We're Largest and Leading Construction Equipment Manufacturer in Kolkata, India

Don't wanna be here? Send us removal request.

Text

0 notes

Text

#bar bending machine#rebar bending machine#jaypee#bar bending machine manufacturer#constructionequipment#Rebar bender#sariya bending machine

0 notes

Text

How to Identify the Most Suitable Bar Cutting Machine for Your DIY Projects

Bear in mind the following factors while choosing your bar cutting machine:

Cutting Capacity - Select a machine with the appropriate cutting diameter and bar type.

Power Source - For small projects, choose a manual model, while hydraulic or electric versions are best for larger work.

Portability - For personal use, choose portable models that are smaller and lighter.

Safety Features - Machines with protective covers and emergency stops are safer.

Budget - Choose a machine that is reasonably priced while still functioning at its intended capacity.

A Detailed Guide on Operating a Bar Cutting Machine

The necessary preparations for step 1 are making sure the machine is ready to operate.

In this case, confirm that all the appropriate equipment is with you the necessary equipment, then verify that the bar cutting machine is placed on a balance work station. Then check that the bar cutter is working properly, and that necessary oil has been added to the machine.

Step 2: Bar Measurement and Marking

Take a tape measure to the material that needs to be cut for determining required length.

Mark with a chalk or marker the place where the cut will be made.

Step 3: Position the Bar

Put the metal bar in the area where it will be cut by the machine.

Ensure the bar is well fastened to avoid any shift while cutting.

Cutting Action: Step 04

For manual machines, use gentle force.

For electric and hydraulic machines, turn on the power switch. Let the machine cut with minimal resistance.

Step 5: Evaluate the Cut

Check the cut's dimensions and precision to ensure they correspond to the expected standards.

If required, employ a file or grinder to refine any parts that might be unpolished.

Precautions to Take when Using a Bar Cutting Machine

To prevent accidents, using a bar cutting machine must come with set safety measures. Here are some of the basic safety procedures you can take:

Protect Yourself – Gloves, protective goggles and steel toe boots must be worn at all times.

Check Machine Condition – Look for worn out blades or missing pieces and parts to ensure nothing is broken before you start working.

Secure the Work Area – Make sure there are no barriers that may obstruct movement of the machine and there is enough illumination.

Follow Manufacturer Guidelines – Instruction booklet must be thoroughly read and all suggested steps followed precisely.

Use Both Hands – Both hands must be in use at all times and focus should not be broken.

Top Bar Cutting Machine Brands

If you’re looking for a reliable and high-quality bar cutting machine, here are some trusted brands:

Jaymac by Jaypee India Limited – Known for durability and precision.

Bosch – Offers compact electric bar cutters.

Makita – Provides versatile and efficient bar cutting solutions.

Hitachi – Known for robust construction and longevity.

0 notes

Text

Top Brands in the Bar Cutting Machine Market for 2025

The correct tools have the potential to either build or destroy a construction – literally. Welcome to the bar cutting machines, which become important machines in any significant construction site. The year 2025 has seen fiercer competition among leading brands than ever before when it comes to innovation, durability and efficiency as factors leading the race. But are there any companies that really make a difference? Let us plunge into the Bar Cutting Machine Market Top Brands of 2025 and see who is dominating it.

Why Bar Cutting Machines Are Critical to Construction

Let us first set the stage before we delve into the leading names in this field. What is it that makes bar cutting machines so indispensable? If you think about cutting steel rebars manually for a multistory building, you would agree that this is indeed tiring, isn’t it? You can have this process made easier and safer by using bar cutting machines which provide accuracy and rapidity.

Anything from bending to cutting, these units can handle them all. Moreover, as construction projects become more intricate, there has been an astronomical increase in demand for trustworthy bar cutting machine providers. Now let's take a closer look at some of the top names in the business.

Leading Brands Revolutionizing the Bar Cutting Machine Industry

1. Jaypee India Limited

When discussing construction equipment, it’s impossible to overlook Jaypee India Limited. Known for their robust and innovative machines, Jaypee has carved out a niche in the industry.

What Sets Them Apart:

Exceptional durability and long-lasting performance.

Advanced technology to ensure precision cuts.

Unparalleled customer service with technical support.

Star Product: The Jaypee C-42 Bar Cutting Machine is a favorite among contractors for its reliability and ability to cut through heavy-duty rebars effortlessly.

