Don't wanna be here? Send us removal request.

Text

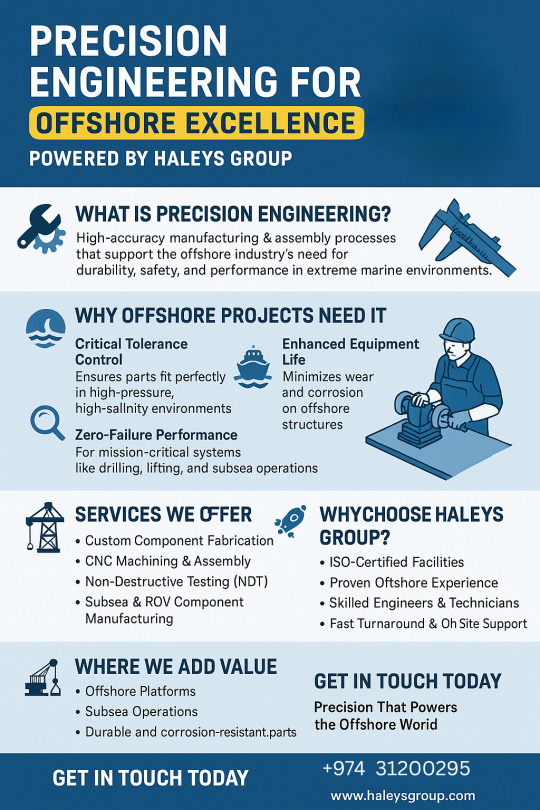

Haleys group guarantee the highest accuracy, reliability, and performance in extreme marine conditions. With state-of-the-art technology and experienced expertise, we supply components and systems to meet high offshore standards. Each project is treated with close attention to detail, guaranteeing safety and operational efficiency. At Haleys Group, precision is not merely a service���it's our assurance to offshore excellence.

0 notes

Text

What Are the Most Critical Inspection and Integrity Services for Offshore and Industrial Safety?

Introduction:

In high-hazard industries such as offshore energy, marine operations, and heavy industry, asset integrity and safety are not discretionary—business critical. Each weld, lift, and load is part of an integrated system that requires reliable performance under adverse conditions. To guarantee this, organizations need to move beyond reaction-driven maintenance and embrace strategic inspection of lifting devices and tackles, integrity management, and technical training.

These services are the building blocks of long-term operational effectiveness, regulatory compliance, and environmental responsibility. From the microscopic detection of a structural defect by non-destructive testing (NDT) to the macroscopic implementation of lifting plans, lifting and rigging equipment management, and steel structure manufacture, an organized inspection and integrity system is critical in avoiding failures and maximizing performance.

This paper delves into the fundamental services driving today's industrial and offshore success—drawing attention to prominent methodologies, practical applications, and key questions that should be asked by any operator, engineer, and HSE expert.

Industrial Inspection and Non-Destructive Examination

Industrial inspection is the frontline method of identifying fault, weaknesses, or deterioration in materials and systems. Lifting appliances inspection and lifting device inspection are central activities within this process. Non-destructive examination allows faults that are not visible to be detected without disassembling the equipment, employing techniques like ultrasonic, magnetic particle, dye penetrant, and radiographic methods.

BHA and Tubular Inspection

Bottom Hole Assembly (BHA) and tubular inspections are essential in drilling operations. These areas of weakness can result in catastrophic operational failure. Internal surface, thread, and hardbanding inspections are performed using techniques like magnetic flux leakage and ultrasonic testing.

Inspections are used to ensure the integrity of reused assets—where damage and fatigue may not be immediately apparent.

Lifting Equipment Inspection and Testing Services

Equipment inspection of lifting gear is a priority service, especially offshore. Equipment like slings, hoists, cranes, and shackles should be tested to confirm that it conforms to operational requirements. Testing involves:

•Proof load testing

•Destructive and non-destructive testing

•Lifting tackle inspection

•Dimensional analysis and lifting gear inspection

•Certification (LOLER, DNV 2.7-1)

Offshore deployment of lifting equipment requires a stringent inspection before deployment. Independent third-party certification guarantees consistent, unbiased reports. Compliance is key, whether you're looking for lifting equipment testing near me or shipping worldwide

IMDG Inspection: Ensuring Dangerous Goods Compliance

IMDG inspections guarantee sea transport of dangerous goods in a safe manner. Packages and containers are inspected for leakage, corrosion, adequate labeling, and documentation.

