Don't wanna be here? Send us removal request.

Text

Packaging Machines and Filling Solutions for Diverse Industries

In today’s fast-paced manufacturing environment, packaging machines play a pivotal role in ensuring that products are packed, labeled, and sealed efficiently. From food and beverages to pharmaceuticals and cosmetics, the right packaging machineries can streamline production lines, improve productivity, and reduce costs.

Packaging machines help manufacturers automate repetitive tasks, minimize human error, and maintain product integrity. Whether it’s filling liquids into bottles, labeling products, or applying seals, packaging machinery is designed to meet industry-specific demands, improve consistency, and enhance operational efficiency.

In the food and beverage industry, for instance, packaging machines ensure that each product is sealed with care, preserving its freshness while complying with safety standards. In the pharmaceutical industry, machines ensure that medications are packaged with utmost precision, with the necessary safety seals and labeling for consumer protection.

Key Types of Packaging Machines and Their Functions

Packaging machines are designed for a range of applications, and selecting the right machine is critical for ensuring smooth production. Below are some of the main types of packaging machines:

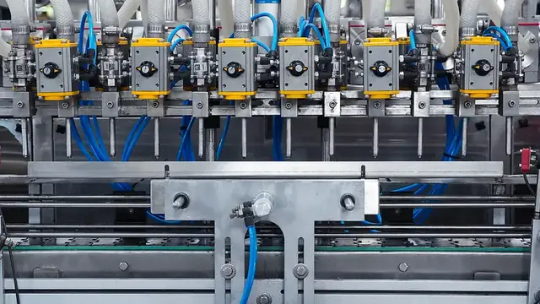

Filling Machines: These machines are used to fill products into containers, such as bottles or jars. Whether it's liquid, cream, or powder, filling machines ensure precise, consistent filling to avoid wastage and ensure proper measurements.

Labeling Machines: Labeling machines automate the process of applying labels to products. They are used in various industries to ensure that each product is properly branded and that compliance information is included.

Capping Machines: Capping machines are responsible for sealing containers with caps or lids, ensuring the product is securely sealed for storage and transport.

Inspection Machines: These machines check the accuracy of labels, the presence of caps, or the correct filling level. They ensure that products meet quality standards before they are shipped out.

Each of these machines plays a crucial role in automating production lines and reducing the dependency on manual labor, allowing businesses to scale production efficiently.

Filling Machines: Precision and Efficiency Across Industries

Liquid Filling Machines: Ensuring Accuracy and Efficiency

Liquid filling machines are essential for industries like food, beverage, and pharmaceuticals, where liquids need to be dispensed into containers with high accuracy. These machines are designed to handle various liquid types, such as water, juices, oils, and syrups, ensuring consistent and precise filling with minimal waste.

Liquid filling machines manufacaturer work on the principle of filling containers using methods such as volumetric filling, piston filling, or gravity filling. Each method is designed for specific types of liquids and containers, allowing manufacturers to choose the right technology for their products.

Liquid Filling Machines for Food, Pharma, and Cosmetics

In the food and beverage industry, liquid filling machines suppliers ensure that products like beverages, sauces, and oils are filled accurately into bottles, cartons, or pouches. Similarly, in the pharmaceutical industry, these machines are used to fill vials and syringes with medicines, ensuring precision for correct dosages. Cosmetics companies also rely on liquid filling system to fill bottles with shampoos, lotions, and serums.

For enhanced precision, electronic liquid filling machines are available, which provide more accuracy and control over the filling process, making them perfect for pharmaceutical and high-end cosmetic products.

Electronic Liquid Filling Machine: Advanced Solutions for Precision

Electronic liquid filling machines are equipped with advanced sensors and control systems that offer high-precision filling. These machines are particularly important for applications where accuracy is crucial, such as in the pharmaceutical industry, where even small errors in dosage can have significant consequences. With electronic liquid filling machines, manufacturers can track and control each fill precisely, ensuring uniformity across production batches.

Cream and Lotion Filling Machines: Catering to the Cosmetics Industry

Cream and lotion filling machines are specialized devices designed to fill bottles, jars, and tubes with creams, lotions, shampoos, and serums. Lotion filler machines ensure that the right amount of product is dispensed into each container, minimizing waste and ensuring uniformity in packaging.

Cosmetic Filling Machines for Creams, Lotions, Shampoos, and Serums

For the cosmetics industry, packaging is just as important as the product inside. Cosmetic filling machines help businesses maintain consistency in product volume and quality, ensuring that each bottle or jar is filled according to the desired specifications. Whether it’s a thick cream or a thin lotion, these machines are designed to handle different viscosities with ease.

Cream filling machines manufacturer are often equipped with features like adjustable filling volumes, anti-drip nozzles, and automatic capping systems, making them ideal for high-volume cosmetic production lines.

Guide to Choosing the Right Cream Filling Machine

When choosing a cream filling machine, it’s essential to consider the viscosity of the product, the container size, and the desired filling speed. For thicker creams, a piston filling machine is often the best choice as it provides precise control over the filling volume. For more liquid products, gravity or pump-based filling machines may be more suitable.

It’s also important to select a machine that ensures hygiene and ease of cleaning, especially in industries like cosmetics and pharmaceuticals, where product contamination can lead to serious issues.

Powder Filling Machines: Accuracy in Powdered Product Packaging

In industries where powders need to be filled into containers, powder filling machines are essential. These machines use augers, vibrators, or screw conveyors to measure and dispense the powder into bottles, bags, or other containers.

Powder Auger Filling Machines: Ideal for Precision Powder Handling

Powder auger filling machines are widely used in industries such as pharmaceuticals, food, and chemicals, where accurate measurements of powders are critical. These machines use an auger screw to transport the powder into the container, ensuring precise and consistent filling.

The design of the powder auger filling machine allows it to handle different powder types, from fine powders like flour and baby formula to coarse powders like spices or detergent.

Labeling and Inspection Machines: Enhancing Product Identification and Quality Control

Labeling Machines in the Food and Beverage Industry

In the food and beverage industry, labeling plays a crucial role in ensuring that products are properly identified, branded, and compliant with regulatory standards. Beverage Labeling machines are used extensively in this industry to apply labels to a variety of packaging, including bottles, cans, jars, and pouches. These machines ensure that each package carries the necessary product information, including ingredients, nutritional facts, expiration dates, and more.

Flat Bottle Sticker Labeling Machine for Perfect Labeling

The flat bottle sticker labeling machine is designed specifically for flat or irregularly shaped bottles and containers. This machine applies self-adhesive labels to products such as sauces, oils, and drinks. It is especially useful for bottles that cannot be handled by standard round bottle labeling machines. The flat bottle labeling machine ensures precise label placement, making it ideal for applications requiring high accuracy and consistency in labeling.

This machine features automatic label feeding, adjustment for various bottle sizes, and a quick changeover system, making it efficient for food production lines that require high-volume operations.

Spout Pouch Labeling Solutions for Food and Beverages

Spout pouches are commonly used for packaging liquids, sauces, and beverages. Spout pouch labeling machines are designed to apply labels to the spout of flexible pouches, which can be tricky due to the pouch's soft nature. These labeling machines are capable of handling different pouch sizes and can provide tamper-evident labels for safety purposes.

These machines are beneficial for producers of beverages like juices or sauces and manufacturers who use spout pouches for various other liquid products. Spout pouches manufacturer enhance efficiency in production lines, ensuring labels are correctly placed without waste or delay.

