Text

Are you a start-up adhesive factory? How can a small or medium-sized production line achieve low investment and high efficiency?

1. Providing Mature Formulas and Lowering the Threshold for R&D

JCT provide free market-proven silicone sealant basic formulas (such as neutral building sealant, electronic potting adhesive, etc.), and are equipped with engineers to improve according to your requirements.

JCT helps you save the high cost of R&D trial and error and shorten the production cycle by 3-6 months.

2. Full technical support to make up for the lack of experience

JCT provide full-process technical support from equipment installation to mass production, including process debugging, worker training, and quality problem investigation.

On-site service: Engineers can be sent on-site to guide equipment installation and first batch production.

Online support: Establish an exclusive technical group to respond to production problems (such as bubbles, non-solidification, etc.) in real time.

Training courses: Record operation videos (such as vacuum degassing techniques, filling precision control) to reduce learning costs.

3. Flexible configuration of production line equipment to match small-scale needs

JCT recommends starting with a semi-automatic basic silicone sealant production line, and upgrading to a fully automatic line as orders grow to avoid over-investment.

JCT can provide 5L laboratory double planetary mixer that can be used to test the feasibility of a formula to avoid losses caused by putting the formula into production without verification.

4. Strengthen after-sales guarantee and eliminate worries

JCT provide 1-year warranty for the whole machine, lifetime maintenance, and provide troublesshooting solutions within 24 hours.

Spare parts supply: Frequent wearing parts (such as agitators, seals) are supplied at cost price.

Regular return visits: Check the equipment status every quarter and perform preventive maintenance.

Feel free to contact us for the factory price chemical mixing equipments:

Phone: +86-181 3837 3963 (Whatsapp, Wechat)

Email: [email protected]

#machine#equipment#factory#manufacturer#silicone sealant#production line#double planetary mixer#triple shaft mixer#chemical

0 notes

Text

Q&A on Purchasing Silicone Sealant Production Line | JCT Machinery

Recommended strategy

For customers with limited budget and just starting out, JCT recommend: Acid glass glue/basic neutral glue (mature formula, low equipment investment, low technical threshold). For customers who want to do mid-to-high-end projects, JCT recommend: Neutral structural glue/anti-mildew glue (high added value, more professional formula and process).

Questions JCT are often asked

Can the stability of product quality be guaranteed?

The equipment design of JCT's silicone sealant production line follows the glue process requirements: Vacuum system effectively removes low molecules and moisture. The triple shaft mixer can fully disperse the filler. The temperature control system is accurate to avoid cross-linking out of control. Cooperate with providing mature formulas or assisting process debugging to ensure that the glue quality meets the standards.

Can the output and degree of automation be met?

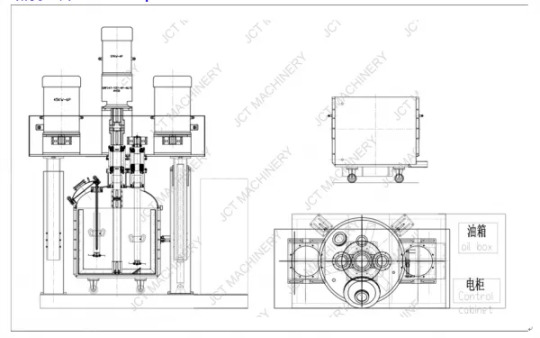

Provide a capacity configuration recommendation table based on the customer's daily output requirements. Provide a fully automatic/semi-automatic silicone sealant production line layout diagram (including automatic feeding, PLC control system, online weighing, etc.) based on the customer's factory size. JCT equipment supports modular expansion, and the capacity can be upgraded/fully automated later.

Do you provide formula / technical training?

JCT not only provides equipment, but also provides mature formulas for neutral/acid silicone sealant (including cost analysis). JCT can send engineers to the customer's factory for technical training, or arrange factory training. We can also provide 5L laboratory double planetary mixer to facilitate customers to develop localized formulas, reduce raw material waste, and ensure smooth large-scale production.

Is the equipment service life and maintenance convenient?

Provide maintenance guides and general consumable parts instructions. The equipment has overload protection, fault alarm and other functions. If there is a problem with the equipment, the after-sales team will respond within 12 hours to avoid customer shutdown. JCT promises a 1-year warranty for all equipment and permanent supply of consumable parts to ensure that there is no shortage of parts after sales.

