Don't wanna be here? Send us removal request.

Text

Project 3 - Final Thoughts

Over a year ago now, I had to drop out of this very paper due to long term illness. I was disappointed, particularly because I had already achieved an A+ for my first assignment. Upon returning at the beginning of Trimester 1, this was the paper I knew I could not drop a second time. When I became unwell with overwork a month ago, the old fear returned. But after I cooled down and got a better grip on the final assignments, I knew that I could push through until the end, and get well after that.

As the trimester progressed, I began to realise rather than teaching one method of sustainable design, the emphasis on writing your own criteria forces you to assume a certain responsibility for what you bring into the world, and how you make that happen. And most importantly, what do you do with it then.

0 notes

Text

Project 3 - Bringing it up to Scratch

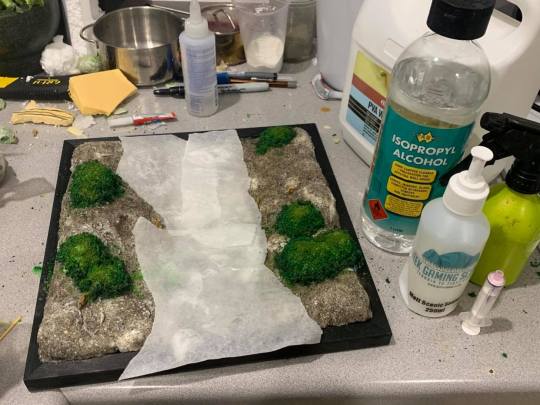

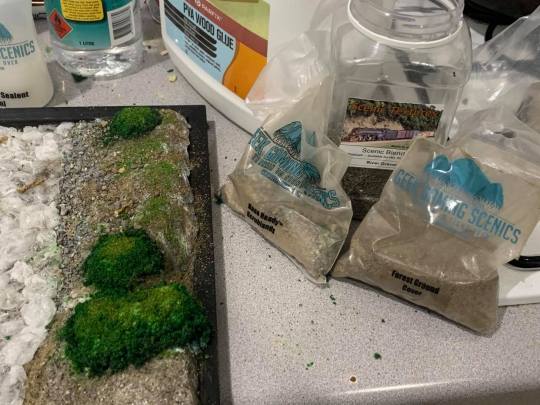

Having photographed the board, I now had the job of using my knowledge of modelling techniques and materials to expand on the existing material qualities and engender a greater level of reality. I began this by applying PVA glue to the whole of the green hedges, and glueing rubberised foam flock to the base in order to hide the join, and make them seem more natural. I followed this by applying successive layers of foam flock from the Geek Gaming Scenics range to highlight this in a gradient. Then I masked off the river, and lightly sprayed the hedges with Isopropyl Alcohol to act as a flow aid, and used a syringe to administer Matt Scenic Sealant, a combination of PVA glue, matt varnish, and water onto the hedges to seal them solidly, the Isopropyl carrying the sealant through each tiny channel and into every gap through capillary action.

Covering the whole board in a light coating of PVA, I sprinkled Scenic Textures River Gravel, Base Ready Scrublands, and Forest Ground Cover, both from Geek Gaming Scenics, gradually up to banks. I repeated the process of masking the banks and spraying the isopropyl and sealant on the bank. However, I had not left enough time for the bushes to dry, which resulted in them leaking dye (as they are designed to do, in order to blend better), down to the riverbank and despite my efforts being trapped under parts of the river’s edge. I was able to remove most of the rich green, but I had to return later and paint the affected areas white, and finally add additional pieces of dehydrated styrene. I polished the project off with a few tufts of varying sizes, and some flowers to brighten it up. I initially had pink ones, but they looked too garish, so I replaced them with a more subtle purple.

Lastly, I photographed the board to contrast it with it’s former self, and once again used Eomer for scale. I am very pleased with this build, both as a personal hobby project, and as a piece of university work. It builds on an existing knowledge base, and develops new methods that will help, if only marginally, alleviate a problem in the word. It stored a huge amount of polystyrene for its size, and weighs a decent amount. I look forward to inspiring my friends to do something similar.

0 notes

Text

Project 3 - Weeds, Water, and Wood

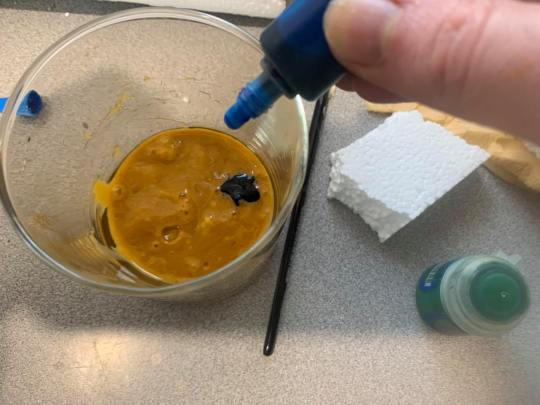

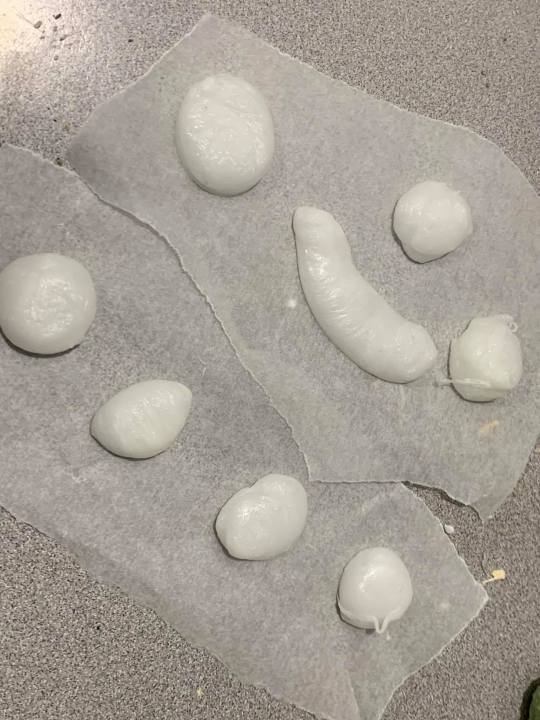

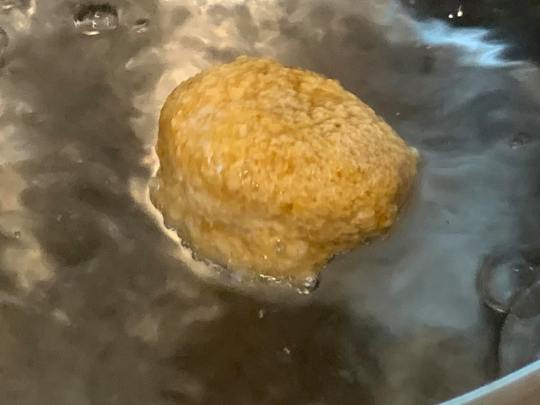

To create the hedges growing near the source of water, I decided to try dyeing the yellow styrene mixture green using blue food colouring. I had also attempted to use paint to no avail. Rolling these into balls, they resembled Brussels Sprouts. They did not grow as much as I had hoped during boiling, and were quite regular in size,but they suited my demonstrative purpose, and I knew that I could resurface them later.

