Don't wanna be here? Send us removal request.

Text

TOTE TANK SPECIALIST

TOTE TANKS LAVA Engineering Company has been manufacturing Offshore / Onshore Tote Tanks for many years now. Client from Oil & gas Industry, chemical Industry, Logistics prefer LAVA TOTE TANKS for Marine transport and as off-shore containers. LAVA Tote tanks are also used as storage tanks, process tanks and Industrial containers for chemical industries, Oil drilling companies, Pharmaceutical companies and others. KNOW MORE

LAVA, Tote tanks manufacturer India, supplies high quality tanks with precision and meets Intermediate Bulk Container standards with capacities ranging from 300 Gallons, 550 Gallons and 1000 Gallons in SS 304 and SS 316L MOC to suit client requirement and applications.

LAVA TOTE Models - DOT - UN 31 A ( DNV 2.7.1 Certified With TOTE Frame)

300 Gallons - 42" X 48" X 45" Size - 200 Kgs

550 Gallons - 42" X 48" X 72" Size - 295 Kgs

793 Gallons - 54" X 54" X 77" Size - 475 Kgs

Accessories Of LAVA TOTE TANK

Filling, Discharge, Drain, Pad Eyes ( as per DNV / EN), Document Holder, Fork lift provision and bottom Support Legs.

0 notes

Text

TRAILER TANK SPECIALIST

TRAILER TANKS

ADR TRANSPORT TRAILER TANKS LAVA Engineering Company has extensive manufacturing experience to manufacture ADR classified and non-classified transport trailer tanks with different material grades suitable to carry Oil, Hazardous & Non Hazardous chemicals, Food grade Liquids, Juices, Wine, Beer and other Liquids. These trailers are designed for Oil drilling companies, Chemical companies, Food industries that meets Indian, American & European standards. KNOW MORE

As we are an ADR Trailer Tank manufacturer Europe, our clients include MNC companies from Europe, America that have chemical and hazardous code requirement to comply IMDG, CFR 49, CCOE & ASME XII design code specific for transport trailer tanks.

CHEMICAL AND ACID TRANSPORT TRAILER LAVA Acid transport tank trailers & Semi trailers are constructed as per ASME XII design code and are fabricated to ASME IX weld standards applicable for Hazardous and Non Hazardous chemicals KNOW MORE The model tank and semi trailers are stimulated with FE analysis before under taking fabrication to ensure structural integrity at operational mode. The DRY Bulk trailer tanks are supplied to customers with specifically designed to trim excess weight to carry more material and balance COG vehicle stabilization.

The Acid tanks are fitted or welded to the chassis of the trailer depending COG requirement. The design stimulation is carried out to ensure simultaneous braking and turning payload of the maximum load at stress points. The semi trailers are equipped with Formed beam chassis, landing Legs, ABS twin braking, Radial Tyres, Chemical spill arrangement & other accessories to meet clients with specific needs.

The Acid tank mounted on the trailer along with pipe lines and manifold are FRP lined, Rubber Lined, Lead Lined to carry Hazardous chemical liquids with Aluminum / Stainless Steel / GRP insulation to hold up to 200 Deg C.

DRY BULK TRANSPORT SEMI TRAILER LAVA DRY BULK transport trailers are manufactured with Single and Multi-compartment tanks with variable compartment sizes are available from 50 BBL to 150 BBL. KNOW MORE

LAVA trailer Tanks are manufactured to customer specific designs of flanges, manholes, pipelines, outlets and an extensive range of variations and accessories that are available to suit Road conditions of particular country.

LAVA Semi Trailer tanks manufacturer, supplies tanks, which are equipped with emergency Trailer Roll-Over protection, Anti Slip Gruts, Collapsible Hand rails, Glass wool Insulation to accommodate heat up to 200 Deg C, Liquid Spill Collection area, Cassis Guard, ABS Braking, Triple Axle Suspension, Standard 2” Kingpin for universal acceptance and many more.

