Don't wanna be here? Send us removal request.

Text

Optimized for Google SEO & Translated to English

Laser Welding vs. Traditional Welding: Optimization and Comparison for Handmade Steel Crafts

Welding plays a crucial role in the production of handmade steel crafts, directly impacting the final product’s precision, durability, and aesthetic quality. In recent years, laser welding has gained popularity as an advanced technique, offering significant advantages over traditional welding methods like arc welding and TIG welding.

Laser Welding vs. Traditional Welding: A Detailed Comparison

How Laser Welding Optimizes Handmade Steel Crafts Production

1. Precision Welding for Complex Designs

Handmade steel crafts often feature intricate patterns, delicate structures, and artistic details. Laser welding’s high precision enables fine welds without excessive heat, making it ideal for engraved metalwork, sculptural designs, and decorative joinery.

2. Reduced Heat-Affected Zone for Better Quality

Traditional welding methods generate excessive heat, leading to warping, discoloration, and material degradation. Laser welding focuses energy precisely, creating a small heat-affected zone (HAZ). This prevents unwanted deformation, ensuring that handmade steel sculptures, jewelry, and metal ornaments retain their intended shape.

3. Enhanced Aesthetic Appeal with Minimal Finishing

One of the major challenges in traditional metal welding is the need for extensive grinding, polishing, and rework to achieve a clean finish. Laser welding produces smooth, nearly invisible weld seams, reducing the need for post-processing and making the final product more visually appealing—a critical factor in luxury metal crafts and high-end handmade steel products.

4. Faster Production and Lower Labor Costs

Efficiency is key in handmade steel fabrication.

5. Versatility Across Different Metals and Applications

This allows for more creative freedom in crafting custom steel decor, furniture, and industrial-grade handmade components.

Conclusion: Why Laser Welding is the Future of Handmade Steel Craft

For artisans and manufacturers seeking better precision, stronger welds, and enhanced aesthetics, laser welding is a game-changer. As the demand for high-quality metal craftsmanship grows, laser welding technology is set to become the preferred welding method for handmade steel products.

0 notes

Text

Ultrasonic Welding of Lithium Battery Components: Technical Insights and Application Advantages

Ultrasonic welding is an efficient and environmentally friendly bonding technology widely used in lithium battery manufacturing. It achieves molecular bonding between materials through high-frequency vibration energy, ensuring the durability and conductivity of welded components. This article delves into the applications and advantages of ultrasonic welding technology in lithium battery components.

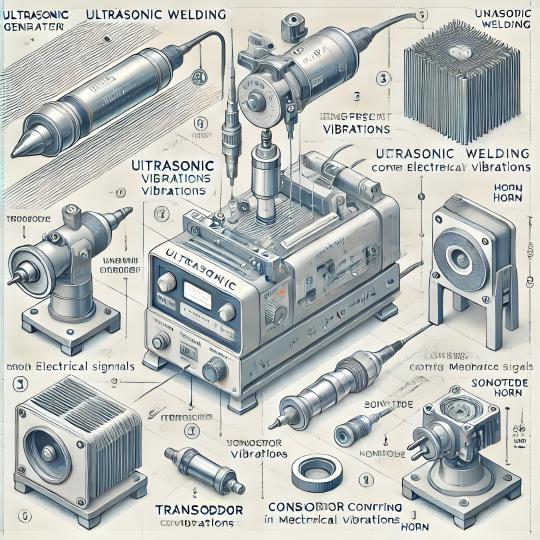

1. Principles and Characteristics of Ultrasonic Welding Technology

Ultrasonic welding uses high-frequency mechanical vibrations to generate frictional heat at the contact surface, causing the materials to interweave and fuse. No adhesives or solder are required; welding is achieved solely through vibration and pressure.

Key Characteristics

2. Applications of Ultrasonic Welding in Lithium Battery Components

Lithium batteries are complex structures comprising cathodes, anodes, separators, electrolytes, and casings. Ultrasonic welding plays a critical role in the following components:

1. Tab Welding

The cathode and anode tabs are welded to conductive plates or busbars, ensuring efficient current transfer.

