Don't wanna be here? Send us removal request.

Text

What Are the Types of PVC-Coated Fabrics?

1. PVC-Coated Polyester

Structure & Strength: These fabrics are made by coating a polyester scrim with liquid PVC, then curing—it offers tensile strength, tear resistance, and excellent dimensional stability thanks to the woven base and adhesive layer Wikipedia+1.

Performance: They're waterproof, resistant to dirt, mildew, chemicals, UV rays, and highly durable Wikipediaherculite.com.

Customization: Available in opaque to translucent forms, and can be heat-sealed with strong, RF or hot-air welded seams Wikipedia.

2. Nylon & Acrylic Variants

Nylon PVC-Coated Fabrics: Lightweight with excellent abrasion resistance—ideal for gear and backpacks ioxfordfabric.com.

Acrylic-Coated Polyester: Especially UV-resistant, commonly used for awnings and outdoor furniture ioxfordfabric.com.

3. Fire-Retardant PVC Coated Fabrics

Used in applications where fire safety is essential—these fabrics are treated to meet industrial fire safety standards ioxfordfabric.com.

4. Industrial-Grade & Ripstop Tarpaulins

For heavy-duty outdoor use, strong woven polyester or ripstop fabrics with PVC coatings offer high resistance to water, abrasion, and environmental challenges zjmsd.com.

What Makes SIOEN PVC-Coated Fabrics Special?

While I couldn’t access the direct SIOEN-specific page, Lucky-Tech mentions being the exclusive Indian partner for SIOEN’s technical textiles, implying flexibility, premium quality, and custom engineering in their offerings luckytech.in+1.

Furthermore, Lucky-Tech’s PVC and PVDF-coated fabrics boast:

High durability and weather resistance.

UV and flame-retardant properties.

Smooth aesthetics and high tensile strength.

Sustainable manufacturing practices luckytech.in.

Quick Comparison Table

Fabric TypeKey AttributesPVC-Coated PolyesterRobust, waterproof, UV-resistant, customizable, durableNylon PVC-Coated FabricLightweight, abrasion-resistant, suitable for motion-based applicationsAcrylic-Coated PolyesterExcellent UV-persistence; ideal for outdoor shade structuresFire-Retardant PVC FabricsTreated for fire safety standardsRipstop/Heavy-Duty PVC TarpsExtremely tough, water-resistant, abrasion-proof for rugged outdoor usage

In Summary

SIOEN’s portfolio of PVC-coated fabrics, as distributed by Lucky-Tech in India, likely includes:

Industrial-strength polyester variants with options for UV, flame, and mildew protection.

Customized solutions engineered for tensile structures, tents, factory roofs, flexitanks, etc.

These fabrics are engineered for long-term performance in architectural, industrial, and outdoor applications. If you're looking for specifics like denier, coating thickness, or certifications, I recommend reaching out directly to Lucky-Tech or browsing their product listings.

0 notes

Text

How to Choose the Right PVC Fabric for Tensile Applications

In today’s modern world, where advanced technology shapes every industry, architecture has seen remarkable innovations — and tensile structures are a shining example.

Tensile fabric structures have been around for decades, from simple tent-like shelters to massive canopies covering shopping malls, stadiums, parking lots, and industrial spaces. Early tents used guy ropes and poles to create tension, allowing the fabric to resist wind, rain, and snow. Fast forward to today, and tensile architecture blends art, engineering, and sustainability to transform outdoor and indoor spaces alike.

However, the secret behind a durable, flexible tensile structure lies in choosing the right fabric. So, how do you pick the perfect PVC fabric? Let’s break it down.

📌 What Are Tensile Fabric Systems?

At its core, a tensile fabric structure uses tensioned fabric membranes supported by wires, cables, steel frames, or other support systems. This pre-tensioning removes creases and gives the fabric a clean, crisp look that stands strong against weather and wear.

Two common shapes dominate tensile design:

Saddle: Technically called a hyperbolic paraboloid, this shape features two peaks and two valleys, creating a warped grid that’s both practical and dramatic.

Cone: Inspired by volcanoes, cone-shaped structures use stacked hoops or radial supports. By combining saddles and cones, architects create endless design possibilities.

Tensile structures are not just stunning — they’re practical, sustainable, and flexible for all kinds of applications, from stadium roofs to elegant walkway covers.

✅ Why PVC-Coated Polyester Is the Best Choice

When it comes to tensile fabric materials, PVC-coated polyester is the go-to option — and for good reason!