0 notes

Text

OFFSHORE TANK SPECIALIST

OFFSHORE TANKS LAVA Engineering Company extensively manufacture products for leading offshore oilfield drilling companies who are using our products for their operations in India, Middle East(UAE, Iran, Oman, Saudi Arabia, Qatar, Kuwait, Bahrain) and Europe with AMSE, DNV 2.7-1 / 2.7-3 / 2.22 / EN 12079 -1, IMDG certified offshore tanks, chemical tanks along with lifting frames, 500Gallon Baskets, 1000Gallon vertical tank container, KNOW MORE

Established offshore division in 2012, LAVA Engineering supplies offshore tanks, offshore& onshore Acid tanks for Hazardous and Non Hazardous chemicals to major Global Oil & Gas companies like Baker Hughes, Halliburton, Superior Energy, BG, Schlumberger and others. The company’s design and manufacturing facilities are located in INDIA with close proximity & connectivity to Cochin / Chennai sea port for export to any part in the world.

As a leading Offshore Tanks manufacturer, we follow Design & engineering, production line QC and stringent post production testing, which ensures that all LAVA containers meet with the stringent DNV 2.7-1/EN 12079-1 requirements for off shore containers.

ACID MIXING TANK WITH RUBBER/ FRP LINING LAVA Engineering manufactures offshore acid mixing tanks as per DNV 2.7-1 ( EN 12079 ) specifications.LAVA Offshore & Onshore Acid tanks are also offered with full customization program on tanks with Rubber Lining / FRP lining / PE lining KNOW MORE

LAVA offshore chemicals tanks are also transportable with permitted load of 25,000 Kgs Max.Nitric Acid Tank Container

LAVA Off-Shore Acid Mixing Tank Technical Specification

Capacity-500 Gallon, 1000 Gallon, 2000 Gallon, 5000 Gallon, 6000GallonDesign Code-ASME VIII, DNV 2.7-1Shell & head-IS 2062, SA 516 Gr 70, SS 304, SS316LLining-Rubber Lining / FRP lining / PE liningMax Lift Load-25,000 KgsOperating Pressure-ATMTest Pressure-2 Bar

OFFSHORE BATCH MIXER LAVA Engineering manufactures Off-shore tanks with Batch Mixers to suit Onshore / Offshore specifications with capacity of 30BBL, 50BBL and 100BBL. LAVA Batch Mixers are also offered with full customization on Turbine mixer for the Batch Tank, FRP lining of the Batch Tank, Hydraulic Pump, Centrifugal Pump, Diesel / Electric Engine with Shifting Gears, Manifolds, Control Panel and others. LAVA Offshore Tanks with Batch Mixers also come with customer’s own paint color and Logo KNOW MORE

LAVA Batch Mixer Tank Technical Specification

Capacity-30BBL, 50BBL, 100BBLMOC-IS 2062, IS 4923, SS 304, SS316LLining-FRP liningMixer-Turbine MixerBatch Tank-Tank with Hydraulic Agitator & mountCentrifugal Pump-Acid resistant pumpEngine-Diesel / Electric Engine with Gear Box

OFFSHORE BOX CONTAINER LAVA, Offshore Box Container Manufacturer, supplies DNV 2.7-1 Offshore dry container (10ft, 20ft, 30ft, 40ft), open top container, half height container, cargo basket, mini container, etc are all types built to customer specifications and can be supplied with DNV 2.7-1 Certified Sling and Shackles. KNOW MORE

LAVA Offshore Container Technical Specification

Dimension-10 X 8 X 8.6 ftInternal Dimension-9.2 X 7.4 X 7.3 ftDesign Code-DNV 2.7-1 / EN 12079 -1Capacity-14M3Tare-2400 KgsPayload-7,750 KgsSlings-Optional - DNV 2.7-1 certified Designed , Built & certified to DNV 2.7-1, BS EN 12079 : 2006 , ISO / CSC

MUD SKIPS AND OFFSHORE BASKETS LAVA Mud storage tanks manufacturer, supplies Drilling Mud Skips and Offshore Baskets, which provides an provide an efficient and safe way to transport drilling waste from your site to a site for treatment or disposal in the oil rings. KNOW MORE

These skips / Baskets are designed and manufactured to DNV2.7-1 /EN12079 and can optionally be supplied with DNV certified slings and shackles. The single walled mud tanks are constructed to safely carry / handle oil wastes at all times.