Failure during this inspection process may lead to heavy penalties, safety accidents, or environmental violations.

Thickness Survey Services

Thickness surveys using ultrasonic gauges measure corrosion and material thinning in vessels, tanks, and pipelines. These measurements are essential for operational decision-making and preventive maintenance. Surveys may be undertaken during shutdown or even in-service, permitting continuous operations.

Industrial Safety and Operator Training

Training and certification are necessary to provide competent handling of lifting equipment and tackles examination. Safety-critical positions have specialized qualifications like:

•Appointed Person (Lifting Operations)

•Rigger Certification

•Crane and Forklift Operators

•Manlift and Earth-Moving Operators

•Lifting Supervisor

These courses include safety, signaling, equipment restrictions, and emergency procedure. Qualified staff also provide loler lifting accessories examination compliance during the lifting process.

Specialized Engineering and Offshore Services

Marine and Offshore Engineering Support

Comprises design, load path analysis, precision engineering for offshore, fatigue analysis, and lifting inspection support for tough marine operating conditions.

Tensile and Load Testing

Computerized load and tensile testing of lifting equipment testing provides traceable results and standard-compliant performance.

Turnaround and Shutdown Optimization

Maintenance plans integrate maintenance and minimize downtime by combining mechanical, electrical, and inspection activities.

Gap Analysis & Crane Load Path Inspection

Determine deviations from compliance, inspect lifting gear inspection, and analyze fatigue in load-carrying crane components offshore

Lifting Plan Implementation

Detailed planning allows for safe lifting—from rigging inspections to lifting tackle checks—by certified staff

Reverse Engineering & Test Equipment Rentals

3D prototyping and custom modeling of out-of-production parts (e.g., CCUs) prolongs asset life. Short-term access to certified rigging and lifting equipment for projects with fluctuating needs is provided

Rope Access and Helideck Safety

Specialized teams carry out inspections in hard-to-reach areas via rope access. Friction testing provides a helideck grip for safe aircraft landings.

FAQ

How frequently should lifting equipment be checked?

The frequency of inspection varies with usage and environment. Equipment is normally inspected every 6–12 months, or more in offshore or high-risk services.

Why is third-party inspection necessary for offshore lifting equipment?

Unaffiliated inspections provide impartial evaluations, verifiable outcomes, and certification, all of which are essential in responding to offshore regulatory and client demands.

What is a thickness survey, and why is it necessary?

Thickness survey applies ultrasonic testing to quantify material loss from corrosion in tanks, vessels, or pipelines—preventing failures and maintenance planning.

Can thickness surveys be performed during operations?

Yes, ultrasonic thickness measurements can often be performed in-service, reducing downtime and allowing continuous operation while assessing structural integrity.

What is dimensional analysis in lifting inspections?

Dimensional analysis ensures lifting equipment dimensions are within design tolerances and have not changed due to wear, corrosion, or modification.

Conclusion

From tools and tackles lifting to loler lifting accessories, a strong inspection and maintenance program improves safety, reliability, and sustainability. Each service—ranging from NDT and offshore engineering to technical certification—is an integral part of the overall objective: safe, efficient operations in high-risk environments.

With industries experiencing stricter regulations and tougher conditions of operation, strategic inspection and competency-based training are becoming differentiators. Organizations that make these a priority are better able to safeguard human life, protect the environment, and maintain operational excellence.

