Don't wanna be here? Send us removal request.

Text

As Italy continues to lead in ceramic innovation, the need for reliable, high-purity zirconium silicate is only growing. Indian manufacturers, with their ability to deliver bulk quantities of refined zircon for manufacture, are helping European ceramic companies maintain quality, meet demand, and stay globally competitive.

Read More: https://astrongroup.in/

#ZirconiumSilicate #ZirconiumSilicateManufacturing #ZirconForManufacture

0 notes

Text

With high standards in zirconium silicate manufacturing, deep industry expertise, and a commitment to global quality, Indian suppliers are becoming indispensable partners to UK ceramic producers. Whether you're sourcing zircon for manufacture or exploring premium zircon products for your next batch of tiles or sanitaryware, India offers reliable, scalable, and quality-driven solutions.

Read More: https://astrongroup.in/

#ZirconiumSilicate #ZirconiumSilicateManufacturing #ZirconForManufacture

0 notes

Text

If you're looking for trusted zircon powder exporters to Turkey, Astron Group brings together quality, expertise, and global reach. From Zr-P5 and ZrS5 to our advanced HL Series, we deliver zircon products that power performance across ceramics, refractories, and industrial materials.

Read More: https://astrongroup.in/

#ZirconiumSilicate #ZirconiumSilicateManufacturing #ZirconForManufacture

0 notes

Text

India to Italy: Supplying Zirconium Silicate for Europe’s Leading Ceramic Industries

Introduction

Italy stands as one of the global leaders in ceramic production — renowned for its artistry, innovation, and precision in tile and sanitaryware manufacturing. At the heart of this excellence lies a crucial raw material: zirconium silicate. Sourced for its high-temperature resistance, opacity, and stability, zircon has become essential to Italian ceramic manufacturers.

Indian manufacturers — particularly those with advanced zirconium silicate manufacturing capabilities — have rapidly become preferred partners for Italian industries. In this blog, we explore why the supply of zircon products from India to Italy is growing and how trusted Indian exporters are playing a vital role in Europe’s ceramic success story.

Why Zirconium Silicate Is Critical for Ceramics

Zirconium silicate (ZrSiO₄) is a naturally occurring mineral processed into a fine powder and widely used in:

Ceramic tiles and sanitaryware

Glazes and frits

Refractory linings

Casting and foundry applications

Its chemical stability, low thermal expansion, and opacifying properties make it a core ingredient in Italian ceramic formulations — especially for achieving brightness and smooth surface finishes in tiles and tableware.

India’s Advantage in Zirconium Silicate Manufacturing

India has emerged as a global hub for zirconium silicate manufacturing, offering competitive pricing, consistent product quality, and large-scale production capabilities. Leading zircon flour manufacturing companies in India, like Astron Group, combine advanced machinery with deep industry experience to produce zircon powders that meet European standards.

Our popular grades include:

Zr-P5 and ZrS5 – High-purity grades ideal for premium glazes

Zr-325 and Zr-200 – Fine mesh powders used in refractory and industrial ceramics

HL Series (HL-50, HL-40, HL-20) – Customized solutions for manufacturers seeking cost-effective zircon alternatives without compromising on quality

Why Italian Ceramic Manufacturers Choose Indian Zircon Suppliers

✅ Product Consistency

Our powders are milled to uniform particle sizes, ensuring smooth blending and stability in ceramic glaze applications — a key requirement for Italy’s premium tile brands.

✅ Purity and Whiteness

We source high-grade zircon sand and refine it into zirconium silicate with high refractive index and low impurity levels, which enhances glaze opacity and brightness.

✅ Strong Export Expertise

With decades of export experience, Indian companies like ours ensure smooth shipment processes, EU-compliant documentation, and on-time delivery to ports in Italy.

✅ Custom Solutions for Zircon for Manufacture

Our R&D and technical teams work closely with ceramic producers to offer application-specific zircon blends that enhance performance and reduce waste during manufacture.

