Don't wanna be here? Send us removal request.

Text

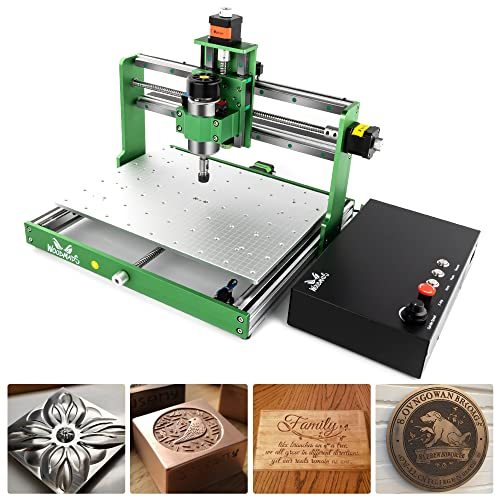

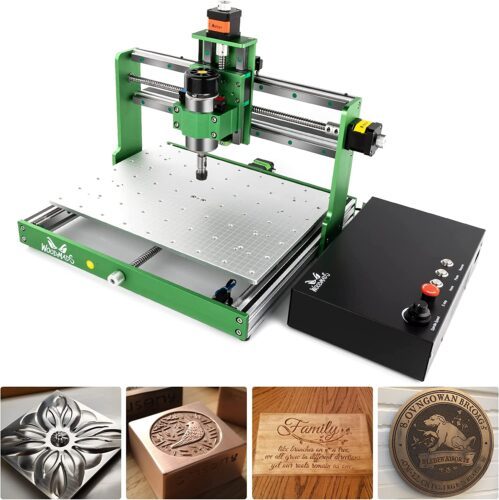

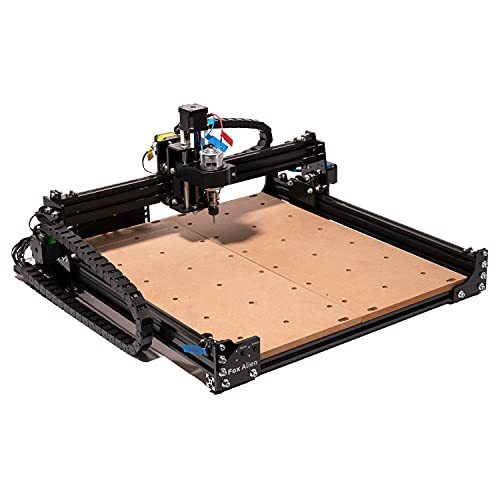

FoxAlien x WoodMads WM-3020 CNC Router Review

Are you an avid woodworker or an aspiring DIY enthusiast? If so, you'll know that having the right tools and equipment is essential to achieving quality results. One tool that has become increasingly popular in recent years is the CNC router. These machines allow for precise cutting, carving, and shaping of wood, metal, and other materials. One of the most promising options on the market is the FoxAlien x WoodMads WM-3020 CNC Router. In this review, we'll take a closer look at this machine's working area and review its features and capabilities. Overview of the WM-3020 CNC Router from FoxAlien x WoodMads The WM-3020 CNC Router from FoxAlien x WoodMads is the perfect choice for woodworking and machining needs. This robust CNC router is designed for precision and accuracy, making it ideal for creating intricate carvings, detailed shapes, and complex designs. It features an impressive cutting area of 30”x20”x3.5” with a variable speed spindle ranging from 10,000-24,000 RPMs to handle different materials. The router also comes equipped with a 3HP high-torque spindle motor and 4.2KW VFD inverter to ensure maximum power and control while operating even the toughest jobs. The WM-3020 has an incredibly simple user interface that allows operators to easily switch between different tools, speeds, and settings without any difficulty. The router also provides real-time feedback on its performance so you can make changes as needed during a job. Plus, its open-source software makes it compatible with almost any CAD/CAM programs available today so you can get the most out of your project without needing to adjust or purchase additional software packages. Overall, the WM-3020 CNC Router from FoxAlien x WoodMads is the ideal choice for anyone who wants reliable performance at an affordable price point. Its robust design ensures precision cuts every time and its user-friendly interface makes it easy to use even for beginners. With this versatile machine in your workshop, you can create professional quality projects quickly and accurately – making it the perfect tool for any woodworker or machinist looking to take their projects to the next level! Unboxing and Setting Up the CNC Router Unboxing and setting up the FoxAlien x WoodMads WM-3020 CNC Router is a task that can be done in a few simple steps. The first step is to remove the CNC router from its packaging. It will come with all the necessary components, which should include an AC power supply, stepper motors, spindle motor, controller board, various tools for assembly and maintenance, and other accessories such as end mill bits and collets. Once you have all the components out of the box, it's time to begin assembly. Start by attaching the stepper motors to the frame of your CNC router. Once this is done, connect each motor to its respective driver on the controller board. Make sure all connections are secure before powering on your machine. Next, attach your spindle motor to your machine's gantry- ensure it is properly aligned before moving on to the next step. Finally, connect your AC power supply to both the controller board and spindle motor. Once everything is connected correctly, you'll need to configure some settings on your CNC router's control software. This will depend on what type of material you're cutting and how precise you want your results to be. Adjusting speed settings as well as other parameters can help ensure that your project turns out just right. After these settings have been adjusted properly, you're ready to begin using your new WM-3020 CNC Router! Materials and Tools Needed to Use the Router The FoxAlien x WoodMads WM-3020 CNC Router is a powerful and versatile tool for making precision cuts on various materials. To ensure that you are using the router safely and effectively, it's important to have the right tools and materials on hand. Here's what you'll need to get started: Materials: - A sturdy, level surface or workbench for mounting the router - The material you plan to cut (wood, plastic, metal etc.) - Safety gear such as goggles and gloves in case of flying debris Tools: - A router bit with the correct profile for your desired cut - Clamps or other support devices to hold down materials while machining - Thickness calipers or measuring tape to measure the thicknesses of materials accurately - Lubricants such as cutting oil or wax for cleaner cuts and longer life of your tools - An air compressor and hose for keeping dust away while cutting Performance Tests with Different Materials

