Don't wanna be here? Send us removal request.

Text

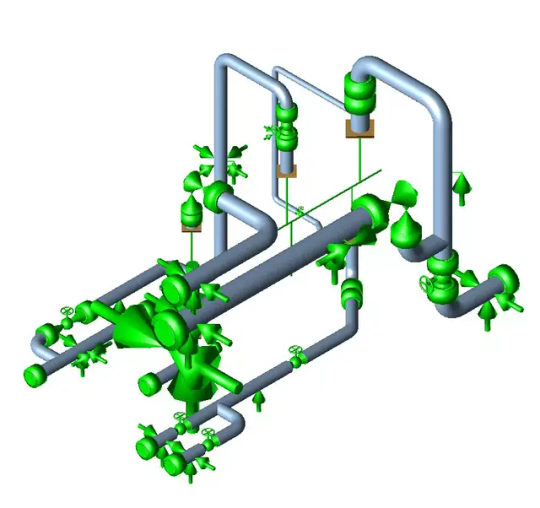

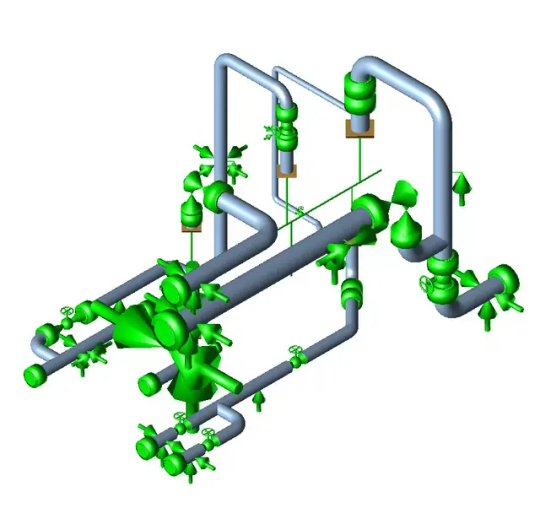

Ensure the safety and integrity of your piping systems with expert Piping Stress Analysis services from MECS Engineering Inc. Our comprehensive analysis evaluates stress distribution, thermal expansion, and other critical factors that could affect your system's performance. By identifying potential weak points, we help you prevent failures and ensure long-term operational efficiency.

0 notes

Text

Professional Stress Analysis Engineer for Reliable Systems

A stress analysis engineer at MECS Engineering Inc. specializes in assessing structural components and piping systems to ensure their reliability under operational stresses. Our engineers apply advanced techniques to predict potential failures, guiding design improvements and ensuring compliance with industry standards. Rely on our team to safeguard the integrity of your systems.

0 notes

Text

Obtain P.Eng. Certification for Your Engineering Projects

Obtain professional P.Eng. Certification for your engineering projects with the help of MECS Engineering Inc. Our licensed engineers provide the necessary expertise and verification to ensure your designs meet regulatory and safety standards. With our P.Eng. services, you can confidently move forward, knowing your projects are compliant and built to last.

0 notes

Text

Comprehensive Piping Engineering Solutions for All Industries

With a focus on excellence, MECS Engineering Inc. delivers top-tier Piping Engineering solutions tailored to your specific needs. Our team of skilled engineers designs, analyzes, and optimizes piping systems for various industries, ensuring efficiency, safety, and compliance. From conceptual design to detailed engineering, we provide comprehensive piping solutions.

0 notes

Text

The Unsung Hero Behind Safe Pipelines: Stress Analysis in Industrial Engineering

In the evolving world of industrial infrastructure, Piping Stress Analysis has emerged as a foundational element in ensuring system safety, efficiency, and longevity. From oil refineries to HVAC installations, accurately understanding how pipes respond to operational forces is not just a technical requirement—it’s a safety imperative. At the heart of this process stands the Stress Analysis Engineer, a professional whose expertise prevents disasters before they happen.

Understanding the Core: What is Piping Stress Analysis?

Piping Stress Analysis involves a detailed evaluation of pipe systems to determine whether they can endure real-world pressures—including internal fluid dynamics, temperature shifts, mechanical forces, and external loads—without damage or failure. Engineers use this analysis to assess critical issues like:

Thermal expansion

Mechanical vibration

Deadweight and dynamic forces

Without proper analysis, the consequences can be severe: from minor leaks to catastrophic pipeline failures. Therefore, industries must adhere to international safety standards like ASME B31.1, B31.3, ISO, and ANSI.

Why Modern Industries Can’t Ignore Stress Analysis

Prevents Structural Failures It minimizes the chances of leaks, cracks, or bursts due to stress overload.

