Nanjing KY Chemical Machinery Co., Ltd. is a technological and innovative leader in twin screw extruder industry. Founded in 1993, Nanjing KY Chemical Machinery Co., Ltd. is currently the largest parallel co-rotating twin screw extruder manufacturer in China and Asia with an annual output of 250-450 sets. It has installed more than 8000 sets of extruder systems worldwide, covering chemical, plastic, textile, food and pharmaceutical industries. http://www.keyatwinscrew.com/

Don't wanna be here? Send us removal request.

Text

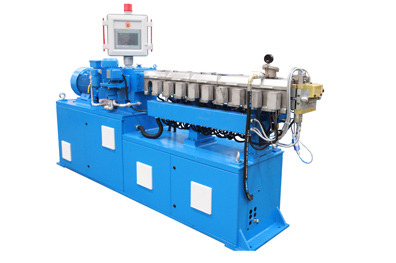

HKY / SKY Two Stage Extruder

https://www.keyatwinscrew.com/products/sky-two-stage-extruder/

HKY / SKY series two-stage extrusion system: the first stage is HK or SK series high speed and high torque co-rotating twin screw extruder, the second stage is single screw extruder to form a two-stage compound extrusion system.

The system combines twin screw high speed, strong mixing with single screw low speed, low temperature and weak shearing characteristics to enhance advantages and avoid disadvantages. It is the preferred model for mixing and modifying heat-sensitive and shearing-sensitive materials efficiently nowadays. The main granulation methods are air-cooled hot cutting and eccentric water mist granulation. They can also be matched with drawing strip cold cutting and water ring hot cutting.

HKY / SKY series two-stage extrusion system: the first stage is HK or SK series high speed and high torque co-rotating twin screw extruder, the second stage is single screw extruder to form a two-stage compound extrusion system.

The system combines twin screw high speed, strong mixing with single screw low speed, low temperature and weak shearing characteristics to enhance advantages and avoid disadvantages. It is the preferred model for mixing and modifying heat-sensitive and shearing-sensitive materials efficiently nowadays. The main granulation methods are air-cooled hot cutting and eccentric water mist granulation. They can also be matched with drawing strip cold cutting and water ring hot cutting.

Applications of HKY / SKY Two Stage Extruder:

PVC Cable Material and XLPE Peroxide Crosslinking Material

Soft PVC Medical Material

Hard PVC Products

EVA Foamed Shoe Bottom Material

PE Low Smoke Halogen Free Resistance Fuel

Main Features of HKY / SKY Two Stage Extruder:

Plasticization, mixing and homogenization of twin screw processing section

Open melt feeding single screw extruder without backpressure, and exhaust and devolatilization can be carried out at the same time.

Soft extrusion of materials through the template of single screw extruder

Air-cooled granulation, eccentric water mist granulation, stretch granulation and water ring granulation can be selected according to material properties.

Smaller power and area

Fully automatic raw material mixing and granulation process to reduce labor costs

Easy to operate, excellent safety and stability

0 notes

Text

SK53 Twin Screw Extruder

https://www.keyatwinscrew.com/products/sk53-twin-screw-extruder.html

Overview of SK53 Twin Screw Extruder

SK53 mini twin screw extruder can be used in engineering plastics, color masterbatch, functional masterbatch, blending modification and other industries.

In order to adapt to the high temperature and high wear resistance of Engineering plastics, HIP hot isostatic pressing technology is used in the material selection of cylinder and screw for SK53 twin screw extruder.

Device parameters of SK53 twin screw extruder

Model

Motor power (KW)

Screw speed (RPM)

Aspect ratio

Output (KG/h)

Size of main equipment (Length Mx, width Mx and height M)

SK53

110/160

600/900

36~60

400~700

5.5x 0.8x 1.6

It has the advantages of high wear resistance and corrosion resistance; for example, when the customer's working formula in PA, PP + glass fiber or carbon fiber + flame retardant, it is recommended to use high wear resistance material (SAM10); if the customer's working material not only requires to wear resistance but also has certain acidity and alkalinity, it needs to consider using corrosion resistance material (SAM26/39). In view of the lateral forced feeding of carbon fibers, a special feeding screw design is adopted, which effectively solves the problem that the material is fluffy and can not be fed

Hot isostatic pressing (HIP) is to place the product in a sealed container and apply the same pressure in all directions to the product. At the same time, SK53 mini plastic twin screw extruder machine can be sintered and densified under the action of high temperature and high pressure. Thermo-isostatic pressure is an indispensable means and technology for the production of high performance materials and the development of new materials.