Label Inspection Systems: Ensuring Label Accuracy

Label inspection systems are critical in industries where the correct application of labels is essential. These systems are designed to inspect labels for proper placement, alignment, and content accuracy. They play an especially important role in industries like pharmaceuticals, food, and beverages, where incorrect labeling could result in costly recalls or regulatory violations.

Bottle Label Inspection System for Quality Assurance

The bottle label inspection system checks for label accuracy, ensuring that each bottle is labeled correctly before it leaves the production line. It examines whether the label is positioned in the right spot, if the text and barcode are readable, and whether the label is free from defects. The system can also detect missing labels or defective ones, ensuring that only quality products reach consumers.

Label inspection systems can be integrated with print and apply label machines, creating a seamless process from printing to applying and inspecting labels on each bottle.

Security Seal and Tamper-Evident Labeler Machines

For products that require tamper-evident seals, such as medicines, food items, and beverages, security seal and tamper-evident labeler machines provide an added layer of safety. These machines apply labels that show clear evidence if tampering has occurred. They are critical for consumer protection and regulatory compliance.

These machines are commonly used in the pharmaceutical industry to apply seals to bottles or vials of medicines. Similarly, in the food and beverage industry, tamper-evident labeling helps maintain product integrity by reassuring consumers that the product is unopened and safe for consumption.

Pharmaceutical Labeling: Ensuring Compliance in the Pharmaceutical Industry

The pharmaceutical industry has some of the strictest packaging and labeling requirements to ensure patient safety and compliance with regulations. Pharmaceutical labeling machines play a crucial role in automating the process of applying labels to bottles, vials, ampoules, and other containers containing drugs or medical products.

Pharmaceutical Labels for Personalized Medicine

As personalized medicine grows, the need for customized labeling has increased. Pharmaceutical labels for personalized medicine are used to ensure the accurate identification of patient-specific treatments. These labels often include unique information, such as patient names, dosages, and administration instructions, making it essential for pharmaceutical packaging machines to handle the complexity of these labels.

Pharmaceutical labeling machines, equipped with print and apply labeling systems, can print the required personalized data directly onto the labels, ensuring accuracy and preventing errors that could impact patient safety.

Pharma Packaging Machines for Precise and Safe Packaging

Pharma packaging machines are designed to meet the stringent regulatory requirements of the pharmaceutical industry. These machines automate the process of filling, sealing, and labeling pharmaceutical products. Whether it's bottles, blister packs, or vials, pharma packaging machines ensure that each package is sealed securely, labeled correctly, and ready for distribution.

For high-volume pharmaceutical production, automated systems such as blister inspection systems and label inspection systems ensure that each unit of medication is properly packaged, sealed, and inspected for any defects before reaching the market.

Packaging Machines for High-Efficiency Operations

Cartonators and Flow Wrap Machines: Efficient Carton Packaging

For packaging that involves placing products into cartons, cartonators play an important role. These machines fold and seal cartons around products, ensuring that they are securely packed for shipping and distribution.

The automatic cartonator machine automatically forms, fills, and seals cartons, making it ideal for industries like food and beverages, pharmaceuticals, and consumer goods. This machine provides increased efficiency by reducing manual labor and speeding up the packaging process.

Similarly, automatic flow wrap machines are used to wrap products such as bars, biscuits, or candy in a plastic film. These machines ensure tight and secure wrapping, which is vital for protecting products during transport and storage.

Shrink Sleeve Applicators: Creating a Tight and Secure Seal

Shrink sleeve applicators are used for applying shrink sleeves to containers, ensuring a tight and tamper-evident seal. These machines are especially useful for packaging products like bottled beverages, personal care items, and cleaning products. The shrink sleeve forms a tight fit around the container when heat is applied, ensuring product protection and an enhanced visual appeal.

The automatic shrink sleeve applicator machine is designed for high-speed production and can handle various container shapes and sizes. This machine helps reduce costs and increase productivity by automating the shrink-wrapping process.

Capping Machines: Ensuring Proper Seals for Containers

Capping machines are essential in many industries for sealing bottles and containers securely. Whether the product is a beverage, cosmetic item, or pharmaceutical product, capping machines help maintain freshness and ensure that the product remains tamper-proof.

Linear Capping Machines for Consistent Seal Application

Linear capping machines apply caps to containers with great accuracy, ensuring each bottle or jar is sealed properly. These machines are used in high-volume production lines, especially in the food and beverage industry, where ensuring freshness is crucial.

Rotary Screw Capping Machines: Ensuring Robust Closure Systems

Rotary screw capping machines are designed for sealing containers with screw caps. These machines offer high-speed capping, ensuring that each cap is securely applied without damaging the product or packaging. The robust design of rotary screw capping machines makes them ideal for use in industries like pharmaceuticals, chemicals, and beverages.

Stand-Alone Label Applicators: Streamlining the Labeling Process

For smaller production lines or specific labeling needs, stand-alone label applicators provide flexibility and efficiency. These machines apply labels to products or containers independently, making them an ideal solution for businesses that don't require full automated packaging systems. Stand-alone label applicators are easy to integrate into existing packaging lines and can handle various types of labeling, from front and back labels to wrap-around labels.

Blister Inspection Systems: Enhancing Pharmaceutical Packaging

Blister packaging is widely used in the pharmaceutical industry for tablets, capsules, and other products that need individual compartments. Blister inspection systems are designed to ensure that these packs are properly sealed, free from defects, and contain the correct number of units. These systems automatically inspect blister packs for issues like missing pills, incorrect sealing, or damaged packaging, which can compromise the product's safety and effectiveness.

Automated blister inspection helps manufacturers meet strict regulatory standards and guarantees that consumers receive only the highest-quality products. These systems typically use high-speed cameras and sensors to inspect every pack as it moves down the production line. Any defective units are immediately flagged for removal, ensuring that only the correct, defect-free products make it to the market.

Specialized Filling Solutions: Level and Volumetric Filling Machines

Filling machines are essential in various industries, especially where precision and consistency are crucial. Level and volumetric filling machines are designed to handle specific filling needs based on the type of product and container.

Volumetric Filling Machines: Ensuring Consistent Quantities

Volumetric filling machines measure and dispense exact amounts of liquid into containers. These machines are ideal for products like beverages, oils, and chemicals, where it is essential to maintain uniform filling levels for each container. The volumetric technology ensures that each product is filled to the same level, reducing waste and enhancing product consistency.

These machines typically use positive displacement pumps or other advanced methods to ensure the correct amount of liquid is dispensed each time. Whether it's a liquid filling line machine for large-scale operations or a smaller, manual system for specialty products, volumetric filling machines provide an accurate and reliable solution.

Level Filling Machines for Uniform Fill Heights

Level filling machines are designed to fill containers to a specific height, ensuring that every container in the production line is filled to the same level. This is especially important in industries where the appearance and consistency of products are key to brand presentation, such as in cosmetics, food, and beverages.

These machines use sensors to determine the precise fill level, and the system adjusts automatically to ensure uniformity in every container. This type of filling machine is particularly useful when the product being filled is sensitive to the height of the fill, such as in pharmaceutical labeler machine or beverage bottling.

Packaging Machines for High-Efficiency Operations

Automatic Cartonator Machines: Efficient Carton Packaging

The automatic cartonator machine is an essential piece of equipment in packaging lines where products need to be placed in cartons. This machine automates the process of forming, filling, and sealing cartons, which is especially useful in industries like food and beverages, cosmetics, and pharmaceuticals.