About Author

CS Jassi

I am a seasoned engineering professional with 34 years of experience in the oil & gas and power sectors, specializing in EPC projects, manufacturing, quality assurance, and regulatory compliance. As General Manager at HALEYS Group Middle East, I lead engineering, fabrication, and compliance operations, ensuring adherence to ISO, API, ASME, AWS, and DNV standards. My expertise in offshore containers, pressure vessels, and advanced materials enables me to contribute valuable insights on engineering advancements, safety regulations, and industry best practices. A mechanical engineer with ASNT NDT Level III and IRCA Lead Auditor certifications, I am dedicated to knowledge sharing, research, and technical writing, supporting industry professionals in navigating evolving standards and best practices

0 notes

Text

Why Offshore Fabrication Requires Precision Engineering for Safety?

Introduction:

Offshore locations are among the most hazardous and difficult workplaces on the planet. Equipment and structures employed in the energy, oil and gas, and marine sectors have to withstand severe weather, high pressure, and ongoing mechanical stress. Under such harsh circumstances, precision engineering services offshore is not an added advantage—it is necessary. Safety, performance, and longevity of steel structure for offshore fabrication are largely dependent on accuracy at each phase of design, production, and assembly.

The Role of Precision Engineering in Offshore Safety

Offshore precision engineering services include the precise activity of designing and producing parts with very close tolerances. This is done to ensure every part functions exactly as designed. Accuracy is imperative in offshore fabrication. An error of even the smallest magnitude in structural alignment, weld depth, or component fitting can cause serious safety hazards—like leaks, structural failure, or unscheduled downtime.

Precision engineering ensures that:

Load-bearing structures are aligned to transfer weight effectively

Welds are crack-resistant, corrosion-resistant, and certified, uniform

Components just fit, eliminating on-site rework

Points of stress are calculated to reduce fatigue and eventual failure

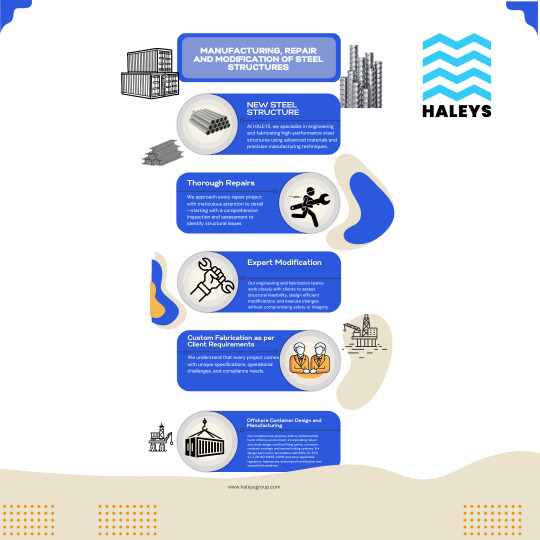

Steel Structure Offshore Fabrication:

Challenging Precision by Design: Steel offshore structure comprises the fabrication of important components like support frames, skid units, walkways, and platform substructures. These are the building blocks of offshore platforms and processing facilities. Due to severe marine conditions—high salinity, humidity, wind, and vibration—each manufactured component needs to go through stringent certification requirements like DNV, API, and ISO.

Engineering Design Services for Offshore

Engineering design services offshore involve high-level calculations, modeling, and simulations to create safe, functioning, and regulation-compliant equipment and structures. This covers anything from the engineering design for offshore firms for helidecks and lifting frames to containerized modular solutions

Precision-Engineered Offshore Rental Solutions

Offshore rental services are more than the supply of equipment—they're precision-engineered solutions designed to endure the brutality of adverse marine environments. Whether short-term usage or project-based operations, offshore rental services deliver access to certified, tested, and ready-to-run equipment that works predictably under pressure.

Precision Engineering Guarantees Rental Equipment:

Meets DNV 2.7-1 and DNV 2.7-3 standards

Survives repeated cycles of deployment offshore

Retains structural integrity under lifting, stacking, and shipping conditions

Complies with demanding safety, corrosion resistance, and load-bearing requirements

FAQ

What Is Offshore Container Fabrication and What Makes It Unique?

Offshore container fabrication consists of the designing and manufacturing of heavy-duty units (CCUs) for the transportation of material and equipment in marine and oilfield applications. They have to meet international standards for safety and durability

Most Important Features of Offshore Container Fabrication:

Made from high-strength, corrosion-resistant steel

Manufactured to DNV 2.7-1 / DNV 2.7-3 certification requirements

Features certified lifting points, door seals, and internal bracing

Subjected to load testing, NDT inspections, and third-party approvals

What are the typical Testing and Certification procedures during Offshore Fabrication?

