Don't wanna be here? Send us removal request.

Text

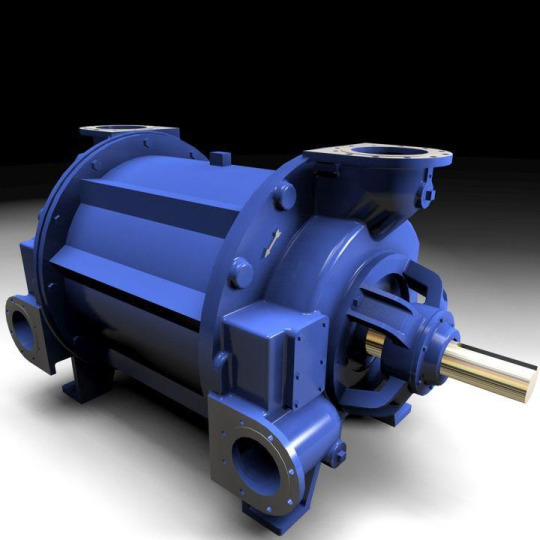

How to Select the Best Liquid Ring Pumps and Compressors Manufacturer for Your Business?

Selecting the right liquid ring pumps and compressors manufacturer is a critical decision for any business that relies on vacuum and compression technologies. These systems play an essential role in industries like chemical processing, pharmaceuticals, food and beverage, power generation, and wastewater treatment. Choosing a dependable manufacturer ensures long-term efficiency, reduced downtime, and optimal performance of your systems.

With a growing number of manufacturers in the market, identifying the best one for your specific needs can be a challenge. This guide will help you understand the key factors to consider when choosing the ideal liquid ring pump and compressor partner for your business.

1. Understand Your Application Requirements

Before approaching a manufacturer, it’s important to define your process requirements:

What medium will the pump or compressor handle (air, gas, vapor, etc.)?

Is the application continuous or intermittent?

What is the required capacity, vacuum level, and pressure?

Once you are clear about the technical specifications, it becomes easier to evaluate whether a liquid ring pumps and compressors manufacturer can meet your operational expectations.

2. Evaluate Manufacturing Expertise and Capabilities

Not all manufacturers offer the same level of engineering precision or product quality. Look for a manufacturer that:

Has a proven track record in designing and producing liquid ring pumps and compressors.

Offers standardized models as well as customized solutions tailored to specific industries.

Maintains in-house design, machining, and testing facilities to ensure quality control.

Also, consider their compliance with certifications like ISO or CE which reflect adherence to international standards.

3. Check Material Quality and Build Standards

Durability and long-term performance are directly tied to the materials used in construction. Ask potential manufacturers about:

The grade of stainless steel, cast iron, or other metals used.

Corrosion resistance in challenging industrial environments.

Quality checks and testing protocols before dispatch.

A trustworthy manufacturer will be transparent about materials, offering full technical documentation.

4. After-Sales Support and Service Network

Even the most reliable equipment requires maintenance and support over its lifecycle. Choose a manufacturer that provides:

Easy access to spare parts and service technicians.

On-site installation, training, and troubleshooting assistance.

Preventive maintenance contracts to reduce unexpected breakdowns.

Efficient after-sales support often separates average manufacturers from exceptional ones.

5. Reputation and Client Feedback

Look for case studies, customer reviews, or referrals from businesses similar to yours. Reputable manufacturers often have:

A long-standing presence in the market.

Positive word-of-mouth among peers in your industry.

Documented success in handling both small and large-scale installations.

While flashy marketing may look impressive, it's real-world performance and customer satisfaction that truly matter.

6. Innovation and Technological Advancements

Technology is constantly evolving, even in mechanical systems like liquid ring pumps and compressors. Consider a manufacturer that:

Offers energy-efficient designs to lower operational costs.

Incorporates smart control systems and sensors for monitoring and diagnostics.

Keeps up with international trends and upgrades their product range accordingly.

This forward-thinking approach ensures your business won’t be stuck with outdated technology.

Conclusion

Choosing the right liquid ring pumps and compressors manufacturer is an investment in your business’s reliability, efficiency, and future growth. By focusing on technical compatibility, manufacturing quality, service reliability, and innovation, you can confidently select a partner that supports your success across every stage of your operations.Get in touch with trusted Liquid Ring Pump and Compressor experts today and explore efficient, customized solutions tailored to your industry needs and visit: https://www.kakatipumps.com/

0 notes

Text

Liquid Ring Vacuum Pumps in India: What’s New in 2025?

As industrial applications continue to evolve, liquid ring vacuum pumps remain a cornerstone of dependable and efficient vacuum generation. With their robust design, durability, and ability to handle wet and dirty gases, these pumps are widely used in industries such as pharmaceuticals, food processing, paper, chemical manufacturing, and power generation. In 2025, India’s liquid ring vacuum pump sector is witnessing significant transformations driven by innovation, sustainability, and global demand.

The Indian Market: Expanding Horizons

India has steadily emerged as a key player in the global vacuum pump market. Backed by strong engineering capabilities and cost-effective manufacturing, the country has become a preferred destination for sourcing these high-performance machines. Liquid Ring Vacuum Pump Manufacturers in India are increasingly catering not just to domestic needs but also to global demands from Southeast Asia, Europe, and Africa.

What makes Indian manufacturers stand out is their ability to combine international quality standards with competitive pricing. In 2025, this trend continues with a stronger emphasis on R&D, customized engineering solutions, and environmental compliance.

Key Trends Driving the Market in 2025

1. Energy Efficiency and Eco-Conscious Designs

Modern industries are moving toward greener technologies. Liquid ring vacuum pumps are now being designed with reduced energy consumption in mind. Indian manufacturers are adopting advanced impeller designs, variable frequency drives (VFDs), and smart monitoring systems that significantly improve the operational efficiency of these pumps.

2. Smart Integration and IoT Compatibility

With Industry 4.0 taking firm root, pumps are no longer just mechanical devices. IoT-enabled vacuum pumps can now monitor pressure levels, operating temperatures, and maintenance cycles in real-time. This predictive maintenance feature helps reduce downtime and boosts productivity, especially in critical process industries.

3. Compact and Modular Designs

Space-saving and modular construction have become a necessity for many industries. Liquid ring vacuum pumps manufactured in India are being redesigned to be more compact while maintaining or even enhancing performance. This shift is particularly beneficial for SMEs and export-focused industries with limited plant space.

4. Export Quality Compliance

Increased emphasis on compliance with international standards such as ISO, CE, and ATEX ensures that Indian-made pumps can meet global expectations. Many Liquid Ring Vacuum Pump Manufacturers in India are investing in certifications and quality systems to strengthen their global footprint.

5. Customized Engineering Solutions

2025 sees a rising demand for application-specific solutions. Whether it's corrosion-resistant materials for chemical plants or food-grade pumps for processing units, manufacturers are offering tailored designs that meet unique industrial requirements.

Future Outlook: Growth Through Innovation

The coming years hold immense promise for the Indian vacuum pump industry. With supportive government policies, increased industrialization, and growing international trust in Indian engineering, the market is projected to grow steadily.

Moreover, Indian manufacturers are expected to adopt more sustainable production techniques and integrate renewable energy into their operations. From better metallurgy to more intelligent controls, every aspect of liquid ring vacuum pump design and manufacture is undergoing transformation.

Conclusion

The year 2025 marks a new chapter for liquid ring vacuum pumps in India, one defined by smart technology, energy efficiency, and global competitiveness. With a strong focus on quality, customization, and innovation, Liquid Ring Vacuum Pump Manufacturers in India are not only meeting current industrial needs but also preparing for the future of smart manufacturing.

If you're looking to stay ahead in your industry with reliable vacuum solutions, now is the time to explore the latest advancements coming out of India’s thriving pump manufacturing ecosystem.

Request a free quote today and discover how advanced Indian-made vacuum pumps can enhance your operational efficiency.