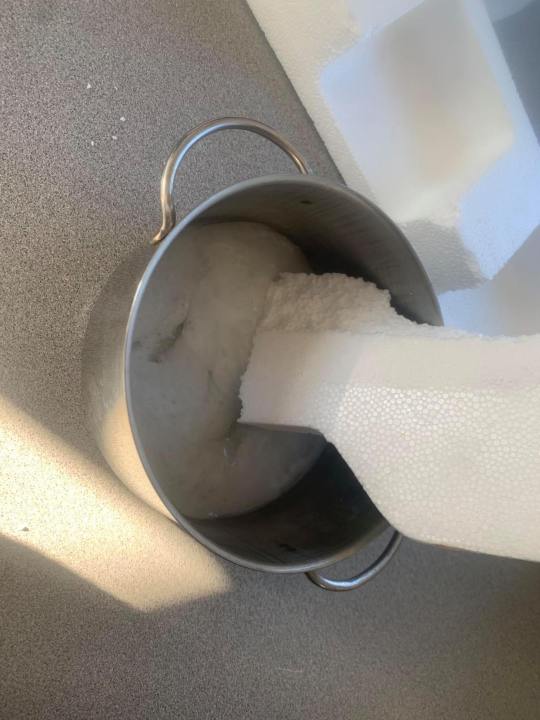

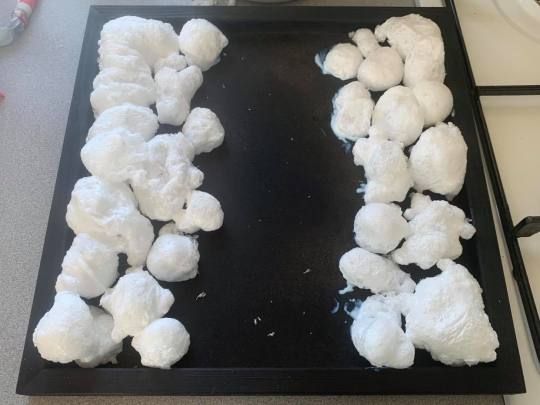

For the river, I mixed up a large batch of white styrene and separated it out into smallish lumps as I wanted to get the most air expansion within each. The first batch took about an hour, and I had to repeat the process twice more. I took each one out while it was still hot, and pressed it in before it had time to dry. this meant there would still be air trapped and giving the transparent quality. As an additional fixative, I ran over it with the heat gun on a low setting, which surprisingly made the crests of the waves fizz and foam. Result! I had just achieved an even greater level of realism.

Finally for the driftwood, I mixed up a small batch of yellow foam, scribbling on the surface in pen to give it a darker appearance. This did not quite work, but I stretched and twisted it anyway before forming the pieces into branches and glueing them to the water and the bank. From here I pulled out my black paper and took several photographs using Eomer, Third Marshal of the Riddemark on his horse Firefoot for scale.

0 notes

Text

Project 3 - Creating the Banks

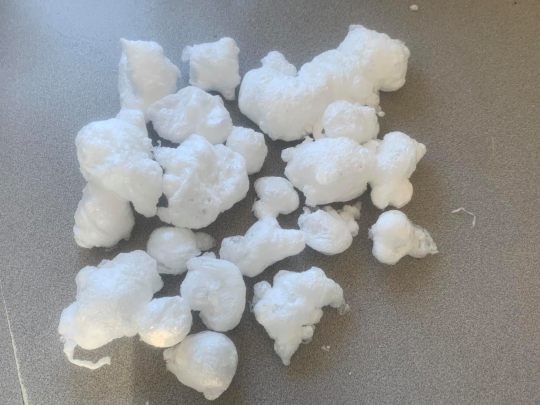

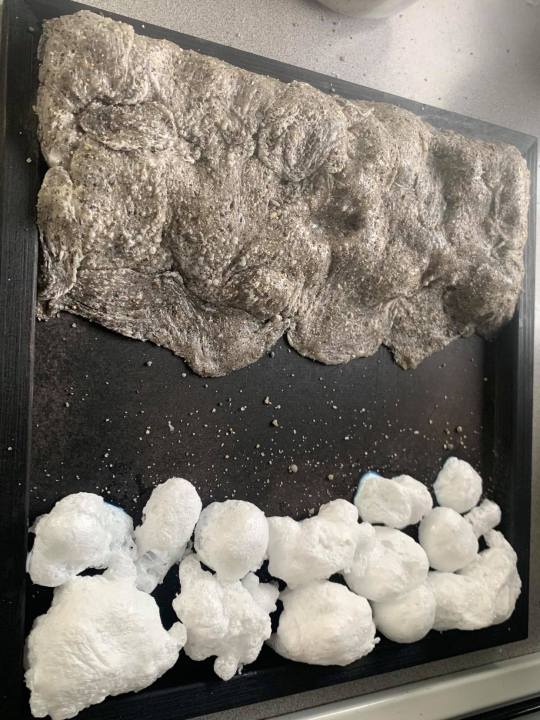

For my diorama, I knew that I would need to raise the sides of the display board to create both banks of the river. I achieved this using “Styrene Bagels”, pieces of white styrene bagels which I boiled. Once I had made enough, I set to work removing the rounded undersides so they would glue better on the table. Cutting one in half, I found a surreal, alien scene within. I glued these into the reverse of an artists hardboard that I had painted black, and mixed up a combination of styrene and sand. This I applied over both banks, filling in the gaps, but allowing for gentle variations in the landform. I also mixed up a variant using a small amount of yellow insulation styrene to simulate the wet sand on the riverbed.

And yes, I did use all that polystyrene in this project.

0 notes

Text

Project 3 - Defining Minimum and Maximum

In this project, my goal is to derive the maximum qualitative utility from polystyrene waste while doing the the minimum quantitative environmental damage.

Maximum

Since quality can be defined in different ways by different people, an individualistic approach ought to be taken, and the objects created be valued in a similar way to art. When concerned with mass production of single use plastic products, it is easy to forget what an extraordinary material plastic is, and what unique properties it possesses. Given the amount of waste plastic currently being produced, we have this extraordinary material in abundance. Therefore, my definition of Maximum in this project is the greatest qualitative utility from waste plastic.

Minimum

However, plastic waste poses a danger to both humans and wildlife and must be controlled in order to alleviate the problem. We produce and consume it in appallingly huge quantities because of its short-term convenience. If we were to find semi-permanent ways of keeping it out of landfills or the ocean, then that would be a worthwhile step on the way to complete regulation of the plastics industry. Therefore, my definition of minimum, is the least amount of plastic waste deposited back into the environment, and ideally none.

0 notes

Text

Project 3 - Reviewing my Criteria

1. Design must innovate in a way that balances technological advancement with human need in order to act as a conduit for social progress.

While the term human need might be a little stretched in this case, the material advancements put in their context of qualitative recycling could be said to represent a form of social and technological progress.

2. The form of a designed object is the physical expression of its function.

In this case, the form is one of a natural and somewhat idyllic environment, ironically made from polystyrene. The expressive quality here is that by keeping polystyrene out of our environment and focussing what we have already made into concentrated forms like this one, we can continue to enjoy a world that is not rife with plastic waste.

3. Designed objects must create agency by enabling the user to complete an otherwise difficult or impossible task and create empathy by communicating an emotional understanding of the task to those around them.

These processes allow waste polystyrene to be broken down and used in a unique and constructive way, where they would otherwise end up thrown out. The fact that they have been repurposed, and will be valued rather that causing long term harm should have some empathetic resonance.

4. The material choices of the designer must be appropriate to the functional life of the object and can be sustainably broken down to their component parts.