Ensures Legal Compliance Meets rigorous safety and regulatory benchmarks across global industries.

Optimizes Long-Term Costs Avoids frequent repairs or unplanned downtimes.

Improves Operational Reliability Keeps pipelines running without interruption, ensuring productivity.

Supports Smarter Design Guides engineers to develop efficient layouts using minimal materials while ensuring durability.

The Specialist in Action: What Does a Stress Analysis Engineer Do?

A Stress Analysis Engineer is tasked with analyzing piping systems to predict their behavior under operating and fault conditions. Using a blend of technical knowledge, software tools, and code compliance, they help avert costly and hazardous issues.

Typical Responsibilities Include:

Using specialized tools like CAESAR II, ROHR2, and AutoPIPE to simulate stress conditions

Designing proper support systems (anchors, hangers, expansion joints)

Advising layout adjustments for better stress distribution

Documenting compliance with engineering standards and codes

Evaluating responses to environmental forces like earthquakes or wind

Skills That Define an Effective Stress Analyst

To succeed in this specialized role, engineers require:

Mastery in stress analysis platforms

Deep understanding of materials, thermal dynamics, and fluid mechanics

Strong command of piping design codes (e.g., ASME, ANSI)

Analytical and decision-making capabilities

Clear communication for cross-team collaboration

Industries Where Stress Analysis is Vital

Oil & Gas High-pressure systems in offshore and onshore drilling demand constant analysis to ensure integrity.

Power Plants Steam and gas lines undergo extreme thermal fluctuations—precision stress handling is key.

Chemical and Petrochemical Plants Aggressive chemicals and varying conditions make these systems vulnerable to stress-related wear.

Pharmaceutical and Food Facilities Sterile and pressurized environments require robust, compliant piping systems.

Commercial HVAC Building-scale heating and cooling systems benefit from stress assessment to avoid premature wear.

Tools Empowering Today’s Stress Engineers

Stress engineers use cutting-edge technology to simulate physical realities and predict outcomes:

CAESAR II – Industry leader in pipe stress analysis

AutoPIPE – Comprehensive tool for piping and structural evaluations

ROHR2 – Widely adopted in European markets

ANSYS – Ideal for advanced Finite Element Analysis (FEA)

SolidWorks Simulation – Assists in preliminary design stress testing

Real-World Engineering Challenges in Stress Analysis

Thermal Effects: Expanding or contracting pipes due to temperature swings

Mechanical Vibrations: Equipment-induced stress from pumps and turbines

Improper Support Design: Misplaced supports lead to uneven load distribution

Dynamic Forces: Shock loads from seismic activity or fluid surges (water hammer)

Charting the Path: Becoming a Stress Analysis Engineer

Want to build a career in this critical domain? Here's a simple roadmap:

Get a Mechanical Engineering Degree

Train in Specialized Software Tools (like CAESAR II, AutoPIPE)

Secure Relevant Certifications (e.g., piping code standards)

Build Experience in industrial environments under senior professionals

Stay Updated on technology, standards, and simulation methodologies

What’s Next? Trends Shaping the Future

BIM Integration: Seamless collaboration through Building Information Modeling

AI-Driven Simulations: Using machine learning to predict risk zones

Cloud-Based Analysis: Enabling remote and collaborative project execution

Eco-Conscious Design: Focus on green engineering and sustainable materials

Final Thoughts: The Backbone of Infrastructure Safety

A well-executed Piping Stress Analysis doesn't just ensure operational efficiency—it protects lives, investments, and the environment. And it is the Stress Analysis Engineer, with their sharp insights and tools, who ensures our pipelines remain strong and safe.

0 notes

Text

Professional Stress Analysis Engineer for Reliable Systems

A stress analysis engineer at MECS Engineering Inc. specializes in assessing structural components and piping systems to ensure their reliability under operational stresses. Our engineers apply advanced techniques to predict potential failures, guiding design improvements and ensuring compliance with industry standards. Rely on our team to safeguard the integrity of your systems.

0 notes

Text

Comprehensive Piping Engineering Solutions for All Industries

With a focus on excellence, MECS Engineering Inc. delivers top-tier Piping Engineering solutions tailored to your specific needs. Our team of skilled engineers designs, analyzes, and optimizes piping systems for various industries, ensuring efficiency, safety, and compliance. From conceptual design to detailed engineering, we provide comprehensive piping solutions.

