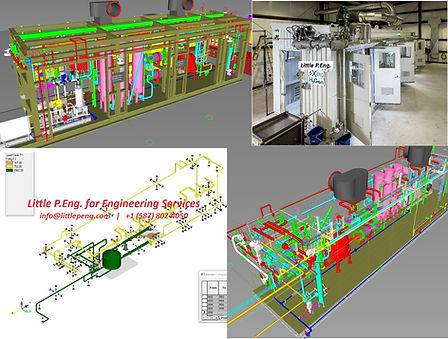

Piping Engineering / Pipe Stress Analysis Services across Canada. Little P.Eng. for Engineering Services proudly presents its licensed Professional Canadian Piping Stress Engineer; Located in Calgary Alberta, we serve our clients across Canada. Our professional piping stress engineers have a bachelor’s degree in mechanical / structural engineering and province license (P.Eng.) in Alberta, Saskatchewan, British Columbia, and Ontario. We review, validate, certify, and stamp piping and structural packages. Highly trained pipeline & piping engineers, specializing in piping stress analysis & finite element analysis in Calgary, Alberta, Canada & globally. Piping Stress Analysis is our specialty. Our primary focus is to provide expert piping engineering services. Combined with specialized training and depth of experience, we utilize industry leading tools, technologies, and methodologies to provide practical solutions. Tel: +1(587)802-4050 Email: [email protected] 3705 Fonda Way SE #18, Calgary, AB T2A 6G9

Don't wanna be here? Send us removal request.

Text

特务们都在中美之间干的什么样的勾当。 李老师帐号就是袁莉、余茂春、周封锁动人捧红的。 但李老师这个帐号被水军保护,被太多的网友投诉,敏感信息泄露给中共安全人员。

0 notes

Text

特务们都在中美之间干的什么样的勾当。 李老师帐号就是袁莉、余茂春、周封锁动人捧红的。 但李老师这个帐号被水军保护,被太多的网友投诉,敏感信息泄露给中共安全人员。

0 notes

Text

Little P.Eng. Engineering for Silo Design Services: Your Trusted Partner in Safe and Efficient Storage Solutions

In the realm of industrial storage, silos play a crucial role in ensuring the safe and efficient storage of bulk materials. From agricultural products to industrial chemicals, the design and construction of silos demand a high level of expertise and precision. Little P.Eng. Engineering, a leader in the field of engineering consulting, stands out as a trusted partner for silo design services. Our commitment to safety, innovation, and client satisfaction sets us apart in delivering superior storage solutions.

Comprehensive Silo Design Services

At Little P. Eng. Engineering, we offer a comprehensive range of silo design services tailored to meet the unique needs of each client. Our services encompass:

Custom Silo Design: Every project begins with a thorough understanding of the client's specific requirements. We design custom silos that accommodate various materials, including grains, cement, coal, and chemicals, ensuring optimal storage conditions and easy material handling.

Structural Analysis: Our team of experienced engineers conducts detailed structural analysis to guarantee the stability and durability of the silo. We utilize advanced software and methodologies to simulate different loading conditions, including wind, seismic, and thermal loads, ensuring the silo can withstand external forces.

Material Selection: Choosing the right materials is crucial for the longevity and safety of the silo. We guide our clients in selecting the most suitable materials, considering factors such as corrosion resistance, material strength, and cost-effectiveness.

Safety and Compliance: Safety is at the forefront of our design process. We ensure that all our silo designs comply with relevant industry standards and regulations. Our designs incorporate safety features such as pressure relief systems, explosion vents, and emergency access points to protect both the stored materials and the personnel.

Retrofit and Rehabilitation: In addition to new silo designs, we also offer retrofit and rehabilitation services for existing silos. Our team assesses the current condition of the silo and provides cost-effective solutions to enhance its performance, safety, and lifespan.

Why Choose Little P.Eng. Engineering?

Expertise and Experience: With years of experience in the field, our team of engineers possesses the knowledge and skills necessary to deliver high-quality silo designs. Our expertise spans various industries, allowing us to cater to a diverse clientele.

Innovative Solutions: We leverage the latest technologies and engineering practices to develop innovative solutions that meet the evolving needs of our clients. Our commitment to continuous improvement ensures that we stay ahead of industry trends and advancements.

Client-Centric Approach: At Little P.Eng. Engineering, client satisfaction is our top priority. We work closely with our clients throughout the entire design process, from initial consultation to project completion, ensuring their needs and expectations are met.

Quality Assurance: Quality is embedded in every aspect of our work. Our rigorous quality assurance processes ensure that each silo design is meticulously crafted and thoroughly reviewed to meet the highest standards of excellence.

Sustainable Practices: We are committed to promoting sustainability in our designs. Our silo designs incorporate eco-friendly materials and energy-efficient features, contributing to a greener and more sustainable future.

Benefits of Using Finite Element Method (FEM) for Silo Design

The Finite Element Method (FEM) is a powerful computational tool widely used in engineering for analyzing complex structures. In the context of silo design, FEM offers numerous advantages that enhance the design process, ensuring safety, efficiency, and cost-effectiveness. Here are the key benefits of using FEM for silo design:

1. Accurate Stress and Strain Analysis

Detailed Stress Distribution: FEM allows for a detailed examination of stress and strain within the silo structure. This is crucial for identifying potential failure points and ensuring the design can withstand various loading conditions.

Complex Load Combinations: Silos are subjected to multiple types of loads simultaneously, including dead loads, live loads, wind loads, and seismic loads. FEM can accurately simulate these complex load combinations and their effects on the structure.

2. Versatility in Material Modeling

Different Material Properties: FEM can model different materials used in silo construction, such as steel, concrete, and composites, accounting for their unique properties and behaviors under load.

Nonlinear Behavior: FEM handles nonlinear material behavior, which is essential for capturing the true response of materials under high stress or large deformations.

3. Geometric Flexibility

Complex Geometries: Silos often have complex geometries, including cylindrical shapes, hoppers, and various structural attachments. FEM can easily accommodate these complex shapes, providing accurate analysis results.

Detailed Structural Components: FEM allows for the inclusion of detailed structural components such as stiffeners, supports, and reinforcements, ensuring a comprehensive analysis.

4. Dynamic Analysis Capabilities

Seismic Analysis: FEM is particularly effective for dynamic analysis, such as simulating seismic events. It can model the response of the silo to ground motions, helping to design structures that can withstand earthquakes.

Wind-Induced Vibrations: FEM can also analyze the effects of wind-induced vibrations, which is critical for tall and slender silo structures.

5. Thermal Analysis

Temperature Effects: FEM can simulate the effects of temperature changes on the silo structure, including thermal expansion and contraction, which are important for assessing the integrity of the silo in different environmental conditions.

6. Optimization and Design Iterations

Design Optimization: FEM allows for iterative design processes, where different design configurations can be tested and optimized for performance, cost, and material usage.

Safety and Efficiency: By accurately predicting the structural behavior, FEM helps in designing safer and more efficient silos, reducing the likelihood of over-design or under-design.

7. Visualization and Interpretation

Graphical Representation: FEM provides graphical representations of stress, strain, and deformation, making it easier for engineers to interpret the results and communicate findings.

Failure Mode Identification: Visualization tools help in identifying potential failure modes and understanding how different parts of the silo interact under load.

Conclusion

Using the Finite Element Method in silo design significantly enhances the accuracy, efficiency, and reliability of the design process. It enables engineers to model complex geometries, analyze various load combinations, account for material properties, and optimize designs. By providing detailed insights into the structural behavior of silos, FEM ensures that these critical storage structures are safe, durable, and efficient, ultimately leading to better performance and cost savings in silo construction and maintenance.