Since Polystyrene cannot apparently be broken down further than this state and may never biodegrade, the functional life of this object must be infinite. This criteria was formulated on the grounds of creating and using fresh materials rather than recycled scrap. However, I think that a utilitarian argument could be made in favour of my object, that at least the material is being stored in some creative capacity, rather than in a landfill or finding its way out into the environment.

5. Design is the moral and ethical statement of the designer and must therefore be based in experience.

I have been building miniature scenery for many years and have often lamented that while I can create beautiful things that give my own existence some meaning, this also generates some non-recyclable waste which harms the planet. I kept much of this for years in the garage in hopes of finding a use for it and am happy to finally be putting it to a practical purpose.

0 notes

Text

Project 3 - Ideation based on Experimentation

Through my experimentation, I found that polystyrene has many varied expressive material qualities when treated in different ways. Therefore it would be logical to expressas many of these as practical in a single model. Given my passion for miniature making, and the interesting textural properties of my samples, I decided that I would make a miniature environment featuring as many different types of material as possible, and then add some paint and miniature scenic elements to provide greater realism and compliment the styrene elements. This will be a design intervention aimed at reducing the level of plastic waste in model making, through recycling the waste into beautiful objects of personal value which have designed permanence, and exist outside of a capitalist framework.

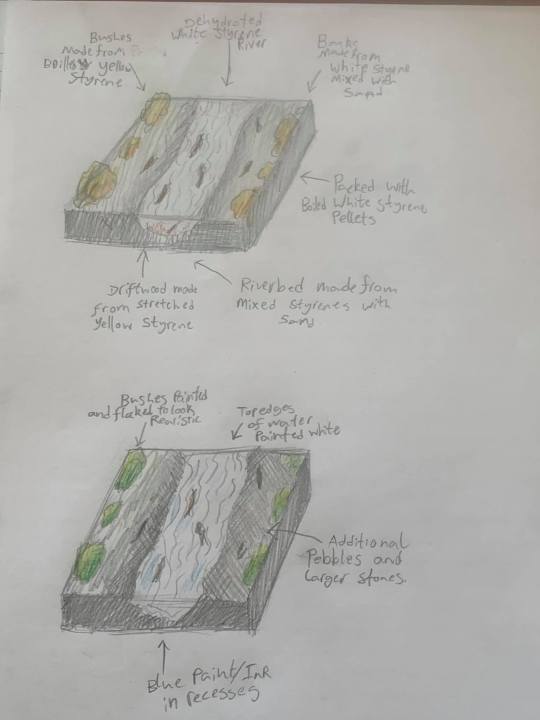

My proposed scene a section of fast flowing river, made from the dehydrated white styrene, with riverbanks made from a white styrene/sand mixture and packed with boiled white styrene pellets. The edges are dotted with bushes made from boiled yellow styrene, and driftwood is scattered around, made from stretched yellow styrene.

The second stage will be the application of paints, foam flocks, stones, and other particulates to assist with the realism of this piece.

0 notes

Text

Project 3 - Identify a design opportunity by trying to give your answers to the following questions

Have any issues drawn your attention during your research into the artefacts, objects or precedent approaches?

While researching plastics, I found out very little I was not peripherally aware of and was disturbed by all of it. Much of what we buy is plastic, even if we do not know it, and almost all is eventually discarded as waste, even though we do not have long term solutions for that waste.

Are they significant or serious enough to warrant interventions? Why do you think so?

Yes, as plastic pollution is one of the biggest problems that humanity is going to have to deal with over the next century. We need systematic reforms on a global level to reassess our toxic and destructive relationship with plastic waste.

Are you interested in dealing with the issues? Why do you think it is worth working on?

I find the issue too distressing to think about most of the time, especially given other people’s casual relationship with throwaway plastic packaging, and their self-absolution in the vague hope that everything will be recycled, even though it is far more profitable for petrochemical companies to simply produce new plastics. I would argue that political reform to prevent this would be far more useful than bashing my head repeatedly against a wall, trying to find design solutions to political problems. However, this does not mean that there are not pragmatic design innovations to be made to make use of the plastic waste we already have.

Have there been any attempts to resolve the issues? How effective were they?

While many attempts have been made by action groups and sometimes governments to stem the flow of commercial plastics, we are far too complacent in our relatively comfortable lives to ever want to give up the ease that they provide, even when reasonable alternatives are available. For instance, when the current government came to power in 2017, they put a ban on all single use plastic shopping bags. This was a small step, and initially inconvenient to some, however it proved that we do not need single use plastics, and they should be phased out completely.

What do you think is the root cause of the issues?

I think the root cause is that because plastic is such a versatile and ubiquitous material, we do not value it, and have no qualms about discarding it without a second thought. Looking back at the last 100 years, it would be easy to spot that we have built our comfortable modern world on the limited amount of oil on planet earth, which can be made into energy as well as plastics. We have blindly pursued the bottom line and deregulated to the point where multinational corporations are as powerful as governments, and as long as something like plastics are profitable to produce, then they will keep producing them, regardless of the long-term consequences.

Is it related to materials, production, or distribution? Are there better options available?

Yes, but it very much depends on what is meant by ‘better’. Plastics are unsurpassed in areas such as permanence and resistance to light, air, and water. This is largely because they are chemically stable, but this also means that they will not break down. There are certainly functionally acceptable options available such as waxed paper, cardboard, or compostable materials, but none that have the same lustre and universality as plastic.

Is it associated with human behaviour including beliefs, instincts, habits, or traditions? How rigid are they?

People will buy plastic wrapped food at the supermarket because it is there, and they need to eat. People will buy clothing made from plastics because it is cheap and warm, and they need to wear something. They will buy the food and the clothes regardless of the packaging or materials. The essential problem is not one of supply and demand, but of deprivation and necessity for profit. Moral and ethical complicity through coercive commerce.

Are the issues known to the public? Can awareness mitigate the issues? Is there ignorance or indifference?

There tends to be moderate to good theoretical understanding, but almost total practical indifference, because everyone of mine and my parents’ generation have relied on plastic products for a great part of their lives. Some brands have switched back to waxed paper or cardboard as a way to appeal to the environmentally conscious, and this shows that it could be possible to fully return to older, more sustainable methods of packaging.

Are there any potential antagonists? Can they be approached, persuaded, or overwhelmed?

Under our current system of neoliberal capitalism, with its emphasis on choice, free markets, and personal responsibility, we are formally all to blame, as we are all consumers. However, we often do not have the effective freedom to choose what we consume, as it may only ever be possible to buy the cheapest items, which most likely come wrapped in plastic.

I would argue that we need political reform in order to combat this problem, as the companies who produce the plastic waste will not stop on moral, ethical, or sustainable grounds, while it is more profitable to continue to produce plastics. And it terrifies me to think that humanity may be the first species in the universe to walk open eyed and fully conscious into our own extinction.