Cartonators are highly efficient and can handle large volumes of packaging at high speeds. The process begins with the machine forming a carton from flat board material. The product is then placed inside, and the carton is sealed to secure the contents. Automatic cartonators ensure that each carton is sealed properly, reducing human error and increasing productivity on the packaging line.

In addition to their speed and efficiency, cartonators help ensure consistent packaging quality, which is essential for maintaining brand standards and meeting regulatory requirements.

Automatic Flow Wrap Machines: Wrapping with Speed and Precision

Flow wrap machines are widely used in the food and confectionery industries to wrap products such as bars, biscuits, and snacks. These machines use continuous flow wrapping technology to wrap products tightly and securely in a protective film, ensuring that they are well-packaged for transport and retail.

Automatic flow wrap machines are designed for high-speed production and can wrap large volumes of products efficiently. They can be easily adjusted to handle different product sizes, and the wrapping film is automatically cut and sealed to fit the dimensions of the product. This makes flow wrapping a versatile solution for manufacturers looking to improve packaging speed and reduce labor costs.

The flow wrap machine provides a secure, hygienic, and visually appealing package that enhances the shelf appeal of products, especially in the highly competitive food and beverage markets.

Shrink Wrap Collating and Bundling Machines: Efficient Multi-Pack Packaging

Shrink wrap collating and bundling machines are used to group multiple products together in a single package, which is then shrink-wrapped for a secure, tamper-evident seal. These machines are particularly useful in industries like beverages, pharmaceuticals, and retail, where multiple items need to be packaged together for easy storage and shipping.

These machines are designed to efficiently group products into bundles, apply the shrink film, and shrink-wrap them into a tightly sealed package. The shrink wrap ensures that products remain together during transport and storage, preventing damage and ensuring the items are not tampered with.

In addition to providing protective packaging, shrink-wrapped bundles often feature clear, attractive packaging that enhances product visibility and makes it easier for customers to view and purchase.

Capping Machines: Securing Product Containers

Capping machines are an integral part of packaging lines in industries that require products to be sealed with a cap, lid, or closure. These machines ensure that the product is securely sealed, maintaining freshness, preventing contamination, and ensuring compliance with industry standards.

Linear Capping Machines for Consistent Seal Application

Linear capping machines apply caps to containers with precision and speed. These machines use linear motion to place and screw caps onto bottles or jars, ensuring that the caps are tightly sealed to prevent leaks or contamination. Linear capping machines are commonly used in industries like food, pharmaceuticals, and chemicals, where a secure seal is necessary for product integrity.

The key advantage of linear capping machines is their ability to handle high-speed production lines with minimal downtime, making them ideal for large-scale manufacturing operations. The precise control mechanisms allow for accurate cap placement and consistent sealing across production runs.

Rotary Screw Capping Machines: Ensuring Robust Closure Systems

Rotary screw capping machines are designed for high-volume operations where the speed of capping is a priority. These machines use a rotating mechanism to apply screw caps to containers at high speeds, ensuring that each cap is securely sealed to maintain the quality and safety of the product.

Rotary screw capping machines are commonly used in the beverage, pharmaceutical, and chemical industries. These machines are versatile and can handle a wide range of bottle sizes and cap types, making them ideal for diverse production needs. The high-speed operation ensures that large quantities of products are capped and sealed efficiently, increasing overall production capacity.

Conclusion: The Future of Packaging and Filling Machines in Modern Manufacturing

As industries evolve and consumer demands change, the need for high-quality packaging and filling machines continues to grow. From liquid filling machines that ensure precision in beverages and pharmaceuticals to label inspection systems that guarantee product accuracy, packaging solutions are becoming more advanced, versatile, and efficient.

The future of packaging machines lies in increased automation, precision, and customization. As technology continues to advance, manufacturers will be able to further streamline production lines, reduce waste, and ensure consistent product quality. Whether it’s a shrink sleeve applicator, pharmaceutical labeling machine, or blister inspection system, the machines that handle filling, labeling, capping, and inspection will continue to be critical in maintaining the quality and safety of products across industries.

youtube

0 notes

Text

Comprehensive Guide to Labeling Machines: Types, Applications, and Technologies

What is a Labeling Machine?

Labeling machines are devices used to apply labels to products or packaging. These machines are an essential part of modern manufacturing and packaging lines, ensuring that products are properly identified, branded, and compliant with industry standards. They can apply various types of labels, including stickers, barcodes, or regulatory information, to containers of different shapes and sizes.

Labeling machines are typically used in high-volume environments to improve efficiency, consistency, and accuracy in the labeling process. With the integration of automation, they are able to handle repetitive tasks, allowing manufacturers to scale their operations while maintaining high standards of quality and compliance.

The design of a labeling machine varies based on the product type and the application. For instance, a Jar Labeling Machine is designed for round containers, while a Square Bottle Labeling Machine is built for angular packaging. Additionally, industries such as pharmaceuticals, food, and beverages require highly specialized machines to meet regulatory requirements.

Importance of Labeling in Different Industries

Labeling is more than just an aesthetic tool—it's a critical aspect of product identification, compliance, and marketing. In industries such as pharmaceuticals, food, and beverages, labels are necessary for ensuring that products meet legal standards and are safely consumed or used.

Pharmaceuticals: Pharmaceutical labeling machine must ensure that labels are clear, accurate, and compliant with health regulations. These machines often need to print detailed information, such as ingredients, dosage instructions, and warnings.

Food and Beverages: In the food industry, food labeling machines help ensure that nutritional information, ingredients, and expiration dates are correctly printed. This is crucial for consumer health and safety.

Cosmetics: Cosmetic labeling machines need to apply precise labels to a variety of containers, often requiring intricate designs and regulatory compliance (e.g., vegan, cruelty-free, or organic certifications).

Beverages: Machines like the water bottle label machine or pet bottle labeling machine are designed to handle high-speed production and ensure proper labeling of bottles, cans, and cartons.

In each case, the labeling machine provides a cost-effective solution for labeling products quickly and accurately while meeting industry-specific standards.

Types of Labeling Machines and Their Applications

Jar Labeling Machines: Perfect for Round Containers

Jar labeling machines are designed to label cylindrical or round containers such as jars, bottles, and tubes. These machines can apply a variety of label types, including front and back labels, wraparound labels, and shrink sleeves, depending on the product's shape and material.

Key features of jar labeling machines include their ability to handle a variety of container sizes and the flexibility to apply labels in different orientations. Some machines come with automatic label detection and adjustment systems to ensure precise application every time.

These machines are especially common in industries like food (for jams, sauces, and spreads) and cosmetics (for creams and lotions). Their versatility and efficiency make them indispensable in high-volume production lines.

Key Features of Jar Labeling Machines

Automatic Label Detection: Ensures that each label is aligned correctly on the container.

Speed: Capable of labeling hundreds of jars per minute.

Customizable: Ability to apply various types of labels, including wrap around labeling.

Adjustable: Suitable for different sizes of jars and bottles.

Square Bottle Labeling Machines: Precision and Flexibility

A square bottle labeling machine is designed to handle the challenges posed by angular or flat-sided bottles. These machines are crucial for industries that package products in square or rectangular containers, such as sauces, beverages, or pharmaceuticals.

Square bottle labeling machine manufacturers often offer machines that can apply labels to both the front and back of a container simultaneously, ensuring full coverage and high-speed production. These machines are engineered to handle the irregular shape of square bottles while maintaining the accuracy of label placement.

They can be customized to fit various container sizes, offering flexibility in production. Many square bottle labeling machines are also equipped with print and apply labeling systems, enabling them to print variable data such as batch numbers, manufacturing dates, and expiry dates directly on the labels.