Contact Us

For reliable and innovative silo design services, trust Little P.Eng. Engineering. Our team is ready to partner with you to develop storage solutions that meet your specific needs and exceed your expectations. Contact us today to learn more about our services and how we can assist you in achieving your storage goals.

Little P.Eng. Engineering Your Partner in Engineering Excellence

Website: www.littlepeng.com

Phone: +1 (587) 802-4050

Email: [email protected]

Tags:

Little P.Eng. Engineering

material selection

engineering consulting

corrosion resistance

structural analysis

innovative engineering

silo design

agricultural silos

client-centric approach

engineering excellence

grain storage

bulk storage solutions

sustainable silo design

safety compliance

thermal loading

quality assurance

explosion vents

custom silo design

advanced engineering software

silo rehabilitation

emergency access points

cement silos

industrial storage

chemical storage

eco-friendly materials

coal silos

seismic loading

wind loading

pressure relief systems

retrofitting silos

Bulk Material Handling & Processing

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Montréal, Quebec; Houston Texas; Torrance, California; El Segundo, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

0 notes

Text

Piping Stress Analysis and Supports Design Services

In the world of industrial piping systems, ensuring the reliability, safety, and efficiency of your pipelines is paramount. Our company specializes in providing comprehensive piping stress analysis and support design services, tailored to meet the unique needs of your projects. Here's how we can help you:

Why Choose Our Services?

Expertise and Experience

Our team of seasoned engineers possesses deep expertise in piping stress analysis and support design. With years of experience in the industry, we have successfully delivered solutions for a wide range of projects, from small-scale installations to large industrial complexes.

Advanced Software and Tools

We utilize state-of-the-art software such as CAESAR II, and AutoPIPE to perform detailed stress analysis. These tools allow us to accurately model your piping systems, identify potential issues, and develop robust solutions.

Customized Solutions

Every project is unique, and we understand the importance of tailored solutions. Our team works closely with you to understand your specific requirements and constraints, ensuring that our designs align perfectly with your operational goals.

Compliance with Industry Standards

Our designs adhere to the latest industry standards and codes, including ASME, ANSI, API, and EN. This ensures that your piping systems are not only efficient but also compliant with all regulatory requirements.

Comprehensive Support Design

We provide detailed support design, including hanger and support selection, layout optimization, and load calculations. Our goal is to minimize stress and movement in your piping systems, thereby enhancing their longevity and performance.

Our Services

Piping Stress Analysis

Conducting stress analysis to evaluate the effects of thermal expansion, pressure, weight, and other loads on piping systems.

Identifying potential stress points and failure risks.

Providing solutions to mitigate stress-related issues, ensuring the integrity and safety of your pipelines.

Support Design and Optimization

Designing and selecting appropriate supports, hangers, and restraints.

Optimizing the layout of supports to minimize stress and movement.

Conducting load calculations to ensure that supports can handle the anticipated loads without failure.

Thermal Expansion Analysis

Analyzing the effects of temperature changes on piping systems.

Designing expansion joints and loops to accommodate thermal movements.

Ensuring that thermal expansion does not compromise the structural integrity of your piping systems.

Seismic and Dynamic Analysis

Evaluating the impact of seismic events and other dynamic forces on piping systems.

Designing supports and restraints to withstand dynamic loads.

Conducting modal and response spectrum analyses to predict and mitigate the effects of dynamic events.

Failure Analysis and Troubleshooting

Investigating the root causes of piping system failures.

Providing recommendations for corrective actions and design improvements.

Implementing solutions to prevent recurrence and enhance system reliability.

Industries We Serve

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Why Stress Analysis and Support Design Matter

Proper piping stress analysis and support design are crucial for several reasons:

Safety

Preventing leaks, ruptures, and other failures that could pose safety hazards to personnel and the environment.

Reliability

Ensuring the continuous and efficient operation of your piping systems, minimizing downtime and maintenance costs.

Compliance

Adhering to industry standards and regulations, avoiding legal and financial penalties.

Cost Efficiency

Reducing the risk of costly repairs and replacements through proactive design and analysis.

Get in Touch

Ready to enhance the safety, reliability, and efficiency of your piping systems? Contact us today to discuss your project and learn more about our piping stress analysis and support design services. Our team is dedicated to delivering the highest quality solutions to meet your needs.

Tags:

CAESAR II

piping stress analysis

seismic analysis

ASME standards

AutoPIPE

thermal expansion analysis

oil and gas piping

power generation piping

industrial piping systems

support design

failure analysis

petrochemical piping

expansion joints

chemical piping

API compliance

manufacturing piping

SAP2000

load calculations

troubleshooting

wastewater systems

thermal movements

expansion loops

support optimization

dynamic analysis

ANSI codes

pharmaceutical piping

hanger selection

EN standards

food and beverage piping

water systems

Pipe Stress Analysis Services

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Montréal, Quebec; Houston Texas; Torrance, California; El Segundo, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

0 notes

Text

Little P.Eng. Engineering: Comprehensive Silo Design Services

When it comes to storing bulk materials safely and efficiently, the design of silos plays a crucial role. Little P.Eng. Engineering offers expert silo design services tailored to meet the specific needs of various industries. Our team of experienced engineers is dedicated to providing innovative and reliable solutions, ensuring your silos are designed with the utmost precision and safety.

Why Choose Little P.Eng. Engineering for Silo Design?

Expertise in Structural Engineering Our engineers possess extensive knowledge and experience in structural engineering, enabling us to design silos that are not only robust but also optimized for cost-effectiveness and functionality.

Customized Solutions We understand that each project is unique. Our team works closely with clients to develop customized silo designs that cater to their specific storage requirements, environmental conditions, and operational needs.

Compliance with Standards Little P.Eng. Engineering ensures that all our silo designs comply with relevant industry standards and regulations. We prioritize safety and durability, adhering to the highest engineering standards to provide reliable storage solutions.

Advanced Design Tools Utilizing state-of-the-art design tools and software, our engineers perform detailed analyses and simulations to predict the behavior of silo structures under various conditions. This allows us to optimize the design for performance and longevity.

End-to-End Service From initial consultation and conceptual design to detailed engineering and construction support, Little P.Eng. Engineering offers comprehensive services throughout the entire project lifecycle. Our goal is to deliver seamless and efficient project execution.

Our Silo Design Services Include:

Structural Analysis and Design: Ensuring the structural integrity and stability of silos under different load conditions.

Material Selection: Recommending the best materials for construction based on the stored material properties and environmental factors.

Foundation Design: Designing strong and stable foundations to support the silo structure and prevent settlement issues.

Seismic and Wind Load Analysis: Performing detailed analyses to ensure the silo can withstand seismic activities and high wind loads.

Thermal and Insulation Considerations: Addressing thermal expansion and contraction issues, as well as insulation requirements for temperature-sensitive materials.

Operational Efficiency: Designing for easy loading, unloading, and maintenance to enhance operational efficiency.

Industries We Serve

Little P.Eng. Engineering provides silo design services to a wide range of industries, including:

Agriculture: Grain storage silos, feed silos, and other agricultural storage solutions.

Manufacturing: Silos for storing raw materials, chemicals, and finished products.

Food Processing: Silos for storing food ingredients, bulk products, and processing materials.

Energy: Storage solutions for coal, biomass, and other energy resources.

Mining: Silos for storing ore, minerals, and other extracted materials.

Contact Us

Ready to start your silo design project? Contact Little P.Eng. Engineering today to discuss your requirements and discover how our expertise can benefit your storage solutions.