0 notes

Text

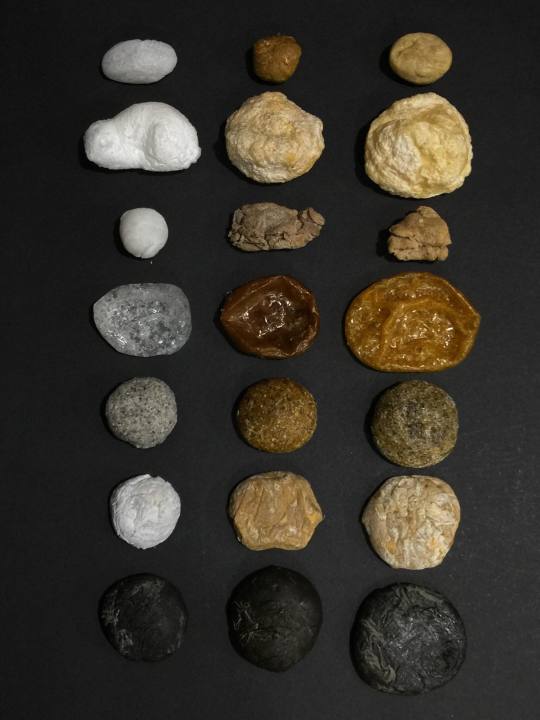

Project 3 - C Experiments

C1. Mixing with sand

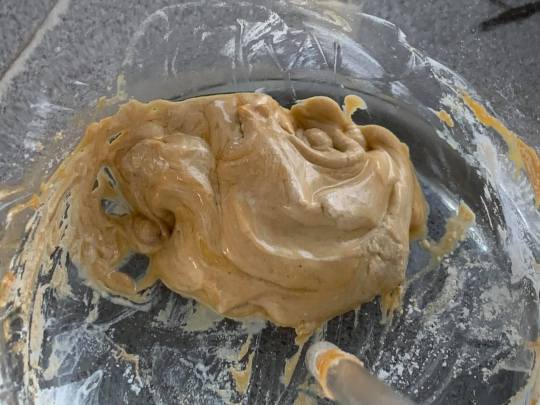

Preparing the mixture, I deliberately left it slightly runny so as to better interact with the sand. On mixing I found that the translucent white goo allowed the various colours to show through, almost like the plastic was acting as medium for a pigment. Apart from a characteristic shine and a smoothness to the surface, the experiment looks like a coagulated ball of sand, but at a small scale would appear to have with the smooth, dappled appearance of polished concrete. The following two types of styrene mix produced mostly identical results, except with different colouration that lacked the natural look of the first. When mixing the yellow styrene, it often broke off into strands and stuck to the sides while I was trying to mix in the sand. It felt somewhat unnatural and ugly as a process but yielded some interesting results.

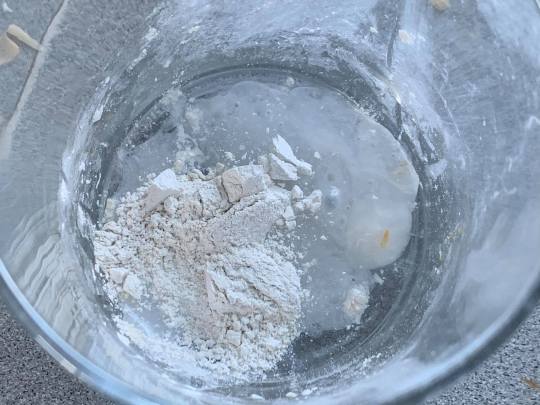

C2. Mixing with plaster

Upon initial mixing, the two materials seemed to integrate well, with the porous plaster absorbing the acetone from the loose mixture. To avoid waiting longer than I needed to, I continued to feed polystyrene into the container until the mixture was sufficiently thick. The mixture was white and opaque and did not stick to the sides of the glass. This seems to be a property of plastics, that they effectively confer to anything connected to them, as once they reached a certain concentration of plastic to acetone, they could pick up loose pieces from the wall of the container. Out of the three samples, only the white styrene mixture has begun to set properly yet. This has caused it to develop a cracked and wrinkled surface, while the other two still resemble cookie dough sprinkled with flour. Hopefully, once the Acetone has evaporated, I will see the plaster set firmly within the mixture.

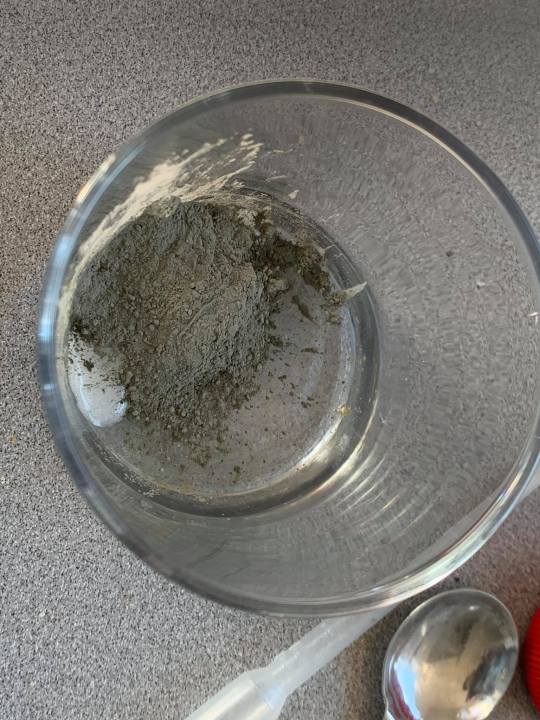

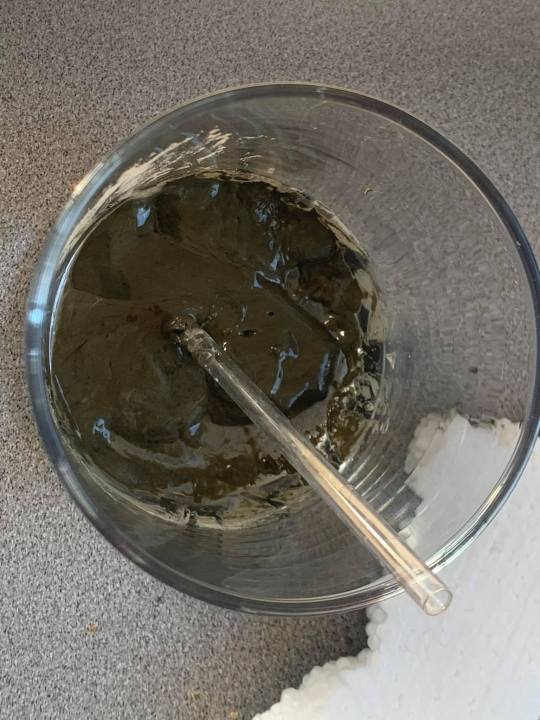

C3. Mixing with cement

This procedure was much the same as C2. The result was a much looser mixture, as I had to add additional acetone in order to mix it properly, and additional polystyrene to clear it up. Because of the polystyrene density, mixing the yellow polystyrene mixture took about twice as long. Because I did not mix in sand as would be usual to make concrete, the resulting products are almost black, with the second two being different shades of muddy brown. The surface is wrinkled like elephant skin and contains white streaks from where the material has stretched into strands and reattached themselves to the body, giving the appearance of veining in some kind of volcanic rock. However, I assumed initially that this would be quick to set, as it produces its own heat. But as of five hours later, it has yet to begin setting properly. I will check back in the morning to see if anything has changed. It is possible that either the acetone has some adverse effect on the chemical process of the cement, or that both the cement and plastic are binders, and the cement needs something to bind in order to set efficiently.