0 notes

Text

HK Large Extruder Production System

https://www.keyatwinscrew.com/products/hk-large-extruder-production-system.html

Introduction of HK Large Extruder Production System

KY also offers a larger-scale HK twin screw extruder, with the commonly used screw diameters ranging from 110 mm to 165 mm (HK110-165) available for user selection. According to the material and process, the process components with a length-diameter ratio of 72:1 can be provided, and enough reaction residence time can be provided to achieve the best dispersion and mixing effect.

Large twin screw extruders are mainly used for polyolefin granulation, which is particularly common in petrochemical enterprises. The usual PE and PP granulation is the typical operation of this application. HK125 large twin screw extruder has a large market share in special extrusion, such as UHMWPE fiber and lithium battery diaphragm extrusion.

Advantages of HK Large Extruder Production System

The parts in the processing section are common to AK and SK series to ensure continuous process consistency

Keya exclusively uses a series of newly designed and developed screw originals, which can meet the requirements of different working conditions and make them have a wider range of processing adaptability

Using German standard spline, optimized tooth profile, with higher bearing capacity

Accurately calibrate the coaxiality of the whole machine assembly

Strict ELP is performed before leaving the factory to ensure that users are provided with the highest product quality

Large twin screw extrusion machine also has many successful applications in polymer devolatilization and reactive extrusion. Special extrusion and professional applications can contact KY for consultation. KY has many years of experience in the production and process of large-scale equipment, plus a good manufacturing system can provide users with more and larger production systems.

0 notes

Text

KY-Lab Twin Screw Extruder

https://www.keyatwinscrew.com/products/ky-lab-twin-screw-extruder.html

Overview of KY-Lab Twin Screw Extruder

Since its establishment in 1993, KY has been devoted to the development and manufacture of small laboratory twin screw extruders. On the 9th anniversary of the introduction of HK and SK series twin screw extruder, KY introduced two new KY-Lab Twin Screw Extruders, namely, the new high torque HK26 and the super high torque SK26, with a diameter of 26mm. This model is specially designed for universities, scientific research institutes, and R&D departments of enterprises. It fully meets the tasks of teaching, formulation R&D, proofing, and small-batch production.

KY-Lab Twin Screw Extruder Has Obvious Advantages over Other Models

The clearance between the screw and cylinder is smaller, which is convenient for discharging and cleaning.

Modular structure, interchangeable 4D/6D barrel, standard screw element design.

Reliable synchronous amplification to HK and SK series products.

Spline sleeve and nose are the new quick-opening structure, clearing and screw replacement combination is more convenient.

The cooling pipes and wiring of the whole machine are all inside the base, which ensures the smoothness of the base surface and is easy to clean.

With the coaxial solenoid valve imported from Germany, the response time is reduced by 90% compared with the conventional solenoid valve, the cooling efficiency of the cylinder is higher, and the temperature control accuracy can be maintained at <1 Celsius.

Movable base. The whole machine is supported by four strong universal wheels. Only one person can easily use mobile devices.

Adopt KY independent intellectual property rights KY laboratory extruder for sale smart operation system software V5.0 as the whole machine control system, combine KY and Germany Germany in respective control technology superiority, guarantees the entire machine control intellectualization and the accuracy.

KY has professional Lab Scale Twin Screw Extruder for sale, contact us now.

The application scope of KY-Lab Twin Screw Extruder:

Homogenization of Polymers

Combination of rubber and plastic (elastomer)

Matrix Production

Modification of Engineering Plastics

Modification of General Plastics

Cable Material

Filling and Mixing Modification

Flame Retardant and Reinforcement Modification

Degradable plastics

High-Temperature Polymers

0 notes

Text

SK Series Co Rotating Twin Screw Extruder

https://www.keyatwinscrew.com/compounding-system/sk-series-co-rotating-twin-screw-extruder/

SK series twin screw extruder is the crystallization of more than 30 years'experience in the equipment manufacturing industry, more than 400 kinds of material technology application and thousands of working conditions verification of KY. Screw diameter can be selected from 26 mm to 135 mm.

SK Series double screw extruder adopts the welding and manufacturing process of international leading standards. It provides the best stability and reliability in operation and has successfully succeeded in replacing imported products in China.

e, the system is smaller and equipped with more powerful lubrication and cooling system, which enables users to use extruders safely and quietly.

British BiBBY torque limiter with high sensitivity and reliability can effectively avoid equipment shutdown due to improper operation or accidental overload.

Siemens's global joint insurance ILE0 series inverter motor has the characteristics of high efficiency, energy-saving, safety and so on. It provides technical support and service for localization.