Fun Fact: Jaypee’s equipment is used in some of India’s tallest skyscrapers!

2. Bosch Construction Equipment

A global powerhouse, Bosch brings its expertise in engineering to the construction sector with cutting-edge bar cutting machines.

What Sets Them Apart:

User-friendly interfaces.

Eco-friendly designs that reduce energy consumption.

High-speed operation without compromising safety.

Star Product: The Bosch Rebar Cutter 3000 combines speed with precision, making it ideal for large projects.

Why They Matter: With a strong presence in over 60 countries, Bosch ensures quality and accessibility.

3. Makita Heavy Industries

Makita’s reputation for high-quality power tools extends to their bar cutting machines, which are a favorite for mid-sized and large construction companies.

What Sets Them Apart:

Lightweight designs for portability.

High torque motors to handle tough rebars.

Affordable pricing without sacrificing quality.

Star Product: The Makita BC-500 is a compact yet powerful machine that punches above its weight.

Pro Tip: Ideal for construction sites with limited space due to its compact size.

4. Hilti Group

Known for their innovation and customer-centric approach, Hilti’s bar cutting machines are redefining what’s possible in construction equipment.

What Sets Them Apart:

Integration with digital tools for seamless project management.

Precision engineering for error-free cuts.

Extended warranties and service plans.

Star Product: The Hilti RBX-800 stands out for its ability to cut through multiple bars simultaneously.

Did You Know? Hilti’s machines are frequently used in high-speed rail projects.

5. Koblenz Machinery

A rising star in the market, Koblenz offers budget-friendly solutions without compromising on performance.

What Sets Them Apart:

Cost-effective machines for small contractors.

Easy maintenance and robust designs.

Excellent after-sales support.

Star Product: The Koblenz K-Cut 3500 is a top choice for its versatility and affordability.

6. Hyundai Construction Equipment

Hyundai isn’t just about cars; they’re also making waves in the construction world with high-performance bar cutting machines.

What Sets Them Apart:

Sleek, ergonomic designs.

Cutting-edge technology for minimal waste.

Exceptional durability.

Star Product: The Hyundai HC-1000 offers unmatched precision, perfect for intricate projects.

7. Tata Construction Solutions

A household name in India, Tata’s bar cutting machines are trusted by contractors nationwide.

What Sets Them Apart:

Local manufacturing ensures affordability.

Machines built for Indian construction conditions.

A vast network of service centers.

Star Product: Tata’s TC-500 is celebrated for its ability to withstand heavy workloads.

8. Komatsu Equipment

Komatsu brings its heavy machinery expertise to bar cutting machines, focusing on efficiency and sustainability.

What Sets Them Apart:

Machines optimized for energy efficiency.

High-capacity models for mega projects.

Superior build quality.

Star Product: The Komatsu K-Cutter Pro is a beast designed for industrial-scale projects.

Emerging Trends in the Bar Cutting Machine Market

As we look toward 2025, several trends are shaping the industry:

Automation: Machines equipped with AI for precision and efficiency.

Sustainability: Brands focusing on eco-friendly models.

Portability: Lightweight and compact designs for easy transport.

Digital Integration: Smart features for monitoring and diagnostics.

Conclusion

In 2025, the leading companies in the market of bar cutting machines are raising the stakes with a blend of innovation, quality and customer-centric solutions. Picking the right brand can change your projects whether you are a contractor, builder or distributor. You can get options from Jaypee India Limited’s strong devices to Hyundai’s slim designs—but it is up to you to decide.

Related Blogs

A. 8 Reasons to buy JAYMAC® Bar Cutting Machine. B. Main uses of a Bar Cutting Machine. C. What is the Price of Concrete Mixer Machine in India? D. Ahmedabad’s Top Bar Bending Machine Manufacturer

FAQs

1. What should I consider when buying a bar cutting machine?

Look for durability, precision, and after-sales service. Don’t forget to consider the machine’s capacity and ease of use.

2. Which is the most affordable bar cutting machine brand?

Koblenz Machinery offers budget-friendly options without compromising on performance.

3. Are there eco-friendly bar cutting machines?

Yes, brands like Bosch and Komatsu focus on sustainability with energy-efficient models.

4. Why is Jaypee India Limited a top choice?

Jaypee offers durable machines, excellent after-sales support, and advanced technology.

5. Can bar cutting machines handle all rebar sizes?

Most machines can handle a range of sizes, but check the specifications to match your project needs.