Final Thoughts

Curiously enough, the sand turned out to be the most interesting and unique of the mixture experiments. While I was hoping that either the plaster or the cement would yield some kind of interesting construction material with useful, slightly flexible properties, most of the experiments are a semi dry blob, while the sand, particularly the with the white styrene, has already hardened into a material analogous to concrete, and which displays the material properties of the sand within. This could potentially have both structural and scenic uses including concrete, riverbanks, riverbeds, or anywhere else with small stones. Larger stones and other scenic elements such as soil or greenery could also be incorporated to diversify a model landscape. This might seem like a frivolous use of plastics. However, all this styrene is waste plastic that I either saved after a project or took off people’s hands when they would have thrown it away. This at least gives it a productive and qualitative purpose, out of the landfill, and away from the sea, and wildlife.

0 notes

Text

Project 3 - B Experiments

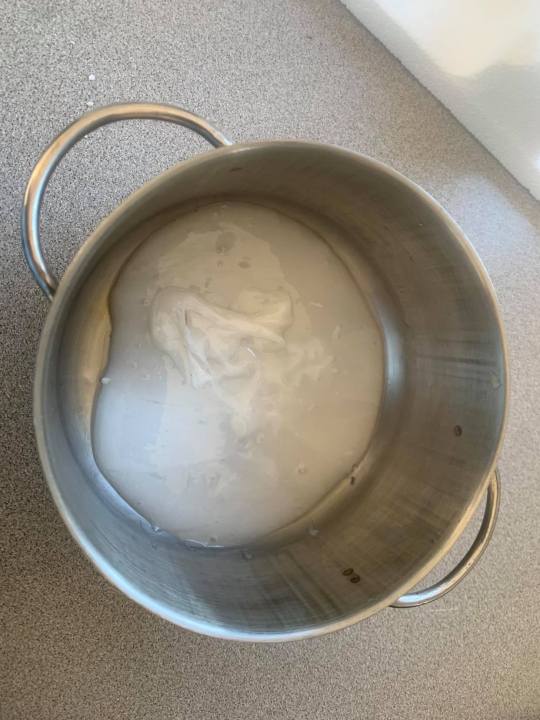

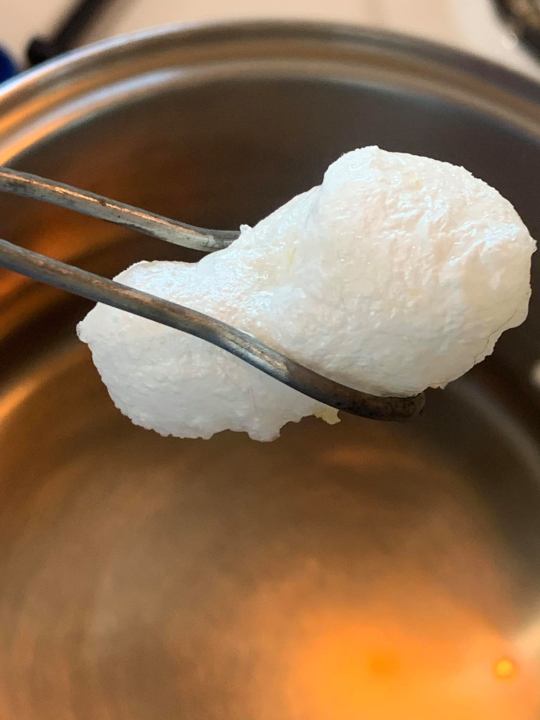

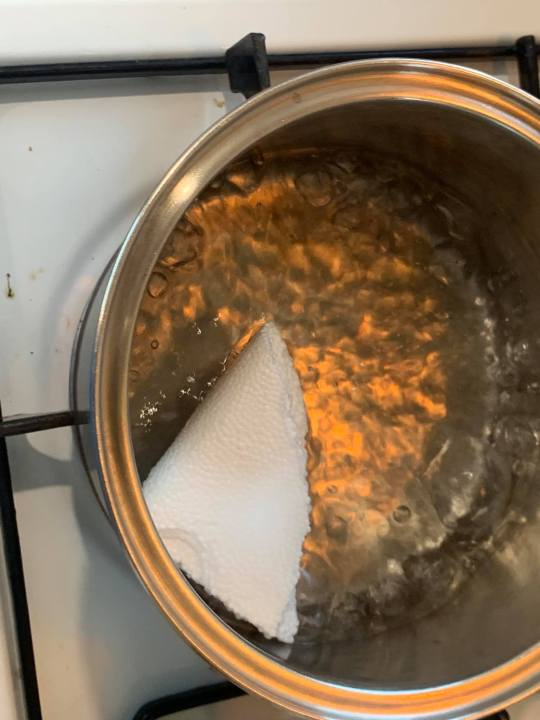

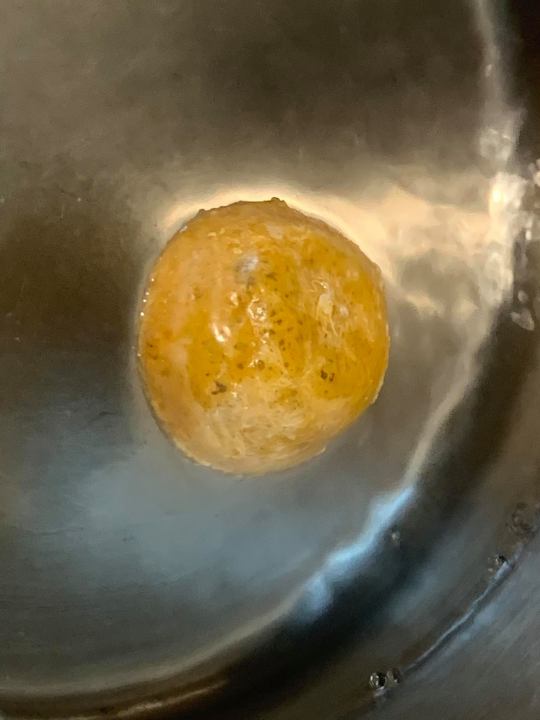

B1. Boiling to evaporate the acetone

I began by dissolving the standard amount of white expanded polystyrene in acetone. I then boiled water in the kettle, and half filled a saucepan. After removing the slime from the glass, I dropped it into the water and observed it over the next five minutes. It floated on the surface, and over time doubled in size, something I attributed to the expansion of any air remaining within and developed a tough outer shell. Its shape was somewhat random, dictated by the internal pressure, its position in relation to the side of the saucepan, and the initial rounded shape of the slime. The shell had a rough, wrinkled surface, occasional bubbles, and craters from where they had burst. My first thought was that it resembled a packing peanut – small and lightweight, but with a tough and durable outer surface.

As a control, I attempted to boil an ordinary piece of white expanded polystyrene. Apart from some smoothness to the bubbles, no noticeable change occurred. This suggests that due to the chemical stability of polystyrene, the polymers must be broken down before any changes of state can occur.

Next, I repeated the same process for the yellow insulation foam and the white/yellow mixture. The yellow foam swelled to four to five times its original size, holding a great deal more air. I noticed a steady stream of residue falling from the underside of the polystyrene, which suggested that some of the plastic may have found its way into the water itself. The resulting piece felt like some kind of crispy fried food, with a far rougher and more varied surface. The skin is brittle, and the part exposed to the water is flatter and denser, as it evolved to float on the surface. In some places there is a faint white skin, suggesting that it may have been coated in plastic residue from the previous piece. The white/yellow mixture was much the same, except slightly smaller, as well as combining the brittle and plastic qualities from the previous two experiments.