LAVA Offshore Mud Skips Technical Specification

Dimension-7.5 X 6.5 X 4 ftInternal Dimension-6.8 X 6 X 3.3 ftDesign Code-DNV 2.7-1 / EN 12079 -1Capacity-3.5M3Tare-1500 KgsPayload-8,000 KgsSlings-Optional - DNV 2.7-1 certified Designed , Built & certified to DNV 2.7-1, BS EN 12079 : 2006 , ISO / CSC

DNV 2.7-1 OFFSHORE TRANSPORTABLE CONTAINER LAVA Engineering, DNV 2.7-1 Offshore tank manufacturer, supplies offshore UN portable tanks with DNV 2.7-1 (EN 12079), ASME VIII design standard to serve Oil and Gas Drilling and chemical companies. LAVA transportable Horizontal 2000 Gallon Acid tanks are used for safe transport and storage of wide range of liquids and are manufactured in Stainless or Mild steel with RUBBER lining / FRP lining / EPOXY Lining /LEAD Lining for Hazardous Acids like HCL, Sulphuric Acid and others. KNOW MORE

LAVA 2000G tanks have full walkway and collapsible handrails to ensure at most safety during offshore operation. Two Lifting provision with DNV slings are provided, center lifting with DNV standard Lugs and the other corner lifting with corner casting. The liquid Discharge can be Top discharge or Bottom discharge as per client requirements

Specification

Approvals-IMDG, DNV 2.7-1, EN 12079Certification-DNV 2.7-1, EN 12079, Vertical Tank in Rectangular FrameVessel Design Code-ASME VIII – DIV 1Dimensions-2991 mm X 2438 mm X 2591 mm (h)Capacity-2000 USG Nominal (7600 Litres) (+/-3%)Design Temperature--20 C to +60 CLining Material-Rubber Lining, FRP Lining Bottom – Type ISO Corner Casting on Bottom Corners

0 notes

Text

ISO TANK CONTAINER SPECIALIST

ISO TANK CONTAINER LAVA Engineering Company designs and builds UN portable ISO tank containers with ASME VIII / ISO668 design standards for storage and transport of all edible Liquids, chemicals, Oils and Gases. LAVA ISO Tank Containers conforms to the International Maritime Organization Standards (IMO) which allows LAVA Containers to be used for imports/exports in for countries like INDIA, Middle East, AFRICA, USA, CANADA, EUROPE,US and other parts of the world through Sea, Rail and Road transport.

KNOW MORE

Some Of Our Approved Model ISO Tank Containers

T1 ISO tank container for Wine / Juices and Light liquids T3 ISO tank container for Petrol, Diesel, Jet Fuel, Crude Oil (ATF), Bitumen T4 ISO tank container for Edible / Non Edible Oils T11 ISO tank container for Non hazardous chemicals T14 ISO tank container For Hazardous Chemicals and Acids like HCL / Caustic / sulfuric acid/ Ferric Chloride) with Rubber lining / FRP lining Inner / PE lining T20 ISO tank container for Bromine T50 ISO tank container for LPG / Ammonia Gas / Propane SWAP Tank container for cargo above 28,000 Litres to 35,000 Litres We have the facility and experts in the design and fabrication of DV Box Container and Tank containers to serve the worldwide Food industries, Chemical Industry, Oil Drilling & exploration companies, Oil field Equipment service companies, Pharmaceutical companies, Nuclear and Defense Industries. We apply the same precision and engineering excellence throughout the whole of our extensive range of Containers with International design standards of ASME / ISO/ API /DNV.

T1 ISO TANK CONTAINER LAVA Engineering manufactures UN portable T1 – ISO Tank Containers in exclusivity for Juice and Wine manufacturers as per ISO 668 design code.