Feel free to contact us:

Phone: +86-181 3837 3963 (Whatsapp, Wechat)

Email: [email protected]

0 notes

Text

Introduction To Unsaturated Polyester Resin (UPR) Production Line | JCT Machinery

Main Equipments of UPR Production Line

1. Reactor

For esterification reaction, control temperature and pressure.

2. Condenser

To recover water generated during esterification and improve reaction efficiency.

3. Vacuum System

To improve product purity and reduce bubble formation.

4. Measuring Equipment

To accurately control the proportion of raw materials.

5. Stirring Device

To ensure uniform mixing of materials and accelerate reaction speed.

6. Cooling System

To cool to a temperature suitable for adding diluent.

7. Storage Tank

To store finished products for convenient packaging and transportation.

8. Filtration System

To filter impurities and improve resin quality.

9. PLC

To achieve automatic control and improve production efficiency and stability.

Unsaturated Polyester Resin Production Process

1. Raw Material Preparation The raw materials include polyols, unsaturated dibasic acids, saturated dibasic acids and intiators. The ingredients need to be measured to ensure accurate ratios. 2. Esterification Reaction High-temperature esterification reaction is carried out in a reactor. The reaction temperature is usually controlled at 180-220℃ for several hours to produce unsaturated polyester prepolymers. During the reaction, the by-product water needs to be recovered through a condenser. 3. Cooling and Dissolving After the reaction is completed, the temperature is gradually reduced, and diluents such as styrene are added to adjust the viscosity and reactivity of the resin. 4. Degassing and Filtration The bubbles in the system are removed through a vacuum degassing system to improve the purity of the resin. Filter out impurities to improve the quality of the final product. 5. Finished Product Storage and Packaging The produced resin enters the storage tank and is stored in barrels or cans according to market demand.

Technical Features of UPR Production Line

High efficiency and energy saving

Environmental emission

Stable quality

Safe and reliable

0 notes

Text

Why Choose PVA Glue Production Line Turnkey Project? | JCT Machinery

PVA Glue Production Process

1. Raw Material Preparation

Main Raw Materials: PVA powder, water, vinyl acetate (VAc), thickener, plasticizer, filler, preservative, etc.

PVA powder is dissolved in water in a heated stirring kettle to form a transparent viscous liquid.

2. Reaction Polymerization

In reactor, the dissolved PVA liquid is subjected to emulsion polymerization with vinyl acetate to form a stable emulsion structure.

Control the temperature, pressure, and stirring speed to ensure uniform reaction.

3. Emulsification & Thickening

Add thickeners (such as CMC, starch) and plasticizers (such as glycerin) to adjust the viscosity and fluidity of the glue.

Use a high speed disperser or emulsifier to ensure that the ingredients are fully mixed to improve the uniformity and stability of PVA glue.

4. Cooling & Filtration

After the reaction, PVA glue needs to be cooled to room temperature and filtered to remove impurities to ensure the purity of the finished product.

5. Storage & Filling

PVA glur is placed in a storage tank and packaged after being left for a period of time.

It is packaged in barrels, bottles or bags using an automatic filling machine and sealed before leaving the factory.

PVA Glue Production Line Features

✅High Degree of Automation: Optional PLC control system to improve production stability and efficiency. ✅Environmental Protection and Energy Saving: Adopts water-based formula, no solvent pollution, in line with environmental protection standards. ✅Customizable Production: It can produce PVA glue with different viscosity and solid content, suitable for a variety of industry needs. ✅High Adhesion and Low Odor: Suitable for bonding materials such as wood, paper, leather, textiles, etc.

0 notes

Text

Jacketed Reactor And Pipe Coil Reactor | JCT Machinery

Jacketed Reactor

The outer wall is provided with a jacket, in which a heating or cooling medium (such as steam, hot or cooling water, etc.) flows. The heating or cooling medium exchanges heat with the reaction materials through the jacket, thereby achieving temperature control.

Pipe Coil Reactor

Pipe coils (usually spiral or annular pipes) can be installed inside and outside, and the heating or cooling medium circulates through the coils, and heating or cooling is achieved through heat exchange between the coils and the reaction materials.

1. Heat Exchange Efficiency

Jacketed Reactor: The heat exchange efficiency of jacketed reactor is relatively low, because the heat needs to be transferred to the reaction material through the jacket wall, and the heat transfer rate of this process is slow.