0 notes

Text

Piping Stress Analysis: The Critical Role of a Stress Analysis Engineer in Modern Industries

In today's complex industrial landscape, Piping Stress Analysis is a crucial process that ensures the safety, efficiency, and longevity of piping systems. Whether in oil and gas, power plants, chemical industries, or HVAC systems, understanding how pipes behave under various stresses is essential. At the heart of this process is the Stress Analysis Engineer, a specialist who safeguards infrastructure by predicting and mitigating potential failures.

What is Piping Stress Analysis?

Piping Stress Analysis is the evaluation of pipe systems to ensure they can withstand internal pressures, external loads, temperature fluctuations, and dynamic forces without failure. This process involves calculating how different stress factors—such as thermal expansion, vibration, and weight—affect the integrity of pipelines.

Without proper stress analysis, piping systems are vulnerable to leaks, ruptures, and costly downtimes. This is why industries heavily rely on accurate analysis to comply with international safety standards like ASME, ANSI, and ISO.

Why is Piping Stress Analysis Important?

Safety Assurance: Prevents catastrophic failures that could endanger lives and the environment.

Compliance with Standards: Meets legal and regulatory requirements for industrial operations.

Cost Efficiency: Reduces maintenance costs by predicting potential issues before they escalate.

Operational Reliability: Ensures continuous operation without unexpected shutdowns due to pipe failures.

Design Optimization: Helps in designing efficient piping layouts that can handle stress with minimal material use.

The Role of a Stress Analysis Engineer

A Stress Analysis Engineer is responsible for performing detailed stress evaluations on piping systems. Their expertise combines engineering principles, software tools, and industry codes to predict how pipes will behave under various operational conditions.

Key Responsibilities:

Conducting Piping Stress Analysis using advanced software like CAESAR II, AutoPIPE, or ROHR2.

Ensuring that pipe supports, anchors, and expansion joints are correctly designed and placed.

Collaborating with design teams to adjust layouts for stress reduction.

Preparing detailed reports to demonstrate compliance with engineering codes.

Addressing dynamic loads, such as seismic activity or wind forces.

Essential Skills for a Stress Analysis Engineer:

Proficiency in stress analysis software.

Strong understanding of material science and fluid mechanics.

Knowledge of international piping codes (ASME B31.1, B31.3, etc.).

Analytical thinking and problem-solving abilities.

Effective communication to collaborate with multidisciplinary teams.

Industries That Rely on Piping Stress Analysis

Oil & Gas Complex pipeline networks transporting high-pressure fluids require constant stress evaluation.

Power Generation Thermal stresses in steam and gas pipelines make analysis vital for plant efficiency.

Chemical & Petrochemical Corrosive substances and variable temperatures increase the risk of stress-induced failures.

Pharmaceutical & Food Processing Hygienic piping systems must maintain structural integrity under cleaning cycles and pressurization.

HVAC Systems Large-scale heating and cooling systems in commercial buildings benefit from stress analysis to avoid system breakdowns.

Tools and Software Used in Piping Stress Analysis

A Stress Analysis Engineer leverages various tools to simulate real-world conditions:

CAESAR II: The industry standard for pipe stress analysis.

AutoPIPE: Used for comprehensive piping and structural analysis.

ROHR2: Popular in Europe for static and dynamic stress evaluation.

ANSYS: For detailed finite element analysis (FEA).

SolidWorks Simulation: Useful in design validation.

Common Challenges in Piping Stress Analysis

Thermal Expansion: High-temperature variations can cause significant pipe movement.

Vibration Issues: Pumps and compressors introduce vibrations that can fatigue pipe materials.

Support Placement: Incorrectly placed supports can lead to overstressing certain pipe sections.

Dynamic Loads: Handling seismic loads or water hammer effects requires specialized analysis.

How to Become a Stress Analysis Engineer

If you're interested in pursuing a career as a Stress Analysis Engineer, here’s a quick roadmap:

Educational Background: A degree in Mechanical Engineering or a related field.

Software Training: Gain hands-on experience with stress analysis tools.

Certifications: Obtain certifications related to piping codes and stress analysis.

Industry Experience: Work under senior engineers to understand real-world applications.

Continuous Learning: Stay updated with evolving industry standards and technologies.

Future Trends in Piping Stress Analysis

Integration with BIM (Building Information Modeling) for better collaboration.

AI and Machine Learning to predict stress points faster and more accurately.

Cloud-Based Analysis Platforms for remote engineering collaboration.

Sustainability Focus: Designing piping systems that are both efficient and eco-friendly.