Optimizing Processing Section

The processing section of the SK series double screw extruder can be flexibly configured for transportation, plasticization, mixing, shearing, homogenization, devolatilization and pressure according to the technological requirements of users' materials.

The screw and barrel can be made of HIP powder metallurgy material, which can achieve high wear resistance, high corrosion resistance and other extensive fields of operation.

The involute spline of the German standard (DIN5480) is adopted to meet the requirements of higher torque and higher speed.

Optimized screw size-diameter ratio (D0:D=1.55), reliable inter-model amplification effect

Internet-based New Generation Control System

The control system of SK series twin screw extruder can choose conventional instruments, PLC, PCC, DSC to meet different needs.

Modular design, the touch screen can be compactly installed on the mainframe

Customized programming design is satisfied with the upstream and downstream matching equipment of different mixing projects

Provide formulation, project management functions, process and production data visualization

Integrating computer technology, mobile Internet technology and industrial automation technology to realize real-time data management and control of multi-terminal

Parameter of SK Series Co-rotating Twin Screw Extruder

SK Series Co-rotating Twin Screw Extruder Model

Production capacity kg/hr (reference value)

Material Process Category

Typical Material

SK26

SK36

SK53

SK63

SK73

SK96

SK136

Filling modification

PE, PP, EVA, etc. + calcium carbonate, talcum powder, titanium dioxide

5~10

45~90

150~300

300~500

600~800

1200~1500

1800~2700

ABS, PC, PS, etc. + aluminum hydroxide, magnesium hydroxide, antimony oxide

PP, PA, ABS, etc. + iron powder, magnetic powder, ceramic powder

10~20

90~135

180~300

380~500

700~900

1300~1800

1800~3000

blending modification

PP, PE, PS + SBS; PP, PA + epdmpp + NBE; EVA + silicone rubber, etc

5~10

60~100

150~240

270~450

500~750

1000~1700

1600~3000

PE, PA, PC, CPE + ABS; ABS + TPU; PBT + pet; PP + PE, etc

5~10

45~90

120~240

270~380

450~600

1000~1500

1200~3000

Masterbatch

PE, PP, ABS, EVA, PS, etc. + pigment and other additives

3~8

45~75

150~230

270~360

380~500

900~1200

900~1800

Functional Masterbatch

Degradable masterbatch: PE, PS, etc. + starch, etc

3~8

45~90

140~230

230~330

380~500

900~1200

900~1800

Flame retardant masterbatch: PP, PA, ABS, PBT, etc. + flame retardant and other auxiliaries

3~8

60~100

150~270

300~450

500~750

1200~1700

1500~2700

Double control masterbatch: PE + antifogging agent, stabilizer, etc.; high insulation masterbatch; cooling masterbatch; rheological modified masterbatch

3~8

45~75

100~150

270~360

420~540

900~1200

900~1800

Carbon black masterbatch: PE, EVA, ABS, etc. + carbon black

3~8

30~60

90~150

230~330

380~500

800~1000

900~1500

Glass fiber (carbon fiber) reinforced modification

PP, PBT, ABS, as, PA6, PA66, PC, POM, PPS, pet, etc. + long fiber or short fiber or whisker

5~10

75~120

180~270

300~450

450~700

900~1400

1500~2400

PP, PBT, ABS, as, PA6, PA66, PC, POM, PPS, pet, etc. + carbon fiber

5~10

45~90

150~240

270~330

380~500

900~1200

1000~2100

Special materials

EVA hot melt adhesive, polyurethane

3~8

45~90

90~140

150~230

300~380

700~800

700~1500

Fluororubber, fluoroplastics

3~8

30~60

60~120

150~230

230~300

600~750

700~1400

Optical cable coating material, acetate fiber, PP cigarette filter material

3~8

45~90

150~230

300~380

450~600

1200~1500

1500~2400

TPR shoe sole

3~8

90~150

230~300

450~500

700~800

1300~1700

1500~3000

Luminescent plastics, antibacterial plastics, UV resistant plastics, PE crosslinkable tube materials

3~8

60~90

180~270

330~450

500~600

900~1200

1000~1800

Various cable materials

HDPE, LDPE, LLDPE, MDPE insulation material and sheath material; PE radiation crosslinking cable material; PE silane crosslinking cable material

3~8

45~90

150~230

270~380

450~600

750~1000

1000~1700

Flame retardant polyolefin cable material, PP cable material

3~8

90~120

180~270

380~450

600~700

1100~1400

1200~1800

Low smoke and low halogen flame retardant PVC cable material

5~10

30~60

120~180

230~300

380~500

800~1000

900~1500

Reactive extrusion

Polyamide polycondensation, polyester melt polymerization, polyurethane addition polymerization, polycarbonate polycondensation, bulk continuous polymerization of POM