2. Cell Connection

In multilayer cell stacks, ultrasonic welding enhances electrical conductivity and mechanical strength between cells.

3. Module Assembly

In battery modules, multiple cells are welded into a single unit to support high current output and stable performance.

4. Protection Circuit Welding

The protection circuit module (PCM) is welded to the cells, ensuring the safe operation of the battery pack.

3. Ultrasonic Welding Process

Process Flowchart

4. Comparison Between Ultrasonic Welding and Traditional Welding

Technology Comparison Table

5. Advantages and Precautions of Ultrasonic Welding

1. Advantages

2. Precautions

6. Future Trends

With the rapid growth of the electric vehicle and energy storage markets, the demand for lithium batteries is soaring, driving the continuous advancement of ultrasonic welding technology. Key future trends include:

0 notes

Text

Detailed explanation of the application of ultrasonic welding in blister packaging

With the advancement of technology, ultrasonic welding, as an efficient and environmentally friendly processing technology, has become an important production method for blister packaging. This article will deeply analyze the principle of ultrasonic welding, its role in blister packaging and its specific application cases.

The application of ultrasonic welding technology in blister packaging perfectly combines high efficiency, environmental protection and low cost, and is suitable for multiple industries from electronic products to food packaging. In the future, with the rise of intelligent equipment and new materials, ultrasonic welding will further expand its application areas and inject new vitality into the packaging industry.

0 notes

Text

Applications and Advantages of Ultrasonic Welding in Plastic Packaging

Plastic packaging is widely used in the food, medical, and consumer goods industries, and innovation in packaging technology is key to improving product quality and production efficiency. Ultrasonic welding, as an efficient and eco-friendly plastic bonding technology, plays an increasingly important role in the plastic packaging industry. This article will introduce the principles, applications, and advantages of ultrasonic welding, along with examples and diagrams for easier understanding.

Applications of Ultrasonic Welding in Plastic Packaging

1. Food Packaging

Ultrasonic welding is widely used for sealing plastic bags, attaching straws, and welding beverage box caps in the food industry. For example, a juice packaging production line that employs ultrasonic welding has increased production speed by 25% while ensuring a contamination-free welding area, guaranteeing food safety.

2. Medical Packaging

The medical industry demands high levels of sealing and hygiene for packaging. Ultrasonic welding is commonly used for sterile syringe packaging, reagent kit sealing, and more. For instance, a medical company using ultrasonic welding for sterile syringe packaging achieved compliance with ISO 11607 standards and reduced production costs by 30%.

3. Consumer Goods Packaging

Ultrasonic welding is used for sealing shampoo bottle caps in the personal care industry. This technology ensures a secure seal while improving the product's appearance. For example, a brand optimized its bottle cap production process using ultrasonic welding, reducing material waste by 20%.

4. Specialized Packaging

In multi-layer composite materials or waterproof packaging, ultrasonic welding ensures strong bonding. For instance, vacuum bags used for frozen food employ ultrasonic welding to extend shelf life and enhance compression resistance.

Advantages of Ultrasonic Welding

Case Studies and Results Table

Chart: Comparison of Ultrasonic Welding and Traditional Heat Sealing

Future Trends

1. Intelligent Welding Equipment

With the development of Industry 4.0, ultrasonic welding equipment is becoming more intelligent. Future equipment will integrate real-time monitoring and quality control functions to make welding more precise and efficient.

2. Compatibility with New Materials

The development of new composite materials is driving the continuous evolution of ultrasonic welding technology. In the future, it will be compatible with more functional and biodegradable plastic materials.

3. Green Manufacturing

Thanks to its eco-friendly characteristics, ultrasonic welding will play a greater role in the packaging industry's green transformation. Lower energy consumption and less pollution will be key development directions.

0 notes

Text

Ultrasonic Welding: An Efficient Solution for Data Cable Production

In modern life, data cables are indispensable tools. However, traditional welding methods often face challenges such as low efficiency and unstable quality. To address these pain points, ultrasonic welding technology has emerged. With its advantages of efficiency, eco-friendliness, and stability, it has become a popular choice in the data cable production industry.