Phone: +1 (587) 802-4050

Email: [email protected]

Website: https://www.littlepeng.com/blog-little-p-eng-for-engineers-tra/categories/bulk-material-handling

Tags:

material selection

structural engineering

operational efficiency

structural analysis

foundation design

innovative engineering

wind load analysis

silo design

agricultural silos

seismic load analysis

grain storage

compliance with standards

bulk material storage

manufacturing silos

insulation requirements

food processing silos

construction support

mining silos

energy storage silos

thermal considerations

advanced design tools

cost-effective design

customized silo solutions

storage solutions

project lifecycle

feed silos

silo stability

safety in silo design

reliable storage

industrial silos

Bulk Material Handling & Processing

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Montréal, Quebec; Houston Texas; Torrance, California; El Segundo, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

0 notes

Text

Little P.Eng. Engineering: Expert Silo and Bin Engineering Design Services Across Canada and the United States

At Little P.Eng. Engineering, we specialize in delivering top-tier engineering design services for silos and bins across Canada and the United States. Our expertise ensures that your storage systems are safe, efficient, and tailored to meet the specific needs of your industry.

Why Choose Little P.Eng. Engineering for Silo and Bin Design?

Unmatched Expertise Our team of seasoned engineers brings extensive experience in designing robust and efficient silos and bins, ensuring optimal performance and safety.

Tailored Solutions We understand that each project is unique. Our solutions are customized to meet your specific storage requirements, environmental conditions, and operational needs.

Compliance with Regulations We ensure that all our designs comply with local and international standards, providing peace of mind that your storage systems meet the highest safety and quality benchmarks.

Cutting-Edge Technology Leveraging the latest design tools and technologies, we perform detailed structural analyses and simulations, optimizing every aspect of your silo and bin design.

Comprehensive Services From initial consultation and conceptual design to detailed engineering and construction support, we offer end-to-end services to ensure a seamless project execution.

Types of Silos and Bins

Understanding the various types of silos and bins is essential for selecting the right storage solution for your needs. At Little P.Eng. Engineering, we specialize in designing a wide range of silos and bins to meet diverse storage requirements.

Types of Silos

Tower Silos

Concrete Silos: Built using concrete stave, slipform, or precast concrete panels, these silos are known for their durability and long service life.

Steel Silos: Made from galvanized steel, these silos are easy to erect and cost-effective, suitable for storing dry bulk materials.

Bunker Silos: Constructed using concrete walls, these silos are ideal for storing large quantities of silage, grains, and other materials that can be compacted.

Bag Silos

These are large, sealed plastic bags used for temporary storage of grains and silage. They are flexible and can be used in various locations.

Horizontal Silos

Trench Silos: Excavated into the ground, these silos are lined with concrete or plastic and are suitable for storing silage.

Bunker Silos: Above-ground versions of trench silos, often used in agricultural settings for storing large volumes of silage.

Types of Bins

Hopper Bins

Designed with a conical bottom, these bins allow for easy discharge of stored materials. They are commonly used for grain storage and feed.

Flat Bottom Bins

These bins have a flat bottom and are suitable for long-term storage of dry bulk materials. They are often used in agricultural and industrial settings.

Square Bins

Typically used in industrial applications, square bins are designed for efficient use of space and easy integration into existing systems.

Methods for Analysis and Design

To ensure the structural integrity and operational efficiency of silos and bins, Little P.Eng. Engineering employs advanced methods for analysis and design. These methods help us predict and mitigate potential issues, ensuring reliable and safe storage solutions.

Structural Analysis

Finite Element Analysis (FEA)

FEA is used to simulate and analyze the structural behavior of silos and bins under various load conditions. This method helps identify stress points and potential failure areas, allowing for optimized design.

Load and Stress Analysis

We perform detailed analyses to understand the effects of static and dynamic loads on silos and bins. This includes considering the weight of stored materials, wind loads, seismic activity, and thermal expansion.

Seismic and Wind Load Analysis

Silos and bins must be designed to withstand environmental forces such as earthquakes and high winds. We use advanced modeling techniques to ensure stability and safety under these conditions.

Design Considerations

Material Selection

Choosing the right materials for construction is crucial. We consider factors such as the properties of the stored materials, environmental conditions, and the required durability of the structure.

Foundation Design

A strong and stable foundation is essential for supporting the weight of silos and bins. We design foundations to prevent settlement issues and ensure long-term stability.

Thermal and Insulation Considerations

Thermal expansion and contraction can affect the structural integrity of silos and bins. We address these issues by incorporating appropriate insulation and design features to manage temperature variations.

Operational Efficiency

Our designs prioritize ease of loading, unloading, and maintenance. We consider factors such as access points, ventilation, and safety features to enhance operational efficiency.

Compliance with Standards

Ensuring compliance with local, national, and international standards is a key aspect of our design process. We adhere to industry regulations to provide safe and reliable storage solutions.

Design Codes for Silos and Bins

Adhering to established design codes and standards is crucial for ensuring the safety, reliability, and efficiency of silos and bins. These codes provide guidelines for materials, construction practices, load calculations, and other critical aspects of design. At Little P. Eng. Engineering, we rigorously follow these codes to deliver high-quality storage solutions.

Key Design Codes and Standards

ACI 313: Design and Construction of Concrete Silos and Stacking Tubes for Storing Granular Materials

The American Concrete Institute (ACI) provides comprehensive guidelines for the design and construction of concrete silos and stacking tubes. This code addresses the structural integrity, load considerations, and construction practices specific to concrete storage structures.

AISC: American Institute of Steel Construction Standards

AISC standards are essential for the design and construction of steel silos and bins. These standards cover aspects such as steel material properties, design loads, connections, and construction practices to ensure the safety and durability of steel structures.

ASCE 7: Minimum Design Loads for Buildings and Other Structures

The American Society of Civil Engineers (ASCE) provides guidelines for determining the minimum design loads for various structures, including silos and bins. ASCE 7 includes provisions for dead loads, live loads, wind loads, seismic loads, and other environmental factors.

Eurocode 1: Actions on Structures

Eurocode 1 provides comprehensive guidelines for determining actions on structures, including silos and bins, in Europe. This standard covers a wide range of load types, including permanent, variable, and accidental actions, ensuring a holistic approach to structural design.

Eurocode 3: Design of Steel Structures

Eurocode 3 offers detailed guidelines for the design of steel structures, ensuring the safety and performance of steel silos and bins. This code includes provisions for material properties, structural analysis, and construction details.

Eurocode 8: Design of Structures for Earthquake Resistance

For regions prone to seismic activity, Eurocode 8 provides specific guidelines for designing structures, including silos and bins, to withstand earthquake forces. This standard ensures that structures are capable of maintaining their integrity and functionality during and after seismic events.

NFPA 68: Standard on Explosion Protection by Deflagration Venting

The National Fire Protection Association (NFPA) provides guidelines for protecting silos and bins from explosion hazards. NFPA 68 focuses on deflagration venting, offering design criteria and safety measures to mitigate the effects of explosions.

AS/NZS 1170: Structural Design Actions

In Australia and New Zealand, the AS/NZS 1170 standard outlines structural design actions, including load considerations for silos and bins. This standard ensures that structures are designed to withstand various environmental and operational loads.

Load Considerations

Design codes provide detailed guidelines for determining and applying various loads to silos and bins. These loads include:

Dead Loads

The weight of the structure itself, including walls, floors, roofs, and any permanent fixtures.

Live Loads

Loads resulting from the stored materials, as well as any temporary loads such as maintenance equipment or personnel.

Wind Loads

Forces exerted by wind pressure, which can significantly impact the structural integrity of tall and slender silos.