Trusted Indian Zircon Flour Manufacturing Company: Astron Group

At Astron Group, we specialize in manufacturing and exporting high-performance zircon products for industrial use. As a reputed zircon flour manufacturing company, we are committed to quality, consistency, and customer satisfaction.

We support ceramic manufacturers in Italy by supplying:

Zirconium silicate in different mesh sizes

Tailored zircon blends for frit and glaze applications

Large-volume exports with flexible packaging

Technical documentation and testing certificates

Applications of Zircon for Manufacture in Italy

Indian zircon products are widely used in:

Wall and floor tile glazing

Porcelain sanitaryware

Ceramic tableware and crockery

High-end design tiles requiring extra whiteness and shine

Industrial refractories and castables

Final Thoughts

As Italy continues to lead in ceramic innovation, the need for reliable, high-purity zirconium silicate is only growing. Indian manufacturers, with their ability to deliver bulk quantities of refined zircon for manufacture, are helping European ceramic companies maintain quality, meet demand, and stay gZircon for Manufacturelobally competitive.

#zircon products#zirconiumsilicate#zirconiumsilicatemanufacturing#Zircon flour manufacturing companies#Zircon for Manufacture

0 notes

Text

With high standards in zirconium silicate manufacturing, deep industry expertise, and a commitment to global quality, Indian suppliers are becoming indispensable partners to UK ceramic producers. Whether you're sourcing zircon for manufacture or exploring premium zircon products for your next batch of tiles or sanitaryware, India offers reliable, scalable, and quality-driven solutions.

Read More: https://astrongroup.in/

#ZirconiumSilicate #ZirconiumSilicateManufacturing #ZirconForManufacture

0 notes

Text

Why Indian Zircon Flour Manufacturers Are Becoming Key Partners for UK Ceramic Producers

Introduction

The ceramics industry in the United Kingdom has seen a steady rise in demand for high-quality raw materials—especially zircon flour, a critical component in ceramic glazes, sanitaryware, tiles, and refractories. Among the top sources for this vital raw material, Indian zircon flour manufacturers have emerged as key partners for UK ceramic producers, thanks to their unmatched quality, consistency, and export expertise.

In this blog, we’ll explore why this trend is growing, what makes Indian zircon products globally competitive, and how India’s leading suppliers are supporting the UK’s ceramics market with zirconium silicate-based materials.

What Is Zircon Flour and Why Does It Matter?

Zircon flour is a fine powder produced from natural zirconium silicate (ZrSiO₄). It is widely used in:

Ceramic glazes to enhance whiteness, opacity, and surface finish

Refractory materials for thermal insulation and high-temperature resistance

Foundries and glass production as a stabilizer

Abrasive industries for durability and strength

For UK ceramic manufacturers, the performance of glazes and the final product’s finish depend significantly on the quality and particle size of zircon flour.

The Rise of Indian Zircon Flour in the UK Market

As the ceramics industry in England and across the UK continues to evolve, zircon for manufacture is now a priority in procurement strategies. Indian zircon suppliers are gaining market preference due to several key advantages:

1. High-Quality Zirconium Silicate Manufacturing

India is home to some of the most advanced zirconium silicate manufacturing facilities, equipped with precision milling and processing technology. Manufacturers focus on purity, uniform particle size, and strict quality control—ensuring products meet the demands of UK industries.

2. Consistent Product Range and Customization

Top Indian manufacturers offer a full spectrum of zircon products, including:

Zr-P5 & ZrS5 – Known for excellent whiteness and dispersion in glazes

Zr-325 & Zr-200 – Used in refractories and foundries

HL Series (HL-50, HL-40, HL-20) – Tailored solutions for ceramics and advanced applications

This diverse range gives UK buyers the flexibility to choose materials suited to their production needs.

3. Strong Export Capability and Logistics Support

Reputed zircon flour manufacturing companies in India have a robust export infrastructure. With experience in shipping to England, they offer timely delivery, documentation support, and trade compliance—making them a trusted link in global supply chains.