Pipe Coil Reactor: The heat exchange efficiency of pipe coil reactor is high, because the contact area between the coil and the reaction material is large, and the heat can be transferred to the reaction material more quickly, which is particularly suitable for processes that require rapid heating or cooling.

2. Applicable Materials

Jacketed Reactor: Applicable to various viscosity materials, especially when processing high viscosity and high density materials. The jacket design can ensure uniform heating or cooling during the reaction process.

Pipe Coil Reactor: It is more suitable for materials with low or medium viscosity. When processing high viscosity materials, the coil may encounter resistance, resulting in unsatisfactory heating or cooling effects.

3. Applicable Scenarios

Jacketed Reactor: Commonly used in large-scale production, high-viscosity materials or chemical reaction processes that require a long reaction time, suitable for long-term and stable reaction operations. Suitable fo reaction processes that require more precise temperature control, such as the synthesis of unsaturated resins and polyester resins.

Pipe Coil Reactor: Commonly used in small-scale or medium-sized production, especially reaction processes that require rapid temperature control, such as certain polymerization reactions, catalytic reactions, etc. Suitable for applications with rapid heating or cooling.

4. Equipment Footprint and Space Requirement

Jacketed Reactor: Due to the external structure of jacket, jacketed reactor is larger in size and occupies more space, especially when large-scale production is required, a larger footprint may be required.

Pipe Coil Reactor: The design of pipe coil reactor is usually more compact and occupies relatively less space, which is suitable for use in environments with relatively small spaces.

If you want to know more about reactor, click.

0 notes

Text

Main Equipments of Epoxy Resin Production Line | JCT Machinery

Main Equipments of Epoxy Resin Production Line

1. Raw Material Conveying System

Liquid Raw Material Storage and Transportation: Liquid raw materials such as epichlorohydrin, epoxy soybean oil, chlorinated paraffin, etc. are stored in storage tanks and transported to reactor through a pumping system.

Solid Raw Material Transportation: Solid raw materials (such as curing agent, catalyst, etc.) are usually delivered to reactor by a screw conveyor or a pneumatic conveying system.

2. Reactor

Function: Reactor is mainly used for the synthesis reaction of epoxy resin. The production of epoxy resin usually involves the chemical reaction of epoxy compounds (such as epichlorohydrin) and curing agents to form high molecular polymers. The design of reactor should take into account the reaction temperature, pressure, stirring speed and other parameters to ensure that the reaction is complete and uniform.

Feature: Reactor is usually a jacketed reactor, and the reaction temperature can be adjusted by the jacket temperature control system. Reactor is equipped with an agitator to ensure uniform mixing of raw materials and promote the reaction.

3. Vacuum Degassing System

Function: During the production of epocy resin, some raw materials may produce bubbles or impurities, which will affect the quality of the final product. Vacuum degassing system extracts the gas in reactor to remove these unnecessary gases, ensure the stability of the reaction process and improve the quality of the product.

Equipment: Vacuum pump, vacuum box, etc.

4. Cooling System

Function: The heat generated during the reaction process may cause the temperature to be too high, so reactor needs to be equipped with a cooling system to keep the reaction temperature within a controllable range. The common cooling method is jacket cooling, which reduces the temperature by flowing water or coolant in the outer jacket of reactor.

Equipment: Cooling tower, cooling water circulation system, etc.

Epoxy Resin Production Process

The production process flow of epocy resin usually includes raw material preparation (epoxy compound and curing agent, etc.), mixing reaction (carried out in reactor), cooling and degassing, filtering impurities, final molding and packaging, etc. The whole process requires strict control of reaction conditions, such as temperature, time, stirring speed and curing agent addition, to ensure product quality.

Features and Advantages of Epoxy Resin Production Line

High Degree of Automation: Epoxy resin production line usually adopt automated control, which can improve production efficiency and product consistency while reducing labor costs.

High-precision Control: During the reaction process, key parameters such as temperature, time, pressure, stirring speed, etc. are precisely controlled to ensure stable product quality.

Environmental Protection and Safety: Epoxy resin production line should meet environmental protection requirements, reduce harmful gas emissions, and the equipment design should have high safety performance to avoid dangers during the reaction process.

0 notes

Text

Different Types Of Silicone Sealant | JCT Machinery

Recently, a group of foreign customers came to JCT's factory to learn how to make silicone sealant, and saw how high quality the JCT 5L double planetary mixer is! We made neutral silicone sealant and acidic silicone sealant.

Many customers have asked JCT: which silicone sealant is better sold? Different silicone sealants have different application scenarios, and the performance characteristics of silicone sealant are also different.