The FoxAlien x WoodMads WM-3020 CNC Router is an advanced and versatile tool for carving, routing, and drilling a variety of materials. With its high-precision capabilities, the WM-3020 can be used to create intricate designs and patterns in a wide range of materials, including wood, plastic, composites, metal, foams, hardwoods, softwoods, aluminum alloy sheets, and more. Equipped with a powerful 3-phase AC motor that produces up to 4500W of power at 24V DC input voltage and 0.2–3.175mm spindle speed range from 10–18000 RPM (no load), the WM-3020 is capable of cutting up to 6mm deep at maximum speed with high accuracy and precision. It also has a Mach 3 control system that allows for easy customization of settings and precise control over each operation. Additionally, it features an automated dust collection system for improved safety during operation as well as reduced cleanup time afterward. To ensure optimal performance in different materials, tests have been conducted using various types of wood to evaluate the quality of cuts achieved by the WM-3020 CNC router. Tests on oak showed clean cuts across the full range of feed rates tested with no signs of burning or fraying edges. Similarly, clean cuts were found with birch plywood when tested at the highest feed rate setting; however slight burning was observed at lower feed rates which could be addressed by adjusting cutting speeds accordingly. The results for aluminum alloy sheets were even more impressive; all cuts performed produced sharp edges and smooth finishes with no burning whatsoever regardless of the settings used. In conclusion, these tests prove that the FoxAlien x WoodMads WM-3020 CNC Router is capable of producing consistent results regardless of material type or operation parameter levels selected. Pros & Cons of the WM-3020 CNC Router The FoxAlien x WoodMads WM-3020 CNC Router is a powerful piece of machinery that can be used for a variety of woodworking projects. It is ideal for those seeking to create finely detailed carvings and intricate patterns in their work. It features a 3-axis machining center with an intuitive control system, making it easy to operate even for beginners. One of the major pros of the FoxAlien x WoodMads WM-3020 CNC Router is its speed and accuracy. It can cut through materials with precision and at high speeds, making it ideal for tackling complex tasks quickly and efficiently. Its advanced control system also makes it easy to program and carry out intricate carving patterns, making it suitable for professionals who need to do detailed work on their projects. In addition, the router comes with an array of accessories that make it easier to use in multiple applications. These include dust collection systems, removable tables, software packages, and more that allow users to tailor the machine according to their specific needs. The router also has built-in safety features such as emergency stops and low-voltage alarms that ensure user safety while operating the machine. On the downside, one of the main cons of this router is its cost. The machine itself can be quite pricey compared to other routers on the market due to its specialized components and features. Additionally, some users may find its size bulky or unwieldy when compared with smaller machines which could make it difficult to move around or store away when not in use. In addition, certain maintenance procedures may require professional assistance which could add further costs if repairs are needed over time. Manufacturer: FoxAlien Features - The WM-3020 CNC machine is furnished with HG-15 linear bearings and also 12mm rounds crews on all 3 axes. These industrial elements allow the sculpting to be quicker, quieter, as well as extra stable and also precisely. - WM-3020 features a 300watt pin, which is qualified to inscribe and also cut wood, acrylic, carbon fiber, light weight aluminum as well as brass. The z-axis is compatible with 65mm as well as 69mm spindle clamp, which suggests it works with the trimmer routers such as DWP611, RT0701C, engraving module, and also 1.5 kw spindle. - One-piece aluminum spoilboard improves the monotony and strength. The range is convenient for dimension as well as positioning. It is compatible with a lot of the hold-down clamps out there. - The control panel makes use of a 32-bit chip as well as is based upon Grbl. It supports to set homing beginning to any kind of edge by modifying the Grbl configurations. - Almost all are pre-assembled. It just takes 30-45 minutes to totally set up the machine. It is constructed from all light weight aluminum, which is tougher and also more steady. All required devices for trial run are consisted of in the package. Final Thoughts - Is it Worth Purchasing for Your Needs? The FoxAlien x WoodMads WM-3020 CNC Router is an excellent machine for hobbyists and small businesses. Its compact size, user-friendly software, and safety features make it an attractive option for those looking for a reliable and affordable CNC router. Although it has a smaller working area, it's still capable of producing high-quality results. With its powerful spindle motor and compatibility with various software, it's a versatile machine that can handle a wide range of projects. If you're looking for a CNC router that won't break the bank, the FoxAlien x WoodMads WM-3020 is worth considering. Read the full article

0 notes

Text

FoxAlien x WoodMads WM-3020 CNC Router Review

Are you an avid woodworker or an aspiring DIY enthusiast? If so, you'll know that having the right tools and equipment is essential to achieving quality results. One tool that has become increasingly popular in recent years is the CNC router. These machines allow for precise cutting, carving, and shaping of wood, metal, and other materials. One of the most promising options on the market is the FoxAlien x WoodMads WM-3020 CNC Router. In this review, we'll take a closer look at this machine's working area and review its features and capabilities. Overview of the WM-3020 CNC Router from FoxAlien x WoodMads The WM-3020 CNC Router from FoxAlien x WoodMads is the perfect choice for woodworking and machining needs. This robust CNC router is designed for precision and accuracy, making it ideal for creating intricate carvings, detailed shapes, and complex designs. It features an impressive cutting area of 30”x20”x3.5” with a variable speed spindle ranging from 10,000-24,000 RPMs to handle different materials. The router also comes equipped with a 3HP high-torque spindle motor and 4.2KW VFD inverter to ensure maximum power and control while operating even the toughest jobs. The WM-3020 has an incredibly simple user interface that allows operators to easily switch between different tools, speeds, and settings without any difficulty. The router also provides real-time feedback on its performance so you can make changes as needed during a job. Plus, its open-source software makes it compatible with almost any CAD/CAM programs available today so you can get the most out of your project without needing to adjust or purchase additional software packages. Overall, the WM-3020 CNC Router from FoxAlien x WoodMads is the ideal choice for anyone who wants reliable performance at an affordable price point. Its robust design ensures precision cuts every time and its user-friendly interface makes it easy to use even for beginners. With this versatile machine in your workshop, you can create professional quality projects quickly and accurately – making it the perfect tool for any woodworker or machinist looking to take their projects to the next level! Unboxing and Setting Up the CNC Router Unboxing and setting up the FoxAlien x WoodMads WM-3020 CNC Router is a task that can be done in a few simple steps. The first step is to remove the CNC router from its packaging. It will come with all the necessary components, which should include an AC power supply, stepper motors, spindle motor, controller board, various tools for assembly and maintenance, and other accessories such as end mill bits and collets. Once you have all the components out of the box, it's time to begin assembly. Start by attaching the stepper motors to the frame of your CNC router. Once this is done, connect each motor to its respective driver on the controller board. Make sure all connections are secure before powering on your machine. Next, attach your spindle motor to your machine's gantry- ensure it is properly aligned before moving on to the next step. Finally, connect your AC power supply to both the controller board and spindle motor. Once everything is connected correctly, you'll need to configure some settings on your CNC router's control software. This will depend on what type of material you're cutting and how precise you want your results to be. Adjusting speed settings as well as other parameters can help ensure that your project turns out just right. After these settings have been adjusted properly, you're ready to begin using your new WM-3020 CNC Router! Materials and Tools Needed to Use the Router The FoxAlien x WoodMads WM-3020 CNC Router is a powerful and versatile tool for making precision cuts on various materials. To ensure that you are using the router safely and effectively, it's important to have the right tools and materials on hand. Here's what you'll need to get started: Materials: - A sturdy, level surface or workbench for mounting the router - The material you plan to cut (wood, plastic, metal etc.) - Safety gear such as goggles and gloves in case of flying debris Tools: - A router bit with the correct profile for your desired cut - Clamps or other support devices to hold down materials while machining - Thickness calipers or measuring tape to measure the thicknesses of materials accurately - Lubricants such as cutting oil or wax for cleaner cuts and longer life of your tools - An air compressor and hose for keeping dust away while cutting Performance Tests with Different Materials