To verify offshore structures and equipment conform to international safety and performance levels, several testing and certification procedures are carried out during fabrication.

Routine Offshore Fabrication Quality Controls:

Non-Destructive Testing (NDT) for weld integrity

Load testing and dimension checks

Documentation: WPS, PQR, MTC, DCR, DVR

Third-party inspection to DNV, ABS, or BV certification

How do precision engineers apply precision engineering to the proof load testing of Qatar CCUs offshore?

In offshore CCU proof load testing in Qatar, precision-calibrated tools are employed to apply peak loads. Careful measurement eliminates the possibility of the container's lifting points, frames, and welds not meeting DNV 2.7-1 or 2.7-3 standards—proving them ready for use offshore.

What is the importance of precise load calibration for offshore lifting equipment?

Genuine load calibration assures valid proof load testing of offshore CCUs in Qatar. Miscalibrated systems have the potential to pass unsafe equipment or fail safe equipment, resulting in costly delays or hazardous conditions offshore.

Key Applications of Precision Engineering:

Calibrated load cells employed

Stress points are strictly monitored

Certified processes are rigidly applied

Data taken for traceability

Lifting geometry was correctly simulated

How do precision-engineered fittings improve the safety of hydraulic systems?

Accurate fittings cut off leaks, minimize pressure loss, and provide compatibility with hydraulic hose assemblies. This is particularly crucial in offshore and industrial applications where pressure dependability is paramount.

Key Factors:

High-pressure sealing capability

Corrosion-resistant materials

Vibration-resistant fitting design

Exact dimensional tolerances

CONCLUSION

About the Author

CS Jassi

I am a seasoned engineering professional with 34 years of experience in the oil & gas and power sectors, specializing in EPC projects, manufacturing, quality assurance, and regulatory compliance. As General Manager at HALEYS Group Middle East, I lead engineering, fabrication, and compliance operations, ensuring adherence to ISO, API, ASME, AWS, and DNV standards. My expertise in offshore containers, pressure vessels, and advanced materials enables me to contribute valuable insights on engineering advancements, safety regulations, and industry best practices. A mechanical engineer with ASNT NDT Level III and IRCA Lead Auditor certifications, I am dedicated to knowledge sharing, research, and technical writing, supporting industry professionals in navigating evolving standards and best practices

0 notes

Text

🚧 Ensure Safety with Expert Lifting Equipment Inspection! ???? At HALEYS Group, we are the experts in Lifting Equipment Inspection to international safety standards. From shackles and slings to cranes and hoists — we guarantee your lifting equipment is 100% certified, compliant, and fit for high-performance operations.

✅ LOLER-Compliant Inspection ✅ Offshore & Onshore Lifting Equipment Testing ✅ Load Testing, Certification & Reporting ✅ Qualified Inspectors | Quick Turnaround | Industry Leaders Trust Us https://haleysgroup.com/service/inspection-integrity-management-and-specialized-services/

📞 Call us now: +974 7909 1992 📍 Serving Qatar & the Middle East

🔍 Don't wait for a failure — schedule your lifting equipment inspection today and keep operations safe, smooth, and compliant.

0 notes

Text

Offshore Lifting Appliances Inspection – Safety Comes First with Haleys Group ????

At Haleys Group, we recognize that offshore activities require precision, reliability, and un compromising safety. That's why we provide full-scale Lifting Appliances Inspection solutions in Qatar and the GCC.

Our trained engineers and inspectors guarantee that your lifting gear complies with all international standards and is prepared to deliver in the harsh offshore environment. 📞 Contact Haleys Group Today 📱 Call/WhatsApp: +974 31200 295 📧 Email: [email protected] 🌐 www.haleysgroup.com

🔗 Partner with Haleys for safer and smarter offshore operations.

0 notes

Text

We at Haleys Group are experts in designing and manufacturing offshore containers that satisfy the top global standards for offshore oil & gas, marine, and energy sectors in Qatar.