Visit: https://www.kakatipumps.com/

0 notes

Text

The Rise of Liquid Ring Vacuum Pump Manufacturing in India’s Industrial Sector

India’s industrial landscape has undergone a remarkable transformation in recent years, with sectors such as chemicals, pharmaceuticals, food processing, and power generation experiencing substantial growth. Among the critical components driving efficiency and performance in these sectors is the liquid ring vacuum pump, a versatile and reliable solution for vacuum generation. As demand for high-performance vacuum technology surges, liquid ring vacuum pump manufacturing in India has seen an unprecedented rise.

Why Liquid Ring Vacuum Pumps?

Liquid ring vacuum pumps are prized for their simple design, durability, and ability to handle wet, dry, and slightly corrosive gases. They are widely used in applications such as:

Vacuum distillation in chemical plants

Moisture removal in food processing

Filtration and drying in pharmaceuticals

Deaeration in paper and pulp industries

Condenser evacuation in power plants

This versatility has created strong domestic and international demand for these pumps, positioning India as a significant player in the global vacuum pump market.

Growth Factors Driving Indian Manufacturing

Several key factors have contributed to the growth of liquid ring vacuum pump manufacturers in India:

1. Government Support and Industrial Policies

India's "Make in India" initiative and various production-linked incentive (PLI) schemes have provided manufacturers with the support needed to scale operations, invest in R&D, and upgrade technology. These initiatives have played a pivotal role in encouraging local manufacturing of high-performance vacuum systems.

2. Skilled Engineering Talent

India boasts a large pool of skilled engineers and technicians who specialize in mechanical design and fluid dynamics. This technical capability has helped local manufacturers develop robust, energy-efficient, and application-specific vacuum solutions.

3. Cost-Effective Production

Competitive labor and manufacturing costs allow Indian companies to offer quality products at lower prices. This cost advantage has made Indian-made vacuum pumps attractive to both domestic buyers and global importers looking for high performance at a reasonable cost.

4. Export Opportunities

Indian manufacturers are increasingly exporting to regions like the Middle East, Southeast Asia, Africa, and Europe. As a result, many companies have aligned their production to meet international quality standards such as ISO and CE certifications.

5. Innovation and Customization

Modern industries require tailored vacuum solutions to meet specific process requirements. Indian manufacturers have been quick to adopt automation, digital monitoring, and material enhancements to deliver custom-built vacuum pumps for niche applications.

The Future of Liquid Ring Vacuum Pump Manufacturing in India

The future looks promising. With increasing investments in infrastructure, pharmaceuticals, and sustainable energy, the demand for efficient vacuum systems is only expected to grow. Indian manufacturers are actively expanding their production capacities and incorporating eco-friendly, energy-efficient technologies to stay ahead of global trends.

Moreover, the growing emphasis on sustainability is pushing companies to develop oil-free and water-saving vacuum systems, ensuring that India's manufacturing ecosystem remains both innovative and environmentally responsible.

Conclusion

The rise of liquid ring vacuum pump manufacturers in India reflects a broader trend of technological self-reliance and industrial capability. With a perfect blend of innovation, cost-effectiveness, and skilled manpower, India is rapidly becoming a global hub for vacuum pump solutions.

Ready to Explore Reliable Vacuum Pump Solutions?

If you're in the market for durable, efficient, and affordable vacuum solutions, it's time to explore what Indian manufacturers have to offer. From custom configurations to industry-standard models, you’ll find exactly what your operation needs.

Contact us today for detailed information, visit our website https://www.kakatipumps.com/

#Liquid Ring Vacuum Pump Manufacturing#Liquid Ring Vacuum Pump Manufacturers in India#vacuum pumps manufacturers and suppliers

0 notes

Text

Double Stage Vacuum Pump Buying Guide for Indian Customers

Vacuum pumps play a crucial role across a wide range of industries in India from pharmaceuticals and chemical processing to food packaging, electronics, and more. Among the various types of pumps, double stage vacuum pumps stand out for their enhanced efficiency, deeper vacuum capabilities, and reliable operation in demanding environments.

If you're a buyer, engineer, or decision-maker looking to invest in a quality double stage vacuum pump, this comprehensive guide is for you. Whether you’re replacing an old unit or installing a system from scratch, this blog will help you make an informed decision tailored to Indian industrial conditions. Working with experienced Double Stage Vacuum Pump Manufacturers in India ensures you get equipment designed for local needs, supported by accessible service and spare parts.

Choosing the right pump from reliable Double Stage Vacuum Pump Manufacturers in India can significantly impact your system’s performance, operational efficiency, and long-term return on investment.

What Is a Double Stage Vacuum Pump?

A double stage vacuum pump consists of two compression stages. The first stage removes the bulk of the gas, while the second stage reduces the pressure further to achieve a deeper vacuum. This two-step process makes these pumps ideal for applications requiring higher vacuum levels, consistent performance, and lower ultimate pressure compared to single stage alternatives.

Why Choose a Double Stage Vacuum Pump?

Here are some of the main advantages that make these pumps suitable for various industrial applications in India:

Deeper Vacuum Levels: Perfect for processes like distillation, drying, and degassing.

Stable Performance: Greater efficiency under continuous operation.

Low Maintenance: Designed to handle harsh industrial conditions with fewer breakdowns.

Versatile Application: Used in pharmaceutical, chemical, refrigeration, and packaging sectors.

Key Factors to Consider Before Buying

When evaluating options from double stage vacuum pump manufacturers in India, keep these critical aspects in mind:

1. Vacuum Requirements

Understand the vacuum level your application demands (measured in Torr or mbar). A mismatch can lead to poor performance or energy wastage.

2. Pump Capacity

Measured in cubic meters per hour (m³/h), this determines how quickly the pump can evacuate air. Match the capacity to your system volume and process needs.

3. Material Compatibility

Ensure that the pump’s materials are compatible with the gases or vapors in your application. Corrosion-resistant internals are vital for chemical or moisture-rich environments.

4. Energy Efficiency

Choose energy-efficient models that offer low power consumption without compromising performance. This is particularly relevant for Indian industries focused on sustainable operations.

5. Noise & Vibration Levels

Especially in labs and clean rooms, quieter pumps with lower vibration ratings are preferred.

6. After-Sales Service & Spare Availability

Check if the manufacturer offers prompt support, local servicing, and easily available spare parts. Working with reputed double stage vacuum pump manufacturers in India ensures better service coverage and shorter lead times.

Common Applications in Indian Industry

Double stage vacuum pumps are widely used across:

Pharmaceutical Manufacturing: For vacuum filtration, freeze drying, and solvent recovery.

Food Processing: In vacuum packaging and preservation.

Chemical Plants: For evaporation, drying, and degassing.

HVAC Systems: For refrigerant evacuation and leak detection.

Research Laboratories: For controlled atmosphere experiments.

Tips for Long-Term Reliability

Routine Maintenance: Follow the manufacturer’s maintenance schedule.

Monitor Operating Parameters: Regularly check temperature, oil level, and vacuum pressure.

Use Recommended Fluids: Always use pump oils or lubricants specified by the manufacturer.

Install Proper Filters: Protect the pump from dust, particulates, and condensable vapors.

Final Thoughts

Choosing the right double stage vacuum pump is not just about specs, it's about matching performance to process needs, ensuring durability, and securing long-term serviceability. By working with experienced Double Stage Vacuum Pump Manufacturers in India, you can ensure the right balance of quality, affordability, and ongoing support.

Ready to Make the Right Choice?

Whether you're upgrading your existing system or setting up a new process line, don’t compromise on performance. Invest in a double stage vacuum pump that delivers long-term value and reliability.

Contact us today for detailed information, visit our website https://www.kakatipumps.com/

0 notes

Text

Understanding Vacuum Pumps: A Complete Guide for Buyers

https://www.kakatipumps.com/vacuum-pumps-manufacturers-and-suppliers.php

Whether you're venturing into industrial automation, research labs, or cleanroom environments, selecting the right vacuum pump is crucial to ensuring smooth operations, product quality, and process efficiency. However, with so many types, specifications, and technologies available, choosing the right equipment can be a daunting task especially if you're a first-time buyer.

This comprehensive guide walks you through the key aspects of vacuum pumps, from how they work to what to consider when selecting one. By the end, you'll be equipped with the knowledge to confidently choose the best solution for your application.

What is a Vacuum Pump and How Does It Work?