Seismic Loads

Forces generated by seismic activity, which are critical for designing silos and bins in earthquake-prone regions.

Thermal Loads

Effects of temperature variations on the materials and structure, which can cause expansion and contraction.

Dynamic Loads

Loads resulting from dynamic effects such as vibrations, material discharge, and other operational activities.

Material Selection and Design

Design codes also provide guidelines for selecting appropriate materials and ensuring their proper use in construction. Key considerations include:

Material Properties

Specifications for material strength, durability, and performance under various conditions.

Corrosion Protection

Guidelines for protecting materials from corrosion, especially in environments where stored materials or atmospheric conditions may cause degradation.

Welds and Connections

Standards for designing and executing welds and connections to ensure structural integrity and safety.

Quality Control

Procedures for ensuring the quality of materials and construction practices through inspections, testing, and certification.

Our Silo and Bin Design Services Include:

Structural Analysis and Design: Ensuring the integrity and stability of silos and bins under various load conditions.

Material Selection: Recommending optimal materials for construction based on the properties of the stored materials and environmental factors.

Foundation Design: Creating strong, stable foundations to support your storage systems and prevent settlement issues.

Seismic and Wind Load Analysis: Performing detailed analyses to ensure your silos and bins can withstand seismic activities and high wind loads.

Thermal and Insulation Considerations: Addressing thermal expansion and contraction issues, as well as insulation requirements for temperature-sensitive materials.

Operational Efficiency: Designing for easy loading, unloading, and maintenance to enhance operational efficiency.

Industries We Serve

We provide silo and bin design services to a wide range of industries, including:

Agriculture: Grain storage silos, feed silos, and other agricultural storage solutions.

Manufacturing: Silos and bins for storing raw materials, chemicals, and finished products.

Food Processing: Silos and bins for storing food ingredients, bulk products, and processing materials.

Energy: Storage solutions for coal, biomass, and other energy resources.

Mining: Silos and bins for storing ore, minerals, and other extracted materials.

Serving Canada and the United States

Contact Us

Ready to start your silo and bin design project? Contact Little P.Eng. Engineering today to discuss your requirements and discover how our expertise can benefit your storage solutions.

Phone: +1 (587) 802-4050

Email: [email protected]

Website: littlepeng.com

By choosing Little P.Eng. Engineering for your silo and bin design needs, you are ensuring a high-quality, efficient, and safe storage solution tailored to your specific requirements. Let us help you build the future of your storage systems.

Tags:

material selection

structural engineering

finite element analysis

structural analysis

foundation design

wind load analysis

silo design

agricultural silos

seismic load analysis

compliance with standards

bulk material storage

manufacturing silos

insulation requirements

food processing silos

construction support

mining silos

energy storage silos

thermal considerations

hopper bins

flat bottom bins

Eurocode

steel silos

concrete silos

ACI 313

AS/NZS 1170

bin design

ASCE standards

AISC standards

load stress analysis

NFPA 68

Bulk Material Handling & Processing

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Montréal, Quebec; Houston Texas; Torrance, California; El Segundo, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

0 notes

Text

Seismic Design Solutions Across Canada and USA: Little P.Eng. Leading the Way

In the ever-evolving landscape of infrastructure and industrial development, the importance of seismic design cannot be overstated. Little P.Eng. stands at the forefront of providing cutting-edge seismic design solutions across Canada and the USA. With a robust team of seismic engineers, structural engineers, and piping engineers, Little P.Eng. offers unparalleled expertise in ensuring the resilience and safety of various structures and systems.

Expertise in Seismic Engineering

At Little P.Eng., our seismic engineers are adept at understanding the intricate dynamics of seismic forces and their impact on structures. Whether it's designing earthquake-resistant buildings or retrofitting existing ones to enhance their seismic performance, our team employs state-of-the-art technologies and methodologies to deliver optimal results.

Comprehensive Structural Engineering Services

Our structural engineers play a pivotal role in the development of resilient structures that can withstand seismic activities. From the initial design phase to the final implementation, we ensure that every aspect of structural integrity is meticulously addressed. This comprehensive approach guarantees that the buildings, bridges, and other infrastructures we work on are not only compliant with current seismic codes but also exceed industry standards for safety and durability.

Pioneering Piping Engineering Solutions

Seismic activities pose significant challenges to piping systems, which are critical components of industrial facilities. Little P.Eng.'s piping engineers specialize in designing and analyzing piping systems to ensure they remain operational and safe during seismic events. Our expertise extends to various industries, including oil and gas, chemical processing, and water treatment plants, where the integrity of piping systems is paramount.

Specialized Silo Design for Seismic Resilience

Silos, essential for storing bulk materials, require specialized design considerations to withstand seismic forces. At Little P.Eng., we excel in creating silos that not only meet but exceed seismic safety standards. Our designs incorporate advanced materials and construction techniques to ensure that silos remain stable and secure, even in the most seismic-prone areas.

Innovative Belt Conveyor Systems

Belt conveyors are vital for the efficient transport of materials in various industries. Our seismic engineers work closely with structural engineers to design belt conveyor systems that can endure seismic stresses. This collaboration ensures that our conveyor systems are both efficient and resilient, providing uninterrupted operation even during seismic events.

Storage Tank Design and Analysis

Storage tanks, whether for water, chemicals, or other liquids, are crucial components of many industrial operations. Little P.Eng. offers specialized storage tank design and analysis services that prioritize seismic resilience. Our comprehensive approach includes evaluating site-specific seismic risks and applying advanced engineering principles to ensure that storage tanks remain safe and functional during earthquakes.

Why Choose Little P.Eng.?

As a leading seismic company in North America, Little P.Eng. is committed to delivering innovative and reliable solutions. Our multidisciplinary team of engineers brings together extensive experience and expertise, ensuring that every project we undertake is executed with the highest level of precision and quality. We pride ourselves on our ability to tailor our services to meet the unique needs of our clients, providing customized solutions that address specific seismic challenges.

In conclusion, Little P.Eng. is your trusted partner for seismic design solutions across Canada and the USA. Our comprehensive range of services, from structural and piping engineering to specialized silo and storage tank design, positions us as the go-to seismic company for projects of any scale. Choose Little P.Eng. for unparalleled expertise and a commitment to safety and resilience in the face of seismic challenges.Seismic Design Solutions Across Canada and USA: Little P.Eng. Leading the Way

About Little P.Eng.

Little P.Eng. is a premier engineering consultancy specializing in seismic design and analysis, structural engineering, and piping engineering. With a strong presence across Canada and the USA, we provide innovative solutions that ensure the safety and resilience of various industrial and infrastructure projects. Our team of highly skilled engineers is dedicated to delivering excellence through every stage of the project lifecycle.

Tags:

Structural Engineer

Piping Engineer

Seismic Design

Storage Tank

Engineering Consultancy

Structural Integrity

Seismic Engineer

Silo Design

Bulk Material Storage

Industrial Piping Systems

North America Seismic Solutions

Belt Conveyor

Industrial Facility Safety

Earthquake Mitigation

Seismic Risk Evaluation

Industrial Conveyors

Seismic Resilience

Oil and Gas Piping

Seismic Safety Standards

Advanced Construction Techniques

Site-Specific Seismic Analysis

Seismic Retrofitting

Earthquake-Resistant Tanks

Water Treatment Piping

Seismic-Resistant Silos

Infrastructure Resilience

Seismic Company

Seismic Code Compliance

Chemical Processing Piping

Earthquake-Resistant Structures

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Montréal, Quebec; Houston Texas; Torrance, California; El Segundo, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

0 notes

Text

Little P.Eng. Engineering: Expert Structural Analysis and Load Calculation for Temporary Sheet Pile Walls

When it comes to construction projects requiring temporary support structures, one of the most critical aspects is ensuring the safety and stability of these structures. Temporary sheet pile walls, commonly used for excavation support, soil retention, and water control, must be designed to withstand the forces they will encounter. At Little P.Eng. Engineering, we specialize in providing detailed structural analysis and precise load calculations to ensure that your temporary sheet pile walls are both effective and safe.