Water Bottle Labeling Machines: Meeting High Demand

The water bottle label machine is designed specifically for high-speed, high-volume production of bottled water. These machines are equipped to handle the speed and precision required in the bottling industry, ensuring labels are applied consistently and accurately, even on bottles that move quickly along a production line.

A water bottle labeling machine typically uses wrap around labeling techniques to apply labels around the bottle, creating a seamless look that enhances brand identity. The machine can also apply labels to other types of beverages, including soft drinks, juices, and flavored water, making it a versatile piece of equipment for beverage manufacturers.

These machines are also designed for easy integration with other systems, such as print and apply label printers, to provide essential product information, barcodes, and branding.

Pet Bottle Labeling Machines: Versatile and Durable

The pet bottle labeling machine is specifically designed for labeling polyethylene terephthalate (PET) bottles, which are widely used for beverages, cleaning products, and other liquid packaging. PET bottles require high-performance labeling machines that can handle various bottle shapes, sizes, and materials.

These labeling machines are engineered to apply wrap around labeling and other types of labels with precision and speed. Many pet bottle labeling machines come with high-tech features like automatic label detection, error correction systems, and the ability to print batch numbers or expiration dates.

The versatility of pet bottle labeling machines allows them to handle different bottle sizes, making them ideal for manufacturers looking to streamline their labeling processes.

Food Labeling Machines: Efficient and Compliant

Food labeling machines are crucial for ensuring that food products meet regulatory standards while also offering a clear, appealing presentation. These machines handle a variety of food containers, including jars, cans, pouches, and bottles.

For food manufacturers, the labels must include important information such as nutritional facts, ingredients, allergens, and expiration dates. The labeling machine must be capable of applying labels quickly and accurately while meeting compliance standards set by local authorities.

Food labeling machines are commonly used in large-scale operations, especially in packaging lines for packaged meals, sauces, or beverages. They can be designed to print variable data labels, which change based on product type, batch, or production date. These machines ensure consistent quality control and help maintain food safety standards across the supply chain.

The Role of Food Labeling Machines in Food Safety

Food labeling is critical for consumer safety, providing essential information about allergens, calories, ingredients, and storage instructions. In a fast-paced environment, the efficiency of food labeling machines is paramount for avoiding errors and ensuring timely production.

Specialized Labeling Machines for Unique Applications

Print and Apply Labeling Systems: Streamlining the Process

Print and apply labeling systems are an efficient solution for industries that need to print variable data directly on labels and apply them to products or packaging. These systems integrate printing capabilities with label application technology, allowing manufacturers to print batch numbers, expiration dates, barcodes, QR codes, and other variable data on labels as they are applied to products.

The advantage of print and apply labeling systems is their ability to automate the process of labeling while maintaining flexibility. They are commonly used in industries like food and beverage, pharmaceuticals, and logistics, where tracking and compliance are critical. These systems are designed to keep up with high-speed production lines, ensuring that products are labeled accurately and consistently.

One of the key benefits of a print and apply labeler is its speed and accuracy, which are essential in high-volume production environments. These systems can apply labels to containers of various shapes and sizes, making them versatile enough for a range of applications, from bottles and jars to cartons and cases.

Front and Back Labelers: Versatile Label Application

Front and back labelers are machines designed to apply labels to both the front and back of products in a single pass. This type of labeling is particularly useful for products like bottles, jars, and cans that require labeling on multiple surfaces.

A front and back labeler is typically used in industries such as food and beverage, cosmetics, and pharmaceuticals, where products need to display essential information on more than one surface of the packaging. For example, food products may need nutritional information on one side and ingredients or storage instructions on the other.

These machines offer flexibility, as they can handle a variety of label sizes and orientations, ensuring consistent application for both types of labels. Many front and back labelers are equipped with print and apply labeling technology, enabling the application of dynamic data, such as batch numbers or expiration dates, alongside static product labels.

Ampoule Labelers: Precision in Small-Scale Labeling

An ampoule labeler is a specialized machine designed for labeling small glass vials or ampoules, commonly used in the pharmaceutical, biotechnology, and medical industries. These small containers require precise and delicate labeling to avoid damaging the contents, which are often sensitive to contamination.

Ampoule labelers are engineered to handle the small size of the containers while maintaining a high level of accuracy. They are capable of applying labels to both the body and neck of the ampoule, ensuring that all required information is included. Given the nature of pharmaceutical packaging, these labelers often feature high-speed capabilities and can print batch numbers, serial numbers, and expiration dates on each label.

For industries like pharmaceuticals, where compliance with regulatory standards is mandatory, an ampoule labeler offers an essential solution. These machines help maintain the integrity of the product by ensuring that every ampoule is labeled correctly, which is crucial for traceability, safety, and compliance.

Vial Label Applicators: Ensuring Accuracy and Quality

Vial label applicators are machines specifically designed to apply labels to vials, which are often used for medicines, vaccines, and other laboratory products. Vials, like ampoules, are small and require precise handling during the labeling process to ensure that labels are applied correctly and without damaging the container.

The vial labeler is equipped with mechanisms to handle the tiny dimensions of vials, and these applicators ensure that labels are placed accurately every time. Whether it's a vial label applicator or a fully automated vial labeller, these machines are commonly used in pharmaceutical and biotechnology industries.

In addition to standard labeling, vial labelers can often integrate print and apply label systems to print important data directly onto the labels, such as dosage information, batch numbers, and barcodes. This makes vial labeling machines crucial for ensuring accurate documentation and maintaining product safety and compliance.

Types of Vial Labelers

There are different types of vial labelers based on the specific requirements of the labeling process:

Semi-Automatic Vial Labelers: These machines require manual placement of vials but automate the labeling process, making them ideal for smaller production runs.

Fully Automatic Vial Labelers: These systems automatically feed, label, and verify vials, making them suitable for high-volume production lines.

The right vial labeler depends on factors like production speed, the number of vials to be labeled, and the need for data integration (such as print and apply label machines).

Table-Top Labeling Machines: Compact and Efficient

Table-top labeling machines are compact, portable labeling solutions often used for small to medium production runs. These machines are ideal for small businesses, startups, or operations that require flexibility without the need for large-scale equipment.

Despite their small size, table-top labeling machines are highly efficient and can apply labels to a wide range of product types, including bottles, jars, and tubes. They are especially useful in industries like cosmetics, food, and pharmaceuticals, where businesses may need to label smaller batches of products.

These machines can be configured to apply front and back labels, wrap-around labels, or even shrink sleeves depending on the type of container and the label's intended placement. Their ease of use and compact design make them a great choice for companies looking for an affordable, yet effective labeling solution.

Labeling Technologies and Their Advancements

Wrap Around Labeling: Efficiency in Large-Scale Production

Wrap around labeling is one of the most efficient and popular methods for labeling cylindrical containers such as bottles and jars. In this process, the label is wrapped around the product, covering a significant portion of the surface area. This technique is commonly used in industries like beverages, pharmaceuticals, and personal care products.

The main advantage of wrap-around labeling is its ability to provide full coverage, allowing manufacturers to print more information on the label while enhancing the visual appeal of the product. It also provides an ideal solution for products like water bottles, juices, sauces, and other cylindrical packaging, where the container's round shape benefits from a label that wraps seamlessly.

Modern wrap around labelling machines are designed to handle high-speed production while maintaining accuracy and consistency. These machines are versatile, capable of applying labels to containers of various sizes and shapes, and can also integrate print and apply label systems for batch information, serial numbers, and other dynamic data.