A vacuum pump is a device that removes gas molecules from a sealed environment to create a partial or complete vacuum. This process allows for various scientific, industrial, and manufacturing applications where air and other gases would interfere with desired outcomes. Vacuum Pumps Manufacturers And Suppliers play a crucial role in providing high-performance equipment tailored to meet the specific needs of these applications.

Vacuum pumps function through several mechanisms, such as:

Mechanical displacement – physically moving air or gas out of a chamber.

Entrapment – trapping gases on a surface using condensation or adsorption.

Momentum transfer – accelerating gas particles to a surface where they can be absorbed or redirected.

Main Categories of Vacuum Pumps

Vacuum pumps are categorized based on their method of operation and the level of vacuum they can achieve:

1. Positive Displacement Pumps

These pumps work by expanding a cavity, allowing gases in, and then compressing the volume to push the gases out. Common examples:

Rotary Vane Pumps

Diaphragm Pumps

Scroll Pumps

Ideal for: General-purpose industrial applications, packaging, and vacuum drying.

2. Momentum Transfer Pumps

Also called molecular pumps, these accelerate gas molecules away using high-speed rotors.

Turbomolecular Pumps

Diffusion Pumps

Ideal for: Semiconductor, vacuum coating, and scientific research.

3. Entrapment Pumps

These capture gases through cooling or chemical reactions.

Cryopumps

Getter Pumps

Ideal for: High and ultra-high vacuum applications such as electron microscopy and space simulation.

Key Considerations When Choosing a Vacuum Pump

Purchasing a vacuum pump isn’t just about finding the most powerful unit, it's about finding the right match for your needs. Here are critical factors to evaluate:

1. Application Requirements

What are you using the pump for? Vacuum packaging has very different needs from plasma etching or freeze-drying.

2. Chemical Compatibility

Ensure all pump materials are resistant to the gases or vapors in your process to avoid corrosion or contamination.

3. Flow Rate (Pumping Speed)

Measured in m³/h or L/min, this tells you how quickly the pump can evacuate a volume.

4. Noise and Vibration

In laboratories or precision environments, quieter operation is essential.

5. Maintenance and Cost of Ownership

Some pumps require oil changes, seal replacements, or regular downtime. Understand both initial cost and long-term maintenance needs.

6. Energy Efficiency

Energy-efficient pumps can reduce operating costs and environmental impact over time.

The Importance of Choosing the Right Manufacturer or Supplier

The performance and lifespan of your vacuum system depend heavily on the quality of the pump and by extension, the company that makes or supplies it. Reputable vacuum pumps manufacturers and suppliers don’t just provide equipment they offer:

Customized system recommendations

Technical support and spare parts

Installation and training services

Long-term maintenance plans

When evaluating options, look for:

ISO certifications

Positive customer feedback

Availability of parts and service

Industry-specific expertise

Working with experienced vacuum pumps manufacturers and suppliers ensures you’re not just buying a product, but a reliable solution that supports your process from start to finish.

Future Trends in Vacuum Technology

As industries evolve, so do vacuum technologies. Here are a few trends shaping the future:

Oil-Free & Eco-Friendly Systems: Reduced contamination and more sustainable operation.

Smart Pumps with IoT Integration: Monitor pump performance remotely, reduce downtime.

Miniaturization: Smaller, portable pumps for field applications and mobile labs.

Improved Energy Efficiency: Variable-speed drives and advanced control algorithms to reduce power consumption.

Being aware of these innovations can help you invest in equipment that remains relevant and efficient for years to come.

Conclusion

Vacuum pumps are essential in modern industries but choosing the right one requires more than a quick catalog browse. Understanding the pump types, application requirements, and key specifications ensures you select equipment that delivers performance, efficiency, and reliability.

Whether you need a rough vacuum for packaging or ultra-high vacuum for advanced research, take time to evaluate your options carefully and always partner with a trusted supplier.

Ready to Choose the Right Vacuum Pump?

Don’t let guesswork drive your purchase. Get expert advice tailored to your industry and application from trusted professionals.

Explore our wide range of vacuum pumps designed to meet every industrial and laboratory need.

For more detailed information on specific products and solutions, visit the https://www.kakatipumps.com/

#vacuum pumps manufacturers and suppliers#liquid ring vacuum pump#single stage water ring vacuum pump

0 notes

Text

Advancements in Liquid Ring Vacuum Pump Technology: What Manufacturers and Suppliers Are Doing Differently

Introduction

Liquid ring pumps and compressors have been integral to various industrial applications for over a century. Their simplicity, reliability, and versatility make them ideal for handling wet, dirty, or aggressive gases. However, as industries evolve, so must the technologies that support them. Recent advancements in liquid ring pump and compressor technology are reshaping the landscape, offering manufacturers enhanced efficiency, sustainability, and operational flexibility. Liquid Ring Pumps and Compressors Manufacturers are at the forefront of these innovations, developing solutions that meet the increasingly complex demands of modern industries.

1. Embracing Digitalization: IoT and Smart Monitoring

The integration of Internet of Things (IoT) technology into liquid ring pumps and compressors has ushered in a new era of predictive maintenance and real-time monitoring. Manufacturers can now leverage sensors and cloud-based platforms to monitor parameters such as pressure, temperature, and vibration. This data-driven approach enables early detection of potential issues, reducing downtime and extending equipment lifespan.

For instance, the introduction of smart monitoring systems that utilize AI to predict maintenance needs has led to a 35% reduction in operational downtime. Such innovations are particularly beneficial for industries where unplanned downtime can lead to significant financial losses.

2. Enhancing Energy Efficiency

Energy consumption is a critical concern for manufacturers, especially in energy-intensive processes. Advancements in liquid ring compressor design have focused on improving energy efficiency without compromising performance. Modern compressors are now designed to handle higher capacities with less energy, thanks to innovations like variable speed drives and optimized impeller designs.

Their designs require minimal maintenance and are capable of handling higher capacities with less energy consumption.

3. Advancements in Materials and Construction

The materials used in the construction of liquid ring pumps and compressors have seen significant improvements, enhancing their durability and resistance to corrosive environments. Manufacturers are now utilizing advanced alloys and coatings that prolong the life of these systems, even in harsh chemical and marine applications.

4. Customization and Modular Design

The demand for tailored solutions has led to the development of modular and customizable liquid ring compressors. Manufacturers can now design systems that precisely meet the specific needs of their applications, whether it's handling toxic gases, achieving ultra-low emissions, or fitting into space-constrained environments.

For instance, bespoke liquid ring compressors with features like front pull-out designs for easy maintenance and conical distributors for efficient seal liquid circulation are available. These customizable features ensure optimal performance and reliability in demanding applications.

5. Environmental Sustainability and Emission Reduction

Environmental regulations are becoming increasingly stringent, pushing manufacturers to adopt greener technologies. Advancements in liquid ring compressor technology have focused on reducing emissions and water usage, aligning with global sustainability goals.

Some manufacturers have developed ultra-low emission liquid ring compressors that reduce water usage by 40% and improve gas handling efficiency by 30%, contributing to more sustainable operations. Such innovations not only help in complying with environmental regulations but also result in cost savings over time.

6. Industry-Specific Innovations

Different industries have unique requirements, leading to specialized advancements in liquid ring pump and compressor technology.

Chemical and Petrochemical Industries: In these sectors, compressors are designed to handle highly flammable and corrosive gases such as chlorine and flare gas. These compressors are constructed from materials resistant to corrosion, such as austenitic stainless steel or titanium, depending on the specific application. The use of isothermal compression technology ensures that the temperature rise during gas compression is minimal, maintaining the integrity of the gas and the compressor system. Additionally, the selection of appropriate seal liquids plays a crucial role in the performance and longevity of these systems.

Pharmaceutical Industry: In pharmaceutical manufacturing, liquid ring vacuum pumps are utilized for their ability to handle vapors and gases without contamination. These pumps operate nearly isothermally, reducing the risk of unwanted reactions or explosions. The operating fluid in the compression chamber continuously dissipates the compression heat, facilitating the condensation of vapors and increasing the nominal pumping speed. The choice of operating fluid depends on the specific requirements of the process and the properties of the gases involved.

