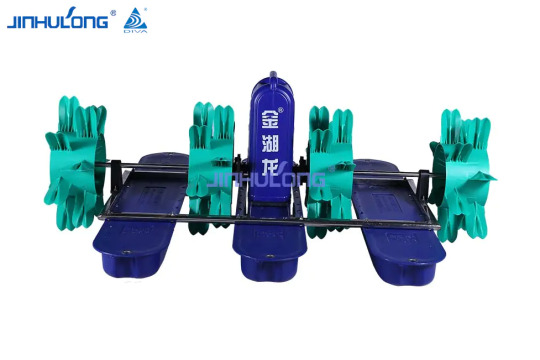

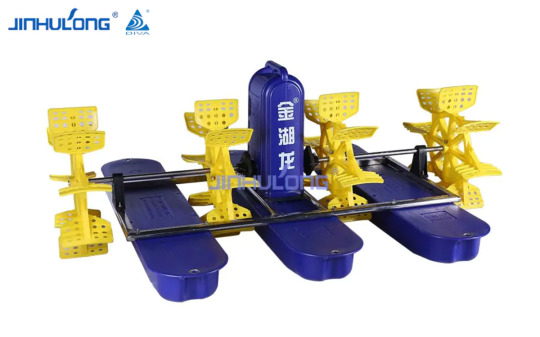

As a farm pond aerators manufacturer and aquaculture aerator factory, we provide fish farming aerators with reliable quality on the basis of demanding product design, reasonable processing flow, and strict examination.

Don't wanna be here? Send us removal request.

Text

Paddle Wheel Aerator Water Cooling to Varying Water Depths and Quality Conditions

Paddle Wheel Aerator Water Cooling Systems have become essential equipment in modern aquaculture and water treatment facilities. Their primary function is to enhance oxygenation and control water temperature, ensuring a healthy environment for aquatic organisms. A key question for many users and operators is whether these systems can effectively adapt to different water depths and varying water quality conditions. This article explores the factors influencing the adaptability of Paddle Wheel Aerator Water Cooling and how they perform under diverse aquatic environments.

Design Flexibility for Various Water Depths

One of the strengths of Paddle Wheel Aerator Water Cooling lies in its flexible design. These systems are often engineered with adjustable paddle wheel sizes and motor power configurations, allowing them to operate efficiently across shallow ponds to deeper reservoirs. The rotation speed and submersion depth can be calibrated to optimize water circulation and oxygen transfer regardless of depth. This adaptability ensures that the aerator’s performance remains consistent, whether installed in shallow nursery ponds or large, deep fish farms.

Impact of Water Quality on Aeration Efficiency

Water quality parameters such as turbidity, dissolved organic matter, and pollutant concentration can influence the aerator’s efficiency. High levels of suspended solids or contaminants may affect water flow and oxygen diffusion. However, modern Paddle Wheel Aerator Water Cooling units are designed with durable materials and robust mechanisms to handle a range of water conditions. Additionally, some models incorporate features like self-cleaning paddles or protective screens to prevent clogging and maintain operational efficiency despite fluctuating water quality.

Temperature and Oxygen Control in Varied Environments

Different water bodies exhibit distinct thermal profiles and oxygen demands. Paddle Wheel Aerator Water Cooling systems are capable of adjusting to these variations through controllable motor speeds and paddle configurations. By modifying operational parameters, the aerator can maintain effective oxygen levels and contribute to temperature regulation, even when water quality and depth vary. This dynamic response is critical in preventing stress and mortality in aquatic species, especially in changing seasonal or weather conditions.

Installation and Customization Options

The ability to adapt to different depths and water qualities is also influenced by installation practices. A reliable Paddle Wheel Aerator Water Cooling provider typically offers customized solutions tailored to site-specific conditions. This may include variable mounting heights, motor power selections, and optional accessories like diffusers or filtration systems. Such customization enhances the aerator’s compatibility with diverse aquatic environments, ensuring suitable performance regardless of external variables.

Maintenance Considerations for Variable Conditions

Operating in waters with varying quality and depth may increase maintenance demands. Sediment accumulation, biofouling, and mechanical wear are common challenges. Nevertheless, well-designed Paddle Wheel Aerator Water Cooling equipment features easy-access components and corrosion-resistant materials to facilitate routine maintenance. Regular inspections and adjustments help sustain adaptability and prolong the aerator’s lifespan across different aquatic scenarios.

Conclusion: Reliable Adaptation Across Diverse Water Conditions

In conclusion, Paddle Wheel Aerator Water Cooling systems demonstrate strong adaptability to a wide range of water depths and quality conditions. Through flexible design, customizable installation, and durable construction, they maintain effective aeration and cooling performance in varying environments. For aquaculture managers and water treatment professionals, selecting a well-engineered Paddle Wheel Aerator Water Cooling solution ensures reliable operation and suitable aquatic health regardless of site-specific challenges.

0 notes

Text

Performance of the Circumferential Aeration Aerator Under High-Load Conditions

The Circumferential Aeration Aerator is known for its ability to perform efficiently under high-load conditions, making it a popular choice in wastewater treatment and other water management applications. High-load conditions often involve increased organic matter or contaminants, which place a greater demand on the aeration system. In such environments, the performance of the aerator can significantly impact the overall efficiency of the treatment process. The Circumferential Aeration Aerator stands out in this context due to its unique design and capability to handle higher oxygen demands, ensuring suitable aeration even under challenging conditions.

One of the key advantages of the Circumferential Aeration Aerator under high-load conditions is its ability to maintain consistent oxygen distribution throughout the water. In high-load situations, traditional aerators often struggle with providing even oxygen coverage, causing some areas of the water to be under-oxygenated while others receive an excess. This can result in the development of anaerobic zones, which hinder microbial activity and slow down the breakdown of organic waste. The Circumferential Aeration Aerator, with its circular design, ensures that oxygen is evenly distributed across the water body, preventing the formation of such zones. This uniform oxygenation is crucial for maintaining the health of the microorganisms involved in the treatment process and for ensuring the overall efficiency of the system.

Moreover, the Circumferential Aeration Aerator is designed to increase oxygen transfer rates, which becomes especially important when dealing with high organic loads. The aerator creates a continuous flow of water, which enhances the contact between the air and water, allowing for a more efficient transfer of oxygen. In traditional systems, higher organic loads often require more energy to achieve the same level of oxygenation. However, the Circumferential Aeration Aerator is engineered to deliver high levels of dissolved oxygen with reduced energy consumption, making it an energy-efficient solution even when operating under high-load conditions. This not only helps in maintaining treatment efficiency but also results in lower operational costs, a significant benefit for large-scale water treatment facilities.

Another important feature of the Circumferential Aeration Aerator under high-load conditions is its ability to adapt to varying water depths and changing operational requirements. As high-load situations often occur in large-scale applications where water depth can vary, the Circumferential Aeration Aerator ensures that oxygen is evenly distributed regardless of water depth. This adaptability is a critical factor in ensuring that the system continues to perform efficiently even when conditions fluctuate, further enhancing its reliability in challenging environments.