Chart: Comparison Between Traditional Welding and Ultrasonic Welding

Principle of Ultrasonic Welding

Ultrasonic welding uses high-frequency vibrations to rapidly create friction and melt the contact surfaces of materials, joining them together. The process is both efficient and eco-friendly, requiring no glue or solder.

Components of Ultrasonic Welding Equipment

Advantages of Ultrasonic Welding

Chart: Typical Applications of Ultrasonic Welding in Data Cable Production

https://mechtechsupply.com/product-category/ultrasonic-series/ultrasonic-welding/

0 notes

Text

Applications and Advantages of Ultrasonic Welding in Battery Components

With the rapid development of the new energy industry, manufacturing technologies for battery components are receiving increasing attention. Ultrasonic welding, as an efficient, clean, and reliable bonding technology, has become a key process in battery manufacturing. Below is an analysis of its main applications and advantages.

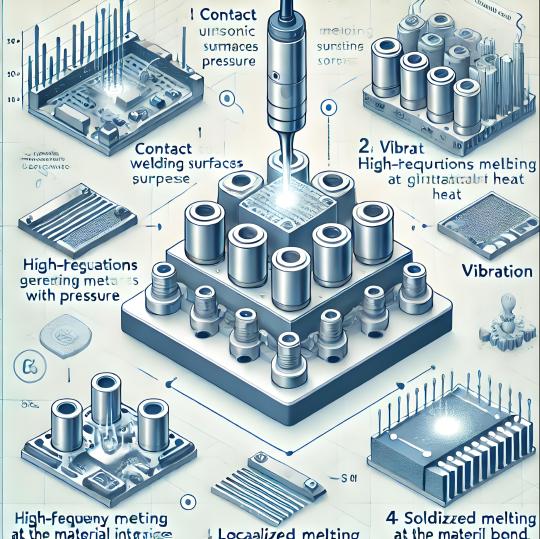

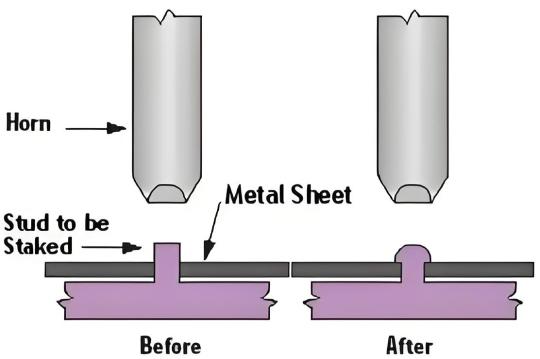

1. Working Principle of Ultrasonic Welding

Ultrasonic welding uses high-frequency mechanical vibrations to generate localized frictional heat at the surface of the materials being welded, enabling the bonding of their molecules. The process consists of the following steps:

2. Application Scenarios and Examples

Ultrasonic welding is widely used in battery components. Specific scenarios and their advantages are summarized in the table below:

3. Comparison of Ultrasonic Welding and Traditional Welding

The table below highlights the advantages of ultrasonic welding compared to traditional welding:

4. Future Prospects

The following chart illustrates the growth trend of ultrasonic welding in the new energy battery manufacturing market (data sourced from industry research reports):

The widespread application of ultrasonic welding in battery components not only improves production efficiency but also provides reliable technical support for green manufacturing. With continuous technological innovation, its importance in the new energy industry will become even more prominent.

0 notes

Text

Ultrasonic Welding for Gaming Console Shells: Durable and Seamless

It provides a clean, strong, and efficient way to bond parts, resulting in sleek designs and durable products. This technology eliminates the need for screws or adhesives, making it a preferred choice for manufacturers.

How Ultrasonic Welding Is Used in Gaming Consoles

Key Benefits for Gaming Console Manufacturers

Visual Example of Ultrasonic Welding Benefits

Why Choose Ultrasonic Welding?

This cutting-edge technology ensures gaming consoles are durable, visually appealing, and environmentally friendly. By streamlining production, manufacturers can create high-quality products that meet the expectations of modern gamers.

0 notes

Text

How Ultrasonic Welding Makes Car Interiors Better

Ultrasonic welding is a modern way to join materials, like plastics and fabrics, without using glue or thread. It’s super useful for making car interiors look smooth and last longer. Let’s explore how it works for decorative parts and seats in cars!