6. Are portable bar cutting machines effective?

Yes, brands like Makita and Koblenz specialize in lightweight designs that pack a punch.

7. What’s the warranty period for bar cutting machines?

It varies by brand. Hilti, for example, offers extended warranties, while others may provide standard 1-year coverage.

8. How do I maintain a bar cutting machine?

Regularly clean and lubricate the machine, check for worn-out parts, and follow the manufacturer’s maintenance guidelines.

9. Are there smart bar cutting machines?

Yes, brands like Hilti are integrating digital tools for enhanced functionality.

10. Which brand is best for large construction projects?

Jaypee India Limited and Komatsu are ideal for heavy-duty, large-scale construction needs.

#Rebar Cutting Machine#Bar Cutting Machine#Sariya Cutting Machine#TMT Bar Cutting Machine#Bar Cutter

1 note

·

View note

Text

Jaypee® India Limited has firmly established itself as a trusted name in the construction industry, delivering world-class equipment that meets the highest standards of performance, reliability, and safety. With over four decades of expertise, we have become the go-to choice for contractors, builders, and engineers seeking innovative and efficient machinery to streamline their projects.

Our commitment to excellence is evident in every product we create, from Bar Bending Machines and Bar Cutting Machines to Concrete Mixers and Material Hoists. As an industry leader in construction equipment manufacturing, Jaypee® India Limited is synonymous with quality and customer satisfaction. Why Choose Jaypee®?

#bar bending machine manufacturer#bar bending machine#bar cutting machine#concrete mixer machine#constructionequipment

0 notes

Text

We are pleased to introduce the WINGET® Bar Bending and Shearing Machines, designed to bring new efficiency and precision to construction and manufacturing projects. This release significantly upgrades earlier models by featuring cutting-edge technologies and innovations designed to meet industry standards.

0 notes

Text

Why Jaypee® Concrete Mixer Machines are Perfect for Your Construction Needs in INDIA

Construction industry efficiency, durability and cost-effectiveness are essential considerations in India. Concrete mixers are indispensable tools on any construction site to produce consistent, high-quality mixtures requiring reliable machinery, such as Jaypee® concrete mixer machine - trusted for their affordability and superior performance. This blog will examine why Jaypee® concrete mixers may be perfect for your construction needs. It will explore their pricing, material quality, after-sales services, spare part availability, and various mixers that cover different applications.

Reasonably Priced Without Compromising Quality Jaypee® concrete mixer machines stand out for their competitive pricing without compromising performance compared to many international brands. While their prices may be less, their performance outshone even them! Here's why.

Jaypee® Industries employs economies of scale in its production process, leading to reduced manufacturing costs passed directly to customers. Plus, their Indian production is made possible by eliminating import duties, making their mixers more cost-effective for domestic buyers.

Streamlined Design: Our company's designs strive to strike a balance between functionality and material usage to maximize durability without unnecessary extravagance. Jaypee® mixers are affordable yet constructed to high-quality standards, guaranteeing efficient output efficiency and consistent performance.

Premium-Grade Materials to Maximize Durability: Durability is of the utmost importance in construction, so Jaypee® concrete mixers are built to last. Their strength lies in the premium-grade materials used: steel and plastic resin, to name just two.

High-Grade Steel: Our mixing drum and structural components are constructed of robust, corrosion-resistant steel for long-term reliability in even harsh environments. Heavy-Duty Bearings: Bearings and joints constructed of industrial-grade materials offer improved stress tolerance to reduce wear and tear over time.

Precision Manufacturing: Each part of a Jaypee® concrete mixer is assembled carefully, guaranteeing smooth operations and reduced breakdown chances. It focuses on high-grade materials, which results in a longer operational lifespan and decreases the frequency and cost of replacements or repairs over time. It is an investment that pays for itself in time.

Jaypee® takes pride in cultivating long-standing relationships with its customers. Its exceptional after-sales service is tailored to provide an effortless experience, making it the preferred choice among construction professionals across India.

Nationwide Support Network: Jaypee® offers an expansive service network, guaranteeing quick support regardless of your construction site. Skilled Technicians: Our knowledgeable technicians are on call 24x7, 365 Days to address operational issues quickly and minimize downtime.

