Don't wanna be here? Send us removal request.

Text

Manufacturing Solutions

Kingstec offers complete solutions to project management, engineering, manufacturing and logistical challenges. We have managed over 5,000 successful projects for our clients close to 40 years, delivering quality products at the right time, right quantity and right price. Custom Overmolded Connectors

How we work

· End to end

· Technical know-how

· Experience

For over three decades, Kingstec has connected Western companies with our high-quality, cost-efficient manufacturing partners in Asia. We take care of all the details – and add value at every step – to help you achieve your business goals.

· Cost-efficient manufacturing partners

· Engineering expertise

· Competitive pricing

· Guaranteed quality

0 notes

Text

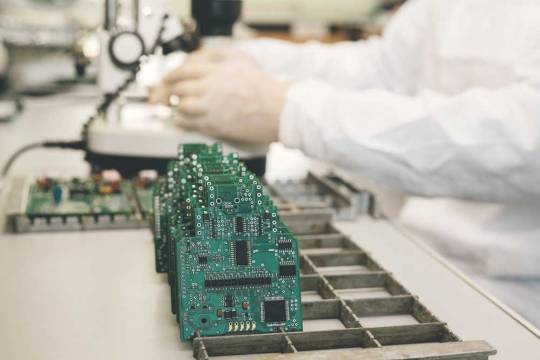

Printed Circuit Board Assembly

Our Asian manufacturing facilities produce racing and performance automotive aftermarket electronics and mechanical components. Electronic Contract Manufacturer

0 notes

Text

Printed Circuit Board Assembly

The Printed Circuit Board, or PCB, is at the heart of any electronic device, regardless of how simple or complex that device is. Kingstec specializes in PCB and PCB assemblies (PCBA), and our skilled team can help you develop and assemble the PCB/PCBA your product requires, no matter how simple or complex.

Kingstec can work with your prototypes of your product design and conduct pilot runs. We’re also fully scalable, so we can grow with you to deliver high volume production. Multi-layer PCBs and assemblies can also be produced, with anywhere from two to ten layers. Our partner production facilities in China meet the highest quality standards, conforming to ISO 9001 and 14001 certifications. All sites are ISO 13485 or TS 16949 certified to accommodate specific industry needs.

Source url : https://kingstec.com/core-capabilities/printed-circuit-board-assembly/

0 notes

Text

Medical Device Contract Manufacturing

Kingstec will manufacture high quality medical device electronic components and mechanical components at our partner facilities in China. Contract Manufacturing

0 notes

Text

Medical Device Contract Manufacturing

Kingstec Technologies Inc. pioneered utilizing offshore contract manufacturers in Asia providing design, engineering, and manufacturing capabilities. Printed Circuit board Assembly

0 notes

Text

Kingstec, Ontario-based Manufacturing Partner, Launches New Website

New Site Showcases Expanded Offerings to MedTech, Performance Automotive Aftermarket, Industrial, Telecom, AgTech and Other Industries

Kingstec, the company offering complete solutions to project management, engineering, manufacturing, and logistical challenges, today announced the launch of its new website at www.kingstec.com . The new site features expanded and frequently updated content for companies in medical technology, performance automotive aftermarket, industrial controls, telecommunications, agricultural technology and more.

For nearly 40 years, Kingstec has partnered with established businesses and startups all over the world, connecting them with trusted manufacturing partners in Asia and seeing projects through from ideation to delivery. Kingstec��s services include project management, engineering, manufacturing, logistics, and more.

Kingstec’s experienced and proactive logistics team helps clients stay ahead of supply chain issues, keeping them informed of important changes in unsettled times. As a result of the pandemic and global supply chain issues, many suppliers are facing component shortages and shipping delays which are driving up costs and drawing out delivery times. With its close ties to China and trusted manufacturing facilities, the Kingstec team can provide clients advance warning of potential challenges and help develop reliable alternative plans.

Kingstec’s president, Wilson Chiu, notes, "We’ve seen longer lead times for all raw materials, along with price increases for these materials. Shipping challenges have also been substantial. Limited shipping capacity and the resulting rise in prices have been difficult. Between a mysterious shortage in shipping containers, reduced travel, reduced port staff – and then the curveball of the blocked Suez Canal, it’s hard to predict what will happen next." He adds, "We’ve had to be very careful and extremely transparent in our conversations about lead time and pricing."