The FoxAlien x WoodMads WM-3020 CNC Router is an advanced and versatile tool for carving, routing, and drilling a variety of materials. With its high-precision capabilities, the WM-3020 can be used to create intricate designs and patterns in a wide range of materials, including wood, plastic, composites, metal, foams, hardwoods, softwoods, aluminum alloy sheets, and more. Equipped with a powerful 3-phase AC motor that produces up to 4500W of power at 24V DC input voltage and 0.2–3.175mm spindle speed range from 10–18000 RPM (no load), the WM-3020 is capable of cutting up to 6mm deep at maximum speed with high accuracy and precision. It also has a Mach 3 control system that allows for easy customization of settings and precise control over each operation. Additionally, it features an automated dust collection system for improved safety during operation as well as reduced cleanup time afterward. To ensure optimal performance in different materials, tests have been conducted using various types of wood to evaluate the quality of cuts achieved by the WM-3020 CNC router. Tests on oak showed clean cuts across the full range of feed rates tested with no signs of burning or fraying edges. Similarly, clean cuts were found with birch plywood when tested at the highest feed rate setting; however slight burning was observed at lower feed rates which could be addressed by adjusting cutting speeds accordingly. The results for aluminum alloy sheets were even more impressive; all cuts performed produced sharp edges and smooth finishes with no burning whatsoever regardless of the settings used. In conclusion, these tests prove that the FoxAlien x WoodMads WM-3020 CNC Router is capable of producing consistent results regardless of material type or operation parameter levels selected. Pros & Cons of the WM-3020 CNC Router The FoxAlien x WoodMads WM-3020 CNC Router is a powerful piece of machinery that can be used for a variety of woodworking projects. It is ideal for those seeking to create finely detailed carvings and intricate patterns in their work. It features a 3-axis machining center with an intuitive control system, making it easy to operate even for beginners. One of the major pros of the FoxAlien x WoodMads WM-3020 CNC Router is its speed and accuracy. It can cut through materials with precision and at high speeds, making it ideal for tackling complex tasks quickly and efficiently. Its advanced control system also makes it easy to program and carry out intricate carving patterns, making it suitable for professionals who need to do detailed work on their projects. In addition, the router comes with an array of accessories that make it easier to use in multiple applications. These include dust collection systems, removable tables, software packages, and more that allow users to tailor the machine according to their specific needs. The router also has built-in safety features such as emergency stops and low-voltage alarms that ensure user safety while operating the machine. On the downside, one of the main cons of this router is its cost. The machine itself can be quite pricey compared to other routers on the market due to its specialized components and features. Additionally, some users may find its size bulky or unwieldy when compared with smaller machines which could make it difficult to move around or store away when not in use. In addition, certain maintenance procedures may require professional assistance which could add further costs if repairs are needed over time. Manufacturer: FoxAlien Features - The WM-3020 CNC machine is furnished with HG-15 linear bearings and also 12mm rounds crews on all 3 axes. These industrial elements allow the sculpting to be quicker, quieter, as well as extra stable and also precisely. - WM-3020 features a 300watt pin, which is qualified to inscribe and also cut wood, acrylic, carbon fiber, light weight aluminum as well as brass. The z-axis is compatible with 65mm as well as 69mm spindle clamp, which suggests it works with the trimmer routers such as DWP611, RT0701C, engraving module, and also 1.5 kw spindle. - One-piece aluminum spoilboard improves the monotony and strength. The range is convenient for dimension as well as positioning. It is compatible with a lot of the hold-down clamps out there. - The control panel makes use of a 32-bit chip as well as is based upon Grbl. It supports to set homing beginning to any kind of edge by modifying the Grbl configurations. - Almost all are pre-assembled. It just takes 30-45 minutes to totally set up the machine. It is constructed from all light weight aluminum, which is tougher and also more steady. All required devices for trial run are consisted of in the package. Final Thoughts - Is it Worth Purchasing for Your Needs? The FoxAlien x WoodMads WM-3020 CNC Router is an excellent machine for hobbyists and small businesses. Its compact size, user-friendly software, and safety features make it an attractive option for those looking for a reliable and affordable CNC router. Although it has a smaller working area, it's still capable of producing high-quality results. With its powerful spindle motor and compatibility with various software, it's a versatile machine that can handle a wide range of projects. If you're looking for a CNC router that won't break the bank, the FoxAlien x WoodMads WM-3020 is worth considering. Read the full article

0 notes

Text

What You Should Know Before Buying a CNC Mill

Are you considering the purchase of a CNC (Computer Numerical Control) mill? With increasing options in precision machining and manufacturing, these specialized tools can provide powerful capabilities for detail-oriented work. Before taking the plunge into investing in a CNC mill, there are important points to consider such as cost and performance; understanding what is available on the market will help you make an informed decision. In this blog post, we'll explore some of the key features to look out for when buying a CNC mill so that you can find one that meets your needs while staying within budget.