Wastewater Treatment: In wastewater treatment plants, liquid ring compressors are employed to improve aeration, gas recovery, and vacuum filtration processes. These compressors are essential for efficient biological treatment processes, ensuring that oxygen is supplied to microorganisms for the breakdown of organic matter. The adoption of energy-efficient liquid ring compressors has led to significant reductions in energy usage, enhancing the sustainability of wastewater treatment operations. Modern systems are also integrated with automated control systems, further optimizing water purification efficiency.

Additional Industry-Specific Use Cases for Liquid Ring Vacuum Pumps

Food and Beverage Industry: In vacuum packaging and freeze-drying processes, liquid ring vacuum pumps offer the benefit of isothermal compression, which protects product integrity by minimizing heat generation. Their ability to handle vapor-laden gas streams makes them ideal for moisture-rich environments.

Power Generation: Vacuum pumps play a key role in condenser evacuation systems, helping improve turbine efficiency and reduce energy consumption. Liquid ring pumps, in particular, are favored due to their durability and consistent performance under variable loads.

Pulp and Paper Industry: These pumps are essential for dewatering and vacuum forming applications. Recent innovations focus on energy-optimized impellers and water recirculation systems, which lower operational costs while increasing output.

7. The Future Outlook

The future of liquid ring pumps and compressors is poised for continued innovation. As industries evolve, there will be a greater emphasis on integrating advanced technologies like artificial intelligence, machine learning, and automation into these systems. Manufacturers will need to stay abreast of these developments to maintain competitiveness and meet the ever-changing demands of the market.

Specialized Advances in Liquid Ring Vacuum Pumps

Recent developments have honed in on the unique demands of liquid ring vacuum pumps, especially for applications requiring reliable, contamination-free, and energy-efficient vacuum solutions. Manufacturers are investing in dual-stage vacuum systems, which achieve deeper vacuum levels while maintaining high operational stability. These systems are especially valuable in industries like pharmaceuticals and electronics manufacturing, where vacuum purity and consistency are critical.

Furthermore, closed-loop water recovery systems are now being integrated into many liquid ring vacuum pump designs. These systems significantly reduce water consumption and environmental impact, an essential advancement in regions with strict water use regulations.

Conclusion

Advancements in liquid ring pump and compressor technology are transforming the manufacturing landscape. From digitalization and energy efficiency to environmental sustainability and industry-specific innovations, these developments offer manufacturers the tools needed to enhance performance, reduce costs, and meet regulatory requirements. By embracing these advancements, manufacturers can ensure their operations remain efficient, competitive, and aligned with future industry trends.

Call to Action

Interested in how cutting-edge liquid ring vacuum pump technologies are reshaping your industry? Whether you're in pharmaceuticals, food processing, wastewater treatment, or energy production, today’s manufacturers are offering smarter, more efficient, and more sustainable solutions. Connect with trusted leaders like https://www.kakatipumps.com/ who are pioneering next-generation vacuum pump systems tailored to your unique needs. From modular designs to water-saving technologies, their expertise ensures your operation stays ahead of the curve.

0 notes

Text

Kakati Pumps: Leading the Way in Two-Stage Liquid Ring Compressors

In today’s fast-paced industrial world, the need for reliable, efficient, and durable compressors is critical for the smooth operation of various processes. Kakati Pumps, a leading manufacturer and supplier, stands at the forefront of providing high-performance Two-Stage Liquid Ring Compressors that meet the diverse and demanding requirements of industries worldwide. With years of expertise and a focus on innovation, Kakati Pumps has become a trusted name for businesses looking for advanced compressor solutions.

What Are Two-Stage Liquid Ring Compressors?

A Two-Stage Liquid Ring Compressor is a type of positive displacement compressor designed to handle gases with a high moisture content, volatile chemicals, or even corrosive substances. Unlike single-stage compressors, which perform the compression in one step, two-stage compressors use two compression chambers to achieve higher pressures and greater efficiency. The two stages of compression allow for a more gradual increase in pressure, improving overall performance and energy efficiency.

The liquid ring part of the system is where the key technology lies. A rotating rotor moves within a housing, and liquid—usually water or a specific non-compressible fluid—is introduced to form a liquid ring around the rotor. This liquid forms a seal that helps compress the gas in the chamber. The addition of a second stage increases the compression ratio and ensures a smoother, more stable operation, particularly for challenging gases.

Why Choose Two-Stage Liquid Ring Compressors?

Kakati Pumps specializes in delivering Two-Stage Liquid Ring Compressors that provide superior performance in a variety of industrial applications. Here’s why these compressors are an ideal choice:

1. Higher Compression Ratios

The primary advantage of a two-stage liquid ring compressor is its ability to achieve higher compression ratios compared to single-stage compressors. This means that gases can be compressed to much higher pressures, making them suitable for applications that require a more powerful and efficient compression process.

2. Energy Efficiency

Due to their two-stage operation, these compressors are highly energy-efficient. The process of compressing gas over two stages minimizes the work required during each stage, resulting in lower power consumption. This translates into reduced operational costs for businesses, making it a cost-effective solution for large-scale operations.

3. Smooth and Pulsation-Free Operation

Two-stage liquid ring compressors provide a pulsation-free, smooth compression process. This is crucial in industries where maintaining constant pressure is important to ensure the quality and consistency of the final product. The liquid ring mechanism also ensures quieter operation, reducing noise pollution in sensitive environments.

4. Handling Wet and Contaminated Gases

One of the unique features of two-stage liquid ring compressors is their ability to handle wet, dirty, or contaminated gases without damaging the compressor components. This makes them ideal for industries such as wastewater treatment, chemical processing, and oil & gas, where gases with a high moisture content or volatile compounds need to be compressed.

5. Durability and Low Maintenance

Kakati Pumps’ two-stage liquid ring compressors are designed for durability. The use of high-quality materials, precision engineering, and corrosion-resistant parts ensures that the compressors can withstand harsh operating conditions, with minimal wear and tear. These compressors are also easy to maintain, reducing downtime and increasing overall system reliability.

Applications of Two-Stage Liquid Ring Compressors

Two-stage liquid ring compressors are highly versatile and are used across multiple industries due to their robust performance and adaptability. Here are some common applications:

Chemical and Petrochemical Industries: Used for gas recovery, solvent recovery, and vacuum distillation processes where high compression ratios are needed.

Oil and Gas: Essential for gas compression in natural gas processing, petrochemical applications, and refineries, where controlling gas flow and pressure is critical.

Wastewater Treatment: These compressors play a key role in aeration and gas handling systems for wastewater treatment, helping to reduce the environmental impact of harmful emissions.

Food and Beverage: Employed in food packaging and vacuum sealing applications, where maintaining a contamination-free environment is crucial.

Pharmaceutical: Used in processes such as freeze-drying, vacuum chambers, and solvent recovery, where precise control over pressure is necessary for product quality and safety.

Power Generation: These compressors are used in various power plant operations, including in gas turbines, to handle high-pressure gases in cooling and ventilation systems.

Why Choose Kakati Pumps for Your Two-Stage Liquid Ring Compressor Needs?

1. Industry Expertise

With years of experience in manufacturing and supplying compressors, Kakati Pumps has built a solid reputation for delivering high-quality two-stage liquid ring compressors. Their team of engineers and technicians possesses in-depth knowledge of compressor systems and can help design and optimize compressors that meet your specific needs.

2. Customization and Flexibility

Every industrial operation is unique, and Kakati Pumps understands that. They offer custom-designed two-stage liquid ring compressors to fit the specific requirements of your business, whether it's size, capacity, pressure levels, or operating environment. This personalized approach ensures optimal performance and cost-efficiency.

3. Premium Quality Manufacturing

Kakati Pumps is committed to providing products that exceed industry standards. Their two-stage liquid ring compressors are manufactured using high-grade materials, subjected to rigorous quality control processes, and tested for performance reliability. This commitment to quality ensures that their compressors provide long-lasting, trouble-free operation.