Making Decorative Parts Look Perfect

Car interiors have lots of decorative parts, like dashboard trims, door panels, and logos. These parts need to fit together tightly and look great.

What Ultrasonic Welding Does:

Why It’s Great:

Strong and Stylish Seat Stitching

Seats in cars often use fabrics like polyester. Instead of stitching with thread, ultrasonic welding melts the fabric edges together to make strong seams and cool patterns.

What Ultrasonic Welding Does:

Why It’s Great:

Why Ultrasonic Welding Is the Best Choice for Car Interiors

Conclusion

Ultrasonic welding helps make car interiors better by creating smooth decorative parts and strong, stylish seats. It’s a fast, clean, and eco-friendly way to improve car designs and ensure they last a long time.

0 notes

Text

How Ultrasonic Welding is Used in Engine Filters and Fuel Systems

Ultrasonic welding is a fast and clean way to join parts together without using glue or screws. Here’s an easy explanation of how it works and why it’s so useful.

1.Ultrasonic Welding in Engine Filters

Engine filters, like air filters, fuel filters, and oil filters, keep dirt and harmful particles out of your engine.

Why It’s Good:

2.Ultrasonic Welding in Fuel System Parts

Fuel system parts, like fuel pumps, pipes, and caps, must handle pressure and prevent leaks. Ultrasonic welding is great for making sure these parts are secure.

Why It’s Good:

Why Ultrasonic Welding is a Great Choice

Conclusion

Ultrasonic welding helps make car parts like engine filters and fuel systems stronger, safer, and better for the environment. It’s fast, reliable, and perfect for creating high-quality parts.

0 notes

Text

Applications of Ultrasonic Welding in Automotive Manufacturing: A Key to Efficiency and Quality

Ultrasonic welding is a highly efficient and eco-friendly joining technology that has become a vital process in the automotive industry. By utilizing high-frequency vibrations to bond materials, it eliminates the need for adhesives, screws, or other fasteners, meeting the stringent demands for precision and strength in automotive manufacturing. This article will explore the applications and benefits of ultrasonic welding in the automotive field.

Major Applications of Ultrasonic Welding in Automotive Manufacturing

Ultrasonic Welding Working Principle

Below is a simplified illustration of how ultrasonic welding works:

Advantages of Ultrasonic Welding in the Automotive Industry

Applications Summary Table

Conclusion

Ultrasonic welding has become a key technology in automotive manufacturing, particularly for plastic components, electronic parts, and safety systems. Its fast, eco-friendly, and reliable performance enhances production efficiency while ensuring product quality.

0 notes

Text

How Ultrasonic Welding Improves Earphone Housing Production

Ultrasonic welding is becoming a go-to solution for manufacturing durable, sleek, and high-performance earphones. This modern technology ensures high-quality assembly while being fast, eco-friendly, and cost-effective. Let’s dive into how ultrasonic welding works and why it’s ideal for earphone housings.

Benefits of Ultrasonic Welding for Earphone Housings

Where Ultrasonic Welding Is Used in Earphone Manufacturing

Comparison: Ultrasonic Welding vs. Traditional Methods

Conclusion

Ultrasonic welding is shaping the future of earphone manufacturing. It delivers stronger, sleeker, and more reliable earphone housings while supporting sustainable practices. If you’re exploring ways to improve your production process, ultrasonic welding is worth considering.

0 notes

Text

Benefits of Ultrasonic Welding in Smartphone Cases and Accessories

As the demand for high-quality, durable, and eco-friendly smartphone products grows, manufacturers are turning to ultrasonic welding. This innovative technique has become essential in producing smartphone cases and accessories, offering unparalleled precision, strength, and sustainability.

What Is Ultrasonic Welding?

Ultrasonic welding uses high-frequency vibrations to generate heat at the contact points of materials, bonding them securely without adhesives or screws. This method is ideal for thermoplastics and thin metals, commonly used in smartphone cases and accessories.