4. Cost-Effectiveness Without Compromising Quality

Indian zircon suppliers provide cost-competitive solutions without cutting corners on quality. With raw material access, efficient manufacturing, and skilled labor, Indian zircon flour is both economical and reliable for UK-based ceramic producers.

Applications in the UK Ceramic Industry

Indian zircon flour plays a critical role in:

Wall and floor tile production

Sanitaryware (toilets, sinks, basins)

Tableware ceramics

Refractory bricks and castables

Glaze and pigment development

The UK's established and emerging ceramic brands prefer zircon sourced from reliable Indian partners due to consistent quality, smoother finishes, and high-temperature performance.

Choosing the Right Zircon Flour Manufacturing Company

When selecting a zircon supplier, UK manufacturers should consider:

Track record in international exports

Range and technical specification of zircon powders

Certifications and quality assurance practices

Support for logistics and documentation

Ability to offer custom grades for specific applications

Final Thoughts

With high standards in zirconium silicate manufacturing, deep industry expertise, and a commitment to global quality, Indian suppliers are becoming indispensable partners to UK ceramic producers. Whether you're sourcing zircon for manufacture or exploring premium zircon products for your next batch of tiles or sanitaryware, India offers reliable, scalable, and quality-driven solutions.

0 notes

Text

If you're looking for a reliable partner for Zirconium silicate manufacturing, or a steady supplier of zircon powder for ceramics, refractories, or industrial coatings, Astron Group is here to deliver. Our Zr-P5, ZrS5, Zr-325, and HL Series powders are engineered for performance, purity, and reliability—making us a preferred choice in India and beyond.

Read More: https://astrongroup.in/

#ZirconiumSilicate #ZirconiumSilicateManufacturing #ZirconForManufacture

0 notes

Text

Trusted Zircon Powder Exporters to Turkey: What Makes Our Products Stand Out

Introduction

As Turkey's ceramic, refractory, and industrial sectors continue to grow, the demand for premium zircon products is increasing rapidly. At Astron Group, we are proud to be one of India’s leading zircon powder exporters to Turkey, delivering consistent quality, reliable logistics, and technical expertise that global manufacturers rely on.

In this blog, we’ll explore what makes our zirconium silicate-based powders a preferred choice for Turkish industries—and why Astron Group is a trusted name in the international zircon flour manufacturing landscape.

The Importance of High-Quality Zircon Powder in Turkish Industries

Zircon powder, particularly in the form of zirconium silicate (ZrSiO₄), is essential in many industrial applications, including:

Ceramic tiles & sanitaryware

Refractories and foundries

Glass manufacturing

Abrasive and casting materials

Turkey’s booming ceramic and construction sectors require zircon raw materials that meet strict quality, consistency, and thermal resistance standards. This is where trusted exporters like Astron Group play a crucial role.

Our Zircon Product Range: Tailored for Performance

As a specialized zircon flour manufacturing company, we produce and export a wide selection of zircon powders, including:

🔹 Zr-P5 and ZrS5

Engineered for high-opacity and whiteness, these grades are widely used in ceramic glazes and coatings. They offer excellent chemical resistance and consistency in particle size.

🔹 Zr-325 and Zr-200

Ideal for refractory and foundry applications, these finely milled powders are known for their thermal stability and purity, making them suitable for high-temperature processes.

🔹 HL Series (HL-50, HL-40, HL-20)

Our proprietary HL Series offers customized zircon grades developed for manufacturers seeking a balance between performance and cost-efficiency. The series is optimized for glaze formulation, structural ceramics, and advanced coatings.

What Makes Our Zircon Powder Exports to Turkey Stand Out?

✅ Consistency in Quality

Our products meet international standards, with strict quality control in place during every stage of zirconium silicate manufacturing—from sourcing raw materials to post-processing and packaging.