What is a CNC Mill and how does it work? A CNC mill is a machine used in manufacturing that employs computer-controlled engineering to produce highly precise parts and products. CNC mills utilize instructions in the form of numerical software to control the cutting process of a workpiece. The machine typically consists of a bed, spindle, motor, cutting tools, and worktable. The cutting tools, which range in shape and size, rotate at high speeds, shaving away material from the workpiece to create the desired shape. The CNC mill allows for incredibly accurate and reliable production, making it ideal for creating complex and intricate parts for various industrial applications. The machine can be programmed to cut and shape a variety of materials, including metals, plastics, and composites, to create three-dimensional objects of nearly any shape. The CNC mill works by utilizing a combination of computer software and hardware to control the process. A CAD (computer-aided design) program creates a digital model of the part or product, which is then translated into a series of instructions in G-code. The G-code provides the instructions for the CNC mill to precisely move the cutting tools and worktable, ultimately creating the desired shape. Once the G-code is loaded into the CNC mill's computer, the machine begins cutting, precisely following the programmed instructions. The operator monitors the process, making adjustments as necessary to ensure the workpiece is produced to specifications. The CNC mill provides a highly automated and precise way of manufacturing complex parts and products. By using a combination of computer software and hardware, the machine produces accurate and reliable results, meeting the demands of modern manufacturing processes. What are the Different Types of CNC Mills and Their Uses? Computer Numerical Control (CNC) mills are essential tools in modern-day manufacturing. CNC mills operate with the use of software and computer programs, which allow them to execute precise cutting and shaping of materials. Different types of CNC mills are available, and they come with varying capabilities to perform diverse functions. Here are the different types of CNC mills and their uses: 1. Vertical Milling Machine: Vertical milling machines are designed to work with flat or rectangular metal surfaces. The spindle is positioned vertically, enabling a wide range of cutting possibilities such as drilling, tapping, and milling. This type of mill is perfect for manufacturing large quantities of flat or rectangular parts. 2. Horizontal Milling Machine: This mill is suitable for cutting and shaping materials from different angles. The spindle is positioned parallel to the worktable, allowing for precision cutting, drilling, and boring. Horizontal milling machines are excellent for producing parts in bulk quantities. 3. Bed Milling Machine: Bed milling machines have a vertically adjustable spindle that moves along the Z-axis. The bed can move along the X and Y-axis, allowing the machine to cut along different paths. Bed milling machines are ideal for creating parts with various shapes and sizes. 4. Turret Mill: A turret mill has a rotating spindle with a cutting tool at the end. This machine has a table that can be moved vertically and horizontally, giving it the capacity to cut and shape intricate forms. Turret mills are perfect for delicate jobs that need fewer cuts and a more precise finish. 5. CNC Router: CNC routers are designed to remove material from a workpiece, allowing it to be formed into a particular shape or pattern. It uses a rotating cylindrical tool that moves along multiple axes, providing precision cutting for objects like wooden decorative pieces, furniture parts, signboards, and architectural moldings. Different CNC mills are available for specific purposes, and the choice of the type depends on the materials, shapes, and productivity needs. While operating CNC mills may require skillful expertise, success hinges on selecting the right type of CNC machine for the particular task at hand. Benefits of Using a CNC Mill for Manufacturing Standard benefits: - Increased accuracy and precision of parts compared to manual methods. - Reduced production time with automated processes. - Ability to produce complex shapes with ease. Emotional benefits: - Feel confident in the quality of your products due to increased accuracy and precision. - Enjoy the satisfaction of creating high-quality parts quickly and efficiently using CNC Mill for Manufacturing technology. Advantages and Disadvantages of CNC Milling Computer Numerical Control (CNC) milling is a type of precision engineering process that utilizes computer-controlled cutting tools to remove material from the workpiece. CNC milling has become a popular manufacturing method due to its accuracy, efficiency, and versatility. However, just like any other manufacturing process, CNC milling has its own advantages and disadvantages that must be considered. Advantages: 1. Precision and Accuracy: CNC milling machines are capable of producing complex and intricate shapes with high precision and accuracy. This is because the cutting tools are guided by the computer, which ensures that the dimensions are consistent throughout the production process. 2. Flexibility: CNC milling machines are extremely versatile and can produce a wide range of products. It is possible to create different shapes, sizes, and forms without the need for different setups. 3. Consistency: CNC milling machines can produce identical parts with high consistency. This means that once the program for a particular part has been created, it can be easily replicated with the same level of accuracy every time. 4. Efficiency: CNC milling machines are highly efficient and can produce a high volume of parts within a short time. This helps to reduce production time and costs. 5. Automation: The use of CNC milling machines reduces the need for manual labor, which can lead to a reduction in costs and an increase in productivity. Disadvantages: 1. High Cost: CNC milling machines are expensive to purchase, install, and maintain. This makes it difficult for small businesses and startups to invest in this technology. 2. Complex Programming: CNC milling machines require complex programming to operate. This means that operators need to have specialized skills and knowledge to use them effectively. 3. Dependence on Electricity: CNC milling machines rely on electricity to operate. This means that power outages or fluctuations can result in downtime and production delays. 4. Limited Material Handling: CNC milling machines are limited in their ability to handle certain types of materials. This means that operators will need to use different machines for different materials, leading to increased costs and longer production times. 5. Lack of Flexibility: While CNC milling machines are highly flexible, they can be limited in their ability to produce certain types of shapes and materials. This means that some parts may need to be produced through other methods, leading to longer production times and increased costs. CNC milling has revolutionized the manufacturing industry by providing accurate and efficient production of various parts and products. However, it is important to consider the advantages and disadvantages of this technology before investing in it. By weighing these factors carefully, businesses can make informed decisions about whether CNC milling is the right choice for their production needs.

Factors to Consider When Purchasing a CNC Mill If you're looking to purchase a CNC mill, there are several factors that you should consider before making your final decision. A CNC mill is a computer-controlled machine that uses rotating tools to remove material from a workpiece. It offers many benefits, such as increased accuracy, repeatability, and automation, which improves efficiency and saves time. Here are the factors that you should take into account when purchasing a CNC mill. 1. Machine Size: The size of the CNC mill that you choose will depend on the size of the workpieces that you're planning to mill. If you're working with large pieces of material, you'll need a larger machine that can handle the size and weight of the workpiece. Conversely, if you're working with small pieces, you'll need a smaller machine to ensure accurate and precise cuts. 2. Machine Capability: Different CNC mills have varying capabilities. You should choose a machine that has the capabilities that you need for your specific application. Factors to consider include the number of axes, spindle speed, and cutting capacity. If you're working with complex parts that require multiple cutting operations, you'll need a machine that has a high number of axes to achieve the required cuts accurately. 3. Machine Accuracy: Precision and accuracy are critical in CNC milling. When purchasing a CNC mill, ensure that it has the required tolerances and accuracy level for your application. The accuracy of a CNC mill is usually measured in microns, so choose a machine with an accuracy level that meets your needs. 4. Machine Price: The price of a CNC mill can vary significantly depending on its capabilities, size, and accuracy. Ensure that you have a budget in mind before purchasing a machine, and choose a machine that offers the best value for your needs. Avoid choosing a machine based on price alone, as lower-priced machines may not have the required capabilities or accuracy levels. 5. Machine Support: When purchasing a CNC mill, ensure that the manufacturer offers excellent after-sales support, including installation, training, and maintenance. Ensure that the manufacturer has a good reputation in the market and is known for providing high-quality and reliable machines. Purchasing a CNC mill is a significant investment, and it's essential to consider several factors before making your final decision. Ensure that you choose a machine that has the required capabilities, accuracy, and support to meet your specific needs. How to Operate a CNC Mill Safely CNC mills are powerful machines that operate on computer-aided designs (CAD) to produce precise cuts and shapes in a variety of materials, including wood, metal, and plastics. However, the safety of the operator and those around the machine should always be a top priority. Here are some guidelines for operating a CNC mill safely: 1. Familiarize yourself with the machine: Before operating the mill, it is important to read and understand the owner's manual. Make sure you know the location of all the emergency buttons, switches, and other safety features. Additionally, make sure you are knowledgeable about the materials and tools that will be used during the milling process. 2. Wear appropriate safety gear: Before operating the CNC mill, it is essential to wear appropriate safety gear. This includes safety glasses, earplugs, gloves, and a dust mask to protect yourself from flying debris, loud noise, and harmful dust particles. 3. Secure the workpiece: Ensure that the workpiece is securely fastened to the mill bed before starting the milling process. Use clamps or other securing devices to prevent the workpiece from moving during the operation. 4. Program the CNC mill: A program must be written and loaded into the CNC machine before it can operate. Always double-check the program for errors before running the machine. Pay careful attention that the program does not exceed the limits of the machine’s settings. 5. Stand clear of the machine: Once the milling process begins, stand clear of the machine and never hold the material by hand. Never lean or get too close to the machine while it is operating, and always remove any loose clothing or jewelry. 6. Monitor the milling process closely: Always be vigilant while the machine is operating to ensure everything is running smoothly. Watch for unusual noises or vibrations, which may indicate something is wrong with the machine or tooling. 7. Clean the work area: Once the milling process is complete, ensure that the work area is clean, and the machine is properly turned off. Remove any remaining debris and relabel the program for future use. Taking the necessary safety precautions before and during milling is vital to reduce the risk of accidents and injury. By following these guidelines, you can ensure the safe and efficient operation of your CNC mill. Conclusion: When shopping for a CNC mill, aspiring machinists and hobbyists should put careful consideration into the budget, performance, brand, and model quality that best suits their specific needs. While this process may seem daunting at first, it ultimately ensures that buyers receive a machine that meets their desires in terms of speed, accuracy, available features and more. Furthermore, some manufacturers offer free trials on certain models to give interested customers an opportunity to test before they buy. Before making any actual purchase decisions or commitments with the seller, prospective buyers should always read reviews or contact other satisfied users for guidance. Ultimately, all those seeking a CNC mill should be dedicated to researching their options thoroughly in order to find the perfect model for their project needs! Read the full article