Why Temporary Sheet Pile Walls Matter

Temporary sheet pile walls are used in various civil engineering projects, including deep excavations, waterfront constructions, and underground structures. These walls serve as temporary barriers that prevent soil movement and water ingress, allowing construction activities to proceed safely.

However, the temporary nature of these walls does not reduce the importance of their structural integrity. Poorly designed sheet pile walls can lead to catastrophic failures, resulting in project delays, additional costs, and significant safety hazards.

Structural Analysis: Ensuring Stability and Safety

At Little P.Eng. Engineering, our approach to structural analysis begins with a comprehensive assessment of the project site. This includes:

Soil Investigation: Understanding the type of soil and its properties is crucial. Soil characteristics such as cohesion, friction angle, and density directly influence the design of the sheet pile wall. We conduct or review thorough geotechnical investigations to gather this essential data.

Load Assessment: Temporary sheet pile walls are subject to various loads, including earth pressure, water pressure, and surcharge loads from nearby structures or machinery. Our engineers meticulously calculate these loads to ensure the wall can withstand them.

Structural Modeling: Using advanced software tools, we create detailed structural models of the sheet pile wall. These models allow us to simulate different load scenarios, assess the wall’s performance, and identify any potential failure modes.

Safety Factor Consideration: Safety is our top priority. We incorporate appropriate safety factors into our design to account for uncertainties in material properties, construction practices, and load conditions.

Load Calculation: Precision and Accuracy

Load calculation is a critical component of the design process for temporary sheet pile walls. Our engineers follow industry standards and best practices to ensure accuracy in our calculations:

Earth Pressure Calculations: We calculate the lateral earth pressure exerted on the sheet pile wall using established methods such as Rankine or Coulomb theories. These calculations consider factors like soil type, wall height, and wall inclination.

Water Pressure Analysis: In cases where the sheet pile wall retains water or is installed below the water table, hydrostatic pressure becomes a significant factor. We perform detailed analyses to ensure the wall can resist these pressures without excessive deformation or failure.

Surcharge Load Evaluation: Construction activities often involve additional loads from equipment, materials, or adjacent structures. We assess these surcharge loads and incorporate them into our design to prevent unexpected wall movement or collapse.

Structural Integrity Checks: Once the loads are calculated, we verify the structural integrity of the sheet pile wall, including checks for bending moments, shear forces, and deflection limits. This ensures that the wall can handle the anticipated loads without compromising stability.

Why Choose Little P.Eng. Engineering?

At Little P.Eng. Engineering, we bring a wealth of experience and expertise to every project. Our team of professional engineers is well-versed in the latest industry standards, and we utilize cutting-edge technology to deliver reliable and cost-effective solutions. Here’s why clients choose us for their temporary sheet pile wall projects:

Comprehensive Analysis: We leave no stone unturned in our structural analysis, ensuring that every aspect of the wall’s performance is considered.

Precision in Design: Our meticulous approach to load calculation ensures that our designs are both accurate and reliable.

Safety First: We prioritize safety in all our designs, incorporating appropriate safety factors and conducting rigorous checks to prevent failures.

Tailored Solutions: We understand that every project is unique. Our designs are customized to meet the specific needs and conditions of your site.

Little P.Eng. Engineering: Expert Structural Analysis and Load Calculation for Temporary Sheet Pile Walls

Conclusion

Temporary sheet pile walls play a vital role in many construction projects, and their design requires careful consideration of various factors. At Little P.Eng. Engineering, we provide expert structural analysis and load calculation services to ensure that your temporary sheet pile walls are safe, stable, and effective. With our attention to detail and commitment to quality, you can trust us to deliver designs that meet the highest standards of engineering excellence.

For more information about our services or to discuss your project needs, please contact Little P.Eng. Engineering today.

Structural Analysis and Load Calculation for Temporary Sheet Pile Walls: Design Codes and Soil Considerations

Temporary sheet pile walls are critical components in construction projects, particularly for excavation support, soil retention, and water control. Their design requires a comprehensive understanding of relevant design codes and a thorough analysis of soil properties. This article outlines the key design codes and soil considerations essential for the structural analysis and load calculation of temporary sheet pile walls.

Design Codes for Temporary Sheet Pile Walls

The design of temporary sheet pile walls must adhere to established engineering standards and codes to ensure safety and reliability. Some of the key design codes and guidelines include:

American Association of State Highway and Transportation Officials (AASHTO) LRFD Bridge Design Specifications:

AASHTO provides guidelines for the design of temporary structures, including sheet pile walls, particularly in transportation-related projects. It emphasizes Load and Resistance Factor Design (LRFD) principles.

Eurocode 7: Geotechnical Design (EN 1997-1):

Eurocode 7 offers comprehensive guidelines for the geotechnical design of structures, including sheet pile walls. It focuses on limit state design principles, considering factors such as soil strength, groundwater conditions, and structural behavior under various loads.

British Standard BS 8002: Code of Practice for Earth Retaining Structures:

BS 8002 provides guidelines specifically for earth-retaining structures, including sheet pile walls. It outlines methods for calculating earth pressures and the design of retaining walls to ensure stability.

Canadian Foundation Engineering Manual (CFEM):

The CFEM offers guidance on the geotechnical aspects of foundation and retaining wall design, commonly used in Canada. It includes methods for analyzing soil properties and calculating earth pressures for temporary structures.

U.S. Army Corps of Engineers (USACE) Engineering Manual EM 1110-2-2504:

This manual is widely referenced for the design of retaining and flood walls, including sheet pile walls. It includes detailed procedures for analyzing earth and water pressures and designing walls to resist these forces.

Soil Considerations in Sheet Pile Wall Design

The performance of a temporary sheet pile wall is heavily influenced by the properties of the soil it interacts with. Accurate soil characterization is essential for the structural analysis and load calculation of these walls. Key soil considerations include:

Soil Type and Classification:

The type of soil (e.g., clay, silt, sand, gravel) determines its strength and behavior under load. Soil classification systems, such as the Unified Soil Classification System (USCS) or the AASHTO soil classification system, are used to categorize soil types.

Soil Strength Parameters:

Cohesion (c) and angle of internal friction (φ) are critical soil strength parameters. These values are obtained from laboratory tests, such as triaxial compression tests or direct shear tests. Cohesive soils (like clays) exhibit cohesion, while non-cohesive soils (like sands) primarily rely on internal friction.

Earth Pressure Theories:

Temporary sheet pile walls must be designed to resist lateral earth pressures. The Rankine and Coulomb earth pressure theories are commonly used to calculate these pressures. Rankine's theory is simpler and assumes no wall friction, while Coulomb's theory considers wall friction and wall-soil interface angles.

Groundwater Conditions:

The presence of groundwater can significantly affect the stability of a sheet pile wall. Hydrostatic pressure exerted by water adds to the lateral load on the wall. Proper drainage or dewatering systems should be considered to manage groundwater levels and reduce water pressure on the wall.

Soil-Structure Interaction:

The interaction between the soil and the sheet pile wall is a complex phenomenon that requires careful analysis. Factors such as wall embedment depth, wall flexibility, and soil compaction influence how the wall will perform under load.