Our specially designed offshore containers are constructed to function in the most challenging offshore conditions, with precise fabrication, strong welding, and high-class finishing that guarantees strength, compliance, and safety. ✅ Why Choose Haleys Group for Offshore Container Fabrication? 🔹 Certified Quality: Fabricated in compliance with DNV 2.7-1 / EN 12079 standards for offshore containers. 🔹 Custom Design Solutions: Tailored for your specific offshore applications – from cargo units and workshop containers to reefer and accommodation modules. 🔹 Corrosion Resistance: Superior coating systems for protection in marine environments. 🔹 Load-Tested & Inspected: Every unit undergoes rigorous testing and inspection for offshore deployment. 🔹 Experienced Team: Decades of experience in fabrication for the oil & gas sector across Qatar and the GCC.

✨ From concept to delivery, we ensure every offshore container meets your operational requirements and international regulatory standards.

📦 Our Offshore Container Capabilities Include:

Cargo Carrying Units (CCUs)

Tool & Workshop Containers

Reefer (Refrigerated) Containers

Chemical Storage Containers

Accommodation Modules

🚀 Serving Clients Across Qatar’s Oil & Gas & Marine Industries Our fabrication yard in Qatar is equipped with state-of-the-art facilities and a highly skilled workforce to deliver projects on time and within budget.

📞 Contact Us Today! 📍 Haleys Group – Qatar 📱 Call/WhatsApp: +974 31200 295 📧 Email: [email protected] 🌐 www.haleysgroup.com

0 notes

Text

We at Haleys Group are experts in designing and manufacturing offshore containers that satisfy the top global standards for offshore oil & gas, marine, and energy sectors in Qatar.

Our specially designed offshore containers are constructed to function in the most challenging offshore conditions, with precise fabrication, strong welding, and high-class finishing that guarantees strength, compliance, and safety. ✅ Why Choose Haleys Group for Offshore Container Fabrication? 🔹 Certified Quality: Fabricated in compliance with DNV 2.7-1 / EN 12079 standards for offshore containers. 🔹 Custom Design Solutions: Tailored for your specific offshore applications – from cargo units and workshop containers to reefer and accommodation modules. 🔹 Corrosion Resistance: Superior coating systems for protection in marine environments. 🔹 Load-Tested & Inspected: Every unit undergoes rigorous testing and inspection for offshore deployment. 🔹 Experienced Team: Decades of experience in fabrication for the oil & gas sector across Qatar and the GCC.

✨ From concept to delivery, we ensure every offshore container meets your operational requirements and international regulatory standards.

📦 Our Offshore Container Capabilities Include:

Cargo Carrying Units (CCUs)

Tool & Workshop Containers

Reefer (Refrigerated) Containers

Chemical Storage Containers

Accommodation Modules

🚀 Serving Clients Across Qatar’s Oil & Gas & Marine Industries Our fabrication yard in Qatar is equipped with state-of-the-art facilities and a highly skilled workforce to deliver projects on time and within budget.

📞 Contact Us Today! 📍 Haleys Group – Qatar 📱 Call/WhatsApp: +974 31200 295 📧 Email: [email protected] 🌐 www.haleysgroup.com

0 notes

Text

Precision Engineering Services for Offshore Operations ???? For the offshore business, a millimeter can make all the difference. At Haleys Group, we are experts at providing top-grade precision engineering solutions to cater to the rigorous needs of offshore and marine businesses. Our skilled engineers ensure all components are engineered with utmost precision and resilience, specifically designed to meet your operational demands and environmental conditions

Our offshore precision engineering solutions include: ✔️ Custom machining and fabrication for offshore platforms and subsea systems ✔️ Reverse engineering of outdated or worn components for refurbishment and optimization ✔️ CNC machining of complex, high-tolerance parts for offshore equipment ✔️ Design and production of bespoke tools and components for lifting, drilling, and structural applications ✔️ Steel structure fabrication and modular assembly for offshore installations

We serve major sectors including oil & gas, marine construction, energy, and offshore wind. All components are manufactured using DNV-certified and corrosion-resistant materials to withstand extreme offshore environments. Our engineering team follows strict quality assurance procedures, ensuring compliance with international standards and client-specific requirements.