KNOW MORE

T1 – UN Portable ISO Tank Container Technical Specification

Size–20ft / 40ft ISO tank container Capacity–26,000 Litres / 44,000 Litres Design Code–ASME VIII, EN 12972 ,ISO 668 MOC–Carbon Steel / Stainless Steel Gross Weight–34,000 Kgs Temperature–-40 to 65 deg C Operating Pressure–1.74 Bar Test Pressure–2.90 Bar

T3 ISO TANK CONTAINER LAVA Engineering manufactures UN portable T3 ISO Tank Containers & Airport storage tanks for Diesel, Jet Fuel (ATF) as per IS 7667 standards.

KNOW MORE

T3 – UN Portable ISO Tank Container Technical Specification

Size–10ft / 20ft / 40ft ISO tank container Capacity–8000 Litres, 24,000 Litres, 44,000 Litres Design Code–ASME VIII, EN 12972 ,ISO 668 MOC–Carbon Steel / Stainless Steel Gross Weight–34,000 Kgs Temperature–- 40 to 65 deg C Operating Pressure–1.74 Bar Test Pressure–2.90 Bar

T4 ISO TANK CONTAINER LAVA Engineering is a UN portable T4 ISO Tank Container manufacturers India. These tanks are for food grade liquids and edible and inedible Oils. Specific customer Design requirement for food grade liquid handling are also undertaken to suit individual industries.

KNOW MORE

T4 – UN Portable ISO Tank Container Technical Specification

Size–10ft / 20ft / 40ft ISO tank container Capacity–8000 Litres, 24,000 Litres, 44,000 Litres Design Code–ASME VIII, EN 12972 ,ISO 668 MOC–Carbon Steel / Stainless Steel Gross Weight–34,000 Kgs Temperature–- 40 to 65 deg C Operating Pressure–1.74 BarTest Pressure–2.90 Bar

T11 ISO TANK CONTAINER LAVA Engineering is the only Indian company to have Prototype approved and fully certified UN T11 ISO Tanks for storage and transport of Non Hazardous chemicals in any country in the world for Road, Rail and Marine operations. LAVA T11 ISO tanks are Type tested as per ISO 1496 /3 and are certified by authorized classification body with ASME, IMDG, CSC, TIR, ADR/ RID, US DOT, TC, UIC and CFR 49.

KNOW MORE

T11 – UN Portable ISO Tank Container Technical Specification

Size–10ft / 20ft / 40ft ISO tank container Capacity–8000 Litres, 24,000 Litres, 44,000 Litres Design Code–ASME VIII, ISO 668 MOC–CS / SS Gross Weight–30,000 Kgs Temperature–+65 deg C Operating Pressure–4 Bar Test Pressure–6 Bar

T14 ISO TANK CONTAINER LAVA Engineering is the only T14 HCL ISO Tank Container manufacturer in India to have Prototype approved and fully certified UN T14 ISO Tank Container for storage and transport of Hazardous chemicals in any country in the world for Road, Rail and Marine operations. LAVA T14 ISO tank containers are Type tested as per ISO 1496 /3 and are certified by authorized classification body with ASME, IMDG, CSC, TIR, ADR/ RID, US DOT, TC, UIC and CFR 49.

KNOW MORE

LAVA T14 tanks are made of Carbon Steel or Stainless Steel with Rubber lining / FRP lining / PE lining inners for storage and transport of Hazardous Chemicals like Hydrochloric Acid (HCL), Caustic Soda, Sulfuric Acid, Ferric Chloride etc. As an ISO Tank Containers Manufacturer India, Lava Engineering supplies T14 ISO Tank containers, which are tested as per ISO 1496 /3 and are prominent with customers in Gulf and Middle East countries like UAE, Iran, Oman, Saudi Arabia, Qatar, Kuwait, Bahrain and Asian countries like Singapore, Malaysia and Vietnam and North American countries like US and Mexico and European countries like Greece, France, Poland and Netherlands.

T14 – UN Portable ISO Tank Container Technical Specification

Size-20ft ISO tank containerCapacity-20 M3Design Code-ASME VIII, EN 12972 ,ISO 668Lining-Rubber Lining / FRP lining / PE liningGross Weight-30,000 KgsTemperature-+65 deg COperating Pressure-4 BarTest Pressure-6 Bar

T22 ISO TANK CONTAINER T22 – ISO Tank Container Technical Specification

KNOW MORE

Lava engineering company manufacturing ISO tank container for bromine liquid (UN no. 1744) storage & transport with all required international certification like ASME SEC VIII DIV -I, ISO (T22), IMDG-T22,CSC,RID/ADR,US DOT – CFR,TIR,TC,UIC

The ISO tank container liner with Lead lining inner suitable for storage of bromine liquid.