1~2

30~50

150~230

300~380

450~600

750~900

700~1500

Post treatment of exhaust devolatilization

Chlorinated polypropylene, super absorbent resin, K-Resin, chlorosulfonated polyethylene, fluoro rubber, etc

1~2

Max75

Max150

Max300

Max450

Max900

Max1500

powder coating

Polyester type, epoxy type, propyl ester type, polyurethane type, acrylate type, etc

3~8

150~230

300~450

600~750

1000~1200

2100~2300

2200~4500

0 notes

Text

HK Series Co Rotating Twin Screw Extruder

https://www.keyatwinscrew.com/compounding-system/hk-series-co-rotating-twin-screw-extruder/

Nanjing KY provides more material selections for the process parts of the HK Series Twin screw extruder. Besides standard nitriding steel and tool steel, the HIP materials made in China also provide higher wear resistance for machines. Different corrosive powder metallurgy materials are also applied to screw element and cylinder bushing manufacture, and their properties are very close to the same.

Nanjing KY provides more material selections for the process parts of the HK Series Twin screw extruder. Besides standard nitriding steel and tool steel, the HIP materials made in China also provide higher wear resistance for machines. Different corrosive powder metallurgy materials are also applied to screw element and cylinder bushing manufacture, and their properties are very close to the same.

Your Premier Twin Screw Extruder Manufacturer——KY

HK Series Twin screw extruder process components, such as screw and cylinder, can be interchanged with AK or SK specifications, and the geometric design is completely consistent. This also means that customers of Nanjing KY AK or SK can seamlessly transfer the original products to newly purchased HK equipment, to achieve higher output or better return on investment.

HK Series Twin screw extruder is a medium-high torque and high-speed extruder launched by Nanjing KY in recent years to meet the new needs of customers. It has gained a huge market share and currently produces more than 120 extruders annually.

HK transmission system including large extruder production system based on Nanjing KY independently developed high-torque gearbox adopts the leading transmission technology in the industry, strengthens the output system of the gearbox with enhanced structure, achieves the ideal result of pure torque output with parallel biaxial output, and greatly improves the safety of gearbox. The transmission parts can be manufactured by German or British torque limiter so that gearboxes and process parts can be safely protected when the torque exceeds the standard.

Parameter of HK Series Co-rotating Twin Screw Extruder

HK Series Co-rotating Twin Screw Extruder Model

Production Capacity kg/hr (Reference Value)

Material Process Category

Typical Material

HK26

HK36

HK53

HK63

HK73

HK96

HK136

Filling modification

PE, PP, EVA, etc. + calcium carbonate, talcum powder, titanium dioxide

5~10

40 ~ 80

130 ~ 260

260 ~ 460

500 ~ 700

1000 ~ 1300

1500 ~ 2300

ABS, PC, PS, etc. + aluminum hydroxide, magnesium hydroxide, antimony oxide

PP, PA, ABS, etc. + iron powder, magnetic powder, ceramic powder

10 ~ 20

80 ~ 120

160 ~ 260

330 ~ 460

600 ~ 800

1200 ~ 1600

1500 ~ 2600

Blending modification

PP, PE, PS + SBS; PP, PA + EPDM; PP + NBE; EVA + silicone rubber etc

5~ 10

50 ~ 100

130 ~ 210

230 ~ 390

450 ~ 650

900 ~ 1400

1400 ~ 2600

PE, PA, PC, CPE + ABS; ABS + TPU; PBT + PET; PP + PE etc

5~ 10

40 ~ 80

100 ~ 210

230 ~ 330

400 ~ 500

850 ~ 1300

1000 ~ 2600

Color masterbatch

PE, PP, ABS, EVA, PS, etc. + pigments and other additives

3~ 8

50 ~ 70

130 ~ 200

230 ~ 310

300 ~ 450

800 ~ 1000

800 ~ 1600

Functional masterbatch

Degradable masterbatch: PE, PS, etc. + starch, etc.