The performance of the Circumferential Aeration Aerator is also bolstered by its reduced maintenance requirements. Traditional aerators often face issues such as clogging or mechanical failure under high-load conditions, which can disrupt the treatment process and cause increased maintenance costs. The Circumferential Aeration Aerator, with its fewer moving parts and robust design, is less prone to such issues. This results in fewer system breakdowns, reduced maintenance needs, and more consistent operation during high-load periods.

In conclusion, the Circumferential Aeration Aerator excels in high-load conditions, providing efficient and uniform oxygen distribution across varying water depths and organic loads. Its ability to maintain suitable oxygenation while reducing energy consumption makes it an effective and cost-efficient solution for water treatment facilities. The aerator’s robust design and adaptability further enhance its performance under challenging conditions, ensuring that high-load situations do not compromise the treatment process. With its advanced capabilities, the Circumferential Aeration Aerator is a reliable choice for handling high-load demands in wastewater treatment and other aeration applications.

0 notes

Text

Impact of Paddle Wheel Aerator Water Cooling on Water Quality Enhancement

Water quality is a concern in various industries, from agriculture to aquaculture, and the use of Paddle Wheel Aerator Water Cooling systems has become a prevalent method to manage and improve it. These systems play a crucial role in maintaining the health of aquatic environments by increasing dissolved oxygen levels, which is essential for the survival and growth of aquatic life. This article delves into the multifaceted impact of Paddle Wheel Aerator Water Cooling on water quality, examining its benefits and mechanisms.

The primary function of Paddle Wheel Aerator Water Cooling systems is to introduce air into the water, thereby increasing its oxygen content. This process, known as aeration, is vital for sustaining life in water bodies, as it provides the necessary oxygen for aerobic organisms to thrive. By promoting oxygenation, Paddle Wheel Aerator Water Cooling systems can prevent the depletion of oxygen that can cause the death of fish and other aquatic organisms, a phenomenon commonly referred to as "fish kill."

Moreover, Paddle Wheel Aerator Water Cooling systems are effective in reducing the concentration of harmful substances in water. By continuously agitating the water, these systems help in the dispersion of pollutants, thereby preventing the formation of anaerobic conditions that can cause the release of toxic gases such as hydrogen sulfide and ammonia. This is particularly important in wastewater treatment facilities, where the buildup of harmful substances can hinder the treatment process and pose a threat to the environment.

Another significant impact of Paddle Wheel Aerator Water Cooling systems on water quality is the promotion of water circulation. The movement created by the paddle wheels not only distributes oxygen evenly throughout the water body but also helps in breaking the stratification that can occur in deeper waters. This stratification can cause the formation of anoxic zones where oxygen is depleted, making them uninhabitable for many aquatic species. By preventing stratification, these aeration systems ensure a more uniform and habitable environment for aquatic life.

The temperature control offered by Paddle Wheel Aerator Water Cooling systems is another aspect that affects water quality. In warmer climates, the evaporation of water can cause an increase in water temperature, which can be detrimental to certain aquatic species. By dissipating heat through the movement of water, these systems help maintain a stable water temperature, which is crucial for the health and survival of aquatic organisms.

Furthermore, Paddle Wheel Aerator Water Cooling systems contribute to the breakdown of organic matter in water. The increased oxygen levels facilitate the process of biodegradation, where organic pollutants are broken down by microorganisms into less harmful substances. This natural process is essential for maintaining water quality and preventing the accumulation of pollutants that can cause eutrophication and other water quality issues.

In conclusion, Paddle Wheel Aerator Water Cooling systems have a profound impact on water quality by increasing dissolved oxygen, reducing harmful substances, promoting water circulation, controlling water temperature, and aiding in the breakdown of organic matter. These systems are a vital component in managing water bodies, ensuring the health and sustainability of aquatic ecosystems. As environmental concerns continue to grow, the role of Paddle Wheel Aerator Water Cooling systems in maintaining water quality will become increasingly significant, making them an indispensable tool in the arsenal of water management solutions.

0 notes

Text

Comparative Energy Consumption of Circumferential Aeration Aerator in Wastewater Treatment

In the context of wastewater treatment, the selection of an aeration system is a critical decision that significantly impacts both the operational costs and the environmental footprint of the treatment process. The Circumferential Aeration Aerator, with its distinct design, has been a subject of interest for its potential energy efficiency. This article aims to provide a comprehensive comparison of the energy consumption of Circumferential Aeration Aerators with other aeration devices, examining their performance in various scenarios.

The Circumferential Aeration Aerator is a type of surface aerator that is designed to distribute air evenly across the entire cross-section of aeration basins, promoting efficient oxygen transfer and mixing. This design is intended to optimize the oxygenation process, which is essential for the aerobic decomposition of organic matter in wastewater. The energy consumption of such a system is a crucial factor in determining its overall efficiency and cost-effectiveness.

When comparing the energy consumption of a Circumferential Aeration Aerator with other aeration devices, such as fine bubble diffusers or mechanical surface aerators, several factors must be taken into account. These include the oxygen transfer efficiency, the power input per unit of oxygen transferred, and the operational conditions of the wastewater treatment plant.

The Circumferential Aeration Aerator, due to its even distribution of air, tends to have a higher oxygen transfer efficiency compared to some other aeration systems. This efficiency translates into lower energy consumption per unit of oxygen transferred, making it an attractive option for energy-sensitive applications. Studies have shown that the Circumferential Aeration Aerator can achieve oxygen transfer efficiencies that are competitive with, and in some cases good to, those of fine bubble diffusers, which are known for their high efficiency but can be more energy-intensive.

However, the energy consumption of the Circumferential Aeration Aerator is not solely determined by its oxygen transfer efficiency. The power input required to operate the system is also a significant factor. The Circumferential Aeration Aerator, being a mechanical system, requires less power per unit of oxygen transferred compared to some other mechanical aerators. This is due to its design, which allows for a more direct and efficient use of energy to move air into the wastewater.

In terms of operational conditions, the Circumferential Aeration Aerator can be more versatile than other systems. It can be easily adjusted to accommodate changes in the volume of wastewater or the required oxygen levels, which can cause further energy savings. This adaptability is particularly important in treatment plants that experience fluctuating influent loads or seasonal variations in oxygen demand.

Despite these advantages, the Circumferential Aeration Aerator is not without its challenges. Maintenance costs and the need for regular inspection to ensure the integrity of the aeration system can add to the operational expenses. However, with proper maintenance and management, these costs can be reduced, and the long-term energy savings can make the Circumferential Aeration Aerator a more economical choice.

In conclusion, the Circumferential Aeration Aerator offers a competitive energy consumption profile when compared to other aeration devices. Its high oxygen transfer efficiency, lower power input requirements, and adaptability to varying operational conditions make it a strong contender for wastewater treatment plants seeking to optimize their energy usage. As environmental concerns and energy costs continue to rise, the Circumferential Aeration Aerator's energy efficiency becomes an increasingly important consideration in the selection of aeration technologies for wastewater treatment.