Comprehensive Maintenance Plans: Jaypee® offers comprehensive maintenance plans to keep your mixer operating at peak condition and extend its lifespan. At the same time, their efficient after-sales service gives customers peace of mind, making We an indispensable partner in their construction endeavors.

Easy Access to Spare Parts: When equipment breaks down, construction delays can be severely disrupted, so having quick access to spare parts is vital. Jaypee® excels in this respect: they offer fast shipping of replacements.

Jaypee® maintains an expansive spare parts inventory, allowing immediate repairs when required.

Affordable Spares: Our spare parts are priced competitively, so maintenance costs remain minimal. Spare parts produced domestically are readily accessible, eliminating delays caused by import logistics. This approach allows mixers to quickly return to full function without extensive downtime, even when they require part replacement.

Concrete Mixers and Their Applications: Jaypee® offers a selection of concrete mixers designed to meet various construction needs. Here is an overview of some of these types and their purposes:

Hand-Fed Concrete Mixers | PBS Contractors, LLC: These small portable mixers are great for small-scale construction tasks. They're manually fed with raw materials for limited concrete production. The drum capacity allows for limited concrete output. Applications: Hopper-Fed Concrete Mixers can be an ideal way to complete projects requiring limited space, from home renovations and repairs to repairs that involve limited access. Their automatic material-feeding hopper makes their operation more efficient while guaranteeing consistent mixing results. Applications: Ideal for medium-scale construction projects such as residential buildings and commercial complexes. Reversible Drum Mixers These advanced mixers allow mixing and discharging operations within the same drum, increasing efficiency while decreasing waste and productivity. Their unique reversible design also minimizes waste while increasing productivity. Applications: Hydraulic concrete mixers are ideal for infrastructure projects like roads, bridges, and irrigation works. Whilst they don't come cheap, they boast unmatched mixing efficiency while being designed for heavy-duty operations—something other mixers simply can't. Applications: Transit Mixers can be utilized in large-scale industrial and infrastructure projects requiring continuous mixing at high capacity. They feature truck-mounted mixers designed to transport ready-mix concrete across long distances while maintaining consistency. Applications: An essential tool in remote site construction, high-rise building construction and urban infrastructure projects. Jaypee® concrete mixer machines have earned an esteemed place among construction professionals across India. Thanks to their combination of affordability, efficiency, and durability, these concrete mixers make an excellent investment choice for projects of all sizes. High-grade materials and unrivalled after-sales support to ensure maximum value is received from every purchase.

We offers an extensive selection of concrete mixers designed to meet specific applications and diverse construction needs. Whether for residential construction, commercial property development, or large-scale infrastructure projects, We can find an appropriate mixer that ensures precision, cost-efficiency, and reliability throughout every phase.

#Concrete Mixer Machine#Concrete Processing#Concrete Mixer Machine Price#ConcreteMixer#ConstructionEquipment#BuildingSolutions#ConstructionMachinery#ConcreteTechnology#ConcreteMixingSolutions

0 notes

Text

0 notes

Text

youtube

Jaypee® Bar Bending Machine Video showing here how to operate a bar bending machine. JAYMAC® Bar Bending Machine is a semi-automatic, durable fast, and cost-effective machine, used for bending reinforcement bars and various forms of round bars. This machine effectively increases the production capacity of your steelyard, minimizing the use of manual labor. Set on a wide body with a heavy-duty gearbox, JAYMAC® Bar Bending Machines boast of a rigid design that helps maintain the performance of the machine year after year. Oil-bathed gearboxes with hardened forged alloy gears provide maximum strength, and innovative features such as push-button bending give operator comfort.

#Bar Bending Machine Manufacturer#Bar bending machine#Rebar bending machine#Construction Equipment Manufacturer#Jaypee Machine#Jaypee Group#Youtube

0 notes

Text

Why Invest in a Bar Bending Machine 2025?

Construction sites often rely on bar bending machines as critical tools that increase efficiency, precision, and overall project quality. Rebar benders play an essential role in reinforcing concrete structures, whether that means large commercial buildings or residential homes. It reduces labor and enhances accuracy. Of all the leading brands, the bar bending machine stands out for its unique features, such as robust design and reliable after-sales service. Functioning like a workhorse, it deftly manipulates steel reinforcement bars in tandem with architectural blueprints. It eliminates human errors and ensures structural integrity. JAYMAC® offers prompt and efficient after-sales support and a wide range of available spare parts that warranty your investment. Our rebar benders increase the production capacity of your steelyard while reducing workforce hours. Furthermore, our unwavering commitment to innovation and technological advancements ensures good returns on your investment over the long term.