Why choose Haleys Group? ✅ Fast turnaround with high precision ✅ Offshore-ready materials and technology ✅ Experienced in challenging offshore conditions ✅ Scalable solutions for projects of any size

Partner with us for precision you can trust and engineering that performs offshore.

📞 Contact Haleys Group today at +974 31200 295 📧 Email: [email protected] 🌐 Visit: www.haleysgroup.com

0 notes

Text

Refrigerated Storage, Ready for Offshore! When it comes to offshore operations, preserving your sensitive cargo is critical. Haleys Group offers offshore-grade reefer containers for rent — built to perform in the toughest marine environments.

✔️ Temperature precision ✔️ DNV 2.7-1 certified ✔️ Safe, secure, and energy-efficient ✔️ Suitable for oil rigs, marine vessels, and remote platforms

🧊 From seafood to medical supplies – we keep it cool!

📞 Book your reefer now: +974 31200295

0 notes

Text

Heavy-Duty Offshore Lifting Made Easy! 🚢 Need reliable crane solutions for your offshore operations? Haleys Group offers robust, certified cranes for offshore service rentals, ensuring safe and efficient lifting for all marine and oilfield projects.

✅ Heavy load handling ✅ Offshore certified equipment ✅ Flexible rental plans ✅ 24/7 support and maintenance

🔧 Trusted by top offshore operators for safety and precision.

📞 Call us now: +974 31200 295 📍 Haleys Group – Offshore Equipment Rental Experts

0 notes

Text

🚧 Ensure Safety with Expert Lifting Equipment Inspection! ???? At HALEYS Group, we are the experts in Lifting Equipment Inspection to international safety standards. From shackles and slings to cranes and hoists — we guarantee your lifting equipment is 100% certified, compliant, and fit for high-performance operations.

✅ LOLER-Compliant Inspection ✅ Offshore & Onshore Lifting Equipment Testing ✅ Load Testing, Certification & Reporting ✅ Qualified Inspectors | Quick Turnaround | Industry Leaders Trust Us https://haleysgroup.com/service/inspection-integrity-management-and-specialized-services/

📞 Call us now: +974 3120 0295 📍 Serving Qatar & the Middle East 🔍 Don't wait for a failure — schedule your lifting equipment inspection today and keep operations safe, smooth, and compliant.

0 notes

Text

Dependable Offshore & Onshore Lifting and Rigging Equipment Rental

Do you need dependable offshore and onshore lifting and rigging equipment rental services? Haley’s Group offers certified equipment for both offshore and onshore operations. Whether it's a short-term project or long term assignment, we offer solutions tailored to safety, efficiency, compliance and industry standards.. From heavy rigging support to lifting gear, we provide timely service and expert support alongside high-quality equipment.

For inquiries or bookings contact us at +974 4441 1234.

Visit https://haleysgroup.com/service/equipment-rental/

Safely and professionally—we fulfill your lifting needs.

0 notes

Text

Precision engineering services for offshore in Qatar

0 notes

Text

At Haleys Group, we provide dependable and efficient crane rental services tailored to meet the needs of various industries including construction, oil & gas, marine, infrastructure, and heavy engineering projects. With a fleet of modern and well-maintained cranes, we ensure safe lifting, transportation, and installation of heavy loads—no matter the complexity or scale of your project.

🚧 Why Choose Haleys Group for Crane Rentals?

✅ Wide Range of Cranes: From mobile cranes and crawler cranes to tower cranes and hydraulic truck cranes, we offer a complete selection to suit every project requirement.

✅ Certified Equipment: All our cranes are fully inspected, certified, and maintained to meet international safety and quality standards.

✅ Skilled Operators: Our licensed and experienced crane operators are trained to handle operations with utmost precision and safety.

✅ Flexible Rental Plans: Whether you need a crane for a few hours, days, or on long-term rental contracts, Haleys Group offers competitive and flexible plans.