Power: 0.75KW Oxygen generating capacity: ≥1.35kgO2/h Power efficiency: 1.2kg02/hkW Pumping capacity: ≥7,200m3/h Wave-making strength: 50mm Amplitude Wave Action Range (Diameter)≥70m Impeller speed: Φ1580900mm Dimensions: 34rpm Weight: 53kg Farming coverage: 4669m2

0 notes

Text

Comparative Advantages of Frequency Conversion Aerator Over Traditional Aeration Systems

In the field of water treatment and aeration, the advent of Frequency Conversion Aerator technology has introduced a paradigm shift in the way oxygen is transferred into water bodies. This innovative system has been gaining traction due to its numerous advantages over traditional aeration devices. The Frequency Conversion Aerator, with its unique design and operation, offers a more efficient, cost-effective, and environmentally friendly solution for aeration needs.

One of the primary advantages of the Frequency Conversion Aerator is its energy efficiency. Traditional aeration systems, such as mechanical surface aerators and diffused air systems, often consume a significant amount of energy to operate. In contrast, the Frequency Conversion Aerator uses a frequency conversion technology that optimizes the energy input, resulting in lower power consumption and reduced operational costs. This is particularly beneficial for large-scale water treatment facilities where energy savings can be substantial.

Another significant advantage of the Frequency Conversion Aerator is its ability to provide precise oxygen control. Traditional systems often struggle with maintaining consistent oxygen levels, which can cause inefficiencies and suboptimal treatment outcomes. The Frequency Conversion Aerator, however, can adjust the frequency of aeration to match the exact oxygen demands of the water body, ensuring suitable dissolved oxygen levels are maintained at all times. This precision not only enhances the treatment process but also prevents the over-aeration of water, which can be harmful to aquatic life.

The Frequency Conversion Aerator also excels in terms of its adaptability. Unlike traditional systems that may require significant modifications or complete replacement to accommodate changes in water volume or treatment requirements, the Frequency Conversion Aerator can be easily adjusted to suit varying conditions. This flexibility allows for a more responsive and adaptable aeration strategy, which is crucial in dynamic water treatment environments.

Maintenance and durability are other areas where the Frequency Conversion Aerator outperforms traditional aeration systems. The fewer moving parts in the Frequency Conversion Aerator reduce the likelihood of mechanical failure, causing lower maintenance costs and a longer lifespan. Traditional systems, with their complex mechanical components, often require more frequent servicing and replacement, which can be both costly and time-consuming.

In terms of environmental impact, the Frequency Conversion Aerator is a more sustainable choice. Its quiet operation and lack of surface disturbance make it less intrusive to wildlife and the surrounding environment. Traditional aeration systems can cause noise pollution and disrupt the natural habitat, which is a significant concern in ecologically sensitive areas.

Lastly, the Frequency Conversion Aerator's performance is less affected by weather conditions. While traditional systems may see a decrease in efficiency during cold weather or high winds, the Frequency Conversion Aerator maintains consistent performance, ensuring reliable oxygenation regardless of the external environment.

In conclusion, the Frequency Conversion Aerator offers a range of advantages that make it a good choice for aeration systems over traditional methods. Its energy efficiency, precise oxygen control, adaptability, low maintenance, environmental friendliness, and consistent performance in various conditions make it an ideal solution for modern water treatment and aeration needs. As the demand for more sustainable and efficient water management solutions grows, the adoption of Frequency Conversion Aerator technology is likely to become increasingly prevalent.

https://www.chinaaerator.net/product/impeller-aerator/super-impeller-type-oxygenator-series/

0 notes

Text

Comparative Analysis of Water Plowing Aerator and Traditional Tillage Methods

In the realm of agricultural practices, the Water Plowing Aerator stands as an innovative tool that has been gaining attention for its potential to change soil management. This article delves into the differences between the Water Plowing Aerator and traditional tillage methods, examining their respective impacts on soil health, environmental sustainability, and crop productivity.

The Water Plowing Aerator, a modern soil aeration technique, operates by injecting water under pressure into the soil, thereby loosening compacted soil layers without the need for physical disturbance. This method contrasts sharply with traditional tillage methods, which involve the mechanical manipulation of soil using tools like plows and cultivators. Traditional tillage, while effective in breaking up soil and preparing seedbeds, has been associated with several drawbacks, including soil erosion, loss of organic matter, and increased greenhouse gas emissions due to the exposure of soil carbon to the atmosphere.

One of the primary distinctions between the Water Plowing Aerator and traditional tillage is the level of soil disturbance. The Water Plowing aeration disrupts the soil structure, preserving the integrity of the soil ecosystem. In contrast, traditional tillage methods can destroy soil aggregates, which are crucial for maintaining soil fertility and water retention capabilities. This difference is particularly significant in maintaining the long-term health and productivity of the soil.

Another key difference lies in the environmental impact of each method. The Water Plowing Aerator reduces the need for fossil fuel-powered machinery, thereby decreasing the carbon footprint associated with soil preparation. Traditional tillage, on the other hand, requires the use of heavy machinery that contributes to greenhouse gas emissions and fossil fuel consumption. Additionally, the Water Plowing Aerator's reduced soil disturbance helps to reduce soil erosion, a significant environmental concern in areas prone to water and wind erosion.

The Water Plowing Aerator also offers advantages in terms of water conservation. By creating channels within the soil, this method allows for better water infiltration and reduces runoff, which is particularly beneficial in arid and semi-arid regions. Traditional tillage, in contrast, can cause increased surface runoff and reduced water infiltration, exacerbating water scarcity issues in certain regions.

In terms of crop productivity, the Water Plowing Aerator can improve root growth by creating a more favorable environment for root penetration and nutrient uptake. This can cause increased crop yields and better resistance to drought and other environmental stresses. Traditional tillage, while effective in preparing the soil for planting, can sometimes cause compaction and reduced root growth, especially in heavy clay soils.

The Water Plowing Aerator's ability to aerate the soil without the need for mechanical disturbance also has implications for soil biodiversity. By preserving the natural structure of the soil, this method supports a diverse range of microorganisms and other soil life, which play a crucial role in nutrient cycling and disease suppression. Traditional tillage, by disrupting the soil structure, can negatively impact these beneficial organisms, potentially causing reduced soil fertility over time.