✔️ Superior Strength and Flexibility

PVC fabric is renowned for its durability and ability to flex under tension. When polyester cloth is coated with PVC, it gains extra strength and can withstand extreme weather, including storms, rain, and intense sun, lasting well beyond 20 years when properly maintained.

✔️ Cost-Effective and Versatile

PVC-coated polyester offers excellent performance at a reasonable cost, making it suitable for both large and small projects — whether you need a permanent or temporary solution.

✔️ Translucency and Design Appeal

One big advantage of PVC is its premium translucency. It lets natural light filter through, creating bright, welcoming spaces below. Plus, with a wide range of colors and textures, architects and designers have the freedom to customize their vision.

✔️ Weather and UV Resistance

PVC’s special coating acts as a barrier against harsh UV rays, extreme temperatures, and moisture. This protective layer keeps the fabric looking fresh for years and reduces maintenance costs.

✔️ Low Maintenance

A big bonus: PVC-coated fabric is easy to clean. Its smooth surface means dirt, dust, and debris can be wiped away effortlessly. Regular cleaning keeps the structure looking new with minimal effort.

✔️ Multiple Applications

PVC’s versatility is unmatched. It’s used for stadiums, airports, awnings, parking shades, tents, truck covers, pond liners, rollup doors, inflatable boats, oil booms, biogas domes, and more. It can even be used in mesh forms for better airflow, sound absorption, and energy efficiency.

🗂️ Key Things to Consider Before You Buy

When selecting the right PVC fabric for your tensile structure, remember to ask:

Is the fabric lightweight enough for your structure’s design?

Is the textile thickness suitable for expected loads and weather conditions?

Is it easy to clean and maintain over time?

🏢 PVC & PVDF Fabrics at Lucky Tech

Lucky Tech brings cutting-edge tensile solutions to your projects. Our PVC and PVDF-coated fabrics power:

Tensile membranes for large spans

Aluminium hangers & tents

Awning canopies & car parking shades

Truck covers & rollup doors

Oil booms & inflatable boats

Bio gas domes, pond liners & flexi tanks

Tensile applications are more than structures — they’re an art form that blends design, function, and sustainability for unmatched value and performance.

✨ Final Thoughts

Whether you’re covering a stadium, shading a parking lot, or designing an iconic canopy, the right PVC-coated polyester fabric makes all the difference.

Ready to make your project stand out? Choose a material that’s strong, flexible, cost-effective, and easy to maintain — and experience how modern tensile design transforms spaces.

Lucky Tech is here to help you bring innovation and reliability to every tensile project.

Let’s build stunning spaces together!

0 notes

Text

Latest Advancements in PVC Coated Fabrics for Tensile Structure

In this modern world, with the latest technology taking up most of the fields, it has placed its foot in the architectural industry. One such innovative design in architecture is the introduction of tensile structures. You must have seen large canopies over the shopping malls, parking areas, and stadiums. Have you ever thought about what these gigantic canopies are? These are nothing but tensile membrane structures. They are the cost-effective and practical option that covers a large area. Do you know why it is the most demanding architectural design? These lightweight PVC-coated fabric structures can be moulded into any shape and size according to your needs. LUCKY-TECH provides you with a distinctive collection of top-quality tensile membranes for the construction of these functional structures, which are a great alternative to conventional constructions. Our tensile design fabrics are ideal for both open and closed buildings, such as shopping malls, airports, and stadiums This blog is your ideal guide to understanding the latest advancements in PVC-coated fabrics for tensile structures. Come, let us explore in detail!

What is PVC-coated fabric?

PVC-coated fabric is one of the most commonly used materials. It is created by coating PolyVinyl Chloride(PVC) on the base material, which is usually polyester. PVC-coated fabrics are known for their flexibility and durability. Moreover, these fabrics have a higher water—and UV-resistant capacity. PVC-coated fabrics are used for the construction of tensile structures and other roofing and industrial applications. These fabrics are highly durable and can last even up to 20 years. LUCKY-TECH brings you the first-grade PVC-coated tensile roof design fabric that is perfect for open and closed buildings

A Breakthrough in architecture: Latest Innovations in PVC-coated fabrics for tensile structure.

Innovations are always a part of development. Even for the PVC-coated fabrics, we can see a breakthrough in recent years. All these advancements focus on enhancing the durability, longevity, and the overall aesthetics of these tensile structures. So, what are the recent advancements? Let us have a detailed look at this!