To that end, the refreshed website features a blog that offers news and updates about how the company is addressing supply chain issues, lockdowns and other current challenges. The blog also offers additional helpful content in multiple formats, including infographics and videos.

For companies seeking manufacturing support, the new site also features expanded content highlighting Kingstec’s capabilities, from PCB assemblies to custom cable assemblies, plastic injection molded parts, and more. There are helpful videos and downloadable data sheets offering more detailed information about each service.

To learn more, visit www.Kingstec.com.

Source Url :

https://kingstec.com/ontario-based-manufacturing-partner-new-website/

0 notes

Photo

Kingstec handles box-build turnkey assemblies from simple enclosures to complex turnkey assemblies, such as those used in medical applications. Medical Device Manufacturing

0 notes

Text

Contract Manufacturing

PCBs and PCB assemblies are everywhere in today’s electronics industry. Find out why partnering with Kingstec gives you the best of both worlds for your contract assembly and manufacturing needs. Medical Device Contract Manufacturing

0 notes

Text

Equipment In China: Why It’s A Smarter Strategy Than You Think – Even Now

China is the “world’s factory,” a global manufacturing hub that produces the vast majority of electronics components used around the world. Those components power everything from smartwatches to cars to appliances, as well as critical medical equipment such as ventilators, ultrasound machines, hospital beds, and more. But with incredibly high tariffs imposed by the US on many of those goods – including medical equipment – is it worth it for manufacturers to stick with their operations in China?

The industry has been divided on that. You’ve probably seen your fair share of stories about major OEMs moving some of their manufacturing operations to other countries. This past spring, as production lines shut down due to COVID, it’s no surprise people were contemplating the benefits of decreasing their reliance on China.

However, does avoiding those tariffs warrant the huge effort it takes to relocate operations? After a long year and many tough decisions, the overwhelming answer has been…no. For most manufacturers, the advantages outweigh the 25% tariffs.

So what are the advantages of manufacturing medical equipment in China?

Advantage #1: Staying in China poses less risk than moving

With change comes risk: that’s a fact of life. Switching manufacturing partners, even within a region, has significant chalenges. Relocating to a whole new country is even more time-consuming, expensive and risky, with a steep learning curve that involves extensive travel, multiple factory tours, work sessions, and more. And it’s a level of risk many aren’t willing to embrace.

According to Forbes, “Manufacturers are sticking with partners they know and trust, despite the tariffs. With restricted travel, de-risking new partners has been incredibly difficult, so most have opted to work with teams they know.”

In addition, China lived through COVID-19 for months before it impacted the rest of the world: that experience has enabled them to be at the forefront of developing strict virus controls. With those controls, the types of shutdowns that happened in the first months of 2020 are highly unlikely, and medical equipment companies will be able to count on continuity and supply chain dependability moving forward.

Advantage #2: A massive, highly-skilled labour force

China has the biggest labour force in the world, topping out at 783 million workers. Unlike countries with comparable populations, like India, they have been a manufacturing hub for 20 plus years, and have the depth and breadth of specialized skills required to build the premium-quality electronics needed for medical equipment.

Advantage #3: Low labour costs

Yes, labour costs in China have been creeping up since minimum wages were instituted in 1995, with jumps related to wage increases in 2010 and 2019 – and they are higher than countries like India or Vietnam. But they are still dramatically lower than in western countries. For example, in Guangdong, a key manufacturing region in China, minimum wage is approximately $2.15 an hour.

Keep in mind that with those marginally higher wages come skills and experience you won’t find in other regions, with greater speed and much more efficient lead times than other countries can provide.

Advantage #4: Quality of logistics and infrastructure

Companies can benefit significantly from China’s established manufacturing history. They have robust infrastructure in place to move everything from raw materials to finished products quickly and efficiently through the country and across international borders. 40% of China’s roads are national highways, and they have 2/3 of the world’s high-speed rail lines, spanning 290,000 km, with trains that can travel up to 250 km an hour. Add modern cities, world-class airports and marine ports to the mix, and you have a setup no other country can come close to.

According to Wharton Magazine, “China has arguably the best physical infrastructure outside the western world.”

Advantage #5: A robust domestic medical device market

The scale of the manufacturing China does for their own medical market is enormous, representing close to $100 billion in health care spending. Which means western companies have access to a market focused on quality and innovation – one they can leverage for their own production and expansion. This also means they can draw on the country’s robust manufacturing supply chain, including top-quality, cost-effective raw materials that can be used for local production.