0 notes

Text

FoxAlien Masuter 4040 CNC Router Machine 3-Axis Engraving Milling

- Brand and Manufacturer: FoxAlien Features - Masuter 4040 is a budget-friendly CNC router with huge workspace of 400 x 380 x 55mm (15.75" x 14.96" x 2.16"). It utilizes a 60W spindle as well as NEMA17 stepper motors. Max moving rate is 2000mm/min and pin rate array is 0 ~ 10000. - The control board is equipped with an upgraded 32-bit chip which works a lot more effective and also secure. It likewise sustains attachments such as offline controller, 300W spindle and power components. (Add-ons offered separately) - Masuter 4040 is qualified to engrave, cut as well as pierce lots of kinds of material such as wood, MDF, acrylic and material etc. Suggested setups: speed-1000mm/ minutes; deepness per pass-0.2 mm; plunge rate-200mm/ minutes. - House function and Emergency-Stop button are incorporated on the machine. The machine will certainly go to house with just push the button. - Almost all are pre-assembled. It takes about 20-30mins to totally setting up. The machine works with Grbl software. It sustains Windows XP/7/10, Linux as well as Mac OS. Maker Info - Model: Masuter 4040 Item Info - Size: 26.38 x 23.62 x 11.81 inches Read the full article

0 notes

Text

MYSWEETY 3 Axis 4540 CNC Metal Engraving Milling Machine

- Brand: MYSWEETY - Supplier: MYSWEETY Features - 500W Spindle & & High Speed The upgraded 3-axis 4540 inscribing machine is furnished with a 500W spindle for more power as well as higher efficiency, making it possible to reduce stainless steel, lightweight aluminum, and also various other metals. The optimum activity rate can reach 5000mm/min, the spindle rate range is 0-11000rpm/ min - Larger Working Area The CNC router machine has a larger inscription area, enhanced to 430 * 390 * 90 mm(16.9 * 15.4 * 3.5 inch). The working table has accurate range lines, which is hassle-free for you to situate and also measure the inscribing material size - Wide Application & & Compatibility The CNC timber machine is compatible with GRBL software program and also supports systems such as Windows XP/7/8/ 10 and Mac OS. Suitable for engraving and also carving stainless steel, timber, lightweight aluminum, brass, plexiglass, leather, PCB, MDF, acrylic, resin, nylon, carbon fiber, PCB, PVC, etc. - Easy to Assemble This CNC wood sculpting machine might be set up in 15-30 mins. The main parts are currently pre-assembled. Cords are clearly identified for fast connection. The control panel, power supply, emergency situation stop, and wires are integrated into a freshly made box for simple as well as safe operation. You simply need several installment actions as well as electrical wiring to start sculpting your projects - Bundle Included Comes with whatever you need. This inscribing machine collection included all parts to put together 4540 cnc machine, integrated controller box, touchscreen cnc offline controller, Z-probe, CNC router bits, English handbook, and much more. We likewise supply a 1-year service warranty as well as fantastic after-sales service, If any kind of concerns, please call us as soon as possible Read the full article

0 notes

Text

Powermatic PM-2X4SPK CNC Router Machine w/ Electro Spindle (1797024K)

- Brand: Powermatic Features - PIN STABILITY: Exclusive gravity cast light weight aluminum gantry supports - FAST MOVEMENT: Precision round screws with recirculating ball bearings - MASSAGING PREVENTION: Flexible nylon track chains safeguard all wires, protecting against massaging and stress and anxiety - TABLE PROTECTION: An MDF spoil board shields the table from damage, as well as can be quickly resurfaced making use of the pre-loaded program - ACCURATE MOVEMENT: High-torque stepper motors regulate each axis - EXACT POSITIONING: Linear guideways, with recirculating sphere bearings, make sure precise and precise positioning of the tool bit Maker Info - PartNumber: PM-2x4SPK - Version: PM-2x4SPK - Service warranty: 5 Year Read the full article

0 notes

Text

Genmitsu CNC Router Machine PROVerXL 4030 for Wood Metal Acrylic MDF

- Brand: Genmitsu - Producer: Genmitsu Features - Easy to Set Up: The pre-assembled component of XYZ axis and cables dramatically lowers effort of assembly, permitting you to start sculpting your tasks in less time. 3-Month Carveco Maker Subscription is consisted of. Turning your ideas into the next enjoyable job or your very own work of art will be much easier with Carveco Maker. We will certainly email you the registration link after you place the order. - Extra Power: New entirely revamped control box and also drive system, sturdy C-BEAM Frame, accuracy NEMA 23 stepper motors, High Power Spindle and consisted of adapter for a decrease in Dewalt DWP611 upgrade. - No added components required: Everything you require out of package, no disrobed kits or addons, the Genmitsu PROVerXL 4030 CNC router already consists of every one of the accessories and elements you require at a budget-friendly rate, consisting of XYZ axis limit switches over, emergency situation quit buttons, speed control, Z-probe and also more. - Accuracy and Performance: Rigid C-beam framework, Leadscrew Driven, Y-axis Dual screw drive, Z-Axis Optical Axis Drive provides much more stability than the typical v-slot drive. It's excellent for a countless selection of reducing, exploration, as well as sculpting operations on various products including timber, MDF, plastics, foams, vinyl, and also light weight aluminum. - Developed to suit your demands: The PROVerXL CNC system is just the start, if you are trying to find an also larger machine obtain the upgrade package offered in 2 extra sizes 24"x 24"( 600 x 600mm), and also up to 40" x 40" (1000 x 1000mm). Equip your machine with High Powered Laser Modules with approximately 15W of true power result. Evolve with your CNC, upgrade as you go, or start huge and reach making MORE. Manufacturer Info - PartNumber: PROVerXL 4030 Read the full article