Offshore Chemical tanks Norway

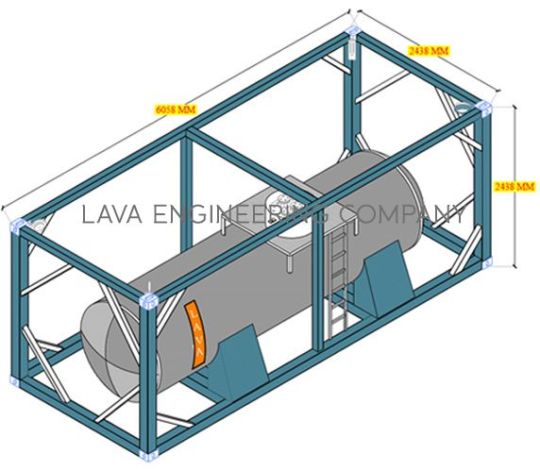

T50 ISO TANK CONTAINER LAVA Engineering manufacture T50 - ISO tank containers and Gas storage tanks for LPG Propane, and other gaseous liquids. We supply LPG storage bullets and LPG transport trailers with CCOE / PESO for Indian operations of Road & Rail and with IMDG & ADR certifications for overseas customers.

KNOW MORE

T50 – UN Portable ISO Tank Container Technical Specification

Size-20ft ISO tank containerL / W / H-6058 X 2438 X 2591 mmCapacity-24,000 LitresDesign Code-ASME VIII, ISO 668Gross Weight-30,000 KgsTemperature-- 40 to +60 deg COperating Pressure-22 BarDesign Pressure-25 Bar

SWAP TANK LAVA Engineering Company also manufactures SWAP tank containers for customers interested to carry Bulk cargo with capacity of 30,000 to 35,000 Litres

KNOW MORE

The frame Dimension varies from 7150 – 7820L X 2550W X 2670H mm depending on the capacity requirement of the customer

The SWAP tank container is ideal for Storage and Road transport application in Gulf and Middle East countries like UAE, Iran, Oman, Saudi Arabia, Qatar, Kuwait, Bahrain and Asian countries like Singapore, Malaysia and Vietnam and North American countries like US and Mexico and European countries like Greece, France, Poland and Netherlands and African countries where the road restrictions are minimal

The SWAP tank container comes with UN classification of T1, T4 and T11 Containers. Special modifications are also provided for T14 containers for Rubber or PE lined inner for Acid chemicals.

The SWAP tank can be customized as specialty containers as per client requirements and shall carry certifications of ASME, IMDG and ISO for specific chemicals.

0 notes

Photo

We supply T50 - ISO tank containers used to store LPG, Propane etc., for both domestic and overseas customers with necessary certifications.

0 notes

Text

Aviation Fuel Storage Tanks

When it comes to aviation fuel storage tanks you can’t take any chances. Contamination could prove serious, so it’s vital to store aviation fuel only in high-quality tanks. That’s why Lava Engineering manufacture tank with uncompromising attention to quality and meticulous attention to detail. Aviation fuel storage tanks also come with several unique features that make them easier to use, easier to maintain and last longer.

Aviation fuel storage tanks to meet your specific need

Every organization has its own fuel requirements. Getting the right tank in the right size with the right combination of providing systems is a complex business, but the Lava Engineering Company have the expertise to guide you through all the options. We make each tank exactly to your requirements. You can be absolutely sure the fuel tank systems will be perfectly suited to your needs. We make aviation fuel storage tanks with double wall, especially for underground storage to avoid from decontamination issues and gives much longer life. We are one priority for storing aviation fuel is to avoid contamination.