Surcharge Loads:

Additional loads from construction equipment, adjacent structures, or stored materials near the sheet pile wall are considered surcharge loads. These loads increase the lateral pressure on the wall and must be accounted for in the design.

Soil Erosion and Scour:

Temporary sheet pile walls in areas prone to soil erosion or scour require special attention. The design must ensure that the wall can withstand the loss of soil support due to erosion, which could lead to wall instability.

Conclusion

The design of temporary sheet pile walls is a complex process that requires adherence to established design codes and a deep understanding of soil properties. By carefully considering soil type, strength parameters, groundwater conditions, and other factors, engineers can ensure that these structures are safe, stable, and effective. At Little P.Eng. Engineering, we specialize in providing precise sheet pile wall structural analysis and load calculation services that comply with the latest codes and standards, ensuring the success of your construction project.

For further information on our services or to discuss your specific project needs, please contact Little P.Eng. Engineering.

Tags:

Little P.Eng. Engineering

structural analysis

professional engineering services

custom engineering solutions

engineering excellence

soil properties

structural design accuracy

water pressure analysis

water control

surcharge load evaluation

safety factors in design

temporary structures

sheet pile wall engineering

wall stability

bending moment check

temporary wall integrity

excavation support

Rankine theory

construction project support

temporary sheet pile wall design

sheet pile wall failure prevention

Coulomb theory

geotechnical investigation

load calculation

earth pressure analysis

shear force analysis

structural modeling

deflection limits

soil retention

construction safety

Structural Engineering Consultancy

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Montréal, Quebec; Houston Texas; Torrance, California; El Segundo, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

0 notes

Text

Pipe Stress Analysis: When It’s Required, Key Requirements, and How to Perform It

Piping systems are critical components in various industries, especially in oil and gas, chemical processing, power generation, and manufacturing. These systems are responsible for transporting fluids and gases under varying pressures and temperatures. As a result, they are subjected to stress, which can lead to failure if not properly accounted for. This is where pipe stress analysis comes into play. It ensures the safety, functionality, and longevity of piping systems by evaluating the forces and stresses that affect the pipes. This article delves into when pipe stress analysis is required, its key requirements, and how to perform it.

When Is Pipe Stress Analysis Required?

High Pressure and Temperature: Piping systems that operate under high pressures and temperatures are more likely to experience significant expansion, contraction, and mechanical stress. Pipe stress analysis is crucial in such cases to ensure the system can withstand these forces without failure.

Thermal Expansion: Pipes that transport fluids at varying temperatures can expand or contract, leading to mechanical stress on the system. In systems with substantial temperature variations, pipe stress analysis is necessary to assess how the piping will react to these changes and to design appropriate expansion loops or expansion joints.

Complex Piping Layouts: In industries with complicated piping configurations, such as refineries and power plants, piping systems may experience uneven stress distribution due to sharp bends, multiple supports, or intersections. An analysis helps ensure that the design can handle these complexities.

Large-Diameter Piping: Larger-diameter pipes are more susceptible to external loads like wind, seismic activity, or vibrations. These external forces can induce significant stresses, making stress analysis essential.

Regulatory Compliance: In many industries, compliance with codes and standards such as ASME (American Society of Mechanical Engineers) or EN (European Standards) mandates that pipe stress analysis be performed to ensure safety and reliability.

Mechanical Equipment Connections: Piping systems that connect to critical mechanical equipment like pumps, turbines, or heat exchangers require stress analysis to ensure that the forces exerted on the equipment do not exceed allowable limits.

Key Requirements of Pipe Stress Analysis

To perform a thorough pipe stress analysis, several factors must be considered:

Design Codes and Standards: The analysis must comply with industry standards and codes such as ASME B31.1 for power piping, ASME B31.3 for process piping, and EN 13480 in Europe. These codes provide guidelines on allowable stress limits, materials, and other critical parameters.

Material Properties: The analysis must account for the material properties of the piping, including yield strength, thermal expansion coefficient, and allowable stress limits under different conditions. Different materials will respond to stress and temperature changes differently.

Piping Layout: The geometric layout, including bends, fittings, supports, and intersections, must be taken into account. The layout can influence the distribution of stress and the flexibility of the system.

External Loads: Wind, seismic forces, and vibrations can impose significant external loads on piping systems, affecting their integrity. These must be included in the analysis, especially in critical installations.

Support Design: Proper support design ensures that the piping system remains stable and prevents excessive displacement. Supports such as hangers, guides, and anchors must be placed at the correct intervals based on the results of the stress analysis.

Thermal Expansion and Contraction: Since most industrial piping systems are subject to temperature fluctuations, the analysis must calculate how thermal expansion and contraction affect the overall stress on the system. This is crucial to avoid overstressing the pipe and its supports.

Fluid Dynamics: The flow of fluids or gases within the piping system can induce dynamic stresses, especially if there are rapid changes in velocity or pressure. An analysis must consider these dynamic effects to ensure safe operation.

How to Perform Pipe Stress Analysis

Performing pipe stress analysis typically involves using specialized software and adhering to a systematic process:

1. Define the System

Start by gathering all necessary information about the piping system. This includes:

Piping layout drawings (P&IDs and isometric drawings)

Material specifications

Operating conditions (temperature, pressure)

Support locations and types

Equipment connections and locations

2. Model the System

Using stress analysis software (such as CAESAR II, AutoPIPE, or Rohr2), create a 3D model of the piping system. This model will include all the piping, bends, elbows, tees, flanges, and supports. The software allows you to input the piping geometry, material properties, and operating conditions.

3. Input Loading Conditions

The next step is to input the loads the piping system will experience. These include:

Internal pressure and temperature

Weight of the pipe and fluid

External loads (wind, seismic, thermal expansion)

Dynamic loads (fluid flow-induced vibrations, transient events like water hammer)

4. Perform the Stress Analysis

The software will calculate the stresses, forces, and displacements in the system based on the input conditions. It will compare the results against allowable stress limits set by design codes. The analysis will also identify any areas of overstress or excessive displacement, which can then be addressed in the design.

5. Evaluate the Results

After running the analysis, the results must be carefully evaluated. Key metrics to review include:

Stresses in each pipe segment (compared to allowable stresses)

Forces and moments on supports and equipment

Displacements at critical locations (e.g., at equipment nozzles)

Support loads and reactions

6. Optimize the Design

If the analysis reveals areas of concern, adjustments should be made to the design. Common solutions include:

Adding or repositioning supports

Incorporating expansion loops or joints

Modifying the layout to reduce stresses

Changing the material or wall thickness of the pipe

7. Verify Compliance

Ensure that the final design meets all relevant codes and standards. This is a critical step for regulatory approval and for ensuring the long-term reliability and safety of the system.Pipe Stress Analysis: When It’s Required, Key Requirements, and How to Perform It

Conclusion

Pipe stress analysis is essential for ensuring the safety, reliability, and functionality of piping systems in industries with high pressures, temperatures, or complex layouts. By following a structured approach and adhering to industry codes and standards, engineers can design piping systems that withstand various stresses, minimize risk, and optimize performance. Whether for new construction or retrofitting existing systems, pipe stress analysis remains a critical part of the design and maintenance process.