0 notes

Text

Powermatic PM-2X2R CNC Router Machine with Router Mount (1797022K)

- Brand: Powermatic - Manufacturer: Powermatic Features - PIN STABILITY: Exclusive gravity cast aluminum gantry supports - QUICK MOVEMENT: Precision round screws with recirculating ball bearings - SAFEGUARDED CABLES: Flexible nylon track chains stop massaging and also tension - TABLE PROTCTION: An MDF spoil board safeguards the table from damages, and also can be rapidly resurfaced making use of the pre-loaded program - ACCURATE MOVEMENT: High-torque stepper electric motors regulate each axis - PRECISE POSITIONING: Linear guideways, with recirculating sphere bearings, ensure specific and exact positioning of the tool bit Producer Info - PartNumber: PM-2x2RK - Model: PM-2x2RK - Service warranty: 5 Year Item Info - Shade: Standard - NumberOfItems: 1 Read the full article

0 notes

Text

Genmitsu 3020-PRO MAX CNC Router Machine for Metal Carving and More

- Brand: Genmitsu Features - Bigger and also much better with an all brand-new additional rigid and also beefy design including an increased Z Height of 72mm double steel X axis overview rails, all aluminum pin holder as well as 300W spindle. All these upgrades make metal carving less complicated, perfect for a limitless selection of boring, as well as sculpting operations on different metals, like brass, copper and also 6061 aluminum, and so on. - Updated straight guide structure and 4040 Y axis profiles highly boost the etching accuracy and also handling strength, getting rid of Z axis wobble concerns that a lot of various other desktop CNC machines have. - : The Upgraded Genmitsu Rotary Roller requires no assembly, and you can conveniently adjust the roller distance without devices called for. - : High Quality Machined Rollers make the brand-new rotating more consistent with better inscription accuracy as well as fewer missed out on motor steps. The polyurethane finish of the rollers offer an improved grip as well as get rid of slipping of the item you are engraving. - : 5mm - 160mm; Length: 10mm-- 195mm. Flexible Roller Distance: 19mm - 76mm (16 various distances, each one 9.5 mm additionally than the last). Read the full article

0 notes

Text

Genmitsu 3020-PRO MAX CNC Router Machine with Clamp Kit

- Brand: Genmitsu Features - Larger as well as much better with an all brand-new added stiff as well as sturdy design including a boosted Z Height of 72mm dual steel X axis guide rails, all aluminum spindle holder and also 300W pin. All these upgrades make steel sculpting simpler, perfect for an endless range of drilling, and also sculpting operations on various steels, like brass, copper as well as 6061 light weight aluminum, etc. - Updated linear guide framework as well as 4040 Y axis accounts extremely improve the etching precision and handling strength, eliminating Z axis wobble problems that a lot of various other desktop CNC machines have. - One-piece machined as well as formed light weight aluminum design makes certain flatness and also stamina of the job system. Integrated measurement scale is practical for product positioning. The platform is compatible with a lot of the CNC secures on the marketplace. - The pre-assembled component of XZ Axis Gantry and Base Assembly decreases the initiative of setting up. You simply require 3 primary installment actions as well as electrical wiring to begin sculpting your projects. All stepper motors are furnished with hand-operated jog wheels making it easy to readjust and place your pin or supply material. - The clamp fits material approximately 1.77" thick and also features easy to tighten up knobs for fast installation or elimination of stock material.This clamp is 65.3 mm size x 20mm width x 50mm elevation. (2.57 x 0.79 x 1.97 in) Read the full article

0 notes

Text

SainSmart Genmitsu CNC Router Offline Control Module for CNC Machines

- Brand: SainSmart - Supplier: SainSmart Features - Offline Control: With SainSmart offline controller component, you can manage the CNC router without connecting to the computer. The CNC router can be placed wherever you desire, such as garage as well as workshop. - Guidebook Control: The area of XYZ Axis can be changed by hand as inscribing starting point. The pin open or close mode additionally can be regulated by hand by this module. - Two-way Access The File: The inscribing filed can be directly recognized once you place the data in the SD card. You can likewise link the offline module to the computer by micro USB cord, then store the documents straight. - Easy to Use: All you need to do is attach the offline component to the GRBL controller board, then you can manage the CNC router with this component. - This offline module is perfectly suitable with Genmitsu 1810-PRO/3018/3018-PRO/ 3020-PRO MAX CNC Router and also other generic 3018PRO CNC Router on the marketplace. Maker Info - PartNumber: 8087 Read the full article

0 notes

Text

Genmitsu 3020-PRO MAX CNC Router Machine - CNC Resin Wood Kit

- Brand: Genmitsu Features - Bigger and far better with an all new extra inflexible and also beefy design including a boosted Z Height of 72mm dual steel X axis guide rails, all light weight aluminum pin holder and 300W spindle. All these upgrades make metal sculpting much easier, optimal for an unlimited range of exploration, and also carving operations on numerous metals, like brass, copper and 6061 light weight aluminum, etc. - Updated linear guide structure and 4040 Y axis accounts very enhance the inscribing accuracy and also handling strength, eliminating Z axis wobble issues that the majority of other desktop computer CNC machines have. - One-piece machined and molded aluminum layout makes certain monotony and also strength of the work platform. Integrated dimension scale is practical for material positioning. The platform works with most of the CNC secures on the market. - The pre-assembled module of XZ Axis Gantry as well as Base Assembly decreases the initiative of setting up. You just need 3 primary installation actions as well as wiring to begin sculpting your projects. All stepper electric motors are outfitted with hands-on jog wheels making it easy to change as well as position your spindle or stock material. - Stabilized resin wood is natural wood imbued with plastic material to the core. It has high sturdiness as well as will certainly not warp or split, stronger and also much more sturdy than other original timber. You can use this supported material timber to inscribe knife deals with, pens and various other personalized jobs. Read the full article