3~ 8

40 ~ 80

120 ~ 200

200 ~ 290

300 ~ 450

800 ~ 1000

800 ~ 1600

Flame retardant masterbatch: PP, PA, ABS, PBT, etc. + flame retardant and other additives

3~ 8

50 ~ 90

130 ~ 230

260 ~ 390

450 ~ 650

1000 ~ 1400

1300 ~ 2300

Double anti-master batch: PE + anti-fog dripping agent, stabilizer, etc. High heat preservation masterbatch; Cooling masterbatch; Rheological modified masterbatch

3~ 8

50 ~ 70

90 ~ 130

230 ~ 310

350 ~ 450

800 ~ 1000

800 ~ 1600

Carbon black masterbatch: PE, EVA, ABS, etc. + carbon black

3~ 8

30 ~ 50

80 ~ 130

200 ~ 290

300 ~ 450

700 ~ 900

800 ~ 1300

Reinforced modification of glass fiber (carbon fiber)

PP, PBT, ABS, AS, PA6, PA66, PC, POM, PPS, PET, etc. + long fiber or short fiber or whisker

5~ 10

70 ~ 100

160 ~ 230

260 ~ 390

400 ~ 600

800 ~ 1200

1300 ~ 2100

PP, PBT, ABS, AS, PA6, PA66, PC, POM, PPS, PET, etc. + carbon fiber

5~ 10

40 ~ 80

130 ~ 210

230 ~ 390

300 ~ 450

800 ~ 1000

900 ~ 1800

Special materials

EVA hot melt adhesive, polyurethane

3~ 8

40 ~ 80

80 ~ 120

130 ~ 200

250 ~ 300

600 ~ 700

600 ~ 1300

Fluorine rubber

3~ 8

30 ~ 50

50 ~ 100

130 ~ 200

200 ~ 250

500 ~ 650

600 ~ 1200

Cable coating material, acetate fiber, pp cigarette filter material

3~ 8

40 ~ 80

130 ~ 200

260 ~ 330

400 ~ 500

1000 ~ 1300

1300 ~ 2100

TPR sole

3~ 8

80 ~ 130

200 ~ 260

390 ~ 460

600 ~ 700

1200 ~ 1400

1300 ~ 2600

Luminescent plastics, antibacterial plastics, anti-ultraviolet plastics, PE crosslinkable pipe materials

3~ 8

50 ~ 80

160 ~ 230

290 ~ 390

450 ~ 500

800 ~ 1000

900 ~ 1600

All kinds of cable materials

HDPE, LDPE, LLDPE, MDPE insulation material, sheath material; PE radiation crosslinked cable material; PE Silane Crosslinked Cable Compound

3~ 8

40 ~ 80

130 ~ 200

230 ~ 330

400 ~ 500

650 ~ 900

900 ~ 1400

Flame retardant polyolefin cable compound, PP cable compound

3~ 8

80 ~ 100

160 ~ 230

330 ~ 390

500 ~ 600

1000 ~ 1200

1000 ~ 1600

Low Smoke and Low Halogen Flame Retardant PVC Cable Material

5~ 10

30 ~ 50

100 ~ 160

200 ~ 260

300 ~ 450

700 ~ 850

800 ~ 1300

Reactive extrusion

Polyamide polycondensation, polyester melt polymerization, polyurethane addition polymerization, polycarbonate polycondensation, polyformaldehyde bulk continuous polymerization

1~ 2

25 ~ 45

130 ~ 200

260 ~ 330

400 ~ 500

650 ~ 800

600 ~ 1300

After treatment of exhaust devolatilization

Chlorinated polypropylene, superabsorbent resin, K-resin, chlorosulfonated polyethylene, fluororubber, etc

1~ 2

Max65

Max130

Max260

Max400

Max800

Max1300

Powder coating

Polyester type, epoxy type, propyl ester type, polyurethane type, acrylate type, etc.

3~ 8

130-~ 200

260 ~ 390

520 ~ 650

900 ~ 1000

1800 ~ 2000

2000 ~ 4000

0 notes

Text

Extruder Parts

https://www.keyatwinscrew.com/compounding-system/extruder-parts/

Nanjing KY is one of the companies with the largest spare parts storage in the whole industry, with more than 55000 varieties. With the first-class warehouse coding management system in the world, it can inquire about the real-time storage situation of spare parts in a very short time to deal with various emergencies of customers. KY provides various twin screw extruder parts.

Nanjing KY is one of the companies with the largest spare parts storage in the whole industry, with more than 55000 varieties. With the first-class warehouse coding management system in the world, it can inquire about the real-time storage situation of spare parts in a very short time to deal with various emergencies of customers. KY provides various twin screw extruder parts.

KY has adopted the first-class brand constant temperature and humidity air conditioning device to ensure that twin screw extruder parts are not affected by temperature, humidity and other external environments in the storage process.

With its own technical accumulation, KY can also provide spare parts for more than 40 kinds of twin-screw extruders of 7 International brands, including mechanical and electrical spare parts such as screw components, cylinders and mandrels.

All spare parts are guaranteed to be new, unused and properly preserved. They are made of imported materials, the best domestic materials and the first-class processing technology, and meet the quality, specifications and performance requirements specified in the quality standards in all aspects.

0 notes