Tags:

Pipe stress analysis

piping code compliance

industrial piping systems

pipe stress software

allowable stress limits

pipe failure prevention

pipe stress optimization

piping system design

stress analysis requirements

stress analysis process

high-temperature piping systems

AutoPIPE stress analysis

wind load on piping

external loads on pipes

dynamic pipe stress

high-pressure piping

pipe stress calculations

ASME piping codes

pipe system safety

CAESAR II pipe analysis

pipe supports design

piping expansion loops

pipe material properties

fluid dynamics in piping

thermal expansion in pipes

piping layout stress

seismic load piping

pipe equipment connections

thermal contraction in pipes

pipe displacement analysis

Piping Stress Analysis

Pipe Stress Analysis Notes

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Montréal, Quebec; Houston Texas; Torrance, California; El Segundo, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

0 notes

Text

Little P.Eng. Engineering: Comprehensive Engineering Services Across Canada and the USA

Little P.Eng. Engineering stands as a premier provider of engineering services, delivering specialized expertise in Piping Stress Engineering, Seismic Bracing, Silo Design, Tank Design, Belt Conveyor Design, Pressure Vessel Design, and CRN Registration. Our engineering solutions adhere to the stringent regulations and codes across Canada and the USA, ensuring safety, efficiency, and compliance for a wide range of industries. Whether you are involved in oil and gas, petrochemicals, food processing, or other sectors, Little P.Eng. Engineering is your trusted partner in delivering innovative, code-compliant designs.

Piping Stress Engineering

In industrial piping systems, ensuring the integrity of pipes under various operating conditions is critical. At Little P.Eng. Engineering, our team of piping stress engineers excels at analyzing the structural behavior of piping systems under different loads, such as thermal expansion, vibration, and seismic events. We employ industry-standard software and adhere to internationally recognized codes such as ASME B31.1, B31.3, and other regional standards to provide detailed stress analysis reports and recommendations for piping support, expansion joints, and anchor placement. Our focus is on reducing the risk of fatigue failure, pipe leaks, or bursts that can lead to costly operational downtime.

Seismic Bracing Engineering

In seismic zones, the safety of mechanical and structural systems depends on proper bracing and design against seismic activity. Little P.Eng. Engineering offers specialized seismic bracing services, ensuring your equipment and piping systems comply with seismic codes such as the International Building Code (IBC) and local standards like the National Building Code of Canada (NBC). We design customized solutions to protect your infrastructure from earthquake-induced damage, minimizing risks to both personnel and equipment. Our seismic bracing engineers conduct thorough site assessments, perform dynamic analysis, and provide detailed recommendations for bracing and supports.

Silo Design

Silos play a critical role in industries that require bulk material storage, such as agriculture, food processing, and chemical manufacturing. Little P.Eng. Engineering provides complete silo design services, from conceptual design to detailed engineering. We ensure that the structural integrity of silos complies with the relevant standards, including ACI 313 (for concrete silos) and ASME standards for pressure and temperature conditions. Our expertise in load calculations, material selection, and structural analysis ensures that your silo will safely and efficiently store bulk materials while withstanding internal and external pressures.

Tank Design

Little P.Eng. Engineering offers expert tank design services for industries ranging from petrochemical to food processing. Our designs conform to codes such as API 650 for welded steel storage tanks, API 620 for low-pressure storage tanks, and ASME Section VIII for pressure vessels. We provide comprehensive design services that include material selection, structural analysis, and foundation design to ensure the longevity and safety of your storage systems. Our expertise extends to tanks of all sizes and configurations, including horizontal, vertical, and underground tanks.

Belt Conveyor Design

Efficient material handling is the backbone of many industrial processes. Our engineers specialize in the design of belt conveyors to optimize material transport across manufacturing plants and industrial sites. Whether you're moving bulk materials or individual products, our team adheres to design standards such as CEMA (Conveyor Equipment Manufacturers Association) and OSHA requirements for conveyor safety. We focus on designing systems that maximize productivity while ensuring the safety and durability of your conveyors. From layout optimization to motor selection and load analysis, Little P.Eng. Engineering covers every aspect of belt conveyor design.

Pressure Vessel Design

Pressure vessels are vital components in industries such as chemical processing, oil and gas, and power generation. At Little P.Eng. Engineering, we offer pressure vessel design services that meet the highest industry standards, including ASME Section VIII Division 1 and 2. Our engineers perform detailed analyses to ensure that your pressure vessels can withstand internal pressures, extreme temperatures, and other operational stresses. We also offer customized solutions for specific requirements, such as cryogenic or high-temperature vessels, ensuring your equipment complies with all applicable safety and performance codes.

CRN Registration (Canadian Registration Number)

For equipment used under pressure in Canada, CRN registration is mandatory. Little P.Eng. Engineering simplifies the process of obtaining a Canadian Registration Number by ensuring your equipment complies with provincial and territorial regulations. Our CRN registration services cover a wide range of equipment, including pressure vessels, piping systems, and fittings. We handle the entire registration process, from preparing the necessary documentation to submitting your application and liaising with the relevant regulatory bodies. Our deep understanding of Canadian codes and standards ensures a smooth, efficient registration process.

Compliance with Applicable Codes Across Canada and the USA

At Little P.Eng. Engineering, we pride ourselves on providing engineering services that adhere to the most stringent standards and codes across Canada and the USA. These include:

ASME (American Society of Mechanical Engineers) Codes: For pressure vessel and piping design.

API (American Petroleum Institute) Standards: For tank and piping systems.

ACI (American Concrete Institute) Standards: For silo and concrete structures.

IBC (International Building Code) & NBC (National Building Code of Canada): For seismic bracing and structural design.

CEMA (Conveyor Equipment Manufacturers Association) Standards: For belt conveyor design.

Our engineers stay current with the latest revisions and updates to these codes, ensuring that your projects remain fully compliant with both national and international regulations. Whether you're operating in the US or Canada, we tailor our services to meet your specific needs and regional requirements.

Why Choose Little P.Eng. Engineering?

Expertise Across Multiple Disciplines: Our engineers are highly skilled across various domains, ensuring that all aspects of your project are handled by specialists.

Tailored Solutions: We customize our designs and services to meet your specific operational needs, industry requirements, and regional codes.

Commitment to Safety: All our services prioritize safety and compliance, helping you avoid costly mistakes and regulatory penalties.

Efficient Project Delivery: With a streamlined process and a commitment to excellence, we ensure timely delivery of all engineering services.

Partner with Little P.Eng. Engineering to benefit from our vast expertise and dedication to excellence across Canada and the USA. Whether you're in need of a piping stress engineer or pressure vessel design services, we have the knowledge and experience to make your project a success.Little P.Eng. Engineering: Comprehensive Engineering Services Across Canada and the USA

For more information on our services or to discuss your specific project needs, contact Little P.Eng. Engineering today. Let us help you navigate the complex engineering landscape with confidence and precision.

Tags:

Piping Stress Engineer

ASME B31.3

Seismic Bracing Engineer

Piping Stress Analysis

Structural Engineering

ASME B31.1

API 650

Pressure Vessel Design

Tank Design

ASME Section VIII

API 620

International Building Code

Seismic Bracing Services

CRN Registration

Silo Design

Bulk Material Storage Design

CRN Number Canada

ACI 313 Silos

Canadian Engineering Services

Pressure Vessel Registration Canada

Oil and Gas Engineering

US Engineering Codes

API Tank Design

Conveyor Equipment Design

Belt Conveyor Design

Petrochemical Engineering

ASME Pressure Vessels

Silo Structural Design

Industrial Conveyor Design

National Building Code Canada

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Montréal, Quebec; Houston Texas; Torrance, California; El Segundo, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

0 notes

Text

Little P.Eng. Engineering for Pipe Stress Analysis Services of Piping Systems Using CAESAR II and AUTOPIPE for Alkaline Electrolysis Systems

In today’s fast-paced and technologically driven world, industries are increasingly relying on advanced piping systems to handle complex operations. One such system is the alkaline electrolysis process, which plays a crucial role in the production of green hydrogen. To ensure the safety, reliability, and efficiency of these systems, proper pipe stress analysis is essential. Little P.Eng. Engineering takes pride in offering world-class pipe stress analysis services using industry-leading software like CAESAR II and AUTOPIPE.