Enhanced durability and longevityThe first and foremost thing in the advancement of the PVC-coated fabric for tensile structures is the durability and longevity of the fabric. Modern-day PVC-coated fabrics are designed in a way that they can withstand any harsh climatic conditions. These fabrics are now more resistant to UV radiation. So, how did the manufacturers achieve this? It can be achieved through remarkable advancements in coatings. PVDF(Polyvinylidene fluoride or polyvinylidene difluoride) has seen many recent advancements.

Increased SustainabilityThe major concern in the architectural industry is sustainability. The PVC-coated fabric has been designed to meet these demands. Earlier, PVC was considered to be the least environmentally friendly product. But with the latest advancements, they have been molded to cause less harm to the environment. Many companies have come up with ideas to manufacture PVC-coated fabrics without the use of harmful chemicals. LUCKY-TECH Membranes brings you 100% recyclable PVC-coated fabrics that are perfect for building tensile structures. This greatly helps to reduce the environmental impacts of the tensile structures.

Improved UV resistanceThe tensile structures are mainly seen outdoors. Hence, it is important to make sure that the PVC-coated fabrics for tensile structures are strong enough to withstand the prolonged exposure to sunlight. Considering this factor, advanced PVC-coated fabrics are formulated with higher resistance to UV radiation. This helps the tensile structure remain free from any degradation and discoloration due to prolonged sunlight exposure.

Improved Fire ResistanceFor any construction project, the priority will always be safety. Like any other safety measure, it is important to ensure that the PVC fabrics for tensile structures have fire-resistant properties. With the help of these advanced technologies, companies have manufactured PVC-coated fabrics that have fire retardancy. These are offered to provide an extra layer of protection.

Advanced Coating TechnologiesWith the help of advanced coating technologies, the PVC fabrics have shown a higher performance rate. They are capable of withstanding any dirt, dust, water accumulating on them. With the innovative technologies, these fabrics have become easier to clean. Nowadays, PVC-coated fabrics come with self-cleaning properties. This can greatly reduce the cost of frequent maintenance. At Lucky Tech Membranes, PVDF lacquering prevents natural and industrial dirt from settling. Aggressive dirt can be cleaned with normal detergent, soap, and water. The fabric is made in such a way that it is easy to clean and maintain.

Aesthetic VersatilityDo you know that these PVC-coated fabrics are available in versatile designs? Nowadays, you can explore PVC-coated fabrics available in an extensive range of colors, sizes, and shapes. You can pick the fabrics that match the overall aesthetics of your projects. You can create a visually appealing outdoor canopy with these versatile fabrics. Some colors may fade over time. But with the advanced technology, you can even find PVC-coated fabrics that will not fade and lose it’s shine.

Flexibility and Tensile StrengthDo you know what tensile strength is? Tensile strength is the ability of the material to withstand any breakage or tear due to tension. Tensile structures are created because of their extreme tensile strength. With the latest advancements in technologies, the PVC-coated fabrics for tensile structures have become more flexible, making them a perfect choice for any outdoor arena construction.

Improved Installations and TensioningAdvancements in installation and tensioning techniques have made it easier and more cost-effective to work with PVC-coated fabrics. Innovative hardware and tensioning systems allow for quicker and more precise installations, reducing labour costs and project timelines.

Energy EfficiencyEnergy Efficiency is a serious thing in this modern world. With the growing technology, the PVC-coated fabrics are manufactured to meet these demands. With technological advancements, some of the PVC-coated fabrics are manufactured with thermal efficiency that helps to regulate temperature and reduce energy consumption within the tensile structures.

Lightweight natureWhile constructing large-scale tensile structures, the main concern is the weight and the need for sufficient supporting elements. The latest PVC-coated fabrics are lightweight and can be suspended with minimal support. You can create large-scale structures with ease and perfection.

Final Thoughts,

Over the last two decades, we have seen a significant advancement in the PVC-coated fabrics. They have been designed to meet the demands of modern-day architectural designs. These PVC-coated fabrics for tensile structures are designed with salient features that include water resistance, fire resistance, and UV resistance. Moreover, it comes with energy efficiency, aesthetic versatility, and advanced coating, making it a perfect choice for outdoor constructions. LUCKY-TECH membranes brings you an extensive collection of premium quality PVC-coated fabrics for tensile structures. For more information, contact us!