B2. Stretching to evaporate the acetone

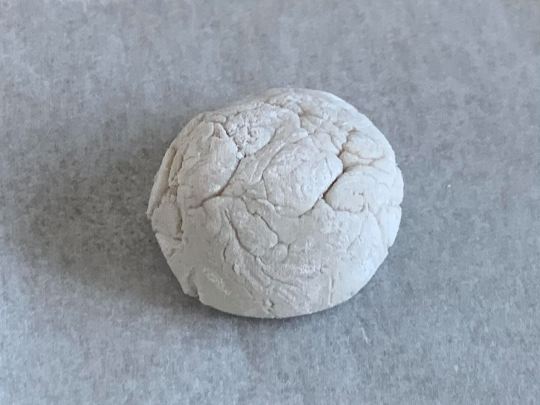

For all three types of polystyrene, I prepared them in the usual manner before stretching them repeatedly for five minutes. The white polystyrene became gradually less stretchy but was always self-adherent. It ultimately became rubber like and was rolled into a ball which does not bounce. Upon drying, it loosely retains the qualities of an unstretched piece after several days but is slightly harder for the acetone having evaporated.

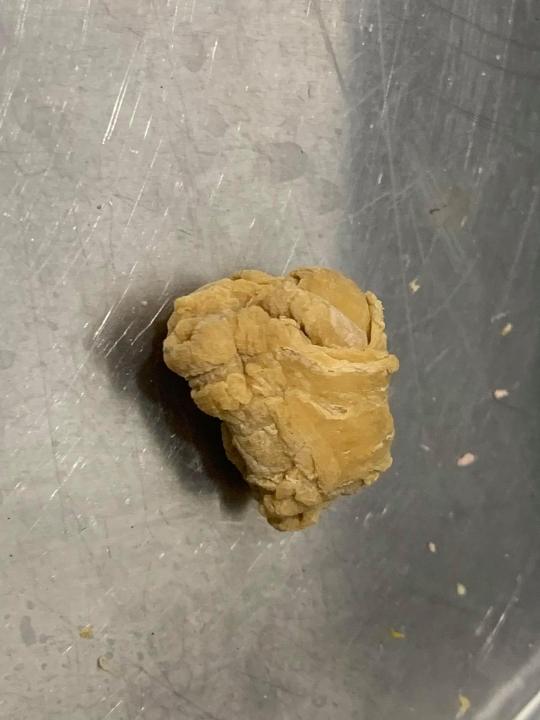

The yellow insulation polystyrene started out very pliable and became rubbery after about two minutes of repeated stretching. After some time however, the area that I was stretching became too tough and aerated to re-join the rest of the object and took on a misted brown opaque appearance. This left a dense, brittle object with a texture similar to a walnut, which will shed the smaller brittle parts of itself on contact.

Lastly, as expected the stretched yellow/white mixture took on a honey-coloured appearance and combined the tough plastic qualities of the white with the brittle disparity of the yellow. However, it seems to have lost these qualities over time, hardening into a solid piece of plastic, as have the others.

I would suggest from this that some aeration is helpful for evaporating the acetone, but too much could prevents the styrene from forming into a smooth single shape.

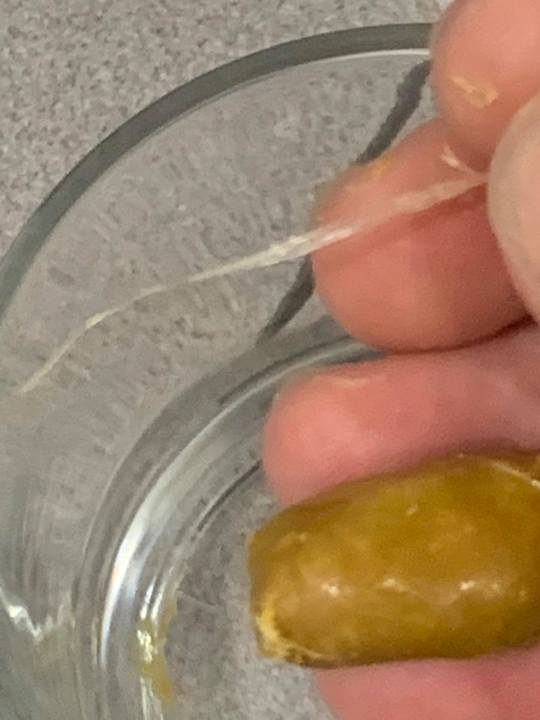

B3. Dehydrating to evaporate the acetone

For this I placed the three pieces in the food dehydrator on a piece of waxed paper and set it to the maximum setting. I had assumed that the heat would remove the acetone from the styrene, which it did. However, I did not anticipate the thermal properties of polystyrene, and soon returned to find that after 20 minutes, all three had greatly expanded from the warm air within, and taken on a translucent quality, except for the white styrene which had become fully transparent. The surface was glossy, making the colours very beautiful. I initially attempted to set them in that state by removing the lid and spraying them with cold water. However, this caused the air pocket within to cool before the plastic, so they collapsed like a souffle. I left them in for another hour until the water had dried, and they had re-inflated. All three retained their shiny appearance upon removal and were slightly flexible for a day or so. Peeling them off the waxed paper showed a slightly frosted surface, which was completely flat, demonstrating that as a thermoplastic, this would adapt to any shape. This seems like a promising material for casting pieces, so much cheaper that casting with resin. One interesting quality was the heavy presence of bubbles within each piece, particularly the white styrene, which had an interesting resemblance to running water.

Final Thoughts

These experiments begin to suggest practical applications for the styrene, including casting, packing, and scenic applications such as lightweight fast-moving water. This is something that is lacking in the terrain building world as the only ways to achieve water currently is to use resin, which is very expensive in large quantities. However, I am concerned about the long-term application of my proposed method of gently heating the styrene, as I understand that Polystyrene yellows with exposure to the sun. I will begin my last set of experiments tomorrow, mixing the different styrenes with various construction materials, namely Sand, Plaster, and Concrete.

youtube

youtube

0 notes

Text

Project 3 - A. Experiments

A1. Dissolution of white expanded packing polystyrene

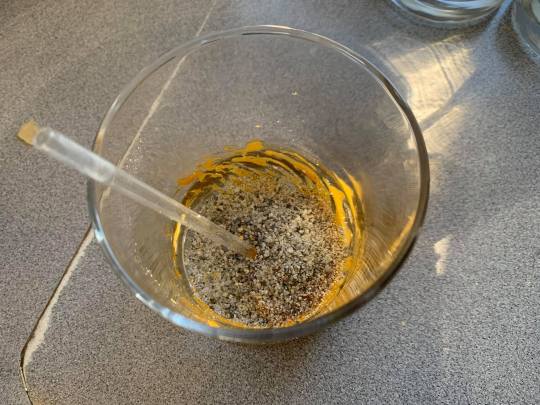

First, I measured out a teaspoon of acetone into the glass in order to set a loose standard for the size of the product. I then broke pieces of white expanded polystyrene and lowered them into the glass with minimal force. Upon contact, the acetone began to bubble as the bonds holding the styrene monomers together broke down. The styrene became a goop, suspended in the acetone. Once it became difficult to break down the polystyrene any further, I decided that it had reached capacity for my purposes. Upon removing the material from the glass, it something like silly putty, tacky to the touch. Once I had rolled it around in my fingers, I found that it soon developed an outer coating, with a resemblance to rubber. I attribute this to the acetone evaporating from the outer surface but creating a barrier of styrene to prevent the acetone within from escaping, thus the rubberised outer shell with a squishy internal texture.