Alkaline Electrolysis Systems: A Key Technology for Green Hydrogen Production

As the world transitions toward cleaner energy sources, hydrogen has emerged as a promising solution to decarbonize various sectors. One of the most reliable methods for producing green hydrogen is through alkaline electrolysis systems. This technology has been widely adopted for its efficiency, scalability, and cost-effectiveness, particularly in industries aiming to reduce carbon emissions. In this article, we explore the fundamentals of alkaline electrolysis, its benefits, applications, and how it plays a crucial role in the future of sustainable energy.

What is Alkaline Electrolysis?

Alkaline electrolysis is an electrochemical process that uses electrical energy to split water molecules (H₂O) into hydrogen (H₂) and oxygen (O₂). The process takes place in an electrolyzer, which consists of two electrodes—an anode and a cathode—submerged in an alkaline electrolyte, usually potassium hydroxide (KOH) or sodium hydroxide (NaOH). When a direct current (DC) is applied, water is separated into its basic components:

At the cathode, water molecules gain electrons and split into hydrogen gas and hydroxide ions (OH⁻).

At the anode, hydroxide ions release electrons, producing oxygen gas and water.

The overall reaction can be summarized as:

2H2O→2H2+O2

This method produces pure hydrogen, which can be used in various industries or stored for future energy needs.

Key Components of Alkaline Electrolysis Systems

An alkaline electrolysis system consists of several critical components that work together to produce hydrogen:

Electrolyzer Cell Stack: This is the heart of the system, where the electrochemical reaction occurs. The cell stack is composed of electrodes (anode and cathode) separated by an electrolyte, usually an alkaline solution.

Electrolyte: A potassium or sodium hydroxide solution acts as the medium through which ions flow during the electrolysis process.

Power Supply: Direct current (DC) power is required to drive the electrolysis process. Renewable energy sources like solar or wind power are increasingly used to generate this electricity, making the process even more sustainable.

Gas Separation System: Once hydrogen and oxygen are produced, they are separated and collected for storage or immediate use.

Benefits of Alkaline Electrolysis Systems

Alkaline electrolysis systems offer several advantages over other hydrogen production methods, such as proton exchange membrane (PEM) electrolysis and natural gas reforming. Some of the key benefits include:

Proven Technology: Alkaline electrolysis has been used for decades, making it one of the most mature and reliable methods for producing hydrogen.

Cost-Effective: The materials used in alkaline electrolysis systems, such as stainless steel for electrodes, are relatively inexpensive compared to the platinum-based catalysts used in PEM electrolysis.

Scalability: These systems can be scaled up to meet industrial needs, making them suitable for large-scale hydrogen production.

Renewable Integration: Alkaline electrolysis can be powered by renewable energy sources, such as solar or wind, making it a key technology in producing green hydrogen.

High Efficiency: Alkaline electrolysis systems offer efficiency levels of up to 70–80%, depending on the design and operating conditions.

Applications of Alkaline Electrolysis

Alkaline electrolysis systems have a wide range of applications, especially in sectors that require large quantities of hydrogen. Some key applications include:

Green Hydrogen Production: Hydrogen produced through alkaline electrolysis, when powered by renewable energy, is classified as "green hydrogen," which can be used to decarbonize industries.

Energy Storage: Hydrogen can be stored and later used in fuel cells or combustion engines to generate electricity, providing a way to store excess renewable energy.

Chemical Industry: Hydrogen is a critical raw material in the production of ammonia, methanol, and other chemicals.

Steel Manufacturing: The steel industry is a major emitter of CO₂. Hydrogen can replace carbon as a reducing agent in the production of steel, helping to reduce emissions.

Transportation: Hydrogen fuel cells are gaining popularity in the automotive, shipping, and aviation sectors as a clean alternative to fossil fuels.

Power-to-X Technologies: Alkaline electrolysis is key to Power-to-X (P2X) solutions, which involve converting surplus renewable energy into hydrogen, which can then be transformed into fuels or chemicals.

Challenges and Future Outlook

While alkaline electrolysis systems offer numerous benefits, there are still some challenges to address for broader adoption:

Energy Demand: Electrolysis requires a significant amount of electricity. The efficiency of the process can be improved, but further advancements in renewable energy technologies are essential to ensure a sustainable supply of power for large-scale hydrogen production.

Infrastructure Development: The widespread use of hydrogen, particularly in transportation, will require significant investments in infrastructure, such as refueling stations and hydrogen pipelines.

Materials and Durability: Alkaline electrolysis systems must improve the longevity of electrodes and other system components to reduce maintenance costs and downtime.

The Role of Alkaline Electrolysis in a Sustainable Future

As industries strive to meet net-zero emissions goals, hydrogen is emerging as a crucial part of the global energy transition. Alkaline electrolysis, with its proven reliability and cost-effectiveness, will play an essential role in producing green hydrogen at scale. Governments and industries worldwide are investing heavily in research and development to optimize alkaline electrolysis systems and integrate them into the renewable energy landscape.

In conclusion, alkaline electrolysis systems are a vital technology for producing clean hydrogen, enabling industries to decarbonize while supporting renewable energy storage and distribution. As innovations in efficiency and scalability continue to emerge, this technology will be indispensable in achieving a sustainable, low-carbon future.

The Importance of Pipe Stress Analysis in Alkaline Electrolysis Systems

Alkaline electrolysis systems are pivotal in generating hydrogen by splitting water molecules into hydrogen and oxygen through an electrochemical process. These systems operate under a range of pressures and temperatures, and the piping involved must handle various stresses, including thermal expansion, vibration, and mechanical loads. Proper pipe stress analysis ensures that these pipes can withstand these forces without failure, ensuring operational safety and efficiency.

Key Reasons for Pipe Stress Analysis in Alkaline Electrolysis Systems:

Safety Assurance: Piping systems in electrolysis plants must operate safely to prevent leaks, ruptures, or catastrophic failures.

Optimal Performance: Ensuring that pipes can handle stress without deformation helps in maintaining the performance and efficiency of the system.

Cost Efficiency: Early identification of potential issues can prevent costly shutdowns or repairs.

Regulatory Compliance: Alkaline electrolysis systems must adhere to stringent safety and environmental regulations. Pipe stress analysis ensures that these requirements are met.

Little P.Eng. Engineering: Expertise in CAESAR II and AUTOPIPE

At Little P.Eng. Engineering, we specialize in providing comprehensive pipe stress analysis services tailored to the unique demands of alkaline electrolysis systems. Our team leverages advanced software tools like CAESAR II and AUTOPIPE to deliver precise, reliable, and actionable insights into piping system performance.

CAESAR II: Industry-Leading Pipe Stress Analysis Tool

CAESAR II is one of the most widely recognized tools for performing pipe stress analysis. It allows engineers to evaluate the stress distribution and deformation in piping systems under various load conditions, including thermal expansion, pressure loads, and external forces. Some of the key features that make CAESAR II essential for alkaline electrolysis systems include:

Comprehensive Load Analysis: CAESAR II evaluates multiple load cases, including deadweight, thermal expansion, and wind or seismic effects.

Dynamic Load Analysis: The software simulates the impact of dynamic forces like vibrations and water hammer, which are critical in ensuring the longevity of piping systems in electrolysis plants.