4. Global Supply Chain and After-Sales Support

Kakati Pumps has a robust global supply network that ensures timely delivery of compressors to customers around the world. In addition, they provide exceptional after-sales support, including installation, maintenance, and repair services. Their customer service team is available to troubleshoot issues and ensure your compressors remain in peak condition throughout their lifecycle.

5. Cost-Effectiveness

Despite the high-performance capabilities of their two-stage liquid ring compressors, Kakati Pumps offers competitive pricing, making it easier for businesses of all sizes to invest in reliable, efficient, and durable compression systems. The energy savings and reduced maintenance costs make these compressors a cost-effective long-term solution.

Conclusion

Kakati Pumps is a leading provider of Two-Stage Liquid Ring Compressors that offer unparalleled reliability, efficiency, and durability. Whether you’re in the chemical, pharmaceutical, food processing, or oil and gas industry, Kakati Pumps provides the right solutions for your gas compression needs. With their focus on quality, custom solutions, and after-sales support, Kakati Pumps ensures that your operations run smoothly and efficiently, all while reducing energy costs and enhancing overall productivity.

Choose Kakati Pumps for your two-stage liquid ring compressor needs, and experience the difference in performance, service, and value.

0 notes

Text

Kakati Pumps: Your Trusted Partner for Liquid Ring Compressors

In the world of industrial machinery, reliability, performance, and efficiency are crucial factors. For businesses looking for advanced solutions in gas compression, Kakati Pumps stands out as a leading manufacturer and supplier of high-quality Liquid Ring Compressors. With a reputation for engineering excellence and customer-centric service, Kakati Pumps delivers tailored solutions for industries ranging from chemicals to petrochemicals, and pharmaceuticals to food processing.

Understanding Liquid Ring Compressors

A Liquid Ring Compressor is a type of positive displacement compressor that uses a liquid—usually water or another non-compressible fluid—to create a seal around the rotating parts. This design ensures that the gas being compressed remains in constant contact with the liquid, which helps in controlling the compression process and preventing overheating. Liquid ring compressors are widely used for handling gases that are wet, have a high moisture content, or require gentle compression.

The versatility and efficiency of liquid ring compressors make them indispensable in various industrial applications. Unlike other types of compressors, these machines can operate in both suction and discharge modes, offering significant advantages in terms of performance and energy efficiency.

Kakati Pumps’ Expertise in Liquid Ring Compressors

At Kakati Pumps, the manufacturing of Liquid Ring Compressors involves advanced engineering, high-quality materials, and precision craftsmanship. Over the years, Kakati Pumps has established itself as one of the most trusted names in the industry for liquid ring compressor systems, known for their innovation, durability, and consistent performance.

Key Features of Kakati Pumps Liquid Ring Compressors:

Versatile PerformanceKakati Pumps’ liquid ring compressors are designed to handle a wide range of gases, including flammable, toxic, and corrosive gases. This versatility makes them an ideal choice for industries such as chemicals, oil and gas, and waste treatment plants, where different types of gases need to be compressed efficiently.

Energy EfficiencyThe use of liquid rings minimizes friction and mechanical losses, ensuring that the compressor operates with lower power consumption. This results in reduced operational costs, making it an attractive choice for businesses seeking to optimize their energy consumption.

Reliable and Robust ConstructionBuilt for durability, Kakati Pumps’ liquid ring compressors are made from high-quality materials that are resistant to wear and corrosion. Whether in harsh environments or demanding industrial processes, these compressors are engineered to withstand continuous operation with minimal maintenance.

Custom Solutions for Specific ApplicationsKakati Pumps understands that every industrial application is unique. That’s why they offer customization options for their liquid ring compressors, ensuring that the compressors are optimized for specific operational needs. From different sizes and capacities to specialized materials for extreme conditions, Kakati Pumps tailors each unit to meet the client's requirements.

Minimal MaintenanceDue to their simple design and fewer moving parts, liquid ring compressors generally require less maintenance than other types of compressors. The liquid ring mechanism also prevents issues like oil contamination and overheating, further reducing maintenance needs and improving system reliability.

Smooth OperationLiquid ring compressors are known for their smooth, pulsation-free operation, which is a critical factor in many industrial applications. This characteristic helps to avoid damage to sensitive equipment and ensures the consistent quality of the final product.

Applications of Liquid Ring Compressors

Liquid ring compressors are used across a wide spectrum of industries, thanks to their adaptability and robust performance. Some of the key applications include:

Chemical and Petrochemical Industry: Used in processes like vacuum distillation, gas recovery, and environmental protection.

Pharmaceutical Industry: Essential in systems that require precise pressure control, such as in the production of medical gases and air handling systems.

Food Processing and Packaging: Often used in vacuum pumps for food packaging and degassing applications, liquid ring compressors maintain the integrity of delicate products.

Oil and Gas: Liquid ring compressors are used in natural gas transportation, oil refineries, and various gas compression applications.

Water Treatment: These compressors are also used in wastewater treatment plants for aeration systems and gas handling.

Vacuum Applications: Liquid ring compressors are ideal for creating and maintaining vacuums in systems requiring stable suction pressure.

Why Choose Kakati Pumps for Your Liquid Ring Compressor Needs?

Industry LeadershipWith years of experience in the field, Kakati Pumps has become an industry leader in manufacturing and supplying liquid ring compressors. The company’s expertise in the design, installation, and maintenance of compressor systems makes it a trusted partner for businesses around the world.

Custom Engineering and DesignKakati Pumps offers custom-engineered solutions to meet the unique needs of every client. Whether you need a high-pressure system for an industrial application or a compact unit for a specific operational requirement, Kakati Pumps has the engineering capabilities to deliver optimal solutions.

Commitment to Quality and PerformanceKakati Pumps adheres to the highest quality standards in manufacturing. Each liquid ring compressor undergoes stringent testing to ensure it performs reliably under the most demanding conditions.

Global Reach and Timely DeliveryWith an efficient distribution network, Kakati Pumps ensures that its liquid ring compressors are available to customers worldwide. The company’s logistics capabilities ensure that products are delivered on time, minimizing downtime for your operations.

Comprehensive After-Sales SupportKakati Pumps provides unparalleled after-sales support, including maintenance, troubleshooting, and spare parts services. Their experienced technicians are ready to ensure that your compressors continue to perform at their best long after the installation.

Conclusion

Kakati Pumps continues to be a frontrunner in the field of Liquid Ring Compressors, offering high-quality, energy-efficient, and reliable solutions to industries worldwide. With a strong focus on innovation, performance, and customer satisfaction, Kakati Pumps is your go-to partner for all your compressor needs. Whether you're dealing with complex industrial processes or seeking a custom solution for a specialized application, Kakati Pumps provides the expertise, technology, and support to ensure smooth and efficient operations.

0 notes

Text

Kakati Pumps: Leading Vacuum Pumps Manufacturers and Suppliers

When it comes to reliable and high-performance vacuum pumps, Kakati Pumps stands out as a prominent name in the industry. Known for their commitment to quality, innovation, and customer satisfaction, Kakati Pumps has established itself as a trusted manufacturer and supplier of a wide range of vacuum pumps. Whether for industrial, laboratory, or commercial applications, Kakati Pumps provides solutions that meet the diverse needs of its global clientele.

The Role of Vacuum Pumps in Modern Industries

Vacuum pumps are essential devices that remove gas molecules from a sealed volume to create a vacuum. This process is vital in various industries such as pharmaceuticals, food packaging, automotive, and semiconductor manufacturing. Vacuum pumps help maintain controlled environments, improve product quality, enhance production efficiency, and even ensure the safety of workers.

For industries that rely on precision and high-performance equipment, the role of vacuum pumps cannot be overstated. High-quality vacuum pumps ensure consistent operation, minimal downtime, and reduced maintenance costs, making them indispensable in today’s fast-paced industrial world.

Kakati Pumps: Expertise in Vacuum Pump Technology

Kakati Pumps has earned a stellar reputation for being one of the leading vacuum pumps manufacturers and suppliers. With years of experience in the field, the company combines advanced engineering practices with the latest technological innovations to deliver vacuum pumps that cater to a variety of applications.