Aviation fuel storage tanks are all made to the highest standards of quality in a spotlessly clean, purpose-built manufacturing facility. Our team has more experience of both manufacturing fuel equipment. We always take the time to fully understand your business needs

#iso tank containers#T14 ISO Tank Containers#aviation fuel storage tanks#tote tank manufactures#offshoretankcontainer

0 notes

Photo

Offshore Tank Container

0 notes

Photo

Iso tank container

0 notes

Text

Chemical ISO Tank Container – Lava Engineering Company

Lava Engineering Company is the leading provider of Chemical ISO tank container for transportation of hazardous and non hazardous of chemicals. We are expert in designing high quality of container, construction and conform to international standards for transportation of chemicals. We are specializing in the multi-modal transportation of chemical iso tank containers and related services even in other countries; also we focus on the specialty chemicals industry covering every aspect of cargo shipments.

Our tank containers are in different capacities ranging from 8000 litres to 44,000 liters with ASME, IMDG, CSC, TIR, ADR/RID, US DOT, TC, UIC and CFR 49 design certification. These tanks are more suitable for transport of chemicals like Hydrochloric Acid (HCL), Caustic Soda, Sulfuric Acis, Ferric Chloride etc. To ensure optimum performance and durability, the tanks are made available with different lining such as Rubber / FRP/ PE Lining that can withstand temperature up to +65 deg C.

Within the chemical industry, Lava Engineering Company is a leading provider of domestic tank container on transportation and domestic off shore services throughout the world. Our chemical iso tank containers are designed to meet specified criteria according to the substance carrying, also highly designed to overcome leakage. We manufacturers the chemical ISO tank to maintain the temperature for sensitive cargo which can be transported by road, rail or ship.

0 notes

Link

0 notes

Text

Features of ISO Tank Container Dimension

A tank container is constructed to the ISO Standards, creating it appropriate for various modes of transportation. The ISO tank container is mainly used for transportation of edible liquids, diesel, hazardous and non hazardous chemicals, powder and gases.

ISO tank container dimension are designed to meet specified criteria according to the substance they will be carrying. Hence it is more reliable and can withstand extreme pressure and damage. They are highly designed from leakage, can maintain a specific temperature for temperature sensitive cargo and they can be transported by road, rail or boat.

Our ISO Tank Container Dimension can be customized according to the customer specification. These tanks are in huge demand among our customers in UAE, Qatar, Oman, Saudi Arabia, Kuwait, Malaysia, Singapore, Vietnam, Greece, France and Poland.

Since the ISO tank container are used for repeated use of bulk liquid transport, Lava Engineering Company manufacturers ISO tank container in various dimension. Our tanks are more safe, reliable and cost effective way to transport bulk liquids.

#iso tank container dimension#iso tank contianer#tote tank container#chemical tank container#offshore chemical tank container

0 notes

Text

Ultimate Features of 550G Tote Tanks

550G Tote tanks are perfect for storing and transporting products such as oil & gas industries, chemical industries, oil drilling companies, pharmaceutical industries and so on in large quantities. These type of containers are useful in bulk packaging capability allow it to be a low cost solution for shipping products.

Lava Engineering company manufacturers and offers various types of tote tanks container and accessories such as valves, funnels, mixers, nozzle kits and more. The most popular size of tote tank is 550G.

Stainless steel Tote tanks are eco-friendly alternative to manufacturers looking to green their processes. Reusable packaging, such as a tote tank, makes a positive impact on the environment, as well as the economy, by reducing labor, shipping and waste disposal costs.

Special features of 550G tote tanks are:

Ø Free from corrosion resistant.

Ø Tote tanks are better in safety and opera ability.

Ø Slopped bottom design helps in easy and safe drainage of chemicals and liquids.

0 notes

Text

ISO TANK CONTAINERS FOR MIDDLE EAST AND EUROPE

ISO tank containers are globally used to transport oils, chemicals and gases around the world and the latest innovation and technology has given rise to intermodal transportation of goods, which is both efficient and economical. Liquid and gas storage transport is made safe with the latest ISO tank containers that are equipped with heating and cooling system, special linings, various insulations, different kinds of accessories and are made of carbon or stainless steel, which makes for the durability and safety of tank containers and the products.