0 notes

Text

Genmitsu CNC 3018-PRO Router Kit Milling Engraving Machine

- Brand: Genmitsu Features - What You Get: Genmitsu 3018-PRO CNC router kit; 1pcs CNC Spindle Motor with ER11 Collet. (Note: They will certainly be shipped independently) - Premium Power Adapter: The 3018-PRO has actually brought security improvements to the adapter, with CE/FCC/UL-approved. Strong constructed for sturdy and also long use performance, making input/output stably also when benefit a long time or work with a laser module. - Offline Controller: The 3018-PRO features an offline controller, you can manually change X, Y, Z-axis without connecting to the computer system as well as download data. - Versatile: Capable of reducing all kinds of plastics, soft light weight aluminum, woods, acrylics, PVCs, and also PCBs, the Genmitsu can be made use of on a wide variety of jobs as well as products. Assembly instructions are provided, but if you obtain stuck, take a look at the SainSmart wiki page or call us with any kind of concerns that develop. - 775 Motor: DC 24V; Speed: 20000/min. Pre-installed electric motor sound suppression PCB offers enhanced performance. It's compatible with Genmitsu 3018 Series CNC router. Applied to lathes, mills, auto hoists, pumps & & conveyors, and so on. Read the full article

0 notes

Text

4 Best CNC Plasma Tables - 2023 Buyer's Guide

When it comes to fabricating metal parts and products, there is no better way to do it than with a CNC plasma table. These machines are extremely precise and can create some of the most intricate designs possible. In this blog post, we will explore some of the best CNC plasma tables - 2023. We will also discuss some of the factors you should consider when purchasing one of these machines. When it comes to purchasing a CNC plasma table, there are several things you'll want to keep in mind. Here are four key factors to consider: 1. Cutting area2. Reliability and support3. Ease of use4. Budget Let's take a closer look at each of these factors:1. Cutting area: One of the most important things to consider is the size of the cutting area. You'll want to make sure that the table you purchase can accommodate whatever projects you have planned. If you're planning on doing a lot of large-scale projects, for example, you'll need a table with a large cutting area. But if you mostly work on smaller projects, you can get away with a smaller table.2. Reliability and support: Another important consideration is the reliability and support of the CNC plasma table you purchase. You'll want to make sure that you're buying from a reputable company that offers good customer service and technical support. That way, if you have any problems with your table, you know you can count on them to help you out.3. Ease of use: Another factor to consider is how easy the table is to use. You'll want to make sure that it's user-friendly and that you won't have any trouble operating it. If you're not comfortable using a certain feature, or if you find the controls confusing, it's probably not the right table for you.4. Budget: Finally, you'll need to consider your budget when purchasing a CNC plasma table. There are a wide range of prices out there, so it's important to find one that fits within your budget. But don't sacrifice quality for price – make sure you're getting a good value for your money.

4 Best CNC Plasma Tables 2023

STV Motorsports SparX510 5x10 CNC Plasma Cutting Table

If you're in the market for a top-quality CNC plasma cutting table, the STV Motorsports SparX510 5x10 is a great option to consider. This table is built with a tough steel frame that can handle even the most challenging projects. It also features an updated control system that makes it easy to use. Plus, the STV Motorsports SparX510 5x10 comes with a one-year warranty, so you can be confident in your purchase. To buy online for best pricing and fast delivery - Click Here Baileigh PT-22 CNC Plasma Cutting Table

The Baileigh PT-22 CNC plasma cutting table is a versatile and powerful machine that can be used for a variety of projects. With its large working area and easy-to-use controls, the PT-22 is perfect for both beginners and experienced users alike. The machine comes with a built-in air compressor, making it ready to use right out of the box. And with its included software, you can easily create custom designs and programs to cut any shape or size you need. Whether you're looking to create one-of-a-kind pieces or mass produce parts, the Baileigh PT-22 is up to the task. For user reviews and to buy online for best pricing and fast delivery - Click Here STV Motorsports SparX4400 4x4 CNC Plasma Cutting Table

The STV Motorsports SparX4400 4x4 CNC Plasma Cutting Table is a powerful, precise and reliable machine that is perfect for any metalworking shop. With its heavy-duty construction and advanced features, the SparX4400 can handle even the most challenging projects. And with its easy-to-use controls and intuitive software, the SparX4400 is also very user-friendly. So whether you're a beginner or a seasoned pro, the STV Motorsports SparX4400 4x4 CNC Plasma Cutting Table is a great choice for your metalworking needs. To buy online for best pricing and fast delivery - Click Here SHUANGBING WELDER Portable CNC Machine with THC for Oxyfuel and Plasma Cutting