Additionally, wrap around labeling helps brands stand out in crowded markets by allowing for high-quality graphics and detailed product information. It is a preferred choice for companies looking to create a professional and uniform look for their products on retail shelves.

Print and Apply Labelers: Key to High-Speed Operations

Print and apply labelers have become a game-changer in industries that require high-speed labeling and printing capabilities. These machines combine two processes: printing variable data onto labels (such as batch numbers, production dates, barcodes, or QR codes) and automatically applying them to the product or packaging.

Print and apply labeling machines are essential in industries like food, pharmaceuticals, logistics, and consumer goods, where labeling accuracy and speed are paramount. The main benefits of print and apply label machines include their ability to keep up with high production rates, reduce errors, and improve traceability throughout the supply chain.

One of the key innovations in print and apply labelers is their integration with automation systems, allowing them to be seamlessly incorporated into production lines without requiring manual intervention. This makes print and apply labeling systems particularly valuable in industries with strict regulatory requirements, such as pharmaceuticals, where accurate labeling is critical for product safety and compliance.

Additionally, print and apply labeling machines can be configured to print on-demand, ensuring that labels are customized to include real-time data, which reduces the need for pre-printed labels and ensures flexibility in production.

Advantages of Print and Apply Label Machines

Increased Speed and Efficiency: Capable of labeling at high speeds without compromising quality.

Reduced Labor Costs: Automation reduces the need for manual labor, lowering overall production costs.

Flexibility: Can print variable data directly on the label, including barcodes, batch numbers, and expiration dates.

Accuracy: Ensures consistent label placement and print quality, reducing the risk of errors.

Print Apply Labeling Systems: Simplifying Complex Labeling Needs

Print apply labeling systems are designed for companies that need both label printing and application in a seamless, integrated process. These systems are particularly effective for products that require unique or changing information, such as food products with different batch numbers, or pharmaceutical items with varying dosages.

In a print apply labeling system, the printer prints the necessary data (such as serial numbers, production dates, etc.), and then the system applies the label directly onto the product or packaging. These systems are ideal for high-speed environments, where they help maintain a high level of accuracy and consistency in labeling.

The combination of print and apply label systems allows companies to avoid pre-printed labels, which can be inflexible and costly. Instead, manufacturers can produce labels on-demand, ensuring they are always up-to-date with the latest product information.

For industries like pharmaceutical labeling machines, food labeling machines, or pet bottle labeling machines, print apply labeling systems ensure that each label is applied correctly and that important information is printed clearly and legibly.

Print and Apply Label Printer: Essential for High-Quality Output

A print and apply label printer is the core of many modern labeling systems, particularly in industries where products are moving through production lines at high speeds. These printers are capable of producing high-quality prints, including text, graphics, barcodes, and logos, which are essential for branding, tracking, and product identification.

The print and apply label printer integrates with various labeling machines to ensure labels are printed and applied with precision. In pharmaceutical production, for example, these printers are used to print critical information such as dosage, expiration dates, and batch numbers. The ability to apply such information directly to the label reduces the chance of errors and ensures the accuracy of product identification.

The primary benefit of print and apply label printers is their ability to provide consistent, high-quality output at a rapid pace. This is essential for industries that require a large volume of products to be labeled quickly, without compromising on quality or legibility.

Conclusion: The Future of Labeling Machines in Manufacturing

youtube

Labeling machines have come a long way in terms of technology, speed, and accuracy. As industries like food, pharmaceuticals, and consumer goods evolve, the need for more efficient and flexible labeling systems continues to grow. Labeling machines, such as pharmaceutical labeling machines, table-top labeling machines, and wrap around labeling systems, are becoming indispensable tools for manufacturers looking to streamline production, improve compliance, and enhance brand identity.

With advancements like print and apply labelers, vial labelers, and ampoule labelers, industries now have access to highly specialized equipment that meets their unique needs. From small-scale operations to large manufacturing plants, these machines are designed to provide maximum efficiency, reduce human error, and ensure that products are labeled accurately and consistently.

As consumer demands for better labeling, clearer product information, and sustainable packaging continue to increase, labeling machines will continue to evolve, incorporating smarter technology, automation, and higher precision. Businesses that invest in cutting-edge labeling technologies are poised to lead the way in product identification and packaging efficiency, ensuring they stay ahead of the competition in an ever-changing marketplace.

0 notes

Text

The Ultimate Guide to Labels: Types, Applications, and Industry Insights

Labels are more than just stickers slapped onto packaging—they're the first touchpoint between your product and the customer. Think of a label as your product’s handshake: it introduces your brand, conveys important information, and entices potential buyers. In industries ranging from cosmetics and personal care to pharmaceuticals and beverages, a label often serves as both a legal necessity and a powerful marketing tool.

For instance, labels for food products must include nutritional information, ingredients, and expiration dates. On the other hand, labels for cosmetics might highlight ingredients like “paraben-free” or “vegan,” resonating with eco-conscious buyers. Whether you're using transparent labels for a modern, clean look or wrap around labels for full coverage, the design and material you choose significantly impact buyer perception.

Moreover, printing labels correctly ensures legibility, durability, and aesthetic appeal. The quality of your bottle labels or labels for vials can either elevate your brand or damage its credibility. That’s why professional labels printing solutions are indispensable in today’s market.

Why Labels Are Critical for Compliance and Consumer Trust

Labels are not just cosmetic—they’re legal. Industries like pharmaceuticals, food, and chemicals are bound by stringent regulations regarding what must appear on packaging. Labels for pharmaceuticals, for instance, are required to display dosage instructions, batch numbers, expiry dates, and sometimes even tamper-evident seals like void labels or anti-counterfeiting labels.

Failing to meet these guidelines can result in product recalls, legal action, and lost consumer trust. For this reason, variable data labels are increasingly used for tracking products through the supply chain with unique serial numbers or barcodes.

Additionally, track & trace labels allow for real-time monitoring, which not only ensures regulatory compliance but also boosts transparency. This is particularly vital in the food and beverage sectors where recalls must be fast and efficient.

Consumer trust is also built through informative labeling. When a label clearly communicates quality and integrity—especially with premium features like embossed labels, metalized labels, or foiling labels—it reassures customers they’re making a smart, safe choice.

Common Types of Labels and Their Unique Features

Paper Labels: Affordable and Versatile

Paper labels remain the most widely used type across various sectors due to their cost-effectiveness and adaptability. They're ideal for products that don’t face harsh environments—like dry goods, office supplies, or temporary items. Paper offers excellent printability, making it perfect for detailed branding and barcode integration.

There’s a reason why paper labels manufacturers and paper labels suppliers are in high demand: their products are used in everything from shipping to food labeling. These labels can be coated or uncoated, depending on the desired finish. Uncoated paper provides a matte, natural feel, whereas coated options offer a glossier look suitable for premium goods.

However, paper labels have limitations. They’re susceptible to moisture and wear, which makes them unsuitable for products exposed to water or friction. That's where film-based options come in—but more on that in the next section.

If you’re looking for affordable, high-resolution, and customizable labeling options, then paper is a safe bet. Just make sure to source from reputable paper labels manufacturers to ensure consistency in quality and adhesion.

Top Paper Labels Manufacturers and Suppliers

Selecting the right supplier is crucial for ensuring label consistency and adhesion quality. Many paper labels suppliers offer custom options including die-cut shapes, specialty finishes, and fast-turnaround digital printing. The best suppliers also provide eco-friendly options, helping brands reduce their environmental footprint.