✅ Advanced Manufacturing Facility

As a full-scale zircon flour manufacturing company, we use cutting-edge technology to produce high-purity zircon for manufacture. This includes automated micronizing systems, calcination units, and precision testing equipment.

✅ Global Logistics Expertise

We’ve optimized our export process to ensure on-time delivery to Turkish ports. Our experience in global logistics enables smooth documentation, customs clearance, and freight coordination.

✅ Industry-Centric Technical Support

Our technical team works closely with buyers in Turkey to recommend suitable zircon grades based on specific applications, whether it's for glazes, castings, or refractories.

✅ Transparent Pricing & Market Alignment

We keep track of global zirconium price movements to offer competitive and stable pricing—essential for long-term B2B partnerships.

Applications of Zircon Products in Turkish Markets

Ceramics Industry – Used for opacifying tiles and sanitaryware

Refractory Materials – Enhances thermal resistance in kilns and casting molds

Glass Production – Offers clarity, thermal stability, and resistance to corrosion

Paints & Coatings – Acts as a stabilizer and filler

Why Turkish Buyers Choose Astron Group

Decades of manufacturing expertise in zircon-based materials

Proven track record as a reliable exporter

Full technical support and documentation for exports

Responsive communication and post-sales service

Capability to scale with bulk orders or custom formulations

Final Thoughts

If you're looking for trusted zircon powder exporters to Turkey, Astron Group brings together quality, expertise, and global reach. From Zr-P5 and ZrS5 to our advanced HL Series, we deliver zircon products that power performance across ceramics, refractories, and industrial materials.

0 notes

Text

If you're looking for a reliable partner for Zirconium silicate manufacturing, or a steady supplier of zircon powder for ceramics, refractories, or industrial coatings, Astron Group is here to deliver. Our Zr-P5, ZrS5, Zr-325, and HL Series powders are engineered for performance, purity, and reliability—making us a preferred choice in India and beyond.

Read More: https://astrongroup.in/

#ZirconiumSilicate #ZirconiumSilicateManufacturing #ZirconForManufacture

0 notes

Text

India’s Leading Zircon Powder Manufacturer: What Sets Our Zr-P5, ZrS5 & HL Series Apart

Introduction

India has become a major hub for supplying high-quality zircon-based materials to industries across the globe. At Astron Group, we take pride in being one of the most trusted names in zircon powder manufacturing, offering a wide range of precision-grade products including Zr-P5, ZrS5, Zr-325, Zr-200, and our specialized HL Series (HL-50, HL-40, HL-20).

In this blog, we’ll walk you through what makes our zircon powder solutions stand out in today’s competitive market—and why industries that rely on zircon for manufacture consistently choose us as their long-term partner.

What Is Zircon Powder and Why Is It Essential?

Zircon powder, derived from Zirconium silicate (ZrSiO₄), is a key ingredient in ceramic glazes, refractory materials, and foundry applications. Known for its high thermal stability, resistance to corrosion, and excellent opacifying properties, it is an indispensable raw material in sectors such as:

Ceramics and sanitaryware

Glass manufacturing

Foundries and casting

Refractories and tiles

Our Premium Zircon Powder Grades: Zr-P5, ZrS5 & HL Series

🔹 Zr-P5 & ZrS5

These are ultra-refined zircon powder grades used in high-precision ceramic applications and advanced coating technologies. Both offer:

Exceptional whiteness

High refractive index

Excellent chemical resistance

Fine, uniform particle size for consistent results

🔹 Zr-325 & Zr-200

These grades cater to industries needing optimized thermal and structural performance. They are commonly used in:

Refractory molds

Tile glazes

Abrasive manufacturing

🔹 HL Series (HL-50, HL-40, HL-20)

Developed to meet the customized needs of different industrial sectors, the HL Series is ideal for clients looking for performance-specific zircon for manufacture. The HL series combines:

High purity zircon

Controlled particle distribution

Versatile application across multiple sectors

A Trusted Name in Zirconium Silicate Manufacturing

As a full-scale zircon flour manufacturing company, we specialize in processing zirconium silicate to industry-grade standards. Here’s how our Zirconium silicate manufacturing process stands out:

✅ Sourcing premium-grade zircon sand

✅ State-of-the-art micronizing and calcining equipment

✅ Strict QC protocols at every stage

✅ Bulk packaging for global exports

✅ Compliance with ISO and international material safety standards

Why Choose Our Company for Zircon Products?