Comprehensive Range of Vacuum PumpsKakati Pumps manufactures a diverse range of vacuum pumps that cater to different industrial and commercial needs. Some of the popular types include:

Rotary Vane Vacuum Pumps: These are widely used for general vacuum applications. They offer excellent performance and reliability in creating a high vacuum, making them ideal for use in laboratories, food processing, and packaging.

Oil Sealed Vacuum Pumps: Known for their ability to create deep vacuum levels, oil-sealed pumps are commonly used in industrial applications where high efficiency is required.

Dry Vacuum Pumps: With no oil required, dry vacuum pumps are perfect for industries that require contamination-free operations. They are commonly used in the semiconductor, chemical, and pharmaceutical sectors.

Piston Vacuum Pumps: These pumps are designed for heavy-duty applications, offering durability and a longer lifespan for industries with higher vacuum requirements.

Claw Vacuum Pumps: These pumps are designed for efficiency and low energy consumption, making them ideal for use in applications like vacuum lifting systems and packaging.

Why Choose Kakati Pumps?

Customization and FlexibilityOne of the key strengths of Kakati Pumps lies in their ability to provide customized solutions. Understanding that each client’s requirements may differ, Kakati Pumps offers a range of customization options, ensuring that their vacuum pumps perfectly match the needs of your business. Whether you need a specific vacuum level, unique materials, or specialized configurations, Kakati Pumps works closely with clients to design the ideal system.

High-Quality Manufacturing StandardsKakati Pumps is committed to producing vacuum pumps that meet the highest quality standards. Their products undergo rigorous testing to ensure reliability and performance in even the most demanding environments. By using premium materials and precision engineering, Kakati Pumps ensures that their pumps deliver superior efficiency and durability.

Global Supply Chain and Timely DeliveryAs a leading supplier of vacuum pumps, Kakati Pumps has built a robust global supply chain, ensuring timely delivery and availability of products. Their efficient logistics network ensures that clients worldwide receive their orders promptly, minimizing any potential delays in production.

Cost-Effective SolutionsWhile quality is a priority, Kakati Pumps also understands the importance of offering cost-effective solutions. By optimizing production processes and maintaining strong relationships with suppliers, the company is able to provide high-quality vacuum pumps at competitive prices, making them accessible to a broad range of industries.

After-Sales Support and ServiceKakati Pumps goes beyond just providing vacuum pumps; they offer comprehensive after-sales support and maintenance services. Their dedicated customer service team is available to assist with troubleshooting, repairs, and regular maintenance, ensuring that your vacuum systems operate at peak efficiency throughout their lifespan.

Applications of Kakati Pumps in Various Industries

Kakati Pumps serves a wide range of industries that require vacuum technology, including:

Pharmaceutical Industry: For processes such as freeze-drying, solvent recovery, and packaging.

Food and Beverage: In vacuum sealing, packaging, and degassing processes.

Chemical and Petrochemical: For applications involving distillation, filtration, and degassing.

Electronics and Semiconductor: For creating controlled environments during manufacturing processes.

Automotive and Aerospace: In systems such as braking, molding, and vacuum testing.

Conclusion

As a trusted name among vacuum pumps manufacturers and suppliers, Kakati Pumps continues to lead the industry with innovative solutions, exceptional quality, and a focus on customer satisfaction. With an extensive range of products, custom solutions, and reliable after-sales support, Kakati Pumps is well-equipped to meet the growing demands of industries worldwide. Whether you're looking for high-performance rotary vane pumps or custom-engineered dry vacuum systems, Kakati Pumps provides the expertise and products that you can depend on for your most demanding applications.

0 notes

Text

Kakati Pumps: Trusted Vacuum Pumps Manufacturers and Suppliers for Industrial Excellence

When it comes to industrial pumping solutions, Kakati Pumps stands as a leading name in the market, renowned for delivering reliable, high-performance vacuum pumps. As a prominent vacuum pumps manufacturer and supplier, Kakati Pumps offers a comprehensive range of products that cater to various industries such as chemical processing, pharmaceuticals, food and beverage, power generation, and environmental systems. Their commitment to innovation, quality, and customer satisfaction makes them a preferred partner for businesses worldwide.

The Role of Vacuum Pumps in Industry

These processes include material handling, packaging, distillation, drying, and solvent recovery, among others. A vacuum is essential for eliminating air or gases from a sealed environment, which is necessary for achieving optimal conditions for various operations. As industries continue to evolve and require more precise, efficient, and energy-saving technologies, vacuum pumps have become integral to achieving higher performance and sustainability in manufacturing.

As a vacuum pumps manufacturer and supplier, Kakati Pumps understands the importance of delivering products that meet the exact needs of different applications while ensuring reliability, longevity, and low operating costs.

Why Choose Kakati Pumps for Your Vacuum Pump Needs?

Comprehensive Range of Vacuum Pumps: Kakati Pumps offers a diverse array of vacuum pumps, including liquid ring vacuum pumps, rotary vane pumps, diaphragm pumps, and oil-free vacuum pumps. This versatility allows businesses to select the perfect pump for their specific operational needs. Whether you're looking for a pump for heavy-duty industrial processes or a lightweight option for laboratory applications, Kakati Pumps has a solution for you.

Custom Solutions for Every Industry: Different industries have unique requirements when it comes to vacuum technology. Kakati Pumps recognizes that no two applications are alike. As such, the company provides customized solutions to ensure optimal performance in specific environments. Whether you require pumps for handling wet gases, vapors, or for precise vacuum control in cleanrooms, Kakati’s engineering team can tailor solutions to meet your exact specifications.

High-Quality Manufacturing Standards: As a leading vacuum pumps manufacturer, Kakati Pumps adheres to rigorous quality standards throughout the manufacturing process. Each pump is built using high-grade materials to ensure durability, performance, and longevity, even in harsh working environments. The company's pumps are also designed for easy maintenance, helping businesses reduce downtime and improve productivity.

Energy Efficiency and Cost Savings: Energy consumption is a significant concern for many industries, especially in high-demand processes. Kakati Pumps’ products are designed to operate with maximum efficiency, ensuring minimal energy consumption and reducing operational costs. Their focus on energy-efficient vacuum pumps helps businesses not only lower their carbon footprint but also save on utility bills, making them a cost-effective solution for long-term use.

Global Reach with Local Expertise: As a leading supplier, Kakati Pumps has established a global presence with a network of distributors and partners. The company works closely with clients to understand their specific needs and provides expert advice and technical support to ensure the best possible solution. Whether you’re based locally or globally, Kakati’s team ensures seamless delivery and support.

Reliable After-Sales Support: Kakati Pumps is committed to building long-term relationships with its customers, offering exceptional after-sales support. This includes installation, training, maintenance, and troubleshooting services to ensure the continued reliability and efficiency of your vacuum pumps.

Industries Served by Kakati Pumps

Kakati Pumps serves a broad range of industries where vacuum pumps are critical to operational success. Some of the major industries include:

Chemical and Petrochemical: Vacuum pumps are crucial for distillation, evaporation, filtration, and other processes in chemical plants. Kakati’s pumps provide consistent vacuum levels, improving the efficiency of chemical reactions and reducing energy consumption.

Pharmaceuticals: In pharmaceutical manufacturing, precise vacuum control is essential for processes such as drying, filtration, and the handling of sensitive materials. Kakati Pumps offers pumps that are compatible with stringent pharmaceutical industry standards.

Food and Beverage: Vacuum pumps are widely used in food packaging, vacuum frying, and other processes to maintain product quality. Kakati’s pumps are designed to ensure hygienic and reliable operation in food-related applications.

Power Generation: In power plants, vacuum pumps are used in condensers, cooling systems, and waste treatment. Kakati’s pumps provide high-performance vacuum solutions that are reliable even in challenging conditions.

Environmental Systems: Kakati Pumps also offers vacuum solutions for environmental and wastewater treatment, where the efficient removal of air or gases is crucial for proper system functioning.

Conclusion: Why Kakati Pumps is the Trusted Partner

As one of the leading vacuum pumps manufacturers and suppliers, Kakati Pumps has built a reputation for providing high-quality, energy-efficient, and reliable vacuum pump solutions. Their comprehensive range of products, custom engineering capabilities, and exceptional customer service make them a go-to choice for industries across the globe. With Kakati Pumps, businesses can trust that they are investing in products that deliver superior performance, cost savings, and operational efficiency.