Film Labels: Durability Meets Aesthetics

Film labels are ideal for products that require resilience and a premium appearance. Made from synthetic materials like polyethylene and polypropylene, these labels are moisture-resistant, tear-proof, and have superior adhesive strength. They’re commonly used in industries like personal care, beverages, and pharmaceuticals.

Polyethylene labels are soft and flexible, making them perfect for squeezable containers such as lotions or shampoos. They stretch with the product without wrinkling or tearing. On the other hand, polypropylene labels are more rigid and offer better chemical resistance, which is why they’re used for food jars, cleaning supplies, and oils.

Film labels offer great design versatility too. You can print them with transparent, metallic, or matte finishes, and they often support embossed, foiling, or security features like holograms. While they might cost more than paper labels, their durability makes them a better long-term investment for high-touch products.

Transparent Labels: Sleek and Modern

Transparent labels are the go-to choice for brands aiming for a minimalist, no-label look. They blend seamlessly with the product’s surface, letting the packaging or contents shine through. This makes them perfect for premium products in cosmetics, beverages, and even gourmet foods.

The transparency of these labels enhances branding by offering a clean, elegant presentation. They’re often used with clear bottles or jars, making them a popular choice for bottle labels manufacturers who serve beauty and drink industries.

But functionality isn’t sacrificed for aesthetics. Transparent film labels are durable, moisture-resistant, and can accommodate custom printing with vibrant colors and white ink for maximum contrast.

Due to their modern appeal, many labels for cosmetics and labels for personal care products are moving towards transparent designs to attract style-conscious consumers. And with the right labels printing technique, your brand can achieve that high-end look effortlessly.

Industry-Specific Labeling Solutions

Labels for Cosmetics and Personal Care Products

The cosmetics and personal care industry is one of the most dynamic sectors when it comes to labeling requirements. With an ever-growing consumer demand for natural ingredients and eco-friendly products, cosmetics packaging must meet both regulatory and consumer preferences. Labels for cosmetics often have to indicate not just ingredients, but also claims like “paraben-free,” “cruelty-free,” or “hypoallergenic,” making accurate and clear labeling essential.

Cosmetic packaging must also withstand elements such as moisture, oils, and temperature fluctuations. This is why many cosmetic brands opt for film labels such as polyethylene labels or polypropylene labels that offer better protection against wear and tear. Moreover, many labels in this industry utilize embossed labels or metalized labels for an extra touch of sophistication.

Since personal care products are often exposed to environments where labels can be damaged (like in the bathroom), using high-quality bottle labels and vial labels ensures your branding stays intact and readable over time. Furthermore, the trend toward sustainable packaging means that eco-friendly paper labels and biodegradable options are becoming more common in the cosmetics industry.

Labels for Food Products and Beverages

Food and beverage labeling is perhaps the most heavily regulated industry when it comes to packaging. The information on food labels must be clear, accurate, and compliant with various international standards, including nutritional content, allergens, expiry dates, and country of origin. This regulatory focus on labels for food products ensures that consumers are fully informed about what they’re consuming, fostering trust in the brand.

But beyond compliance, labels are a vital marketing tool. For example, labels for beverages often carry vibrant, eye-catching designs to stand out in a crowded market. Beverage companies, particularly those in the craft beer, wine, or organic juice sectors, often make use of transparent labels or metalized labels to create a sleek and modern look that appeals to their target market.

In the food industry, wrap around labels are commonly used because they offer full coverage around bottles or cans, providing space for essential product information and an appealing design. Additionally, foiling labels can be used to add a touch of luxury to premium food items, enhancing the product’s shelf appeal.

Labels for Pharmaceuticals and Vials

In the pharmaceutical industry, labels serve a critical role not only in branding but also in ensuring patient safety. Labels for pharmaceuticals must include important information such as dosage instructions, warnings, batch numbers, and expiry dates. This makes it imperative that the labeling process is highly accurate and compliant with local regulatory standards.

Pharmaceutical packaging often uses vial labels that need to be resistant to chemicals and moisture while ensuring legibility. Many pharmaceutical companies also opt for security labels or anti-counterfeiting labels to protect against fraudulent activities, safeguarding both their brand and the consumer.

In addition, labels for pharmaceuticals often require track & trace labels to provide full visibility along the supply chain, ensuring that drugs are delivered to the right place at the right time. Given the critical nature of the pharmaceutical industry, the right labels printing process ensures that information remains intact throughout a product’s lifecycle.

Bottle Labels: A Must for Multiple Sectors

Bottle labels are perhaps one of the most widely used types of labels across multiple industries, ranging from beverages and personal care products to pharmaceuticals. Bottles, being the most common form of product packaging, demand labels that can adhere well to curved surfaces and withstand the rigors of handling, shipping, and usage.

In the beverage industry, bottle labels often feature vibrant colors and intricate designs, leveraging film labels for durability and metalized labels for added prestige. In personal care, polyethylene labels are often chosen for their flexibility and resistance to moisture. Even in pharmaceuticals, vial labels and bottle labels are essential for ensuring that medicines are properly identified and administered.

Since bottles come in various shapes and sizes, custom labels that perfectly fit the contour of the packaging are essential. Whether it’s a round bottle or a square one, the correct bottle labels manufacturers can provide tailored solutions that maintain both aesthetic appeal and functionality.

Track & Trace Labels for Supply Chain Transparency

Track & trace labels are becoming increasingly important in ensuring transparency throughout the product supply chain. With the rise of global trade, consumers and regulators alike demand visibility into the journey of their products, especially when it comes to food, pharmaceuticals, and high-value items.

These labels contain unique serial numbers, QR codes, or RFID tags that allow for real-time tracking. In the pharmaceutical and food industries, where safety and freshness are paramount, track & trace labels can quickly pinpoint the location of a product, allowing for faster recalls or other corrective actions if needed. Variable data labels are often used in conjunction with these systems to print unique data on each label for comprehensive tracking.

Track and trace capabilities go beyond compliance; they foster consumer trust by providing a transparent product journey. Brands that use such labels can not only meet regulatory demands but also enhance their brand reputation by showing consumers that they take product safety seriously.

Security and Anti-Counterfeiting Labels

In today’s global market, counterfeiting has become a significant issue for industries ranging from luxury goods to pharmaceuticals. Security labels and anti-counterfeiting labels provide protection against fraudulent activities, ensuring that consumers receive genuine products.

Anti-counterfeiting measures can include holographic designs, QR codes, barcodes, and UV inks that are only visible under certain light conditions. By incorporating such security features into their labels for pharmaceuticals, labels for food products, or even labels for beverages, manufacturers can protect their brand and customers from counterfeit products.

Void labels, for instance, are used to leave a visible mark once tampered with, making it clear that the product has been compromised. This is particularly important for items like medicines, cosmetics, and food products where consumer safety is of utmost importance.

Void Labels: Tamper-Evident Solutions

Void labels are tamper-evident labels that reveal a message, symbol, or text once the label has been removed or tampered with. These labels are crucial in industries where product integrity is a concern, such as pharmaceuticals, electronics, and even high-end food packaging.

For example, void labels manufacturers often produce tamper-evident seals that make it impossible for the label to be removed without visible evidence of tampering. This provides both a deterrent to theft and a warning to consumers that the product has been compromised. Whether it’s a vial label for a medicine or a bottle label for a luxury beverage, void labels are an essential tool for brand protection.

The use of void labels can be found in both physical and digital form, with the rise of smart labels offering real-time tracking and verification. This type of security ensures that products reach consumers in their original state, protecting both the brand and its customers.