In conclusion, the Water Plowing Aerator represents a significant departure from traditional tillage methods in terms of soil health, environmental sustainability, and crop productivity. Its soil disturbance, reduced environmental impact, water conservation benefits, and support for soil biodiversity make it a promising alternative for modern agriculture. As the world faces increasing pressures on land and water resources, the adoption of the Water Plowing Aerator could play a crucial role in ensuring the long-term viability of agricultural systems.

https://www.chinaaerator.net/product/other-aerators/water-plowing-aerator/

Model: YGS3-90/YGS3-120 Power(W): 90/120 Voltage V/50Hz: 220 Loading Area:1-3/2-5 Power efficiency kg/kW.h: ≥0.45 Aerobic capacity kg/h:≥0.1/≥0.25 Water lifting capacity m3/h: ≥300 No-load noise (A):≤90 Insulation resistance (MΩ): ≥2

0 notes

Text

The Energy Efficiency of Aquaculture Paddle Wheel Aerators in Sustainable Aquaculture Practices

Aquaculture, as a rapidly growing industry, is constantly seeking innovative solutions to enhance productivity and sustainability. One of the critical aspects of maintaining a healthy aquatic environment is ensuring adequate oxygen levels, which is where the Aquaculture Paddle Wheel Aerator plays a pivotal role. This device is designed to increase dissolved oxygen in water bodies, thereby promoting the growth and well-being of aquatic organisms. However, with the increasing focus on energy efficiency and environmental impact, the energy consumption of Aquaculture Paddle Wheel Aerators has become a topic of significant interest.

The Aquaculture Paddle Wheel Aerator operates on a simple yet effective principle: it uses a paddle wheel to agitate the water, creating a flow that enhances the transfer of oxygen from the air into the water. This mechanical aeration method is widely used due to its efficiency and reliability. However, the energy consumption of these aerators can vary significantly based on several factors, including the size of the wheel, the speed of rotation, and the power source.

When assessing the energy efficiency of Aquaculture Paddle Wheel Aerators, it is essential to consider the power source. Traditionally, these aerators are powered by electric motors, which can consume a considerable amount of energy, especially in large-scale operations. However, with advancements in technology, there has been a shift towards more sustainable energy sources, such as solar power. Solar-powered Aquaculture Paddle Wheel Aerators can significantly reduce the overall energy consumption, making them an attractive option for environmentally conscious aquaculture operations.

The size and design of the paddle wheel also play a crucial role in determining the energy efficiency of Aquaculture Paddle Wheel Aerators. Larger wheels can cover a greater surface area and may require more energy to rotate, but they can also provide more efficient oxygenation. On the other hand, smaller wheels may consume less energy but may not be as effective in oxygenating the water. Therefore, finding the right balance between size and energy consumption is crucial for optimizing the performance of these aerators.

The speed at which the paddle wheel rotates is another factor that influences the energy consumption of Aquaculture Paddle Wheel Aerators. Higher speeds can cause increased oxygenation but also result in higher energy use. Conversely, lower speeds may reduce energy consumption but may not provide the necessary oxygen levels, especially in high-density aquaculture systems. Therefore, it is essential to find a suitable speed that balances oxygenation needs with energy efficiency.

In addition to these factors, the environmental conditions in which the Aquaculture Paddle Wheel Aerator operates can also impact its energy consumption. For instance, water temperature, salinity, and the presence of other dissolved substances can affect the efficiency of oxygen transfer. In such cases, the aerator may need to work harder to maintain adequate oxygen levels, causing increased energy consumption.

To further enhance the energy efficiency of Aquaculture Paddle Wheel Aerators, manufacturers are exploring various technological advancements. These include the use of more efficient motors, improved materials for the paddle wheels, and smart control systems that can adjust the speed of the aerator based on real-time oxygen levels in the water. These innovations not only help in reducing energy consumption but also contribute to the overall sustainability of aquaculture operations.

In conclusion, the energy efficiency of Aquaculture Paddle Wheel Aerators is a multifaceted issue that requires a comprehensive understanding of the device's design, operation, and environmental context. By optimizing these factors and embracing technological advancements, the aquaculture industry can significantly reduce the energy consumption of these essential oxygenation tools, contributing to a more sustainable and efficient future for aquatic farming practices.

0 notes

Text

Understanding the Mechanism Behind Technology of Paddle Aerators Suppliers

Paddle Aerators Suppliers are at the forefront of providing innovative solutions for oxygenation in various water bodies, be it in aquaculture, wastewater treatment, or industrial processes. The technology Paddle Aerators Suppliers offer, known as paddle aerators, plays a crucial role in maintaining the health and balance of these environments. This article delves into the intricate workings of paddle aerators supplied by these companies, shedding light on their functionality and the benefits they offer.

Paddle aerators, as supplied by Paddle Aerators Suppliers, are mechanical devices designed to increase the oxygen levels in water. The primary function of these aerators is to facilitate the transfer of oxygen from the atmosphere into the water, which is essential for the survival and growth of aquatic life and the breakdown of organic matter in wastewater. The paddle aerators work by creating a mechanical agitation of the water surface, which in turn increases the surface area exposed to the air, allowing for more oxygen to dissolve into the water.

The operation of paddle aerators supplied by Paddle Aerators Suppliers involves a series of rotating paddles or discs that are submerged in the water. As these paddles rotate, they churn the water, creating turbulence and mixing the water column. This action not only promotes the dissolution of oxygen but also helps in the circulation of water, ensuring that the oxygen-rich water is distributed evenly throughout the body of water. The design of the paddles is such that they are efficient in their operation, requiring energy to maintain the desired level of oxygenation.

One of the key benefits of paddle aerators from Paddle Aerators Suppliers is their ability to operate in a wide range of conditions. These aerators are designed to withstand various weather conditions and can be used in both small and large water bodies. The robust construction of the paddle aerators ensures that they can operate continuously with maintenance, making them a cost-effective solution for long-term oxygenation needs.

Paddle Aerators Suppliers also offer customization options for their aerators, allowing them to be tailored to the specific requirements of different applications. This customization can include the size of the paddles, the speed of rotation, and the materials used in construction, ensuring that the aerators are optimized for efficient oxygen transfer possible.

In addition to their primary function of oxygenation, paddle aerators supplied by Paddle Aerators Suppliers also contribute to the overall health of the water body by preventing the formation of dead zones, where oxygen levels are too low to support life. By maintaining a healthy oxygen level, these aerators help to support a balanced ecosystem, which is particularly important in aquaculture and wastewater treatment facilities.

The environmental impact of paddle aerators from Paddle aerator Suppliers is also a consideration. These aerators are designed to be energy-efficient, reducing the carbon footprint associated with their operation. Furthermore, by promoting the natural processes of oxygenation and circulation, they help to reduce the need for chemical treatments, which can have harmful effects on the environment.

In conclusion, the paddle aerators supplied by Paddle Aerators Suppliers are a vital component in maintaining the health and balance of various water bodies. Their efficient design and operation ensure that oxygen levels are maintained, supporting aquatic life and aiding in the treatment of wastewater. As the demand for sustainable and efficient oxygenation solutions grows, the role of Paddle Aerators Suppliers in providing these solutions becomes increasingly important.