0 notes

Text

PVC Coated Tensile Fabric vs Traditional Roofing: Which One Wins in 2025?

Introduction The Roofing Revolution

In 2025, the choice between PVC coated tensile fabric and traditional roofing has become more strategic than ever. With modern architecture aiming for a balance of style, performance, sustainability, and cost, Luckytech—India’s trusted specialist in tensile structures—presents a comparison to help architects, builders, and clients make informed decisions.

Understanding the Materials

🔹 What is PVC Coated Tensile Fabric?

A lightweight, high-strength synthetic membrane composed of polyester fabric coated with polyvinyl chloride.

Designed to stretch across frames, creating seamless, curved surfaces ideal for canopies, atriums, façades, carports, and sports covers.

Available in a wide range of colors, translucency, finishes, and patterns—customizable for branding and style.

🔹 What Is Traditional Roofing?

Encompasses cement tiles, clay shingles, metal sheets, corrugated steel, and concrete slabs.

Built on rigid frameworks (trusses, rafters), forming steep, flat, or sloped structures.

Widely used and highly reliable due to time-tested performance and materials.

Performance Comparison

Durability & Lifespan

PVC Tensile Fabric: Typically lasts between 15–30 years, depending on coating and climate exposure. UV-resistant fabric minimizes degradation.

Traditional Roofing: Metal sheets may last 30–40 years; concrete tiles can exceed 50 years with proper maintenance.

Weather Resistance & Waterproofing

PVC Tensile Fabric: Offers excellent waterproofing with minimal pooling, plus fire retardancy and mold resistance.

Traditional Roofing: Heavy-duty waterproofing possible with membranes and sealants, although joint leaks and corrosion over time remain concerns.

Structural Flexibility & Aesthetics

Tensile Fabric: Ideal for organic curves, minimalistic design, and elegant canopies. It creates striking structures with natural light play.

Traditional Roofing: Offers an infinite palette of styles, materials, and architectural forms, meeting conventional aesthetics universally.

Installation & Maintenance

Ease and Speed of Installation

PVC Tensile Structures: Installed quickly (days to weeks) with precision-engineered frames. Minimal on-site disruption.

Traditional Roofing: Labor-intensive jobs that may take weeks, with higher structural demands and skilled trade inputs.

Maintenance Requirements

Tensile Fabric: Requires periodic cleaning to remove dirt and debris; occasional tension adjustments, but overall low maintenance.

Traditional Roofing: Demands regular inspections for cracks, rust, broken tiles, re-sealing joints, and dealing with moss/damp.

Cost Analysis

Initial Investment

Tensile Membrane: While frames and engineering can raise upfront costs, overall investment equals medium-range roofing depending on design.

Traditional Roofing: Generally cheaper in material (e.g., metal or tiles), but structural needs and labor may add to cost.

Long-Term Savings

Tensile Fabric: Offers energy efficiency through reflective coatings and natural diffused light—reducing HVAC and lighting costs.

Traditional Roofing: Durable but demands more in maintenance and insulation over time.

Sustainability & Eco‑Impact

Material Efficiency

PVC Coated Fabric: Uses minimal raw materials; energy-efficient production methods.

Traditional Materials: Includes high-energy materials like cement and steel.

Recyclability & Environmental Footprint

PVC Tensile Fabric: Many options are recyclable. Low carbon footprint in production and transport.

Traditional Roofing: Recyclability varies—steel is recyclable, but tiles and treated wood may not be.

Why Luckytech Recommends PVC Coated Tensile Fabric in 2025

Luckytech stands behind premium PVC-coated tensile solutions for multiple reasons:

Customization & Brand Expression: Colors, shapes, lighting integration—ideal for commercial visibility.

Rapid Deployment: Projects completed quickly with minimal disruption.

Energy Efficiency: Natural lighting and reduced heat gain save costs.

Reduced Maintenance: Long-lasting materials need infrequent upkeep.

Eco-Friendly: Aligns with LEED and green building certifications.

Conclusion: Which Option Wins?

For contemporary applications demanding elegance, speed, and sustainability, PVC coated tensile fabric is the roofing material of the future—offering form, function, and environmental benefits in one lightweight package.

However, traditional roofing still holds value in domains requiring long-term durability, structural familiarity, and conventional form.

By 2025, as Luckytech continues pioneering tensile innovation, architects and clients seeking flexible, stylish, and energy-efficient roofing will increasingly choose pvc coated fabric while traditional roofing remains irreplaceable where classic robustness and longevity are paramount.