Cassette Labels: Durable and High-Performance

In industries that require the highest level of durability, such as electronics, media, and specialized equipment, cassette labels are essential. These labels are designed to be highly resistant to abrasion, moisture, and heat, making them ideal for applications where durability is paramount.

Cassette labels are typically used for packaging components like CD/DVD cases, electrical devices, or other high-precision products. Made from high-performance materials, these labels ensure that essential information, such as serial numbers and barcodes, remains intact even under harsh conditions.

Variable Data Labels for Customization and Traceability

As the need for product personalization and tracking increases, variable data labels are becoming an essential tool across many industries. These labels are customizable with information such as serial numbers, barcodes, QR codes, expiration dates, and even personalized messages for customers. Unlike standard labels, which contain static information, variable data labels change with each application, offering enhanced flexibility and functionality.

In industries like food, beverages, and pharmaceuticals, variable data labels help track product batches and expiration dates, providing real-time information that is crucial for inventory management and quality control. These labels are commonly printed using digital printing technology, which allows for on-demand, high-volume printing with maximum accuracy.

Track & trace labels often incorporate variable data elements, allowing businesses to track individual products through each stage of the supply chain. Whether you’re in the business of bottle labels or labels for pharmaceuticals, variable data labels enable unique product identification, which is crucial for ensuring product safety, regulatory compliance, and customer satisfaction.

The Process Behind Labels Printing

Understanding the process behind labels printing is key for businesses seeking to create high-quality, functional, and visually appealing labels. The choice of printing technique affects everything from color quality to durability, making it an important consideration in label design and production.

Various printing methods are used in the label industry, including flexographic printing, digital printing, and offset printing. Each method has its benefits depending on the type of label, material, and order volume. Flexographic printing is commonly used for high-volume runs and is ideal for printing on non-porous materials like plastic films, which are often used for film labels and polyethylene labels.

Digital printing, on the other hand, offers flexibility for smaller runs and customization. It is especially useful for variable data labels where each label needs unique content. This method is also more environmentally friendly as it uses less ink and generates less waste compared to traditional printing methods.

Offset printing is another common technique for high-quality, large-volume printing jobs, typically used for paper labels. The printing method chosen depends on the product’s requirements—whether durability, high-quality finish, or cost-effectiveness.

When working with a labels printing partner, it’s important to communicate your product’s specific needs, such as the type of material, design, and volume. Experienced bottle labels manufacturers and paper labels manufacturers can guide you through the best options to achieve your desired result, ensuring that your product stands out on the shelf while maintaining integrity.

Working with a Reliable Labels Printing Partner

Choosing the right printing partner is vital to getting the perfect label for your product. A reliable labels printing company should offer expertise in various printing methods, excellent customer service, and the ability to handle different label materials, including paper, film, and special finishes like embossed labels or foiling labels.

Working with a printing partner who understands your brand's needs and industry requirements can save you time and money while ensuring the quality of your product’s labeling. In the labels for pharmaceuticals industry, for example, it’s crucial to ensure that all labeling is compliant with local regulations. The right paper labels suppliers or film labels manufacturers will be able to provide expertise in this area, ensuring that the printed labels meet both aesthetic and regulatory standards.

Additionally, a trustworthy labels printing partner will be able to advise you on the best material for your product, whether you need transparent labels, security labels, or wrap-around labels. They can also guide you in selecting the appropriate finishing options, such as matte, gloss, or textured finishes, which add an extra layer of differentiation and professionalism to your products.

youtube

Conclusion: The Future of Labeling Across Industries

The world of labeling is constantly evolving, driven by technological advancements, changing consumer demands, and increasing regulatory requirements. From embossed labels that create a tactile experience to track & trace labels that offer real-time supply chain monitoring, labeling is no longer just about product identification; it’s about communication, functionality, and enhancing the customer experience.

As industries such as cosmetics, food, beverages, pharmaceuticals, and electronics continue to grow, the demand for innovative, durable, and informative labels will only increase. Whether you’re using polyethylene labels, metalized labels, or void labels, the role of labeling in brand identity, product safety, and consumer engagement will continue to expand.

The future of labeling lies in customization, sustainability, and technology. With the rise of anti-counterfeiting labels, variable data labels, and smart labels that incorporate RFID or NFC technology, labels will become even more integral to the consumer experience and product journey.

As businesses strive to meet regulatory demands and consumer expectations, investing in high-quality labels and partnering with professional labels printing services will be crucial for success in an increasingly competitive marketplace.

0 notes

Text

Labelling Solutions Tailored for Every Industry – Maharshi Machines

Discover Maharshi’s versatile and innovative range of labelling machines designed to serve multiple industries including pharmaceuticals, cosmetics, food, beverages, and more.

This infographic visually showcases various high-performance labelling solutions such as Automatic Sticker Labelling Machines, Stand-Alone Label Applicators, Rotary Sticker Labellers, Semi-Automatic Labelling Machines, Top & Bottom Labelling Systems, and Tube Labelling Machines. Each machine is engineered for precision, speed, and adaptability—ideal for both small-scale businesses and high-volume production environments. Whether you need wrap-around, flat surface, or top-bottom labelling, Maharshi offers a solution that ensures consistency and compliance in packaging. For more details, visit - www.maharshi.com

#LabellingMachines#PackagingSolutions#Maharshi#AutomaticLabeller#IndustrialMachinery#RotaryLabelling#TubeLabeller#PharmaPackaging#FMCGLabeling#EngineeringSolutions#PackagingTechnology

0 notes

Text

The Evolution and Efficiency of Modern Bottle Packaging Machinery

Why Bottle Packaging Matters in Today’s Industries The demand for precise, reliable, and efficient packaging solutions has never been higher. In industries such as beverages, pharmaceuticals, and cosmetics, advanced bottle packaging machinery ensures not just attractive presentation but also long-term product integrity. This machinery has transformed the way manufacturers meet volume targets and maintain consistency in packaging.

Glass Bottles and Specialized Machinery When it comes to packaging glass bottles, durability and careful handling are key. Glas bottle packaging machines are engineered specifically for this purpose. These machines delicately yet efficiently manage the packing of fragile containers, ensuring no breakage and maintaining product quality, especially in the beverage and premium spirits sectors.

Tailored Solutions for the Beauty Industry The cosmetics sector requires specialized technology for handling delicate creams, serums, and essential oils. Cosmetic packaging machines are designed to handle small, uniquely shaped bottles with precision filling and sealing mechanisms that ensure hygiene and exact dosage—a crucial need for luxury skincare and makeup products.

Meeting Demand with High-Speed Production Lines As brands scale globally, the need for high-speed bottle production lines becomes vital. These systems enable thousands of bottles to be filled, capped, and labeled per hour, drastically reducing lead times and improving output without compromising accuracy.

Versatility with Bottle Packaging Machines Modern bottle packaging machine solutions offer high adaptability, managing different bottle shapes, sizes, and materials with seamless configuration changes. This flexibility supports product diversification without the need for multiple machines, optimizing operational costs.

From Filling to Sealing: Complete Equipment Solutions An integrated system of bottle packaging equipment goes beyond basic bottle handling. It includes functions like filling, capping, sealing, labeling, and inspection—all under one synchronized setup. These integrated systems are crucial for maintaining flow and reducing production errors.

India’s Leading Manufacturer in Packaging Technology India is fast becoming a hub for efficient machinery. A reputable bottle packaging machinery manufacturer understands the specific requirements of local and international markets, offering durable systems that comply with global quality and safety standards.

