Don't wanna be here? Send us removal request.

Text

Wafer or Butterfly Valves: Characteristics and Materials

Butterfly valves are valves characterized by a disc shutter that rotates around an axis perpendicular to that of the pipe on which they are installed and act. Find out butterfly valves here: https://famaga.com

They are used in many areas: Aqueducts - they are used for interception by exploiting the main characteristics of this type of valve. In fact, being small in size, they make it possible to reduce the overall dimensions with respect to the classic gate valves that are normally used in this field; Engines with positive ignition - it is used both in the carburetor to regulate the air flow and in the injection unit to regulate the flow of the mixture. However, they have the disadvantage of generating significant head losses and other systems are sometimes preferred. Wafer valves are a particular configuration of butterfly valves with four centering ears obtained by casting the valve body. The wafer valves have a number of components necessary for the proper functioning: The valve body - represents the most cumbersome part and the support of the whole component. Usually made of spheroidal cast iron, carbon steel or stainless steel exploiting both the resistance characteristics and the corrosion resistance. Seat - made of elastomeric material and is necessary for sealing to avoid pressure or flow losses. Disc - this is the rotating element that acts as a shutter when the valve is closed and is also made of the same materials as the valve body. These are the main components of the valve but there is also an underlying flange and shaft which are made of the same materials as the valve disc and body. It is important to note that corrosion resistance is the main requirement and various methods such as epoxy powder paints are used for protection. Wafer valves are valves which, as seen, act by rotating the disc. Intermediate positions, however, generate pressure drops and inefficiencies and, for this reason, it is preferable not to use them for flow regulation but only in the two main configurations. Wafer valves, to be introduced on the market, must comply with some important certifications:- UNI EN 10204 3.1: it is a type of certification that certifies that the manufacturer has made the product according to the customer's specifications. In fact, this certificate summarizes the characteristics of the materials used, the results of tests carried out by a department independent of the factory, heat treatments and other properties.- UNI EN 12266-1: concerns the specifications and characteristics of the pressure tests, as well as the acceptance criteria of the same.- UNI EN 1074-1, 1074-2: establishes the criteria to be followed in the design, test and installation of components that transport water intended for human use. Compliance with these standards is a fundamental requirement for the certification of the product and, in this specific case, of important components such as wafer or butterfly valves.

0 notes

Text

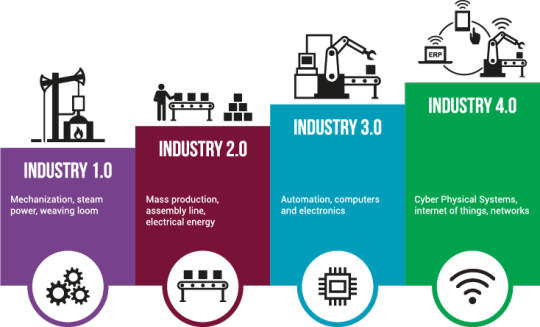

Evolution of Industrial Automation

Gradually, the automation of industrial processes has given rise to significant advances that have allowed companies to implement more efficient, safe and competitive production processes.

Let’s have a look through a brief history about the evolution of industrial automation, especially that ranges from the invention in 1947 of the first transistor, through the discoveries made in electronics, to the PLC , the digital factory and virtual simulation.

In 1947 the original idea was born by the Physicists John Bardeen, Walter Brattain, and William Shokkley, who developed the first transistor at Bell Labs.

Heinrich Grünebaum developed the Alquist engine, which became the godfather of controlled engines. It revolutionized rewinding processes in many years of automation technology.

In 1959 the first computer controlled machining tool appeared. The first Simatic controller on a capstan lathe was presented at the sixth version of the EMO fair in Paris. The logic was still hardwired.

In 1967 AMK introduced the first mass-produced infinitely variable three-phase squirrel-cage current motor. It was a big step forward in the electronic unit. Eight years later another AMK innovation allowed several three-phase motors to be operated with angular syncs for the first time.

In 1968 the success story of the PLC began with the development of Dick Morley's Modular Industrial Control.

In 1978 programming devices of the pre-PC era were very big and heavy. Machine-level CNC programming - once again introduced by AMK - represented a remarkable process.

In 1987 was the beginning of the era of PCs in the automation industry. A customer requested a Beckhoff control system to be equipped with a hard drive. The simplest solution was to integrate a PC. It soon became apparent that the PC could do more than act as a data collector for the control system.

1997 has seen a push for integration: Automation technology increasingly consists of intelligent, decentralized control and control components that can communicate with each other via Industrial Ethernet. Digital Factory and Virtual Commissioning: The world of digital product development merges with automation technology. Control programs for production processes are developed based on simulation.

In 2004 the functionality of the PLC was discovered on a chip.

To sum up, that’s how industrial automation evolved and came to this time. Currently, many new products, items, equipment are added and this field develops over and over.

3 notes

·

View notes