0 notes

Text

Helium Hot air Balloon - We provide high-quality helium and hot air balloons for all events. ✔ Durability & Reliability. ✔ Design flexibility. ✔ High Quality. ✔ Cost Effective

0 notes

Text

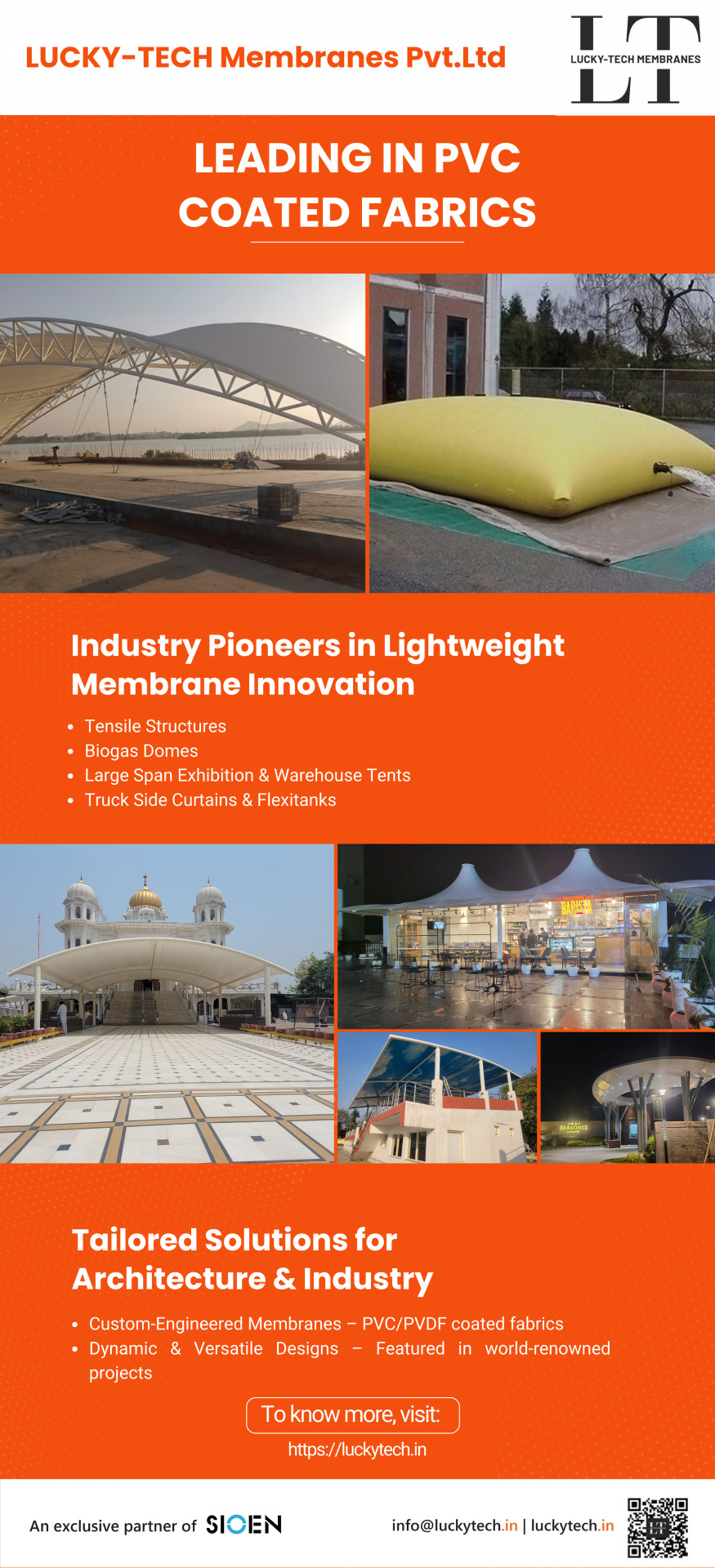

Leading The Industry In PVC Coated Fabrics

Leading The Industry In PVC Coated Fabrics - Lucky-Tech Membranes Pvt Ltd leads India’s PVC-coated fabrics industry with decades of expertise in advanced technical textiles. Pioneering lightweight membrane innovation, they excel in applications like tensile structures, biogas domes, large-span tents, truck side curtains, flexitanks, and more.

1 note

·

View note