✅ 24/7 Support: Our dedicated support team is available round-the-clock to ensure seamless operation and address any on-site challenges.

🏗️ Serving Major Industries:

Offshore & Onshore Construction

Oil & Gas Facilities

Industrial Plants

Infrastructure & Road Works

Marine & Port Services

Contact Us Today 📞 +974 31200295 🌐 https://haleysgroup.com/service/equipment-rental/

#offshorecrane #cranerental #cranerentalforoffshore

0 notes

Text

We understand that one size does not fit all. HALEYS boasts a proven track record in custom manufacturing and the art of modifying steel structures and offshore containers to cater to your specific needs. Our experienced and skilled production team ensures that every structure and container is designed, manufactured, and tested with a keen eye for compliance with the latest industry standards and specifications.

0 notes

Text

Offshore Lifting Equipment Rental in Qatar – +974 31200295 Haleys Group Looking for reliable offshore lifting equipment in Qatar? Haleys Group offers a wide range of certified lifting solutions tailored to meet the demands of offshore operations. From cranes and hoists to spreader beams and slings, we ensure safety, durability, and performance at sea.

✅ High-quality, tested lifting equipment ✅ Available for short-term and long-term rentals ✅ Compliance with international offshore safety standards ✅ Quick delivery across the World

📞 Call us today: +974 31200295 🌐 Visit: https://haleysgroup.com Choose Haleys Group – Powering Qatar’s offshore strength with dependable equipment.

0 notes

Text

Why the Oil and Gas Industry Is Shifting to Offshore Equipment Rentals: Expert Insights & 2025 Trends

Introduction

In today’s competitive oil and gas landscape, especially in offshore fields, operational efficiency, safety, and cost optimization are more critical than ever. Equipment rental services have emerged as a strategic solution, giving operators access to a full spectrum of certified offshore equipment and load testing tools without the burden of capital ownership.

From DNV-ST-E271 2.7-1 & 2.7-3 certified offshore cargo carrying units (CCUs) to waterbags, load cells, and calibrated test weights for lifting equipment testing, rental models empower companies to remain agile, reduce compliance risks, and enhance performance on tight project schedules.

Q1: Why Should Companies Rent Oilfield and Offshore Equipment Instead of Purchasing It?

Rental companies maintain fleets of state-of-the-art equipment that are precision-engineered for optimal performance in demanding offshore and oilfield environments and Offshore platforms and oilfield environments demand robust steel structures designed for harsh conditions. As offshore exploration and production intensifies, particularly in Qatar’s oil fields- renting specialized equipment is proving more beneficial than purchasing. Here’s why:

1. Reduced Capital Expenditure

Heavy investments in offshore CCUs, test weights, reefer containers, or certified rigging equipment can tie up crucial working capital. Renting helps operators preserve liquidity while accessing high-performance assets only when needed.

2. Immediate Access to Project-Ready, Certified Equipment

Rental units come pre-certified with:

Certificate of Conformity (CoC)

Design Verification Reports from approved third-party agencies of NOC / QatarEnergy / QatarEnergy LNG

Load test certifications and maintenance logs

DNV 2.7-1 / ISO 10855 compliance for offshore CCUs

Calibration certificates for load cells and test weights

This eliminates the delay of sourcing, certifying, and validating equipment before mobilization, saving weeks of lead time and avoiding costly rejections from site HSE and inspection teams.

3. Enhanced Flexibility for Project-Specific Needs

Rental contracts can be structured to suit short-term shutdowns, hook load tests, rig moves, or ongoing maintenance campaigns. Whether you need a chemical tank container, a drum basket, or a CSC-certified container, rentals scale as per your project timeline.

4. Operational Agility with Compliance Assurance

Major operators like NOC, QatarEnergy, QatarEnergy LNG, and EPC contractors require full documentation and compliance with local statutory standards. Rental providers ensure:

Quick deployment of ready-to-use equipment

Full traceability of lifting accessories and testing tools

Compliance with ISO, API, DNV, and LOLER guidelines

5. Built-in Maintenance and Support Services

Equipment is fully maintained and pre-inspected before mobilization. Rental agreements often include technical support, on-site servicing, and even equipment replacements, reducing the risk of downtime and enhancing safety offshore.