Here’s what sets us apart as one of India’s leading zircon suppliers:

✔ Consistent Product Quality

Each batch of zircon powder undergoes rigorous testing for purity, fineness, and chemical stability.

✔ Global Export Capability

We export to markets like Italy, England, Poland, Myanmar, Nepal, Turkey, and more—delivering timely, reliable service and logistics.

✔ Tailored Industrial Solutions

Our technical team collaborates with clients to provide the right zircon grade for their specific application.

✔ Transparent Pricing

We monitor global zirconium price trends to provide competitive, fair pricing to our clients across industries.

Serving Key Industries Around the World

As a trusted zircon flour manufacturing company, we cater to a variety of industries:

Ceramics: Opacifier in glazes for tiles and sanitaryware

Refractories: Enhances thermal resistance in kilns and furnaces

Glass & Foundries: Improves surface finish and thermal durability

Paints & Coatings: Used as a stabilizing filler

Final Thoughts

If you're looking for a reliable partner for Zirconium silicate manufacturing, or a steady supplier of zircon powder for ceramics, refractories, or industrial coatings, Astron Group is here to deliver. Our Zr-P5, ZrS5, Zr-325, and HL Series powders are engineered for performance, purity, and reliability—making us a preferred choice in India and beyond.

0 notes

Text

Top Reasons to Choose Reliable Zircon Product Suppliers for Your Business in Poland

Introduction

In Poland’s growing industrial sector, sourcing high-quality raw materials is vital for manufacturing success. When it comes to zircon powder and related products, selecting dependable suppliers can make all the difference in product performance and operational efficiency. Whether you’re in ceramics, refractories, or advanced manufacturing, partnering with trusted zircon suppliers in Poland ensures your business gets the best zircon raw material for your applications.

Why Zircon Powder Quality Matters

Zircon powder, primarily made from zirconium silicate, is widely used for its durability, thermal resistance, and chemical stability. These properties make it essential for industries such as ceramics, foundries, glass, and electronics.

Low-quality zircon powder can lead to inconsistent product quality, higher waste, and increased production costs. That’s why choosing reliable zirconium silicate powder suppliers in Poland is crucial for maintaining competitive advantage.

Top Reasons to Choose Reliable Zircon Product Suppliers in Poland

1. Consistent Quality and Purity

Reliable suppliers adhere to strict quality controls to provide zircon powders with consistent chemical composition and particle size. This consistency is key to achieving precise manufacturing standards and superior finished products.

2. Comprehensive Product Range

Trusted zircon suppliers in Poland offer a wide variety of zircon powders, including different mesh sizes and grades like Zr-P5, ZrS5, Zr-325, and HL series. This variety allows manufacturers to select the exact zircon raw material suited for their unique industrial needs.

3. Timely Delivery and Logistics Support

The ability to deliver on time can impact production schedules significantly. Established suppliers have reliable logistics and export processes tailored to meet Poland’s market requirements, ensuring your zircon powder arrives when needed.

4. Technical Support and Custom Solutions

Top zircon suppliers don’t just sell products—they provide expertise. They help businesses optimize zircon powder use through technical advice and customized formulations, enhancing efficiency and product quality.

5. Competitive Pricing and Transparent Zirconium Price Tracking

A dependable supplier offers fair pricing aligned with current market zirconium price trends. Transparency in pricing helps businesses plan budgets effectively without unexpected cost fluctuations.