Understanding the Role of Rebar Bending Machines in Modern Construction

Rebar bending machine are designed to shape steel reinforcement bars to specific angles that are specific to a project. They eliminate laborious, time-consuming processes that are riddled with human errors. Bar bending machines are ideal for application at construction sites, workshops, and other settings where reinforced steel bars are utilized. Their durable design can withstand rigorous usage. It is versatile, effective, and built to withstand heavy-duty usage. In the ever-evolving construction industry, precision and efficiency are essential in maintaining competitive and productive operations. Among the indispensable tools that support this goal is the bar-bending machine - a piece of equipment designed to effortlessly bend rebar and TMT bars into precise angles required for construction projects. With laborious tasks that demand accuracy, speed, and high-quality results, bar bending machines are quickly becoming a standard in construction sites worldwide.

Benefits of investing in JAYMAC® Bar Bending Machine

Precision and Efficiency: Most top-rated bar bending machines from global brands provide accuracy in bending angles with their preset angle option, and ensure accurate bends each time, compared with manual bending. JAYMAC® rebar benders are fitted with state-of-the-art variable angle features that extend their utility further.

Robust and Durable Design: While most rebar benders are built from high-grade steel and feature a durable structure, bar bending machines manufactured by Jaypee India Limited are built from tool-grade steel. It ensures a longer lifespan and reliable on-site performance.

Ease of Use: While many modern rebar benders come equipped with user-friendly controls, JAYMAC® hasan intuitive ergonomic user interface. It makes them operable by trained as well as untrained personnel.

Safety Features: JAYMAC® rebar benders come equipped with guard rails, an easily accessible emergency stop button, a foot peddle, and other safety features to protect operators from accidents and injuries during operations. The ergonomic control interface adds to the safety and security of the operators.

Prompt After Sales Service: Our service department on stand-by reduces downtime of any project. Readily available spare parts mitigate time-consuming technical snags, ensuring smooth function.

Affordable Pricing of Rebar bending machine: Our rebar bending machines come at competitive prices without compromising on quality or features. It makes them a perfect choice for companies seeking to balance their budget constraints with operational efficiencies. We offer the best of both worlds. Their machines are built to provide value for money, ensuring customers see a return on their investment through prolonged use.

JAYMAC® Bar Bending Machine: A Top Choice for Builders and Contractors

TMT Bar bending machines from the brand We have earned themselves a reliable name in the construction machinery industry, particularly in the realm of rebar benders. Here is why it is considered one of the best investments for builders and contractors.

1. Unmatched Build Quality

Bar benders are crafted from tool-grade steel, ensuring longevity and durability. These machines are designed to withstand the demands of heavy-duty construction, with reinforced steel and premium components that minimize wear over time.

2. Advanced Features

Rebar benders by JAYMAC® come equipped with advanced features that make them versatile and efficient. For example, the preset angle selection feature allows for precise and quick bending, while programmable controls enable operators to customize angles based on specific project requirements.

3. User Friendly Operation

One of the primary concerns with any construction equipment like rebar benders is the availability of spare parts. JAYMAC® has an extensive distribution network, making it easy for contractors to obtain required parts whenever needed. This ensures minimal downtime in case of repairs or maintenance, keeping projects on schedule.

4. Prompt and Dependable After-Sales Service

With an unwavering commitment, we warranty competitive service charges that cover repairs and spare parts. Routine maintenance of worn-out spares ensures glitch-free performance and reduces downtime at construction sites. The savings in labor costs and reduced rework expenses offset the upfront investment. Our bar bending machines are easier to maintain and have a longer life span than the others. They can also handle rebar of various sizes and bend multiple bars simultaneously.

5. Industry-leading warranty:

JAYMAC® offers comprehensive warranties that cover major parts, giving buyers peace of mind. This warranty, paired with reliable after-sales support, makes it a trusted partner in the construction industry.