If you’re looking for a vacuum pump manufacturer and supplier that understands your industry’s needs and can provide tailored solutions, look no further than Kakati Pumps. Contact them today for expert advice and the best vacuum pump solutions for your application.

0 notes

Text

Kakati Pumps: Leading the Way with Liquid Ring Vacuum Pumps for Industrial Excellence

When it comes to reliable and efficient vacuum solutions, Kakati Pumps has earned a solid reputation for providing high-quality pumps for various industrial applications. Among their standout products, the Liquid Ring Vacuum Pump is one of the most widely used and trusted solutions for creating powerful and consistent vacuum conditions. Renowned for its versatility, durability, and energy efficiency, Kakati’s Liquid Ring Vacuum Pumps play a key role in industries such as chemical processing, food production, pharmaceutical manufacturing, and environmental systems.

What is a Liquid Ring Vacuum Pump?

A Liquid Ring Vacuum Pump is a type of positive displacement pump that operates by creating a vacuum through the use of a liquid (usually water or another fluid) as a sealing medium. In this system, a rotating impeller within a cylindrical casing forms a liquid ring as it turns. This ring moves radially outwards, trapping gases in the cavities between the impeller blades, and then expelling the gas through a discharge port.

The liquid used in the pump creates a seal around the pump’s internal components, which prevents air from leaking in and allows the pump to maintain efficient suction. Unlike other types of vacuum pumps, liquid ring pumps are particularly well-suited for handling wet or vapor-laden gases, making them invaluable in many industrial processes that require the movement of gases, vapors, or air under vacuum conditions.

Key Features of Kakati’s Liquid Ring Vacuum Pump

Versatility in Applications: Kakati Pumps’ Liquid Ring Vacuum Pumps are ideal for a wide range of applications. They are particularly useful in industries such as chemical processing, power generation, distillation, solvent recovery, and food processing. These pumps can handle both dry and wet gas loads, making them a highly flexible option for various vacuum requirements.

Efficient Operation: The liquid ring design provides an effective and energy-efficient way to generate vacuum. Since the liquid ring acts as a seal, there is less friction and wear on the pump’s internal parts. This contributes to lower energy consumption, reduced operational costs, and a longer service life for the pump.

Low Maintenance Needs: One of the key advantages of the Liquid Ring Vacuum Pump is its relatively low maintenance requirements. The pump’s design minimizes wear and tear on moving components, reducing the frequency and cost of maintenance. Additionally, the use of a liquid seal helps eliminate the need for complex lubrication systems, further enhancing the pump's longevity and ease of upkeep.

Reliable Performance: Kakati’s Liquid Ring Vacuum Pumps are designed for continuous, high-performance operation, even in demanding environments. Whether you're dealing with vapors, gases, or liquids, these pumps offer steady and reliable vacuum generation to ensure smooth operation of your industrial processes.

Corrosion-Resistant Construction: Given that the pump operates with liquid, it is often exposed to moisture and chemicals. Kakati Pumps ensures that their Liquid Ring Vacuum Pumps are made from corrosion-resistant materials, which helps extend the life of the pump and ensures consistent performance in harsh environments.

Benefits of Choosing Kakati’s Liquid Ring Vacuum Pumps

Handling of Wet and Vapor-Laden Gases: One of the primary reasons industries choose liquid ring pumps is their ability to handle gases and vapors without losing performance. This makes them ideal for processes involving steam, volatile chemicals, or humid environments where other types of pumps may struggle.

Energy Efficiency and Cost-Effectiveness: Kakati’s Liquid Ring Vacuum Pumps are engineered for energy-efficient operation. The design minimizes power consumption while maintaining high levels of performance, making them a cost-effective choice for long-term industrial use.

Self-Priming Functionality: These pumps are capable of self-priming, meaning they can start operation without needing an external vacuum source. This feature makes them especially useful in systems that need to operate autonomously or when frequent startup is required.

Low Noise and Vibration: Liquid Ring Vacuum Pumps are known for their relatively quiet operation compared to other types of vacuum pumps. This makes them a favorable choice for environments where noise levels need to be kept to a minimum.

Why Choose Kakati Pumps for Your Liquid Ring Vacuum Needs?

Kakati Pumps is a trusted brand known for delivering high-performance, reliable, and energy-efficient pumping solutions. The company’s commitment to innovation, precision engineering, and customer satisfaction sets them apart as an industry leader. With a dedicated team of experts and a focus on quality, Kakati Pumps ensures that their Liquid Ring Vacuum Pumps meet the highest standards for reliability, efficiency, and durability.

Whether you are looking for a vacuum pump for a chemical plant, a food processing line, or any other industrial application, Kakati Pumps offers the ideal solution. Their Liquid Ring Vacuum Pumps are designed to deliver consistent performance, low maintenance, and long-term value.

For more information on Kakati Pumps’ Liquid Ring Vacuum Pumps or to inquire about a specific product for your application, get in touch with their team today.

0 notes

Text

Single Stage Water Ring Vacuum Pump by Kakati Pumps: A Powerful Solution for Industrial Applications

Kakati Pumps is a leading name in the field of industrial pump solutions, offering cutting-edge technology for a variety of applications. Among their extensive range of pumps, the Single Stage Water Ring Vacuum Pump stands out as an essential and reliable solution for industries that require efficient vacuum systems. Known for their robustness, ease of maintenance, and energy efficiency, Kakati’s Single Stage Water Ring Vacuum Pump plays a crucial role in a variety of sectors, including chemical, pharmaceutical, food processing, and power plants.

The Single Stage Water Ring Vacuum Pump is a type of rotary displacement pump that operates on the principle of water ring technology. Unlike traditional vacuum pumps that use mechanical seals or dry stages, a water ring pump relies on water as a sealing medium. The pump creates a vacuum by utilizing the centrifugal motion of a rotating impeller within a casing that is partially filled with water.

As the impeller rotates, it forms a ring of water inside the pump casing. This water ring moves outward, trapping air and gases, and then expelling them through a discharge port. This design results in a smooth, efficient suction process that generates a vacuum without the need for lubrication or heavy maintenance. The single-stage configuration means that only one impeller is used in the process, making it a simple yet effective solution for achieving a reliable vacuum.

Key Features of Kakati’s Single Stage Water Ring Vacuum Pump

Energy Efficiency: Kakati Pumps’ Single Stage Water Ring Vacuum Pumps are designed with energy efficiency in mind. The water ring technology minimizes the power consumption required to create the vacuum, making these pumps cost-effective to operate over the long term.

Low Maintenance: The water-sealing method reduces wear and tear on the internal components, which translates into less frequent maintenance. With fewer moving parts compared to other types of vacuum pumps, these pumps offer reliable performance with minimal upkeep.

Versatile Applications: Kakati Pumps’ water ring vacuum pumps are ideal for a variety of industries, including chemical processing, distillation, evaporation, and vacuum drying. They are particularly well-suited for handling vapors, gases, and liquid-ring applications.

Compact and Durable: The single-stage design results in a compact, space-efficient pump that fits well in both large-scale industrial setups and smaller facilities. Its durable construction ensures long-lasting performance even in harsh industrial environments.

Self-Priming and Quiet Operation: The self-priming nature of the water ring pump ensures reliable suction, even when the pump is started dry. Moreover, the operation is generally quieter compared to other vacuum pumps, contributing to a more comfortable work environment.

Benefits of Using Kakati’s Single Stage Water Ring Vacuum Pump

Low Risk of Contamination: Since the vacuum is generated using water, the chances of contamination are reduced compared to oil-lubricated pumps. This makes Kakati’s water ring pumps ideal for applications in sensitive industries such as pharmaceuticals and food processing.

Effective Handling of Wet and Vapory Loads: These pumps are designed to handle wet and vapor-laden gases efficiently, which is a common requirement in industries such as chemical production or solvent recovery. Their ability to function in these conditions without losing efficiency makes them a popular choice.

Cost-Effective Performance: The single-stage design not only reduces the initial investment but also helps lower ongoing operational costs. Less power consumption and fewer maintenance requirements contribute to substantial savings over time.