Comparison of Silicone Sealants

1. Curing Mechanism

Neutral Silicone Sealant: Its curing process is triggered by a neutral catalyst. This type of sealant does not release any acidic substances during the curing process, so it has no sour smell. The reaction of neutral silicone sealant is usually promoted by moisture or humidity.

Acidic Silicone Sealant: Its curing process is caused by the catalytic reaction of an acidic catalyst. During the curing process, acidic silicone sealant releases a small amount of acetic acid, so it has a distinct sour smell.

2. Scope of Application

Neutral Silicone Sealant: Because it does not release acidic substances, it is suitable for a wider range of materials, including stone, aluminum alloy, mirror, plastic, wood, etc. This makes neutral silicone sealant more widely used in fields such as construction, automobiles, electronics and glass curtain walls.

Acidic Silicone Sealant: It is mainly used for bonding non-porous materials such as metal, glass and ceramics. Due to the release of acetic acid, acidic silicone sealant is not suitable for certain acid-sensitive materials, such as aluminum, copper, galvanized steel and other metals, especially in automobiles, construction and electronic products.

3. Curing Speed

Neutral Silicone Sealant: The curing speed is relatively slow, especially in low humidity environments, but its advantage is that it can be constructed in more demanding environments.

Acidic Silicone Sealant: Usually cures faster, suitable for fast construction and sealing work in a short time.

4. Weather Resistance and Durability

Neutral Silicone Sealant: Neutral silicone sealant usually has better weather resistance, aging resistance and UV resistance, and is particularly suitable for applications exposed outdoors for a long time.

Acidic Silicone Sealant: Acidic silicone sealant usually has good weather resistance, but its applicable temperature range and durability are slightly worse than neutral silicone sealant.

5. Environmental Adaptability

Neutral Silicone Sealant: Because it does not release harmful gases, it is suitable for use in applications with high corrosive requirements, especially for electronic equipment, glass decoration and other precision engineering materials.

Acidic Silicone Sealant: Because it releases acetic acid, it is not suitable for sealing materials that require non-corrosive or acid-sensitive.

0 notes

Text

With the requirements of lithium battery increasing, our JCT Machinery battery slurry mixers are becoming hot selling product. Battery slurry is one of the most important things in the battery. The good the battery slurry, the good the quality of battery.

0 notes

Text

The transmission types of double planetary mixer have gear transmission and synchronous belt transmission. Different transmission type has different application areas. Choose according to customer's actual need.

#equipment#machine#industrial#mixer#machinery#chemical#planetary mixer#double arm mixer#vacuum planetary mixer#disperser#transmission#mechanics#factory#difference

0 notes

Text

#equipment#machine#industrial#mixer#machinery#chemical#vertical kneader#aerospace#resin#dental#supplier#manufacturer#factory

0 notes

Text

Vertical kneader, also called propellant kneader, is a machine suitable for mixing ultra high viscosity materials. It can be used to make solid propellant, fiber glass resin, dental resin material.

JCT Machinery is one of the few factories on the world that can design and manufacture vertical kneades.

#equipment#machine#machinery#industrial#industry#vertical kneader#mixer#propellant mixer#aerospace#planetary mixer#dental care#resin

0 notes

Text

Double planetary mixer have different transmission methods. Look what characteristics they have! Choose the transmission methods according to your production conditions.

#equipment#machine#industrial#mixer#machinery#chemical#planetary mixer#dual shaft mixer#double planetary mixer#vacuum planetary mixer

0 notes

Text

JCT Machinery is professional in making high speed disperser, double planetary mixer and triple shaft mixer.

These three high speed dispersion machines can be used in different materials. If you are confused what equipment you need, feel free to contact us, we are pleased to give you advice.

#equipment#machine#industrial#mixer#machinery#chemical#high speed dispersing machine#high speed disperser#double shaft mixer#double planetary mixer#planetary mixer#triple shaft mixer#multifunctional dispersing power mixer#multi shaft mixer#twisted blade mixer

0 notes

Text

0 notes

Text

#equipment#machine#industrial#mixer#machinery#sigma mixer#chemical#double arm mixer#z blade mixier#sigma blade mixer#polymer clay

0 notes

Text

Why there are some holes on the reactor? What function do they have?

#machine#equipment#industrial#reactor#chemical#chemical reactor#stainless steel reactor#reaction kettle#machinery

0 notes