0 notes

Text

The Impact of Aquaculture Paddle Wheel Aerators on Water Quality

In the realm of aquaculture, maintaining suitable water quality is paramount for the health and productivity of aquatic organisms. One of the key tools employed to achieve this is the aquaculture paddle wheel aerator. These devices are designed to enhance the oxygen levels in water bodies, thereby improving the overall water quality. This article delves into the various ways in which the aquaculture paddle wheel aerator influences water quality, examining its benefits and potential drawbacks.

The primary function of an aquaculture paddle wheel aerator is to introduce oxygen into the water, a process known as aeration. This is achieved through the mechanical action of the paddle wheels, which churn the water and create a flow that facilitates the dissolution of oxygen from the air into the water. The increased oxygen levels are crucial for the survival and growth of fish and other aquatic species, as they require a certain amount of dissolved oxygen to breathe.

One of the significant impacts of the aquaculture paddle wheel aerator on water quality is the reduction of harmful substances. By promoting the circulation of water, these aerators help to distribute nutrients more evenly, preventing the accumulation of waste products and uneaten food in certain areas. This even distribution helps reduce the growth of harmful bacteria and pathogens, thereby reducing the risk of illness.

Moreover, the agitation caused by the aquaculture paddle wheel aerator can also help to break up stratification in the water column. Stratification occurs when different layers of water have different temperatures and densities, which can cause pockets of low oxygen and high concentrations of harmful substances. By mixing these layers, the aerator ensures a more uniform distribution of oxygen and nutrients throughout the water body.

The use of an aquaculture paddle wheel aerator can also have a positive impact on the growth of beneficial microorganisms. These microorganisms play a vital role in the natural filtration process, breaking down organic matter and converting it into nutrients that can be used by plants and other organisms. By maintaining a healthy population of these microorganisms, the aerator contributes to a more balanced and stable ecosystem.

However, it is also important to consider the potential negative effects of using an aquaculture paddle wheel aerator. For instance, excessive aeration can cause the release of carbon dioxide from the water, which can decrease the pH levels and create an acidic environment that is detrimental to aquatic life. Additionally, the mechanical action of the paddle wheels can cause physical stress to fish and other organisms if the aerator is not properly managed.

Another consideration is the energy consumption of the aquaculture paddle wheel aerator. While these devices are generally considered to be energy-efficient, they still require a power source to operate. This can cause increased operational costs and a carbon footprint, which may be a concern for environmentally conscious aquaculture operations.

In conclusion, the aquaculture paddle wheel aerator plays a crucial role in maintaining and improving water quality in aquaculture systems. By increasing oxygen levels, promoting the circulation of water, and supporting the growth of beneficial microorganisms, these aerators contribute to a healthier and more productive aquatic environment. However, it is essential for operators to carefully manage the use of these devices to avoid potential negative impacts such as stress to aquatic organisms and energy consumption. With proper implementation and monitoring, the aquaculture paddle wheel aerator can be a valuable tool in the pursuit of sustainable and efficient aquaculture practices.

0 notes

Text

Exploring the Versatility of Paddle Wheel Aerator for Sale

The Paddle Wheel Aerator For Sale has emerged as a popular choice for enhancing water quality and promoting a healthy aquatic ecosystem. These devices are designed to increase the oxygen levels in water bodies, which is essential for the survival and growth of aquatic life. The question that arises is, which types of water bodies are suitable for the installation of the Paddle Wheel Aerator For Sale? This article aims to provide a detailed analysis of the various water bodies where the Paddle Wheel Aerator For Sale can be effectively utilized.

One and foremost, the Paddle Wheel Aerator For Sale is ideal for use in ponds. Whether it's a small backyard pond or a large commercial fish pond, these aerators can significantly improve water quality by increasing dissolved oxygen levels. The gentle movement of the paddles creates a ripple effect that helps in the circulation of water, preventing the formation of stagnant zones where harmful bacteria can thrive.

Another type of water body where the Paddle Wheel Aerator For Sale can be beneficial is lakes. Lakes, especially those in residential or recreational areas, can suffer from issues like algae blooms and foul odors due to low oxygen levels. Installing the Paddle Wheel Aerator For Sale can help in mitigating these problems by promoting better water circulation and oxygenation.

The Paddle Wheel Aerator For Sale is also suitable for use in aquaculture facilities. In fish farms, maintaining suitable water quality is crucial for the health and growth of fish. These aerators can be used to ensure that the water remains well-oxygenated, which is essential for the fish's respiration and overall well-being. The even distribution of oxygen throughout the water body also helps in reducing the risk of disease outbreaks.

Municipal water treatment plants can also benefit from the installation of the Paddle Wheel Aerator For Sale. These facilities often require large volumes of oxygen to treat wastewater effectively. By using these aerators, the oxygenation process can be accelerated, causing more efficient treatment and a reduction in the overall treatment time.

In addition to ponds, lakes, and aquaculture facilities, the Paddle Wheel Aerator For Sale can also be used in irrigation systems. Proper aeration in irrigation canals helps in maintaining a healthy environment for the growth of crops. The aerators can help in preventing the accumulation of harmful substances and promote the growth of beneficial microorganisms that contribute to the overall health of the water.

Furthermore, the Paddle Wheel Aerator For Sale can be employed in decorative fountains. These aerators not only enhance the aesthetic appeal of the fountains but also ensure that the water remains clean and oxygen-rich. This is particularly important in public spaces where the water quality can have a direct impact on the health and well-being of the visitors.

The use of the Paddle Wheel Aerator For Sale is not limited to natural water bodies alone. They can also be used in constructed wetlands, which are engineered systems designed to mimic the natural processes of wetland ecosystems. These aerators can help maintain the balance of oxygen and nutrients in the water, which is essential for the proper functioning of the wetland system.

In conclusion, the Paddle Wheel Aerator For Sale are versatile device that can be used in a wide range of water bodies, from small backyard ponds to large-scale aquaculture facilities. Their ability to improve water quality, increase oxygen levels, and promote a healthy aquatic ecosystem makes them an invaluable tool for water management. Whether you are looking to enhance the health of your pond, improve the efficiency of your water treatment plant, or maintain the cleanliness of your irrigation system, the Paddle Wheel Aerator For Sale is a reliable and cost-effective solution.

0 notes

Text

A Comprehensive Analysis Evaluating the Efficiency of Impeller Aerators

Impeller Aerator, as an integral component in the aeration of water bodies, is designed to enhance the oxygenation process, which is essential for maintaining a healthy aquatic ecosystem. These devices are widely used in various applications, including wastewater treatment, aquaculture, and water feature management. The efficiency of an Impeller Aerator is a critical parameter that determines its effectiveness in these applications. This article delves into the factors that influence the efficiency of Impeller Aerators and evaluates their performance in different scenarios.

The efficiency of an Impeller Aerator can be defined as the ratio of the actual oxygen transfer rate to the theoretical oxygen transfer rate. Several factors contribute to the efficiency of these devices, including the design of the impeller, the material used, the operating speed, and the environmental conditions in which they are deployed.