How JAYMAC®Bar Bending Machine Stands Out in the Competition – A Conclusion

Our customer-centric approach, longevity, reliability, efficiency, productivity, and industry-leading warranty are the key aspects that make rebar bender stand out in the competition. In today’s competitive construction industry, having reliable and efficient tools is essential to maintaining productivity. It’s bar bending hits all the checkboxes to ensure project quality. Investing in a bar bending machine is an essential step for any construction company looking to enhance productivity, reduce labor costs, and ensure the precision and quality of their projects. With the benefits of increased efficiency, reduced material wastage, and a safer work environment, Bar bending machine is indispensable for modern construction work. Among many available brands, It’s stands out as a top choice for construction companies, offering competitive pricing, reliable performance, excellent after-sales service, durability, and easy access to spare parts. If you are looking to improve your construction processes and take your business to the next level, a bar bending machine is a smart investment for you.

#bar bending machine#construction#heavymachinery#constructionequipment#2024-2025#Rebar bending machine#rod bending machine

0 notes

Text

Building the world’s foundations with innovation, precision, and reliability – that’s the mark of a true construction equipment manufacturer.

#ConstructionEquipment#BuildingTheFuture#HeavyMachinery#InnovativeEngineering#InfrastructureDevelopment

0 notes

Text

Bar Bending Machine is the perfect solution for your construction needs in the World.

Visit Now: https://www.jaypee.in/bar-bending-machine/

#BarBendingMachine#ConstructionEquipment#RebarBender#HeavyMachinery#ConcreteConstruction#InfrastructureDevelopment#JaypeeIndia#ConstructionTechnology

0 notes

Text

Best Bar Bending Machine Manufacturer in India

JAYMAC® Leading Bar bending machine manufacturer in Kolkata. The importance of technology and control in the construction sector is invaluable. Along with the demand for stronger infrastructure also arises the need for new technologies and techniques.

One of these, Bar Bending Machines, is used to cast and bend iron rods in the world’s construction projects. These machines are an example of an industry that combines modern technology and manufacturing, improving processes, improving the reliability of structures, and ultimately, taking care of the longevity of the built environment. In this article, we try to integrate the different aspects of Bar Bending Machines, bringing to life the original role of Bar Bending Machines by shining a bright light on them. (Read more)

#bar bending machine#construction company#construction#construction equipment#construction industry#sariya bending machine#tmt bar bending machine#mechinery

0 notes

Text

Jaypee brings to you "A wide range of Passenger and Materials hoists that can lift up to 8000kg, with a speed that can reach up to 96m/min built with unmatched resilience and robustness.

More Information

Contact Us:- +91 090512 34444

Website:- www.jaypee.in

#constructionprojects#construction industry#construction equipment#bar bending machine#construction company#construction#mechinery

1 note

·

View note

Text

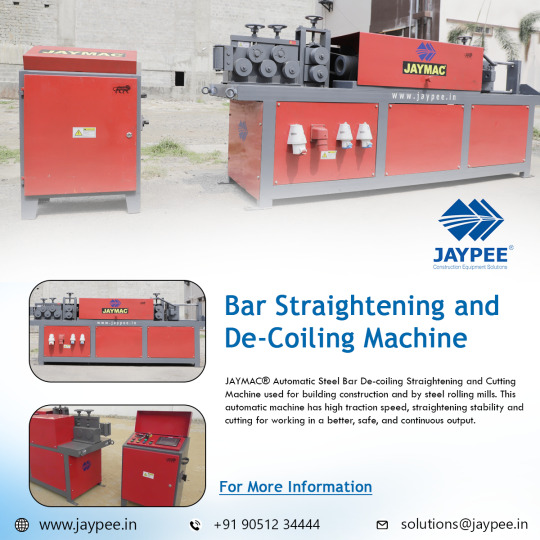

Elevate your construction work with Jaypee India Limited's Bar Straightening and De-coiling Machine. Unmatched quality, unbeatable performance.

For more information

Contact us 090512 34444

Website www.jaypee.in

Gmail [email protected]

#construction#construction equipment#construction company#mechinery#construction industry#constructioninnovation#infrastructure#manufacturing#makeinindia#constructionequipment#constructionmachinery#ConstructionExcellence#machinery#dubai#african#jaypee

0 notes

Text

In the ever-evolving world of construction, the demand for precision and efficiency has never been higher. One of the critical components of this industry is the bar bending machine, a technological marvel that has revolutionized the way we shape and manipulate steel reinforcement bars. In this article, we will delve into the realm of bar bending machines and shed light on the manufacturers in Kolkata, India, who are at the forefront of this transformative industry.

#construction company#Bar Bending Machine#construction industry#Rebar Bending Machine#construction equipment

1 note

·

View note