System:

Robots are now becoming an essential part of supply chain operations. And, in the case of warehouse management robotic system, it is an environment where AI-powered robot automation systems or robots think, work, and process 50 * times faster than humans. They are not only able to lift entire shelves of products and leave inventory at different packing stations, but also make decisions about picking/dropping based on the popularity of an item or nearest supply.

0 notes

Link

Bring the charisma of automation by adding the best warehouse management robotic system provided by GreyOrange.

0 notes

Link

Want to make your warehouse more productive and efficient? Contact GreyOrange to find the ideal Warehouse Execution Software and integrate with your ERP system for excellent management.

0 notes

Video

tumblr

As per the current market demands, it has become necessary to adopt warehouse execution software and warehouse robots for fulfillment and distribution centers to boost product execution and productivity.

0 notes

Text

What Autonomous Mobile Robots Can Do For Your DC?

The autonomous mobile robots’ market is continually evolving. These robots enable multinational manufacturers in the supply chain to integrate these flexible and collaborative robots into their common warehouse automation strategies. Autonomous mobile robots in a warehouse are a simple, efficient, and cost-effective way of handling materials and automating in-house transportation tasks in almost any situation where employees were required to drive carts around the facility.

High quality autonomous mobile robots in a warehouse are available in the market at affordable rates. Also, if someone is looking to replace their existing systems with advanced ones, the WES, automated picking system and sorters are good options. While companies like GreyOrange, Honeywell, etc. are reporting significant successes in both testing and production environments, there remain questions over how to use warehouse solutions such as warehouse execution software when working closely with their human counterparts — used to be. Let's look at the benefits of these robotic solutions.

Autonomous mobile robots in a warehouse:

Autonomous mobile robots (AMRs) offer efficiency and rapid return on investment by automating material handling and transportation in your facility. They are easy to secure, deploy, and free employees from sluggish, dangerous, and dirty logistics operations. AMRs represent a high-growth area of the robotics and automation industry.

They are collaborative and designed to work with humans. Being completely secure is an essential feature for collaborative mobile robots that run in dynamic environments and work with humans. In the event of a human stumbling in front of the AMR, a safety-rated laser scanning system completely blocks the rapid blockage to either replay or prevent a collision.

They have 360-degree security coverage around the robots, which detect obstacles several meters ahead so they can determine what needs to happen next. With the new demand for this technology across all verticals, it is import to deliver a system that does not compromise security. Employees can feel completely comfortable around this technique, if not faster than those at a quicker pace.

Supply Chain Automation Company:

GrayOrange, a leading warehouse automation company, is offering a wide range of warehouse automation companies such as parcel sorter, linear sorter, butler, autonomous mobile robots in a warehouse, etc. Solutions possess goods-to-person technology and advanced facilities. Considering a team of experienced professionals, this major supply chain automation company is catering to the need of many customers related to various Kolams.Looking to buy the best automatic cross-belt sorters at affordable prices, contact or visit its official website.

Also Read : https://bit.ly/34pO3cj

0 notes

Text

The Autonomous Mobile Robots In A Warehouse Are Driving Higher Productivity

Industrial sector robots are evolving from increasingly powerful, stable machines to sophisticated, mobile platforms to meet the broader needs of automation. Amongst the latest and most innovative automation solutions available in the market are Autonomous mobile robots in a warehouse (AMRs). AMR's easy programming and implementation makes them even more attractive to end-users.

Autonomous mobile robots in a warehouse:

AMR or autonomous mobile robots in a warehouse are known for their unique ability to navigate in uncontrolled environments with a high degree of understanding through sensors, blueprints, artificial intelligence, 3D or 2D vision, and more. AMRs differ from automatic guided vehicles (AGVs) according to their degree of autonomy - AMRs are far more independent than AGRs. AMRs will be an essential part of lean operations across a wide range of industrial activities, as they are widely deployed, as they are built to meet specific challenges in specific industrial environments. AMRs are highly innovative compared to a conventional automated guided vehicle (AGV) that is also mobile but uses wires or magnets to navigate a narrowly defined area.

AMRs are holding high capability of navigating dynamic environments. They require very little external input to do this, which is an important capability. The industrial atmosphere, such as construction sites are inherently vibrant. Manufacturing facilities are becoming more dynamic as they advance linear operations. Robots that can operate in these environments will have significant commercial potential, which will initiate process automation without disrupting the need for frequent changes in the production environment.

Top Supply Chain Automation Company:

GreyOrange is an essential provider of warehouse robots for fulfillment and distribution centers globally. It has been working effectively for the last ten years to provide solutions tailored to customer demand. The main objective of this significant supply chain automation company is to bring technological benefits for customers to use. New machinery and software are economically designed and developed. The self-sustaining system can handle the stocks according to the traffic in the warehouse.