Starting with the design of the impeller, the shape, size, and number of blades significantly impact the aeration process. A well-designed impeller can create a high surface area for oxygen to be absorbed by the water, thereby increasing the efficiency of the aerator. The material used in the construction of the impeller also plays a crucial role. Durable materials like stainless steel or high-density polyethylene can withstand the corrosive nature of water and maintain the integrity of the impeller, ensuring consistent performance over time.

The operating speed of the Impeller Aerator is another factor that affects its efficiency. Higher speeds can cause increased oxygen transfer rates, but they also result in higher energy consumption. Therefore, finding the suitable speed for a specific application is essential to balance efficiency and energy usage. The efficiency of an Impeller Aerator is also influenced by the environmental conditions in which it operates. Water temperature, salinity, and the presence of pollutants can all impact the oxygen solubility and, consequently, the efficiency of the aerator.

To evaluate the efficiency of Impeller Aerators, various tests and measurements can be conducted. One common method is to measure the dissolved oxygen (DO) levels in the water before and after the aerator is turned on. The difference in DO levels can indicate the oxygen transfer rate and, by extension, the efficiency of the aerator. Additionally, the power consumption of the aerator can be measured to determine the energy efficiency of the device.

In practical applications, the efficiency of Impeller Aerators can be optimized by selecting the appropriate model for the specific water body and its requirements. For instance, in wastewater treatment, an aerator with a high oxygen transfer rate and energy efficiency is desirable to reduce operational costs. In aquaculture, the aerator should be capable of maintaining suitable DO levels to support the health and growth of aquatic organisms.

Moreover, regular maintenance and monitoring of the Impeller Aerator can help maintain its efficiency. This includes cleaning the impeller to remove any debris or biofouling that may hinder its performance, as well as inspecting the motor and other components for signs of wear or damage.

In conclusion, the efficiency of Impeller Aerators is a multifaceted concept that depends on various factors, including design, material, operating speed, and environmental conditions. By understanding these factors and implementing appropriate selection, testing, and maintenance strategies, the efficiency of Impeller Aerators can be improved, causing improved water quality and a healthier aquatic environment.

0 notes

Text

The Multifaceted Advantages of Deep Water Jet Aerators in Wastewater Treatment Applications

In the realm of wastewater treatment, the quest for efficient and sustainable solutions is an ongoing endeavor. Among the various technologies employed, the Deep Water Jet Aerator stands out as a versatile and effective tool. This article explores the numerous advantages that Deep Water Jet Aerators offer in the context of wastewater treatment, highlighting their role in enhancing the overall process.

One of the primary benefits of Deep Water Jet Aerators is their ability to efficiently oxygenate water bodies. By injecting air or oxygen directly into the water, these aerators facilitate the dissolution of gases, which is crucial for the biological processes involved in wastewater treatment. The enhanced oxygen levels support the growth of aerobic microorganisms, which are essential for breaking down organic matter and reducing the biochemical oxygen demand (BOD) and chemical oxygen demand (COD) of the wastewater.

The design of Deep Water Jet Aerators allows for a uniform distribution of oxygen throughout the water column, which is particularly beneficial in deep-water bodies where traditional surface aeration methods may be less effective. This uniform distribution ensures that all areas of the water body receive adequate aeration, promoting a more balanced and efficient treatment process.

Another advantage of Deep Water Jet Aerators is their adaptability to various water conditions. Whether the wastewater is characterized by high turbidity, strong odors, or a high concentration of pollutants, these aerators can be adjusted to meet the specific needs of the treatment process. Their robust construction and resistance to corrosion make them suitable for use in harsh environments, ensuring a long service life with minimal maintenance requirements.

The energy efficiency of Deep Water Jet Aerators is another significant advantage. Compared to traditional aeration methods, these devices consume less power while providing the same or better oxygen transfer efficiency. This not only reduces operational costs but also contributes to a smaller environmental footprint, aligning with the goals of sustainable wastewater management.

In terms of installation and operation, Deep Water Jet Aerators offer simplicity and flexibility. They can be easily integrated into existing wastewater treatment systems, requiring modifications to the infrastructure. Additionally, the operation of these aerators can be automated, allowing for remote monitoring and control, which further reduces the labor and time involved in the treatment process.

The use of Deep Water Jet Aerators also contributes to the reduction of greenhouse gas emissions. By promoting aerobic conditions, these devices help to decrease the production of methane and other harmful gases that are associated with anaerobic digestion. This not only improves the quality of the treated water but also helps to mitigate the impact of wastewater treatment on climate change.

Furthermore, Deep Water Jet Aerators can play a role in odor control within wastewater treatment facilities. By effectively aerating the water and promoting the breakdown of organic matter, these devices help to reduce the production of malodorous compounds, thereby improving the overall working environment and reducing the impact on neighboring communities.

In conclusion, the advantages of Deep Water Jet Aerators in wastewater treatment are manifold. Their ability to efficiently oxygenate water, adapt to various conditions, and operate with energy efficiency makes them a valuable asset in the pursuit of sustainable and effective wastewater management solutions. As the demand for cleaner water and more eco-friendly treatment processes continues to grow, the role of Deep Water Jet Aerators is likely to become increasingly significant in the future of wastewater treatment.

0 notes

Text

The Mechanism of Deep Water Jet Aerators in Enhancing Dissolved Oxygen Levels

Deep water jet aerator is sophisticated devices designed to improve the water quality in various aquatic environments, such as ponds, lakes, and aquaculture systems. These systems are engineered to increase the dissolved oxygen (DO) levels in water, which is crucial for maintaining a healthy ecosystem and supporting aquatic life. The primary function of a deep water jet aerator is to facilitate the exchange of gases at the water's surface, thereby enhancing the oxygen content. This article will explore the intricate process by which deep water jet aerators achieve this goal, examining their design, operation, and impact on water quality.

The operation of a deep water jet aerator begins with the generation of water jets. These aerators are equipped with high-pressure pumps that force water through a series of nozzles, creating powerful jets that propel into the air. As the water is ejected upwards, it forms a fountain-like display, which is not only visually appealing but also serves a critical purpose in oxygenation. The upward movement of water creates a vacuum effect, drawing in ambient air and entraining it with the water as it rises.

As the water and entrained air mixture reaches its peak height, it begins to fall back into the body of water. During this descent, the water droplets and air bubbles come into contact with a larger surface area of the water, allowing for a greater exchange of gases. Oxygen from the air diffuses into the water, while carbon dioxide and other gases escape into the atmosphere. This process is known as mass transfer, and it is the primary mechanism by which deep water jet aerators increase dissolved oxygen levels.

The efficiency of a deep water jet aerator in increasing dissolved oxygen levels is influenced by several factors. One such factor is the depth of the water body. Deeper waters tend to have lower oxygen levels due to reduced contact with the atmosphere. However, deep water jet aerators are specifically designed to reach these depths, ensuring that oxygen is distributed evenly throughout the water column.