Q2: How is the Industry Evolving When It Comes to Rental Services?

The offshore equipment rental sector is rapidly modernizing. Key trends shaping 2025 include:

IoT-Enabled Load Monitoring: Advanced load cells now offer real-time data via wireless connections, enabling better visibility during heavy lifts and load tests.

Eco-Conscious Assets: Low-emission generators and insulated reefers are reducing environmental impact, supporting the region’s sustainability goals.

Remote Diagnostics and Support: Digital tools allow offshore teams to receive remote assistance for troubleshooting equipment in the field.

Cross-Border Rental Networks: Providers are expanding regionally, offering seamless mobilization for multi-country operations within the GCC.

Q3: What Types of Offshore Equipment Are Commonly Rented in Qatar’s Oil & Gas Sector?

Here’s a breakdown of key rental categories that serve offshore platforms, FPSOs, jack-up rigs, and temporary work bases:

🔹 Offshore CCU Rentals

Offshore Cargo Carrying Unit (CCU) rentals are vital for the safe and efficient transport of equipment, tools, and materials to and from offshore installations.

Types: Open-top containers, closed containers, bottle racks, cargo baskets etc. (Refer below)

Application: Tool transport, chemical storage, equipment logistics

Features: DNV-ST-E271 2.7-1 & 2.7-3 / ISO 10855 certified, offshore-rated paint, pad eyes for safe lifting

Our Comprehensive Equipment Rental Portfolio Includes:

Mini Containers

10 Feet Open Top & Closed Containers

20 Feet Open Top & Closed Containers

Cargo Baskets

Half Height Offshore Containers

Offshore Waste Skips

Offshore Reefer Containers

Bottle Racks

Drum Baskets

Chemical Tank Containers

Offshore Lifting Frames

Steel Pallets

CSC Containers

Offshore Reefer Containers

🔹 Load Testing Equipment Rentals

Offshore operations demand the highest safety and compliance standards, making load testing equipment rentals essential.

Waterbags & Sausage Bags (1t – 550t): For dynamic load testing of cranes, davits, and winches

Calibrated Load Cells (5t – 650t): With real-time monitoring for lifting load validation & Crane ASLI verification

Calibrated Steel Test Weights (20 kg – 800t: Available in modular sets with test tray & traceable calibration documentation

🔹 Lifting and Rigging Rentals

Lifting and rigging rentals provide essential support for safe and efficient operations in oil and gas fields. From chain hoists and hydraulic jacks to certified slings and spreader beams, rental solutions offer high-quality, load-tested equipment designed for heavy-duty lifting tasks.

Equipment: Shackles, chain blocks, slings, spreader bars, lever hoists, chain blocks etc.

Standards/Regulations: Compliant with API, BS EN, ASME and LOLER

Inspection: Supplied with full test certificates and inspection logs

Conclusion

The offshore energy industry is undergoing a critical transformation- shifting from ownership to specialized rental models that deliver speed, safety, and compliance. Whether you’re commissioning a crane, certifying lifting equipment, or mobilizing offshore operations, partnering with a reliable rental provider ensures your project meets industry expectations while staying within budget.

From certified offshore CCUs to load testing packages and rigging gear, rentals are not just a convenience- they are a competitive advantage in today’s offshore oil and gas operations.

About the Author

CS Jassi

I am a seasoned engineering professional with 34 years of experience in the oil & gas and power sectors, specializing in EPC projects, manufacturing, quality assurance, and regulatory compliance. As General Manager at HALEYS Group Middle East, I lead engineering, fabrication, and compliance operations, ensuring adherence to ISO, API, ASME, AWS, and DNV standards. My expertise in offshore containers, pressure vessels, and advanced materials enables me to contribute valuable insights on engineering advancements, safety regulations, and industry best practices. A mechanical engineer with ASNT NDT Level III and IRCA Lead Auditor certifications, I am dedicated to knowledge sharing, research, and technical writing, supporting industry professionals in navigating evolving standards and best practices

0 notes