Exploring the Manufacturing Ecosystem Multiple bottle packaging machines manufacturers operate at different scales, from local providers offering entry-level solutions to global firms supplying fully automated high-volume lines. These manufacturers play a critical role in enabling industries to access technology suited to their production capacities.

How Bottle Packaging Machines Improve Workflow Today’s bottle packaging machines are equipped with digital interfaces, IoT connectivity, and automation features that enhance performance. With real-time monitoring and reduced human intervention, they drastically cut downtime and boost production consistency.

Strategies for Operational Optimization Businesses focused on improving operating efficiency bottle line implementations are investing in smart machinery with energy-efficient motors, faster changeovers, and predictive maintenance. This ensures reduced operational costs and better resource utilization.

A Legacy of Innovation: Maharshi Packaging One notable player in the Indian packaging market is maharshi packaging industries. Known for its innovation and commitment to quality, Maharshi has helped businesses across sectors transition to automated, scalable bottle packaging systems with minimal setup time and optimal output.

Maintaining Quality Control with Bottle Level Machines To ensure uniformity, especially in the food and pharma sectors, the bottle level machine monitors fill levels and rejects under- or over-filled bottles. This maintains product integrity and helps brands meet regulatory and consumer expectations.

End-to-End Automation with Packaging Bottle Machines A complete packaging bottle machine setup integrates filling, labeling, sealing, and palletizing processes. These machines allow for automated production from start to finish, which is critical for meeting tight market timelines and increasing throughput.

Efficient Liquid Filling with Roll-On Technology For industries requiring tamper-evident closures, a roll on filling machine is a game changer. It accurately applies roll-on caps to liquid products such as perfumes and eye drops, ensuring secure sealing without compromising packaging aesthetics.

High-Speed Filling for Bottled Products Where rapid volume is a necessity, a high speed bottle filling machine delivers maximum output in minimal time. These machines are ideal for water, soft drinks, and other mass-produced liquids, significantly lowering cost-per-unit production.

youtube

Conclusion: Packaging Excellence Through Innovation The future of packaging lies in integrated, high-speed, and precision-driven solutions. By investing in advanced technologies—from bottle level inspection systems to roll-on fillers—manufacturers can ensure quality, efficiency, and scalability. Whether you're a startup or an established enterprise, the right bottle packaging machinery can redefine your production capabilities and set you apart in a competitive marketplace.

0 notes

Text

Understanding the Dynamic World of Label Manufacturing: Trends, Innovations, and Industry Insights

In today’s consumer-driven and compliance-focused world, label manufacture plays a pivotal role in product packaging, branding, and safety. Every product on the shelf tells a story—and that story often starts with a label. Whether it's a luxurious skincare item, a food product, or a vial of medicine, the label must capture attention, provide essential information, and endure handling and environmental conditions.

The Evolution of Label Manufacturing

Over the years, label manufacturing has evolved from simple sticker printing to sophisticated, high-tech processes involving specialized materials, advanced adhesives, and regulatory-specific designs. Today’s labels are far more than identification tags—they are communication tools that influence buying decisions, ensure traceability, and fulfill legal requirements.

How Labelling Manufacture Shapes Brand Identity

A brand’s first impression often comes from its packaging. That’s where labelling manufacture plays a critical role. The right label design and finish can elevate a product, convey its premium quality, and build trust. From matte laminates and embossing to holographic effects and smart labels, manufacturing techniques now cater to both aesthetic appeal and functionality.

The Role of Label Printing in Modern Packaging

The importance of label printing for packaging cannot be overstated. In a market saturated with products, packaging becomes the silent salesperson. Labels must be sharp, high-resolution, and capable of showcasing brand elements clearly. They also need to resist wear and tear, making printing techniques like flexography, digital, and screen printing vital components of the process.

Working with Specialized Label Packaging Companies

As businesses grow, many turn to label packaging companies to streamline operations. These companies offer not just label production, but design consultation, compliance expertise, and even logistics support. This one-stop-shop approach ensures that the packaging process aligns seamlessly with product launch timelines and industry regulations.

Why Packaging and Labeling Companies are Critical to Success

Packaging and labeling companies are integral to supply chains across sectors. Whether you're in food, cosmetics, chemicals, or pharmaceuticals, having a reliable labeling partner ensures consistency, compliance, and scalability. These companies manage everything from artwork setup to final product delivery, making them essential collaborators in branding and logistics.

Choosing the Right Label Manufacturing Company

When selecting a label manufacturing company, businesses must consider more than just pricing. Factors like turnaround time, customization capabilities, material quality, and industry expertise all matter. A good partner can adapt to changes in product lines, accommodate urgent demands, and maintain quality across thousands—or even millions—of units.

Growth of Label Manufacturing in India

India has emerged as a powerhouse in label production, with many international brands now sourcing from a label manufacturer in India. Cost-effective manufacturing, access to skilled labor, and advanced infrastructure have made India a go-to destination for global labeling solutions, particularly in fast-growing markets like FMCG, pharmaceuticals, and e-commerce.

Technology and the Rise of Label Printing Manufacturers

The digital revolution has transformed label printing manufacturers, enabling faster turnaround, variable data printing, and shorter runs with zero compromise on quality. Brands can now test designs in the market, run limited edition packaging, and personalize labels for individual customers—all thanks to cutting-edge digital label printing technologies.

Industrial Labeling Solutions

A reliable industrial label manufacturer provides labels that withstand extreme conditions—heat, cold, moisture, abrasion, and chemicals. These labels are essential in industries like automotive, manufacturing, chemicals, and logistics, where durability is as important as legibility.

Specialization of Product Label Manufacturers

Every product category has its unique labeling needs. That’s where product label manufacturers step in. From curved bottles to pouches, cartons to tubes, these specialists ensure perfect adhesion, visual clarity, and regulatory compliance—helping brands maintain consistency across a diverse product portfolio.

Brand Labels: More Than Just a Sticker

A brand label manufacturer understands that a label is not just about information—it’s about identity. These labels feature high-end finishes, tactile embellishments, and unique textures that make products pop on shelves and resonate with target consumers.

Pharmaceutical Labeling: Accuracy and Safety First

For a pharmaceutical labels manufacturer, precision, safety, and compliance are paramount. These labels must include vital information like dosage, ingredients, expiry, and batch numbers. Additionally, they must adhere to stringent government regulations and be resistant to tampering, ensuring patient safety and legal conformity.

Solutions from Pharma Label Manufacturers

Pharma label manufacturers offer specialized solutions including tamper-evident seals, multi-layer labels for small packaging, and labels suitable for refrigerated or sterilized environments. Their expertise ensures that even in fast-paced production lines, every unit is labeled accurately and compliantly.

Versatile Offerings from Packaging Label Manufacturers

Packaging label manufacturers work across a wide range of sectors, providing everything from eco-friendly paper labels to high-gloss plastic labels. Their ability to produce in bulk while maintaining quality makes them key players in global packaging strategies.

Durability by Drum Labels Manufacturer India

In the industrial chemical sector, safety and durability are non-negotiable. A trusted drum labels manufacturer India provides high-strength labels that resist chemical spills, UV rays, and rough handling. These labels must stay intact under harsh conditions, ensuring the safe identification and transport of hazardous substances.

Conclusion: The Label as a Strategic Tool

In essence, a label is much more than a decorative element—it's a powerful tool that communicates brand value, ensures safety, meets regulatory needs, and enhances user experience. Whether you're launching a new skincare line, exporting chemical drums, or distributing medicine, choosing the right labeling partner can set your brand apart.

youtube