Another factor that affects the performance of deep water jet aerators is the water temperature. Warmer water holds less dissolved oxygen than colder water, making it more challenging to maintain adequate oxygen levels in warmer climates. However, deep water jet aerators can still effectively increase oxygen levels in warmer waters by increasing the frequency and intensity of the water jets.

The design of the deep water jet aerator also plays a crucial role in its efficiency. Some models are equipped with adjustable nozzles, allowing operators to control the height and intensity of the water jets. This customization enables the aerator to be tailored to the specific needs of the water body, optimizing the oxygenation process.

Environmental factors, such as wind and wave action, can also impact the performance of deep water jet aerators. Wind can interfere with the water jets, reducing their height and effectiveness. However, in some cases, wind can also aid in the oxygenation process by increasing the surface agitation, which promotes gas exchange.

Maintenance and proper operation of deep water jet aerators are essential for ensuring their longevity and effectiveness. Regular inspection and cleaning of the nozzles and pumps are necessary to prevent clogging and damage, which could reduce the aerator's performance. Additionally, monitoring the dissolved oxygen levels in the water can help operators determine the settings for the aerator, ensuring that the water remains well-oxygenated.

In conclusion, deep water jet aerators are highly effective tools for increasing dissolved oxygen levels in aquatic environments. Through the generation of water jets and the subsequent mass transfer of gases, these devices promote a healthy ecosystem and support diverse aquatic life. By understanding the factors that influence their performance and implementing proper maintenance practices, operators can improve the benefits of deep water jet aerators, ensuring that their water bodies remain oxygen-rich and vibrant.

0 notes

Text

The Impact of Deep Water Jet Aerators on Dissolved Oxygen Levels

The deep water jet aerator is an engineered device designed to enhance the oxygen content within bodies of water. These systems are particularly useful in various applications, such as aquaculture, wastewater treatment, and the management of lakes and ponds, where maintaining suitable oxygen levels is crucial for the health of aquatic life and the efficiency of biological processes. The deployment of deep water jet aerators can significantly influence the dissolved oxygen (DO) levels in aquatic environments, and this article aims to explore the mechanisms through which these devices operate, their benefits, and the factors that can affect their performance.

The primary function of a deep water jet aerator is to facilitate the exchange of gases at the water's surface. By injecting water at high velocity, these aerators create a vortex that brings water from the depths to the surface, where it is exposed to the atmosphere. This process not only allows for the release of carbon dioxide but also promotes the absorption of oxygen from the air into the water. The increased surface agitation caused by the jet aerator enhances the transfer of oxygen by creating more turbulence and a larger surface area for gas exchange.

One of the key benefits of using deep water jet aerators is their ability to prevent stratification, a phenomenon where water forms distinct layers with different temperatures and oxygen concentrations. In stratified water bodies, the deeper layers can become anoxic, or devoid of oxygen, which can lead to the death of fish and other aquatic organisms. By continuously mixing the water column, deep water jet aerators can maintain a more uniform oxygen distribution, ensuring that all levels of the water body have adequate oxygen for the survival of aquatic life.

The efficiency of deep water jet aerators in increasing oxygen levels can be influenced by several factors. Water temperature plays a significant role, as colder water can hold more dissolved oxygen than warmer water. Therefore, the effectiveness of an aerator may vary with seasonal temperature changes. Additionally, the depth of the water body and the presence of any obstructions, such as plants or debris, can affect the performance of the aerator. In deeper water bodies, multiple aerators may be required to ensure adequate oxygenation throughout the entire volume.

Another important consideration is the design of the deep water jet aerator itself. Some models are specifically engineered to optimize oxygen transfer rates, with features such as adjustable flow rates and specialized nozzle designs that improve the surface area of the water exposed to the air. The power source for the aerator, whether it be electric, solar, or gas-powered, can also impact its efficiency and operational costs.

The environmental impact of deep water jet aerators should also be taken into account. While these devices can significantly improve oxygen levels, they also generate noise and can cause some disturbance to aquatic life. It is essential to carefully consider the placement of aerators to minimize any negative effects on the ecosystem.

In conclusion, deep water jet aerators are a valuable tool for managing the oxygen content in various aquatic environments. By understanding the factors that influence their performance and selecting the appropriate model for a specific application, these devices can be used effectively to maintain dissolved oxygen levels. The long-term benefits of using deep water jet aerators include healthier aquatic ecosystems, improved water quality, and more efficient biological processes in wastewater treatment and aquaculture operations. As the technology continues to advance, the capabilities and efficiency of deep water jet aerators will likely continue to improve, further enhancing their role in promoting a sustainable and healthy aquatic environment.

0 notes

Text

Understanding The Principle And Oxygenation Mechanism Of Surge Aerators

Surge aerator plays a crucial role in water treatment and aquatic environments by enhancing the dissolved oxygen content in water bodies. Understanding the principles and mechanisms behind surge aerators is essential for comprehending their effectiveness in oxygenation. In this article, we will delve into the workings of surge aerators and explore how they increase the oxygen content in water.

Surge aerators operate on the principle of utilizing the kinetic energy of water to introduce air into the water column. Unlike traditional aerators that rely solely on mechanical pumps or blowers to deliver air, surge aerators harness the natural movement of water to create turbulence and agitation, thereby facilitating oxygen transfer from the atmosphere to the water.

The primary mechanism through which surge aerators increase the oxygen content in water is by promoting gas exchange at the air-water interface. As water flows over the aerator, it undergoes turbulence and splashing, causing surface agitation and disruption. This turbulence creates a large surface area of contact between water and air, allowing oxygen molecules from the atmosphere to dissolve into the water and carbon dioxide to be released into the air.

Furthermore, the rapid mixing and churning action induced by surge aerators help distribute oxygen-rich surface water throughout the water column. As water is drawn into the aerator and ejected back into the water body, it carries dissolved oxygen from the surface layers deeper into the water, effectively oxygenating the entire water column.

The efficiency of surge aerators in oxygenation is influenced by various factors, including the design and configuration of the aerator, water flow rate, depth of water body, and environmental conditions. Optimizing these parameters is essential for improving oxygen transfer and ensuring effective water oxygenation.

The design of surge aerators typically incorporates features such as inclined ramps, weirs, or baffles to enhance turbulence and mixing. These elements help break up surface water into smaller droplets, increasing the contact area between water and air for efficient gas exchange.

Water flow rate plays a critical role in determining the oxygen transfer efficiency of surge aerators. Higher flow rates result in increased turbulence and agitation, facilitating greater oxygen transfer. However, excessive flow rates may lead to energy wastage and undesirable water turbulence, requiring careful calibration to achieve performance.

The depth of the water body also affects the effectiveness of surge aerators, as deeper water requires greater energy input to achieve adequate oxygenation. Surge aerators are commonly deployed in shallow water bodies such as ponds, lakes, reservoirs, and wastewater treatment lagoons, where their oxygenation capabilities are beneficial.