Key Advantages of Ultrasonic Welding

Applications in Smartphone Manufacturing

Why Ultrasonic Welding Matters

Ultrasonic welding is revolutionizing smartphone manufacturing by combining precision, efficiency, and sustainability. For manufacturers, it offers a competitive edge in delivering high-quality, eco-friendly products that meet consumer demands.

Ultrasonic Welding vs. Traditional Methods

By adopting ultrasonic welding, businesses can streamline production, reduce costs, and contribute to greener manufacturing practices. This technology is shaping the future of the smartphone industry, ensuring better products for a sustainable world.

0 notes

Text

How Ultrasonic Welding Makes Toy Shells More Eco-Friendly and Durable

Ultrasonic welding is an efficient and environmentally friendly plastic assembly technology widely used in the toy manufacturing industry. Let’s dive into how ultrasonic welding contributes to the production of toy shells.

What is Ultrasonic Welding?

Ultrasonic welding uses high-frequency vibrations to generate heat at the contact surfaces of plastic parts. This heat melts the plastic, bonding the pieces together. It is a quick and efficient process that leaves a smooth and seamless joint.

Advantages of Ultrasonic Welding

Below is a table summarizing the main advantages of ultrasonic welding for toy shells and the benefits it provides:

Applications of Ultrasonic Welding in Toy Shells

Key Factors Affecting Welding Quality

Conclusion

Ultrasonic welding is revolutionizing the toy industry with its eco-friendly, fast, and durable assembly capabilities. In the future, as technology continues to advance,

0 notes

Text

Innovative Applications of Ultrasonic Welding in Medical Consumables

Ultrasonic welding is a fast, safe, and environmentally friendly plastic welding technology widely used in the field of medical consumables. By using high-frequency vibrations, ultrasonic welding tightly bonds two plastic components, forming a strong and sealed connection. This technology ensures the quality and safety of medical products. Below are its specific applications and features.

1. Application Areas

Disposable Medical Devices

Pharmaceutical Packaging

Diagnostic Devices

2. Advantages of Ultrasonic Welding

Environmentally Friendly

Ultrasonic welding does not require glue or chemical adhesives, avoiding contamination of medical products, making it ideal for industries with strict hygiene standards.

Fast and Efficient

The welding process usually takes only a few seconds, greatly improving the production efficiency of medical consumables.

Precision and Reliability

Even with very small plastic parts, ultrasonic welding can achieve fine connections, meeting the stringent requirements of medical products.

Excellent Sealing

The welded connections are very strong and seamless, effectively preventing the leakage of liquids or air.

3. Common Issues and Solutions

Material Compatibility

Medical consumables are made from various types of plastics, such as PP, PE, and PVC. Each material requires adjustments to the welding frequency and energy to achieve the best results.

Quality Control

Precise control of welding time, pressure, and energy is needed during the process. Overwelding or insufficient welding may damage the components. Automated equipment can help address these issues.

4. Data Charts

Application Distribution of Ultrasonic Welding in Medical Consumables

Comparison of Ultrasonic Welding Advantages

5. Future Development Directions

In the future, ultrasonic welding technology is expected to become smarter and more efficient, with lower energy consumption and broader material compatibility. Combining it with automated production lines and intelligent inspection systems will further enhance the production efficiency and product quality of medical consumables.

0 notes

Text

What is Ultrasonic Welding?

Ultrasonic welding is a process that uses high-frequency vibrations to quickly bond two plastic or metal components. The principle involves mechanical vibrations generating frictional heat to melt and fuse the material surfaces together.

Key advantages of ultrasonic welding:

Why Ultrasonic Welding Suitable for Drones?

Here are some specific applications in drone manufacturing:

What Ultrasonic Welding Process

Why Drone Manufacturers Choose Ultrasonic Welding

1. Improved Production Efficiency Ultrasonic welding is incredibly fast, with each weld taking only a few seconds, significantly boosting productivity.

2. Reduced Manufacturing Costs Eliminates the need for additional materials like adhesives and screws, and the equipment is simple to operate.

3. Enhanced Product Performance Welded parts have high strength and durability, meeting the demands of drones during flight.

4. Environmentally Friendly No chemical pollution and low energy consumption, aligning with modern industrial sustainability goals.