Why Choose Kakati Pumps?

Kakati Pumps has earned a strong reputation for producing high-quality, reliable pumps that meet the demanding needs of industrial applications. Their commitment to innovation and customer satisfaction ensures that businesses get the best solutions tailored to their specific requirements. With a proven track record in providing efficient pumping systems, Kakati Pumps remains a trusted partner for industries worldwide.

Whether you're looking to improve your existing vacuum system or need a new installation, Kakati Pumps’ Single Stage Water Ring Vacuum Pump offers an ideal solution for maintaining reliable and cost-effective vacuum conditions in a wide range of industrial processes.

For more information or to inquire about purchasing a Single Stage Water Ring Vacuum Pump, contact Kakati Pumps today.

0 notes

Text

Kakati Pumps: Leading the Way in Single Stage Water Ring Vacuum Pumps

In many industrial processes, vacuum systems are essential for ensuring the smooth operation of critical applications, from chemical processing to packaging and power generation. Among the various types of vacuum pumps, the Single Stage Water Ring Vacuum Pump is one of the most reliable and efficient solutions available. With its robust design and versatility, it’s a staple in industries that require stable, high-performance vacuum systems. Kakati Pumps, a leader in pump manufacturing, has established a strong reputation for delivering high-quality Single Stage Water Ring Vacuum Pumps tailored to meet the demands of modern industries.

Understanding Single Stage Water Ring Vacuum Pumps

A Single Stage Water Ring Vacuum Pump operates on a simple yet highly effective principle. This type of vacuum pump uses water as the sealing fluid, which forms a liquid ring inside the pump housing. As the impeller rotates, the liquid ring traps the gas or air being evacuated from the system, generating a vacuum. Since the process occurs in a single stage, these pumps are ideal for creating medium-level vacuum pressures.

Key characteristics of a Single Stage Water Ring Vacuum Pump include:

Simple Construction: The pump consists of fewer moving parts, making it easier to maintain and less prone to mechanical failure.

Energy Efficient: These pumps are designed to operate with minimal energy consumption, making them cost-effective over time.

Low Maintenance: The basic design and the use of water as a sealing medium result in lower maintenance requirements compared to other vacuum pump types.

Versatility: Suitable for handling gases, vapors, and even certain liquids, making it ideal for a wide range of industrial applications.

Why Opt for a Single Stage Water Ring Vacuum Pump?

The Single Stage Water Ring Vacuum Pump is known for its reliability, making it an excellent choice for industries with continuous or heavy-duty operations. The primary advantages of this type of pump include:

Cost-Effective Operation: The simplicity of the design leads to reduced maintenance costs and increased reliability, which translates into long-term cost savings.

Energy Efficient: These pumps consume less power, making them an energy-efficient choice for businesses focused on reducing operational costs and environmental impact.

Durability: The construction of a water ring pump is durable, designed to perform reliably even in challenging environments such as chemical plants or paper mills.

Environmentally Friendly: Since water is used as the sealing fluid, these pumps are less likely to pollute the environment, and the fluid can often be recirculated, further enhancing their sustainability.

Kakati Pumps: Your Trusted Partner for Single Stage Water Ring Vacuum Pumps

With decades of experience, Kakati Pumps is a trusted name in the manufacturing of industrial vacuum pumps, particularly Single Stage Water Ring Vacuum Pumps. Known for their cutting-edge technology and unwavering commitment to quality, Kakati Pumps has become a preferred partner for industries worldwide. Here’s what makes Kakati Pumps the leader in this field:

1. High-Performance Pumps for Diverse Applications

Kakati Pumps specializes in designing and manufacturing Single Stage Water Ring Vacuum Pumps that deliver superior performance in a wide variety of applications. Whether it’s chemical processing, food packaging, or wastewater treatment, Kakati Pumps ensures their pumps are engineered to meet the demands of each specific industry.

Key industries that benefit from Kakati Pumps' Single Stage Water Ring Vacuum Pumps include:

Chemical and Pharmaceutical Industries: Handling volatile, corrosive gases and maintaining consistent vacuum levels.

Food Processing: Assisting in vacuum sealing, packaging, and preserving food products.

Power Generation: Creating a vacuum for condensers and turbines to increase plant efficiency.

Paper and Pulp Industry: Used in dewatering processes during paper production.

Oil and Gas: Essential in gas extraction and vapor recovery systems.

2. Robust and Durable Design

Kakati Pumps understands the importance of reliability in industrial applications, which is why their Single Stage Water Ring Vacuum Pumps are built to last. Constructed with high-quality materials and designed for ease of operation, these pumps are resistant to corrosion and wear, ensuring they stand up to the toughest conditions.

3. Energy Efficiency and Cost Savings

In today’s competitive industrial landscape, energy efficiency is more important than ever. Kakati Pumps focuses on delivering Single Stage Water Ring Vacuum Pumps that not only meet performance expectations but also optimize energy consumption. These pumps are designed to operate efficiently, ensuring businesses can reduce their power consumption and lower their operating costs. With less energy required to achieve the desired vacuum level, these pumps deliver substantial cost savings over the long term.

4. Low Maintenance and Easy Operation

Kakati Pumps’ Single Stage Water Ring Vacuum Pumps are designed for ease of use and minimal maintenance. The simple construction of these pumps, combined with the use of water as the sealing medium, means fewer parts are subject to wear and tear. This reduces the need for frequent repairs and ensures greater reliability in the long run.

The Kakati Pumps Advantage: Why Choose Us?

Choosing Kakati Pumps for your Single Stage Water Ring Vacuum Pump needs offers a range of benefits:

Expert Engineering: Kakati Pumps has years of expertise in the pump manufacturing industry, ensuring that each pump is built with precision and meets the highest standards of quality.

Global Reach: Kakati Pumps delivers vacuum solutions to customers around the world, backed by a robust supply chain and customer support system that ensures quick deliveries and after-sales service.

Competitive Pricing: While Kakati Pumps offers high-quality, durable vacuum pumps, they also provide cost-effective pricing options, making their products accessible to businesses of all sizes.

Outstanding Customer Support: From technical support to installation and maintenance, Kakati Pumps offers exceptional customer service, ensuring that clients get the most out of their investment.

Conclusion

In conclusion, Kakati Pumps is a leading manufacturer of Single Stage Water Ring Vacuum Pumps, offering businesses around the world reliable, energy-efficient, and durable pumping solutions. Whether you're in the chemical, food processing, power generation, or any other industry requiring reliable vacuum solutions, Kakati Pumps has the expertise and technology to deliver high-performance pumps that meet your needs.

0 notes

Text

Kakati Pumps: Excellence in Liquid Ring Vacuum Pump Technology

In the world of industrial processes, vacuum pumps are indispensable tools that facilitate a wide range of applications, from chemical processing to food packaging and beyond. One of the most widely used vacuum pumps in various industries is the Liquid Ring Vacuum Pump. Known for its versatility, efficiency, and reliability, the Liquid Ring Vacuum Pump has become an industry standard, and Kakati Pumps is a leading manufacturer providing high-quality solutions.

What is a Liquid Ring Vacuum Pump?

A Liquid Ring Vacuum Pump is a type of positive displacement pump that uses a liquid—typically water or a specific process fluid—as a sealing fluid to create a vacuum. The pump operates by drawing gas or vapor into a chamber where it is trapped by the liquid ring that forms around the rotating impeller. As the impeller turns, the liquid ring continuously moves, compressing and expelling the trapped air or gas, thus generating a vacuum.

Unlike other types of vacuum pumps, the Liquid Ring Vacuum Pump operates without the need for complex mechanisms like diaphragms or pistons, making it highly reliable and simple in design. These pumps are widely used in applications where consistent, efficient vacuum generation is required.

Why Choose a Liquid Ring Vacuum Pump?

The Liquid Ring Vacuum Pump offers several key advantages, making it the go-to solution for many industries:

Reliability: The design of liquid ring pumps is simple and robust, ensuring dependable operation even in demanding environments.

Versatility: These pumps can handle a wide range of gases, vapors, and liquids, including those with high moisture content.