The SHUANGBING WELDER Portable CNC Machine with THC for Oxyfuel and Plasma Cutting is a versatile, powerful machine that can be used for a variety of applications. With its built-in THC (torch height control), the machine is perfect for oxyfuel and plasma cutting, making it a great choice for those who need a versatile machine that can handle multiple tasks. The SHUANGBING WELDER Portable CNC Machine is also easy to use, thanks to its user-friendly controls, making it an ideal choice for both experienced and novice users alike. For user reviews and to buy online for best pricing and fast delivery - Click Here The Benefits of a CNC Plasma Table The benefits of a CNC plasma table are many and varied. In addition to the obvious advantages of increased accuracy and precision, a CNC plasma table can also offer significant increases in productivity. The ability to quickly and easily create complex shapes and designs is a major advantage of using a CNC plasma table, as is the fact that the machine can be operated with very little operator input. This means that businesses can save time and money by investing in a CNC plasma table. There are several other benefits of using a CNC plasma table, including the fact that the machines are very versatile. They can be used to create both small and large parts, and they can be used for a variety of different applications. This makes them an ideal choice for businesses of all sizes. Another advantage of using a CNC plasma table is that they are relatively easy to maintain. The machines do not require a lot of upkeep, and they can be easily repaired if something goes wrong. This makes them a much more cost-effective option than traditional methods of manufacturing. If you are considering investing in a CNC plasma table, then it is important to weigh up all of the benefits before making a decision. The benefits listed above are just some of the reasons why these machines are so popular. When you take into account all of the advantages, it is easy to see why a CNC plasma table could be the perfect choice for your business. How to use a CNC Plasma Table If you're looking to get the most out of your CNC plasma table, there are a few things you need to keep in mind. Here are some tips on how to use a CNC plasma table: 1. Make sure your material is properly secured. This will help prevent the material from moving or shifting during the cutting process, which can result in inaccuracies. 2. Use appropriate cutting speeds and settings for your material. If you're unsure, consult your machine's manual or a professional for guidance. 3. Keep the torch at a consistent height above the material. This will help ensure accurate cuts and minimize wear on the torch tip. 4. Use proper gas pressure and flow rates for your material. Again, consult your machine's manual or a professional for guidance if you're unsure. 5. Make sure your work area is well-ventilated. Cutting with a CNC plasma table produces fumes that can be harmful if inhaled. Following these tips will help you get the most out of your CNC plasma table and ensure accurate, consistent cuts. The Different Types of CNC Plasma Tables CNC plasma tables are available in a variety of sizes and specifications to suit different needs. The most common types are: - Compact CNC plasma tables: These are smaller machines that are typically used for light-duty applications such as hobby work or prototyping. - Commercial CNC plasma tables: These are larger machines that are designed for industrial use. They can handle heavy materials and have greater cutting power than compact CNC plasma tables. - Custom CNC plasma tables: These are made to order according to the specific requirements of the customer. This allows for greater flexibility in terms of size and specification, but also means that custom CNC plasma tables can be more expensive than other types. What to Know Before Purchasing a CNC plasma Table There are a few things you should know before purchasing a CNC plasma table. Firstly, you need to consider the size of the table. The table needs to be big enough to accommodate your project, but not too big that it becomes unwieldy. Secondly, you need to think about power requirements. Plasma tables require a lot of power, so make sure you have the right setup in place. Thirdly, you need to consider the software. The software is what controls the table and allows you to create your projects. Make sure you choose a software that is easy to use and has all the features you need. How to Set Up Your CNC Plasma Table If you want to know how to set up your CNC plasma table, there are a few things that you need to do first. You need to make sure that you have all of the necessary equipment and software installed on your computer. You also need to make sure that you have a good understanding of the G-code language. 2. The next thing you need to do is find a place to set up your table. You need to make sure that the area is well lit and free of any objects that could obstruct the view of the table. It is also important to make sure that the area is large enough for you to comfortably move around in. 3. Once you have found a suitable location, the next thing you need to do is set up your table. You need to make sure that the legs are securely attached to the table and that the table is level. If the table is not level, it could cause problems with the cutting process. 4. After the table is set up, you need to install the software that will be used to control the CNC plasma cutter. This software is typically provided by the manufacturer of the CNC plasma cutter. 5. The next step is to connect the power supply to the CNC plasma cutter. Make sure that all of the connections are tight and secure. 6. Finally, you need to connect the air supply to the CNC plasma cutter. The air supply is typically provided by a compressor. Make sure that the air pressure is set to the correct pressure for the CNC plasma cutter. 7. Once all of the connections are made, you are ready to start cutting. Make sure that you have a good understanding of the G-code language before starting the cutting process. If you do not understand the G-code language, you could damage the table or the cutter. 8. When you are ready to start cutting, select the appropriate file from the software and load it into the CNC plasma cutter. 9. Press the start button on the CNC plasma cutter and let it do its job. 10. When the cutting process is complete, turn off the power to the CNC plasma cutter and disconnect all of the connections. 11. Clean up the area around the table and remove any debris that was generated during the cutting process. 12. Once everything is clean, you are ready to start using your CNC plasma table. If you are in the market for a CNC plasma tables, be sure to keep the factors we’ve discussed in mind. Not all tables are created equal, and you want to make sure you get the best one for your needs. We hope our review has helped narrow down your choices and given you a better idea of what to look for when shopping for a new CNC plasma table. Thanks for reading! Read the full article

1 note

·

View note

Text

MYSWEETY CNC Router Machine 3018 Pro MAX 3 Axis Wood - Engraving

- Brand: MYSWEETY - Maker: MYSWEETY Features - MYSWEETY CNC 3018 Pro MAX- CNC 3018 Pro MAX is an upgraded version of 3018-PRO. Control software: GRBL; Working location: 300x180x45mm; Spindle: 200W spindle, DC24V, 12000r/ min. Supported System: Windows XP/ Win 7/ Win 8/ Win 10. - 200W High Power Spindle- Spindle: 200W, The main shaft embraces 52mm diameter expert air-cooled main shaft, rated at 200W, and the optimal power can reach 300W. - All-aluminum Alloy Body- The etching machine embraces as well an all-aluminum body. The structure is made up of 4040 aluminum and also 10mm thick lightweight aluminum. The XYZ elements are all refined by CNC, non-aluminum plate splicing, high precision, and high toughness. - Wide Application- Suitable for carving wood, plastic, acrylic, PCB CCL, and soft steel like copper and also aluminum, and other materials, however, can not carve difficult steel, jade, and various other very tough appearance of products. - Easy Assembly- Assembly instructions are supplied, however, if you get stuck, call us with any questions that occur. Thanks! Read the full article

0 notes

Text

Genmitsu CNC 3018-PRO Router Kit Milling Engraving Machine Plus Bits

- Brand: Genmitsu Features - What You Get: Genmitsu 3018-PRO CNC router set; 40pcs round nose & & flat nose end mill. (Note: They will certainly be delivered separately) - Premium Power Adapter: The 3018-PRO has actually brought safety and security improvements to the adapter, with CE/FCC/UL-approved. Strong built for sturdy and long use performance, making input/output stably also when help a long time or work with a laser component. - Offline Controller: The 3018-PRO features an offline controller, you can by hand readjust X, Y, Z-axis without connecting to the computer and also download data. - Software: The Genmitsu uses Grbl, high performance, open-source software program for controlling movement, and also runs on Arduino. Its stability as well as simpleness make Grbl an industry standard, there's no absence of assistance and also sources available when you get stuck. - 2 End Mill Sets: Flat nose and round nose. Shank Diameter: 3.175 mm, Cutting Diameter: 0.8 - 3.0 mm (0.8/ 1.0/ 1.2/ 1.4/ 1.6/ 1.8/ 2.0/ 2.2/ 2.5/ 3.0 mm), Cutting Length: 17mm, Overall Length: 38mm, with Nano blue and Titanium covering. Read the full article

0 notes

Text

Genmitsu CNC Dust Shoe ABS Cover Cleaner for 3018 Series CNC Router

Brand and Manufacturer: Genmitsu Features - Compatible with many 3018 collection CNC machines on the market, consisting of 3018-PRO, 3018-PROVer, 3018-PROVer Mach3 as well as 3018-MX3. Simply see to it that your pin diameter is 42mm (1.65 ″) as well as with two 4mm (0.16") screw holes. - This dust footwear is made from top notch clear ABS. The transparent design helps you keep an eye on your operations. Geared up with a 40mm lengthy nylon brush to make best use of vacuum cleaner suction and also assist work as a dirt sweep with high dust elimination efficiency. Keep your machine and workspace tidy while cutting, drilling, as well as sculpting. - Two-Piece Magnetic Design: Durable, light and also flexible, hassle-free for daily use as well as upkeep. Easy to set up as well as mount. Only take 3 steps to end up the installation. - The split layout makes it a lot easier to replace bits. You only need to pop off the lower cover when replacing your bits, no tools required, and avoid other difficult procedures. - The planting brush is much tidy and stronger than other glued ones. You might simply replace the entire base cover when the brush is put on. Do not require to spend much time eliminating as well as including a new brush (If the brush is also long for your bits, we recommend that you might trim it off from the bottom according to the bits length or order a Replacement Base Bottom Cover with 20mm long nylon brush). Producer Info - PartNumber: DS3018 Read the full article

0 notes