How to Identify the Best Zircon Suppliers in Poland

Check for certifications and compliance with European quality standards.

Evaluate their export and supply chain capabilities.

Review customer testimonials and industry reputation.

Confirm their ability to offer tailored zircon powder grades and quantities.

Final Thoughts

For businesses in Poland’s industrial sectors, partnering with reliable zirconium silicate powder suppliers in Poland is a strategic decision that directly impacts product quality and operational efficiency. By choosing trusted zircon suppliers Poland, you ensure access to premium zircon raw material and consistent service that supports your growth and competitive edge.

0 notes

Text

Astron Group is a global leader in high-quality zircon, ceramic glaze, and industrial products. We deliver premium materials with a commitment to excellence, reliability, and expert service. Trusted by industries worldwide for consistent quality and customer satisfaction.

Read More: https://astrongroup.in/

0 notes

Text

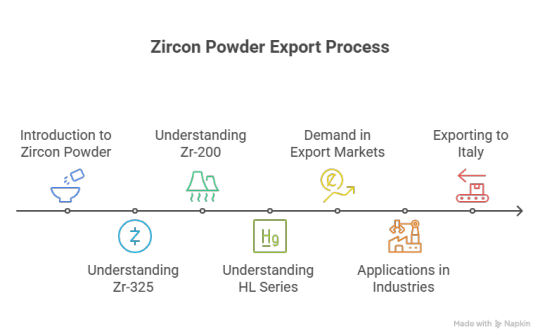

The Complete Guide to Zircon Powder Types: Understanding Zr-325, Zr-200, HL Series for Export

Introduction

Zircon powders play a crucial role in various high-performance industrial applications — from ceramics and refractories to advanced coatings and casting. When it comes to sourcing reliable zircon product types for export, it’s essential to understand the characteristics of each powder grade. This guide explores the widely used Zr-325, Zr-200, and the HL Series, highlighting their technical benefits, ideal applications, and why industries in export markets like Italy are increasingly choosing our products.

What Is Zircon Powder?

Zircon powder, typically derived from zirconium silicate (ZrSiO₄), is valued for its high melting point, chemical stability, and resistance to corrosion and abrasion. It is widely used in the ceramic, foundry, refractory, and glass industries due to its thermal properties and opacifying ability.

As a trusted ceramic zircon supplier, we offer a wide range of zircon products designed for consistent quality and global export demands.

Key Zircon Powder Types for Industrial Use

1. Zr-325 Zircon Powder

Particle Size: Ultra-fine (325 mesh)

Application: Ideal for ceramic glaze, tile manufacturing, and high-precision casting.

Advantage: Smooth surface finish, better dispersion in ceramic bodies, and improved whiteness.

2. Zr-200 Zircon Powder

Particle Size: 200 mesh

Application: Used in refractory bricks, abrasive products, and mold coatings.

Advantage: Superior high-temperature resistance and thermal stability.

3. HL Series Zircon Powders (HL-50, HL-40, HL-20)

Custom-graded for niche applications.

HL-50: Fine-grade for high-gloss ceramic tiles.

HL-40/HL-20: Balanced for refractory linings and ceramic compounds.

Ideal for manufacturers seeking tailored solutions across various industries.

Why Our Zircon Products Are in High Demand for Export

As one of the most reliable zirconium silicate powder suppliers in Italy, we understand the needs of industries that require precise material specifications and consistent quality. Our zircon powders are exported globally with a strong demand from Italy’s ceramic hubs and manufacturing sectors.

Here’s why clients in Italy and across Europe choose us:

Consistent Purity

Strict Quality Control

On-time Export Logistics

Competitive Zirconium Price

Expert Support for Industrial Clients

We also monitor zirconium price fluctuations to ensure transparent pricing for long-term buyer confidence.

Applications of Zircon Products in Global Industries

Ceramic Tiles & Sanitaryware: Improves glaze texture and strength.

Refractories: Used in kilns, furnaces, and high-heat processes.