A2. Dissolution of yellow expanded insulation polystyrene

For the second experiment, I repeated the initial steps from the first. As I fed in the pieces of yellow insulation polystyrene, I found that they were less prone to dissolution. This may be due to the differences in the higher density of material than the white expanded polystyrene, and the surface area of the acetone. However, I was able to get it to the same state as A1 with ease. This proved less ready to adhere and form a skin than the previous, but the skin was slightly tougher and more brittle. Another observation was that when it was still tacky, the material would more readily stretch into strands, which having a greater surface area to volume ratio, hardened quickly into brittle fibres. I attribute this to the more fibrous qualities of the Insulation Polystyrene.

A3. Dissolution of a mixture of white and yellow expanded polystyrene

This time, I found that the two styrenes adhered well to each other as they dissolved, with the yellow colouring becoming paler as it was disseminated between them, until the mixture strongly resembled honey. This mixture shares the qualities of both kinds of Polystyrene, forming a rubbery skin from A1, but with the brittle strands from A2. However, the rubbery quality from A1 gives the otherwise brittle strands greater elasticity and strength, to the point where a single strand can comfortably hold the weight of an entire piece. These fibres could be created by stretching the material, aerating the surface, and allowing the acetone to evaporate. They could then be employed for various purposes, including making artificial vines or other scenic elements, or being mixed into a substance like plaster to make it stronger.

https://drive.google.com/file/d/1RYGZ3MpxhCRUUGoMeBxk9neANqcoj3lv/view?usp=sharing

Final Thoughts

Upon checking the experiment this morning, I found that all three experiments, particularly the white polystyrene had distinctly tougher outer surfaces, that were more prune-like. This would suggest that either more of the acetone has evaporated from the inside, or it has further separated from the styrene and established a more concentrated pocket in the centre. My next step will be how to remove the acetone from the styrene, whether through dehydration, boiling, aeration, or mixed with some kind of reactive substance which will harden when mixed with liquid such as plaster or concrete.

youtube

youtube

youtube

youtube

0 notes

Text

Project 2 - Proposed experiments

A. Dissolution of polystyrene with acetone.

1. Dissolution of white expanded packing polystyrene

2. Dissolution of yellow expanded insulation polystyrene

3. Dissolution of a mixture of white and yellow expanded polystyrene

B. Thermal and physical changes to polystyrene dissolved with acetone.

1. Boiling

2. Stretching acetone slime like Taffy in order to aerate it.

3. Dehydrating

C. Mixtures including polystyrene dissolved with acetone.

1. Mixing with sand

2. Mixing with plaster

3. Mixing with concrete

Following these experiments being carried out, I will devise another set of experiments to ascertain their applications to model making.

These may include but are not limited to:

- Creating a mould

- Casting in a mould

- As a gap filler

- As a textured filler

- As a glue for different pieces of polystyrene

0 notes

Text

Project 2 - Material Transformation Precedents

Melting

As a thermoplastic, Polystyrene becomes a liquid at a certain temperature, and a solid when cooled. This could have applications with mould making, and casting, as well as an adhesive. It is also chemically stable, resistant to most material changes when chemicals are applied. This also means that polystyrene will last upwards of 500 years, so it is crucial that we stop producing it, especially for something as frivolous and decadent as single use packaging.

Polystyrene and Acetone

Exposure to nearly any natural solvent, including petrol, will cause the structure of the foam to break down into its plastic form, releasing the air it contains. This uses a great deal of polystyrene, and results in a slime like substance, where the thickness is determined by the amount of polystyrene added. I expect that this will be the main element of my experimentation, as it seems to be the most readily available method of breaking the polymer chains.

Chemical reforming and casting

One innovator has already created a viable casting material called “Maker Goo” by dissolving Polystyrene with D-limonene, a hydrocarbon solvent found in citrus oil. This creates a casting plastic with a slow drying time and slightly unorthodox finish, but with a gummy bear-like plasticity, and the smell of citrus. Using orange oil with expanded polystyrene can also make a slow drying glue. Concrete is also a popular application for polystyrene, as the thermal qualities and minimal weight combine well with the concrete’s strength and durability. This is far from the most environmentally sound material, but the designed permanence of concrete means that the polystyrene is not going anywhere fast.

Gilchrist,S. (2019, January 6). Polystyrene: The Pros, the Cons, the Chemistry. Let’s Talk Science. https://letstalkscience.ca/educational-resources/stem-in-context/polystyrene-pros-cons-chemistry

Helmenstine,A. (2019, August 10). Dissolve Styrofoam in Acetone. ThoughtCo. https://www.thoughtco.com/dissolving-styrofoam-in-acetone-608924#:~:text=Styrofoam%20is%20made%20of%20polystyrene,a%20small%20volume%20of%20liquid.&text=The%20plastic%20dissolves%20in%20just,organic%20solvent%2C%20not%20just%20acetone.

Killbox. (n.d.). Recycling Styrofoam (EPS) Into Useable Castable Styrene Plastic at Home. Instructables. Retrieved May 17, 2021, from http://www.mang.canterbury.ac.nz/writing_guide /writing/flesch.shtml

plateswithsirtan. (n.d.). How to Make Glue From Recycled Expanded Polystyrene (styrofoam). Instructables. Retrieved May 17, 2021, from https://www.instructables.com/How-to-make-glue-from-recycled-expanded-polystyren/

Thinkenstein. (n.d.). Styrofoam Concrete. Instructables. Retrieved May 17, 2021, from https://www.instructables.com/Styrofoam-Concrete/

0 notes

Text

Project 3 - Polystyrene Background

Polystyrene is a synthetic resin, comprised of styrene monomers which have been polymerised. As a thermoplastic, polystyrene can be reformed into different states through the application of heat.

In its expanded form, polystyrene is 95% air, making it extremely lightweight for its size and material state. It is brittle, being composed of small beads which can themselves be compressed but break apart when pressure is applied. The bonds that hold the material together in this form can be broken down by the application of solvents, most commonly acetone, which due to the majority air content, leaves only a tiny fraction of its original size.

The most common uses for expanded polystyrene nowadays are packaging of appliances, as well as insulation. The levels of air within expanded polystyrene make it an excellent insulator. However, it was formerly used for throwaway food containers due to its insulative properties, and for filling bean bags.

While expanded polystyrene cannot be directly recycled, it can be reformed into useful materials for roads and houses, which is cheaper and more ecologically sound than putting it in landfill. However, the recycling approach often justifies the continued production of the object rather than phasing it out, as there is still a demand for the waste product.

Given the long life of polystyrene, when it enters the ecosystem as waste it can do a great deal of damage. As it is often contaminated with traces of food, much of it is deemed un-recyclable. There have been calls to stop production of polystyrene due to the introduction of dangerous chemicals into the human food chain, as well as the production processes which have harmful health effects on workers. Due to its light weight and ease of fragmentation, polystyrene is often blown away from bins and landfill sites, where it makes its way into the environment with disastrous consequences. Wildlife commonly mistake polystyrene beads for fish eggs, which they eat and are unable to digest, leading to death by starvation.

This seems distressingly similar to the inclusion of lead in petrol, asbestos, or the craze for radium. Almost as if humans are prepared to accept great levels of harm for the sake of convenience or novelty. It is hoped that developments in bacterial research may allow polystyrene to one day biodegrade, rather than lasting for many human lifetimes. I use a mask with vapour grade filters whenever I apply heat to expanded polystyrene and ventilate the area thoroughly. The insulation polystyrene that I use for modelling has no bubbles due to its density, and I have tried to keep as much of it out of circulation as possible.