0 notes

Text

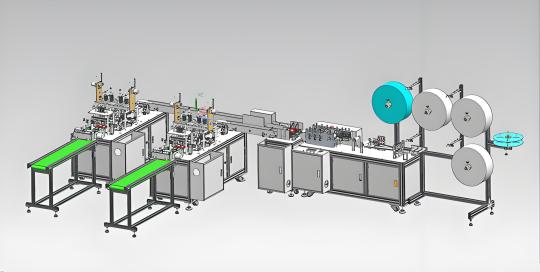

Ultrasonic Welding Technology for Masks: An Efficient and Eco-Friendly Nonwoven Connection Solution

What is Ultrasonic Welding?

Ultrasonic welding uses high-frequency vibrations and pressure to fuse thermoplastic materials at contact points, creating strong yet flexible connections. In mask production, ultrasonic technology enables fully automated and highly efficient production, significantly improving productivity and product quality.

Key Applications of Ultrasonic Welding in Mask Production

1. Ear Loop Welding

Ultrasonic technology rapidly secures elastic ear loops to the mask, delivering a firm and visually appealing weld while improving automation efficiency and product quality.

2. Edge Sealing

Ultrasonic technology ensures high-density sealing along mask edges, significantly enhancing the mask's ability to prevent contamination and provide optimal protection.

3. Nose Bridge Fixation

Using ultrasonic technology, the nose bridge strip is securely fixed to the mask, enhancing the fit to the face, preventing air leaks, and improving overall protection.

Advantages of Ultrasonic Welding Technology

Key Factors to Consider When Choosing Ultrasonic Welding Equipment

1. Power and Frequency

Selecting ultrasonic welding machines with the appropriate power and vibration frequency is critical to meeting production requirements.

2. Automation Level

Consider the equipment's level of automation. Higher automation levels lead to increased production efficiency and improved user experience.

Conclusion

Ultrasonic welding technology is an indispensable solution in mask production. It offers high efficiency, environmental benefits, and cost-effectiveness while ensuring superior product quality. By understanding its applications and selecting the right equipment, manufacturers can significantly enhance production efficiency and meet modern market demands.

0 notes

Text

Ultrasonic Welding: A New Choice for the Medical Industry

Ultrasonic welding is a fast, precise, and eco-friendly welding technology widely used in the medical industry. By using high-frequency mechanical vibrations, it bonds plastic components instantly without the need for adhesives or high heat. This article explains the key uses of ultrasonic welding in simple terms and compares it with traditional techniques.

What is Ultrasonic Welding?

Ultrasonic welding is a process that uses high-frequency sound waves to heat and join materials at their contact points. The steps involved include:

Key features of ultrasonic welding:

Applications of Ultrasonic Welding in the Medical Industry

1. Assembly of Disposable Medical Devices

Ultrasonic welding is commonly used in manufacturing disposable medical devices, such as:

Benefits:

2. Sealing of Diagnostic Devices

Sealing components of diagnostic devices, such as test kits, diagnostic cards, and microfluidic chips, requires high precision—an area where ultrasonic welding excels.

Advantages:

3. Manufacturing of Implantable Devices

Ultrasonic welding is also used in producing implantable medical devices like pacemakers and artificial joints.

Why it works:

4. Sterile Packaging

Medical packaging, such as medication bottles and sterilization pouches, relies on ultrasonic welding.

Welding results:

Summary: Ultrasonic welding stands out in the medical industry due to its speed, eco-friendliness, and precision.

Case Study: Ultrasonic Welding in Microfluidic Chips

Microfluidic chips, used to analyze biological samples, require ultra-precise welding. Ultrasonic welding is the preferred method for these devices due to its precision and cleanliness.

Performance highlights:

The Future of Ultrasonic Welding

As medical technology advances, ultrasonic welding continues to evolve. Future developments may include:

Conclusion

Ultrasonic welding is a reliable, fast, and eco-friendly solution for the medical industry. From disposable devices to high-precision diagnostic tools, this technology enhances product quality and production efficiency. With advancements in smart technology and sustainability, ultrasonic welding will continue to play a critical role in the medical field.

If you’d like to learn more about ultrasonic welding equipment or applications, feel free to contact us!

0 notes