Environmental conditions, such as temperature, wind speed, and humidity, can also impact the performance of surge aerators. Higher temperatures accelerate oxygen consumption by aquatic organisms and reduce the solubility of oxygen in water, necessitating increased aeration rates to maintain adequate oxygen levels.

In summary, surge aerators operate on the principle of harnessing the kinetic energy of water to promote gas exchange and increase the dissolved oxygen content in water bodies. By creating turbulence and agitation, surge aerators facilitate efficient oxygen transfer at the air-water interface and distribute oxygen-rich water throughout the water column. Understanding the mechanisms behind surge aerators is essential for optimizing their performance and ensuring effective water oxygenation in various aquatic environments.

0 notes

Text

Master The Operational And Skill Requirements For Surge Aerator Performance

Surge aerator is an important tool for soil aeration, helping to enhance water penetration and improve soil structure. Understanding operating procedures and acquiring the necessary skills and knowledge are key components for users to unlock the full potential of this equipment. In this article, we delve into the intricacies of operating a Surge aerator, exploring the essential skills and knowledge required for effective use.

The operation of a Surge aerator involves several key steps to ensure efficient soil aeration. The device usually consists of rotating tines or blades that penetrate the soil, creating channels for air, water and nutrients to reach plant roots. The following steps outline the general operational process:

Before operating a Surge aerator, the user should assess the area to be treated. Clearing surfaces of debris, rocks or obstructions ensures smooth operation and prevents equipment damage.

Surge aerators often have adjustable settings that allow the user to control the depth and density of soil penetration. Depending on soil conditions and required aeration levels, the user should set appropriate parameters.

If the Surge aerator is powered by an engine, the user needs to follow the manufacturer's instructions to start the engine. Electric models may need to be connected to a power source, while gas-powered models require fuel and proper starting procedures.

Once the aerator is ready and the engine is running, the user can activate the aeration mechanism. This activates rotating tines or blades that penetrate the soil.

The user guides the Surge aerator through the target area in a controlled and systematic manner. Overlapping channels ensure that the soil can be aerated, and the speed of movement may affect the effectiveness of the device.

During operation, users should monitor the progress of soil penetration. Observing the depth of penetration of the tines and the quality of the soil plug extracted can provide valuable feedback on the effectiveness of aeration.

After the entire area has been treated, the user releases the breather and shuts off the engine. Proper maintenance procedures, such as cleaning and storing the aerator, should be followed to ensure longevity and performance.

Effective operation of a Surge aerator requires certain skills and knowledge on the part of the user to realize its benefits. The following skills and understanding are essential for correct operation:

Users should have a basic understanding of soil conditions in the target area. Different soil types may require adjustments to the aerator settings for performance.

It is crucial to understand the specific features and functions of the surge aerator being used. Familiarity with trim controls, engine operation, and safety features ensures safe, efficient use.

Choosing the right aeration time is crucial. Aeration is usually done during the growing season when the grass or plant can recover quickly. Aeration on overly wet or dry soil may produce suboptimal results.

Skillful operation: Skillful control of the movement of the aerator is very important for even coverage. Users should practice controlled and straight passes to avoid jumps or overlaps that can lead to uneven ventilation.

The ability to adjust penetration depth to soil conditions is a critical skill. The user should be able to assess the degree of compaction of the soil and set the aerator to achieve the desired depth.

Users need to be aware of safety precautions, including the presence of obstacles, potential hazards, and the proper use of personal protective equipment. Safety knowledge reduces the risk of accidents during operations.

Monitoring the characteristics of soil plugs extracted during aeration can provide valuable insights. Users should be able to evaluate plug length, moisture content, and soil structure to gauge the effectiveness of aeration.

Users should know basic maintenance procedures, such as cleaning the aerator, checking the blades or tines for wear, and lubricating moving parts. Regular maintenance ensures the longevity and reliability of your equipment.

Understanding the environmental impact of aeration, such as its role in water conservation and soil health, enables users to make informed decisions and contribute to sustainable landscaping practices.

0 notes

Text

The Importance Of Aquaculture Paddle Wheel Aerator: Enhancing Oxygenation

Aquaculture, the farming of fish and other aquatic organisms, has become increasingly vital in providing a sustainable source of seafood. To ensure the well-being and growth of fish in ponds, an adequate supply of oxygen is crucial. This is where the Aquaculture Paddle Wheel Aerator comes into play. We will delve into the significance of this innovative device and explore how it contributes to the overall health and productivity of fish ponds.

Ensuring Proper Oxygenation: Aquaculture Paddle Wheel Aerators are specifically designed to enrich the water in fish ponds with oxygen. This is achieved through the rotation of paddle wheels, which creates a flow of water and enhances the oxygen transfer process. By increasing dissolved oxygen levels, the paddle wheel aerator promotes healthier and more active fish, resulting in improved growth rates.

Increased Circulation and Mixing: One of the key advantages of the Aquaculture Paddle Wheel Aerator is its ability to increase water circulation and mixing. The rotation of paddle wheels drives water movement, preventing the formation of stagnant areas within the pond. This enhanced circulation ensures that oxygen is evenly distributed throughout the pond, reducing the risk of oxygen depletion in some parts.

Beneficial for Multiple Species: The versatility of the Aquaculture Paddle Wheel Aerator makes it suitable for a wide range of fish species. Whether it is tilapia, catfish, or carp, this aerator enhances the habitat conditions necessary for their growth and survival. The continuous supply of oxygen helps to maintain good water quality, thus reducing stress factors and providing a conducive environment for all types of fish.

Reducing Harmful Algal Blooms: Aquaculture ponds are susceptible to harmful algal blooms, which can deplete oxygen levels and lead to detrimental consequences for fish. The Aquaculture Paddle Wheel Aerator plays a vital role in combating these blooms. Its constant water movement disrupts the growth and accumulation of algae, preventing oxygen depletion and maintaining a balanced ecosystem.

Enhanced Waste Breakdown: In fish ponds, the accumulation of organic waste is a common challenge. The paddle wheel aerator aids in waste breakdown by facilitating the growth of beneficial bacteria that decompose organic matter. The increased oxygen supply also supports aerobic conditions, which accelerate the breakdown process, reducing the risk of water pollution and disease outbreaks.

Energy Efficiency and Cost-Effectiveness: Aquaculture Paddle Wheel Aerators are renowned for their energy efficiency. These devices are designed to improve oxygen transfer while reducing power consumption. The paddle wheel aerator's low operational costs make it an economically viable choice for fish farmers, providing a cost-effective solution for maintaining good pond conditions.

Aquaculture Paddle Wheel Aerators significantly contribute to the success of fish farming operations. By increasing dissolved oxygen levels, improving circulation, and reducing harmful algal blooms, these devices create ideal conditions for fish growth and productivity. With their energy efficiency and cost-effectiveness, paddle wheel aerators are increasingly becoming important tools for the aquaculture industry. Invest in an Aquaculture Paddle Wheel Aerator and unlock the potential for thriving fish ponds and a sustainable seafood supply.

0 notes