Biello, David. ( 2006, February 27). Bacteria Turn Styrofoam into Biodegradable Plastic. Scientific American. https://www.scientificamerican.com/article/bacteria-turn-styrofoam-i/

Lewis, J. (2019, May 7). Why Styrofoam (Expanded Polystyrene) Should Be Banned Everywhere In The World. Medium. https://medium.com/age-of-awareness/why-styrofoam-expanded-polystyrene-should-be-banned-everywhere-in-the-world-4101552f5e2b#:~:text=%E2%80%9CPolystyrene%20breaks%20down%20in%20the,pieces%20of%20polystyrene%20for%20food.%E2%80%9D

Nicoll, J. (2018, July 5). Recycled polystyrene on the rise as quick cost-effective option for aiding construction. Stuff. https://www.stuff.co.nz/environment/105217755/recycled-polystyrene-on-the-rise-as-quick-costeffective-option-for-aiding-construction

Polystyrene. (n.d.). In Britannica. Retrieved May 16, 2021, from https://www.britannica.com/science/polystyrene

0 notes

Text

Project 3 - Ideation (2/2)

Idea 1 - Plastic Pollution and Shopping

Despite my frustrations around the plastics issue, I still think that it would make the most interesting project. If not to recycle the plastics, then to make consumers aware of how much waste their purchases generate; an empathy building exercise, in line with my principles of design from the first assignment.

While the ideal situation would be to go directly to the plastic manufacturers and demand that they change their methods or go to the distributors and ask them to boycott the products, however it is not in their financial interests to do so. Unfortunately, even if this were effective, in the free market this would only allow less scrupulous manufacturers to move in and potentially worse damage.

My first thought is to create a transparent casing to display in a public place to demonstrate how much waste plastic consumers are purchasing. As a warning of the permanence of plastics, and how much we contribute to the problem in a length of time or during an activity such as a weekly shop.

This has a lot of creative and expressive scope, as the tone could vary depending on the severity of the message. For example, a monster made out of plastic would be funny for adults and scary for children, whereas a life-sized simulacrum of the human body, with all the bones and organs simulated with plastic products would be unnerving, as observers would identify with the textures and characteristics more readily, and perhaps be inclined to think about their purchases differently.

This is also reminiscent of The Transparent Woman, a glass statue displaying models of human internal organs that toured around the world. The minimum for maximum in this case is the minimum intrusion for the maximum impact. Nobody likes to be harassed or told that what they are doing is harmful, even if they already know. If people see the consequences of their actions, presented in a different way, it is possible that they will change their ways, and the market will be forced to change as a result.

Idea 2 - Climate Change and Online Shopping

Another approach could be the carbon produced from online shopping, where packages have to travel great distances in order to reach the consumer. I often buy specialist parts or products from the UK or Poland and see them travel from country to country on their way to New Zealand. Given that Amazon is well on its way to becoming an empire, this practice is common and widespread, but uses a huge amount of resources, all for the sake of convenience. I could aim to make consumers aware of their impact on the planet, and perhaps consider more local and sustainable options.

Idea 3 - Plastic Pollution and Model Making

A third option could be to consider my own impact on the planet in a less generic sense, observing my own interests and considering what I could do differently in order to reduce my own environmental harm, and in doing so, encourage others to do the same.

Probably my most environmentally impactful hobby is model making, which uses polystyrene sprues in the making of components, soft plastics for storage and transport, various glues, and paints (and their plastic containers), and most notably, expanded polystyrene.

Much of this polystyrene can be sourced from throwaway packaging. I helped my sister move to a new house two months ago and was able to bring several carloads of Cardboard and Polystyrene home. As nice as this is from a modelling and crafting perspective, it is also highly unsustainable. It is also more useful for creating landforms and supporting structures than for texturing due to the crumbling beaded texture. For this I use insulation foam, which is the same polystyrene, but expanded to a lesser degree. While I try to be as economical as possible with this, I am always left with scraps that I cannot throw away. I have kept most of them in boxes in the garage for the time being.

This is the Tower of Cirith Ungol. It is currently a work in progress, standing over a metre tall, with a base of 2x3 feet. It is made primarily out of extruded polystyrene insulation foam, and cast plaster. I would argue that once it is finished, like any work of art, it will be innately more valuable and worthwhile than the sum of its parts.

So why have this hobby when there are so many other things I could be doing? Because I enjoy it. Because I couldn’t think of doing anything else. One thing that we often fail to consider about plastics when thinking about sustainability, is what remarkable materials they are, being transparent, flexible, and sterile. But we squandered them, without thought for the impact our greed would have on the environment, wildlife, the ecosystem, and ultimately ourselves. If we had known how to use these materials safely and responsibly from the day they were discovered, then plastics might have had a very different image. We could have used them to only create things we needed to last for hundreds of years, and only made beautiful things that brought richness into people’s lives. Instead, we had the throwaway living of the 1950s and the mass consumerism of the 1980s that continues to this day.

But what if rather than cutting out plastics altogether, or recycling them for the benefit of the plastics industry, we reconsider the role of plastics in design? Are there things that need to be built to last rather than throwaway drink bottles and plastic straws? Inevitably. We don’t currently pay the true cost of plastics, as their short-term usefulness far outweighs their long-term damage within the limited lifespan of humans. Also, the ubiquity of plastic has robbed it of its status as an extraordinary material. Instead, it becomes a symbol of the quantitative lives we live, quick, cheap, and valueless. But what if we were to take a qualitative approach to plastics? Looking at their unique qualities, including their long lifespan, and creating objects that are beautiful, useful, expressive, and have a great lifespan of appeal. In short, things that make the human experience richer and more fulfilling.

My final idea for this project is to find a way to utilise those polystyrene scraps in a constructive way, that contains them in a permanent cycle within the confines of my hobby. Through experimentation, the goal will be to create some kind of useful product or compound which can be shared with my wider wargaming hobby community in order to minimise our impact on the planet, while continuing to create things that have designed permanence and are enjoyable for their own sake.

0 notes

Text

Project 3 - Ideation (1/2)

To begin with, I decided it would be useful to narrow down my topics to the world’s current problems, and see how they intersect with my own interests in order to tackle something within my own scope.

Problems with the world

- Climate Change

- Environmental Destruction

- Poverty

- Plastic waste

- The Coronavirus

- Misinformation

- The Rise of Modern Fascism

My Interests

- Politics

- Design

- Wargaming

- Model Making

- Sci-Fi/Fantasy

0 notes

Text

Project 3 - Changing Direction

After some initial research into plastics and recycling (and some harsh comments on the Pringles Facebook page), I decided that the topic is going to be far too distressing to try to address.

Firstly, the amount of investment and effort needed to recycle a plastic bottle vastly outweighs any possible return, especially when you consider the single use nature of many plastic products. The best they can do is perpetuate the cycle, or create semi permanent items like fence posts to delay addressing the problem.

As I’ve said before, plastic pollution is a problem of capitalism and not something that can be addressed through capitalist means.

This is an act of sustained violence. Violence towards the environment. Violence towards wildlife. Violence towards future generations.

Violence endorsed by the state in the name of consumer choice.

In short, it is a political problem that requires a political solution. And while Design may play a role in that, it is far too much for one designer to tackle.

0 notes