Glass & Foundry: Enhances resistance to thermal shock and wear.

Paints & Coatings: Acts as an inert pigment for durable coatings.

As prominent ceramic zircon suppliers, we ensure our products align with the evolving needs of international manufacturers.

Exporting to Italy: Quality You Can Trust

Italy, known for its world-class ceramic and industrial manufacturing, demands nothing short of excellence. Our specialized zircon powders are engineered to meet the rigorous standards of the Italian market. With strong logistics infrastructure and compliance with EU export norms, we are proud to be among the leading zirconium silicate powder suppliers in Italy.

Final Thoughts

Whether you're looking for high-performance Zr-325 for fine ceramics, durable Zr-200 for refractories, or custom HL Series blends for specialized uses, our zircon products are designed for reliability and export excellence. As your trusted ceramic zircon supplier, we are committed to delivering superior products and consistent quality to clients across Italy and beyond.

0 notes

Text

Top Zircon Products for Industrial Use: Why England Chooses Our Zr-P5, ZrS5, and More

In today’s competitive industrial landscape, choosing the right raw materials is critical for quality, durability, and performance. One such material that plays a vital role in various industries across England is zircon product — specifically high-quality zircon powders like Zr-P5, ZrS5, and others. As one of the leading high purity zircon powder suppliers in UK, we take pride in offering premium-grade zircon products tailored to meet England’s diverse industrial needs.

What Makes Our Zircon Products Stand Out?

Zircon powders are essential components used in ceramics, refractory materials, foundries, and electronics. The purity, particle size, and chemical stability of zircon powder directly influence the final product’s quality. Our zircon powders, including Zr-P5, ZrS5, Zr-325, and Zr-200, are manufactured under strict quality controls to ensure consistency and superior performance.

Zr-P5: Known for its fine particle size and exceptional purity, Zr-P5 is widely used in ceramic glazes and advanced refractory applications.

ZrS5: With excellent thermal stability, ZrS5 is ideal for industries requiring high-temperature resistance.

Zr-325 and Zr-200: These powders provide smooth finishes and high durability, making them suitable for various industrial processes.

Why England’s Industrial Sector Prefers Our Zircon Powders

England’s industrial sectors, from ceramics manufacturing to aerospace and electronics, demand zircon powders that guarantee reliability and efficiency. Here’s why our zircon products have become the preferred choice:

Consistent High Purity: Our powders meet rigorous purity standards, ensuring no compromise in product quality.

Custom Particle Sizes: Tailored powders for specific industrial applications improve manufacturing outcomes.

Reliable Export Supply Chain: We ensure timely deliveries across England, backed by seamless logistics support.

Compliance with UK Standards: All products adhere to the quality and safety standards required for use in England’s regulated industries.

Applications of Zircon Products in England

Ceramic Industry: Zircon powders like Zr-P5 improve glaze opacity and thermal resistance, enhancing ceramic durability.

Refractory Materials: High purity zircon withstands extreme temperatures, making it ideal for furnace linings and mold casting.

Electronics: Zircon's chemical stability supports the manufacture of capacitors and insulators.

Foundries: Used as molding materials to improve casting precision and surface finish.

Partner with a Trusted High Purity Zircon Powder Supplier in UK

Choosing the right supplier is as important as choosing the right zircon product. As trusted high purity zircon powder suppliers in UK, we combine technical expertise with a customer-centric approach. Our team works closely with industrial clients in England to understand their unique needs and provide solutions that drive success.

Whether you’re seeking Zr-P5 for ceramic manufacturing or ZrS5 for refractory applications, our zircon products deliver unmatched quality and performance.

Final Thoughts

If you’re in England and require high-grade zircon products that meet strict industrial standards, look no further. Our range of zircon powders, including Zr-P5, ZrS5, Zr-325, and more, is crafted to help your business stay ahead in quality and reliability. Contact us today to learn more about our zircon powders and how we can support your industrial goals.

1 note

·

View note