Lava Engineering Company is a leading provider of ISO tank containers for both domestic and international companies around India, Middle East and European countries owing to the uncompromised commitment to quality, safety and conformance to International Standards.

Some of our approved ISO Tank Container models are: T1 ISO tank container, T3, T4, T11, T14, T20, T50 and SWAP Tank container.

We can customize our transport solutions as per the requirement of different chemical and food industries like, Beverages, Pharmaceutical companies, Oil drilling companies, fuel transport and much more. These ISO tank containers are the most viable option for transport as they are technically designed to withstand as well as preserve the nature of the product.

Our service locations are: Gulf and Middle East countries like UAE, Iran, Oman, Saudi Arabia, Qatar, Kuwait, Bahrain and Asian countries like Singapore, Malaysia and Vietnam and North American countries like US and Mexico and European countries like Greece, France, Poland and Netherlands.

#ISO Tank Containers#ISO Tank Container#ISO Tank Containers for Europe#20ft ISO tank container#T4 ISO Tank Containers#T22 ISO Tank Containers

0 notes

Link

We are the Offshore Tanks Manufacturer for Middle East and Europe, where our products outrun the logistical challenges involved in the best way.

0 notes

Text

SAFETY FEATURES IN ISO TANK CONTAINERS

Tank Containers are largely used to transport Edible and Non-Edible Liquid, Hazardous Chemicals, Powders and Liquefied Gases. Tanks and Containers, which are manufactured following the design standards, safety regulations and International standards are the ISO Tank Containers.

There are many structural and operability features which enhance the safety standards of the ISO Tank Container. Some of them are:

a) Type of Frame. It may be: Structural Frame, Beam structure or a Collar structure

b) Shell of the Tank: It may be made of Carbon Steel / Stainless Steel

c) Lining of the Tank: Rubber Lining / FRP lining / PE lining

d) Manhole / Hatch: Fitted with gasket of different types for different Tanks.

e) Design Code: ASME VIII, EN 12972 ,ISO 668

Lava Engineering, a leading ISO Tank Container manufacturer, supplies different tanks in the range: T1 ISO Tanks, T3, T4, T11, T14, T22 and T50 ISO Tank Containers. These Containers are available in different sizes like 10ft, 20ft and 40ft length. These tanks are made to withstand temperatures from -40 Deg C up to 65 Deg C.

These tanks are tested for operability under pressure, equipped with Lead Lining and are capable to store and transport Edible Liquids and hazardous and Non-Hazardous Chemicals.

#ISO Tank Container#iso tank containers#T1 ISO Tanks#T11 ISO Tank Containers#T14 ISO Tank Containers#T22 ISO Tank Containers#T3 ISO Tank Containers#T4 ISO Tank Containers#T50 ISO Tank Containers

0 notes

Text

TRAILER TANKS WITH MAXIMUM PAYLOAD

Modern Technology has made Transport of Liquid Food Products, Petroleum, Gases and Oils, easy and cost-effective. Proper mode of transportation is the key for successful transportation. Trailer Tanks are the best choice to transport any kind of liquids and gases.

Each type of material carried, requires different container in which they are to be transported. Hence, the Trailer tanks are made of superior grade Aluminum, Carbon Steel or Stainless Steel.

To make the most out of the containers to maximize the payload, many weight saving options are implemented. Consequently, Operability is maximized and maintenance is made simple.

Lava Engineering Company, a renowned manufacturer of trailer tanks, offshore tanks and pressure vessels, offer tanks that meet custom requirements. Any size, any configuration, your requirements are assured to be fulfilled.

Trailer Tanks from Lava Engineering are equipped with Trailer Roll-Over protection, Collapsible Hand rails, Customized Ladder, Glass wool Insulation, Liquid Spill Collection area, ABS Braking, Triple Axle Suspension and many more optional fittings.

Besides these features that enhance operability, Tanks are built in such a way to maintain uniform weight distribution and optimize payloads.

The configuration is not the only catch here. All the trailer tanks, offshore tanks, pressure vessels and other containers are ISO certified and built following specific Domestic and International design codes.

0 notes