Advantage #6: State-of-the-art manufacturing facilities

China has more FDA-registered medical manufacturing facilities (Class II and Class III) than any other country apart from the US. That may be why a number of large medical manufacturers, including Roche and Johnson & Johnson (with Bayer and Novartis announcing upcoming plans), have moved not just production facilities to China, but also R&D operations.

The “Made in China” initiative is also increasing manufacturer confidence in the quality of Chinese goods. President Xi Jinping has committed to making the words “Made in China” synonymous not with cheap, low-quality goods, but with top-quality manufacturing, especially for complex products like medical electronics.

The big disadvantage: 25% tariffs have a huge impact on profitability

Thanks to trade wars between the US and China, tariffs have escalated to punitive levels. And not only do they include finished goods, but also metal alloys (including steel and aluminium) used in many medical devices. From this perspective, there’s no arguing that manufacturing in countries that haven’t had this tariff imposed on them is the cheaper option.

Not all medical items are subject to the tariff, however. There are a few exceptions, which include microwave ablation antennas, tube suspensions used to position X-ray equipment, and food allergen analyzers. Plus, medical device manufacturers can apply for individual exemptions, but that may not be easy: several big medtech firms have had their applications rejected.

As a workaround, some manufacturers have been routing Chinese-made goods through other countries, like Vietnam, adding “Made in Vietnam” labels to avoid the tariffs. We don’t recommend this tactic: both the US and Vietnam frown upon fraudulent labelling, and any companies found doing this are likely to face heavy fines.

Negotiations with the US Government over tariffs continue, and there is hope that with the incoming administration, the issue will be addressed in a way that’s favourable to the industry. However, the outcome of the new Presidency remains to be seen: political analysts predict that Biden is likely to be a little softer with China than Trump has been. But despite some initially promising statements, there’s little indication he will lift the current tariffs.

Ultimately, the talk we’ve been hearing about restructuring supply chains has ended up being mostly that: talk. Despite punitive tariffs and COVID complications, manufacturers have overwhelmingly chosen to stay put. They’re sticking with trusted partners, a skilled workforce, sophisticated manufacturing capabilities, and low labour costs, which for most, outweigh the tariffs.

Kingstec Technologies Inc. pioneered contract manufacturing in Asia and remains an innovative leader in the field. Building on our original success in electronic components, over the decades we’ve worked with companies large and small across a broad spectrum of sectors, from telecommunications to health care to industrial products. At our corporate headquarters in the Greater Toronto Area, we’ve built a team to match our customers’ exacting needs in everything from engineering and quality assurance to logistics and project management.

Source Url : https://www.kingstec.com/manufacturing-medical-equipment-in-china-why-its-a-smarter-strategy-than-you-think-even-now/

0 notes

Text

Medical Device Contract Manufacturing

For more than 35 years, Kingstec has connected growing companies in North America and Western Europe with the world’s workshop: the cost-efficient, highly adaptable contract manufacturers of Asia. Plastic Injection Moulding Services

0 notes

Text

Interactive Infographic: Custom Cable Assemblies

Custom cable assemblies are designed with exact application length measurements as well as the required gauge size of wire to safely carry the intended power load/signal. With this optimization in mind, the custom cable assembly will be an exact fit for the space for which it was intended and will be perfectly matched for power requirements. Plus, there will be no extra weight caused by extra lengths of wire – or by larger gauge sizes of wire due to stock availability. Interact with our infographic to learn more about the benefits of custom cable assemblies!

0 notes

Photo

Wire harnesses and cable assemblies ensure the durability of medical devices and other electronic equipment. Find out how Kingstec Technologies Inc. can support your manufacturing processes. Medical Device Manufacturing

0 notes

Photo

For more than 35 years, Kingstec has connected growing companies in North America and Western Europe with the world’s workshop: the cost-efficient, highly adaptable contract manufacturers of Asia.

0 notes

Photo

Custom cable assemblies are designed with exact application length measurements as well as the required gauge size of wire to safely carry the intended power load/signal. With this optimization in mind, the custom cable assembly will be an exact fit for the space for which it was intended and will be perfectly matched for power requirements. Plus, there will be no extra weight caused by extra lengths of wire – or by larger gauge sizes of wire due to stock availability.

0 notes

Photo

Contract assembly and manufacturing for custom-made components and sub-assemblies, including medical devices. https://www.kingstec.com/

1 note

·

View note