0 notes

Link

If you want to incorporate automation to your warehouse then none other than GreyOrange can be the ideal Supply Chain automation company. Get customized solutions as per your requirements.

0 notes

Text

Why Warehouse Execution Software Can Be A Best-Fit For Your DC

Massive changes in the retail sector have led to massive changes in the supply chain. A growing percentage of e-commerce orders need to be met from distribution centers and warehouses, seeking new concepts to modify existing warehouse systems to meet both retail store replenishment and individual delivery-to- customer requirements. The operators, implementing the warehouse execution software (WES) should consider executing a unified order consolidation approach, taking advantage of loop truncation.

Warehouse Execution Software:

The warehouse execution software provides a unified set of WMS (warehouse management system), and WCS (warehouse control system) functions within an application. This two-in-one method uses a single application to perform both WMS and WCS tasks. The flexibility of WES allows today's e-commerce, omnichannel, and retail distributors to achieve same-day fulfillment and meet growing customer demands. Combining the core functionality of traditional warehouse management and warehouse control systems, warehouse execution software provides a single platform to run and manage busy order fulfillment centers.

Benefits of implementing WES:

The warehouse robots are capable of maximizing the advantages of automated systems while increasing inventory accuracy and reducing labor costs. Implement the functionality required to meet the needs of your business entirely. Flexibility to interface with other applications and host-based systems, such as corporate ERP, PLC, and automated tools. Available customization for customer-specific business rules and interfaces required to accommodate specific needs for your operations. The use of a single system creates stability and typically requires a shorter learning curve for those running the system.

Warehouse Robots:

These fast-growing robots have reduced the time required to complete multiple tasks and have largely replaced human effort. The human labor force needs holidays, sick leaves, paid leaves, lunch breaks, health insurance, and many other benefits. However, all these requirements are eliminated when the robot comes into the picture. Professionals in multitasking, robots can pick up pallets of goods, move entire piles of shelves to shipping stations, and complete tedious jobs better than humans. While some warehouses are purely pick-and-package systems, other warehouses are experimenting with robots designed explicitly for speed-sorting. Multi-robot fulfillment systems are some of the most expensive warehouse automatons that work in the transport of pallets, along with humans. Traveling as a group, these robots can navigate automatically, with guidance from a server. Some bots can also pick up racks and drop them in human-powered workstations.

0 notes

Link

Today, warehouses need to speed up their processes according to the need of the era. In this scenario, warehouse execution software is playing an important role. The supply chain is making changes with automation as needed.

0 notes

Link

Mobile robotics is indeed a growing field, yet it has achieved its greatest success so far in the world of industrial manufacturing.

0 notes

Text

Warehouse Execution Software-The Best Solution To Gain Product Traceability

Manufacturers in many industries are facing increased regulations. These regulations seek producers to find cost-effective solutions to increase product's traceability from the production line through distribution. This is where manufacturers see the benefits of warehouse execution software (WES). If you connect a warehouse execution software to upstream and downstream systems in the supply chain, you can boost the product traceability. It will allow manufacturers to quickly respond to problems within the manufacturing procedures, and ensure they meet regulation standards.

Warehouse Execution Software:

Warehouse execution software (WES) provides the customer with a range of data-gathering tools such as advanced reporting, predictive analysis, prescription analysis, and issue detection. This data can be analyzed to identify common trends and predict operation conditions to ensure that your business is working at peak optimization. This software is generally used in distribution operations. It is said to be functionally equivalent to a construction execution system or MES.

Benefits of Warehouse Execution Software (WES):

Manufacturers with a different WMS and a separate warehouse control system (WCS) often run into traceability issues. However, with WES, manufacturers can implement traceability and control requirements within a single solution. And because WES connects to other systems, the application can orchestrate the process throughout the supply chain. By implementing a tightly integrated WES in the supply chain process, manufacturers can implement traceability and control requirements throughout the supply chain. They can save, track, and efficiently recall contaminated or defective products when necessary - Time, money, and often their saving reputation.

Warehouse Robots:

There are many types of warehouse robots providing different types of functionality, which allow the warehouse to select robotics solutions that assist with different processes. Warehouse operators must understand the options available to implement the correct technologies to suit the needs of the warehouse. We created this guide to provide an overview of the Warehouse Robotics market, the types of warehouse robots, their functions, use cases, and other information warehouse operators need to know to make informed technology investments.

Pros of Warehouse Robots:

The use of robots in the warehouse means that there is a very low probability of errors regarding human labor. Apart from errors, this system only reduces the time it takes to move to different parts of the warehouse. This is why employees focus more on quality control. Traditional workers require breaks for rest and energy rehabilitation. But the robot does not need a break. They can work in long innings.

0 notes

Video

tumblr

With increasing SKUs, growth in e-comms, and growing market demand for same-day order fulfillment, companies can automate their facilities inventory through the warehouse management robotic system offered by the top-notch warehouse automation company.

0 notes