Conclusion:

In every industrial project, Piping Stress Analysis acts as the backbone of safe and efficient operations. Without the vigilance and expertise of a Stress Analysis Engineer, industries would face heightened risks, operational inefficiencies, and regulatory non-compliance.

0 notes

Text

In today's complex industrial landscape, Piping Stress Analysis is a crucial process that ensures the safety, efficiency, and longevity of piping systems. Whether in oil and gas, power plants, chemical industries, or HVAC systems, understanding how pipes behave under various stresses is essential. At the heart of this process is the Stress Analysis Engineer, a specialist who safeguards infrastructure by predicting and mitigating potential failures.

What is Piping Stress Analysis?

Piping Stress Analysis is the evaluation of pipe systems to ensure they can withstand internal pressures, external loads, temperature fluctuations, and dynamic forces without failure. This process involves calculating how different stress factors—such as thermal expansion, vibration, and weight—affect the integrity of pipelines.

Without proper stress analysis, piping systems are vulnerable to leaks, ruptures, and costly downtimes. This is why industries heavily rely on accurate analysis to comply with international safety standards like ASME, ANSI, and ISO.

Why is Piping Stress Analysis Important?

Safety Assurance: Prevents catastrophic failures that could endanger lives and the environment.

Compliance with Standards: Meets legal and regulatory requirements for industrial operations.

Cost Efficiency: Reduces maintenance costs by predicting potential issues before they escalate.

Operational Reliability: Ensures continuous operation without unexpected shutdowns due to pipe failures.

Design Optimization: Helps in designing efficient piping layouts that can handle stress with minimal material use.

The Role of a Stress Analysis Engineer

A Stress Analysis Engineer is responsible for performing detailed stress evaluations on piping systems. Their expertise combines engineering principles, software tools, and industry codes to predict how pipes will behave under various operational conditions.

Key Responsibilities:

Conducting Piping Stress Analysis using advanced software like CAESAR II, AutoPIPE, or ROHR2.

Ensuring that pipe supports, anchors, and expansion joints are correctly designed and placed.

Collaborating with design teams to adjust layouts for stress reduction.

Preparing detailed reports to demonstrate compliance with engineering codes.

Addressing dynamic loads, such as seismic activity or wind forces.

Essential Skills for a Stress Analysis Engineer:

Proficiency in stress analysis software.

Strong understanding of material science and fluid mechanics.

Knowledge of international piping codes (ASME B31.1, B31.3, etc.).

Analytical thinking and problem-solving abilities.

Effective communication to collaborate with multidisciplinary teams.

Industries That Rely on Piping Stress Analysis

Oil & Gas Complex pipeline networks transporting high-pressure fluids require constant stress evaluation.

Power Generation Thermal stresses in steam and gas pipelines make analysis vital for plant efficiency.

Chemical & Petrochemical Corrosive substances and variable temperatures increase the risk of stress-induced failures.

Pharmaceutical & Food Processing Hygienic piping systems must maintain structural integrity under cleaning cycles and pressurization.

HVAC Systems Large-scale heating and cooling systems in commercial buildings benefit from stress analysis to avoid system breakdowns.

Tools and Software Used in Piping Stress Analysis

A Stress Analysis Engineer leverages various tools to simulate real-world conditions:

CAESAR II: The industry standard for pipe stress analysis.

AutoPIPE: Used for comprehensive piping and structural analysis.

ROHR2: Popular in Europe for static and dynamic stress evaluation.

ANSYS: For detailed finite element analysis (FEA).

SolidWorks Simulation: Useful in design validation.

Common Challenges in Piping Stress Analysis

Thermal Expansion: High-temperature variations can cause significant pipe movement.

Vibration Issues: Pumps and compressors introduce vibrations that can fatigue pipe materials.

Support Placement: Incorrectly placed supports can lead to overstressing certain pipe sections.

Dynamic Loads: Handling seismic loads or water hammer effects requires specialized analysis.

How to Become a Stress Analysis Engineer

If you're interested in pursuing a career as a Stress Analysis Engineer, here’s a quick roadmap:

Educational Background: A degree in Mechanical Engineering or a related field.

Software Training: Gain hands-on experience with stress analysis tools.

Certifications: Obtain certifications related to piping codes and stress analysis.

Industry Experience: Work under senior engineers to understand real-world applications.

Continuous Learning: Stay updated with evolving industry standards and technologies.

Future Trends in Piping Stress Analysis

Integration with BIM (Building Information Modeling) for better collaboration.

AI and Machine Learning to predict stress points faster and more accurately.

Cloud-Based Analysis Platforms for remote engineering collaboration.

Sustainability Focus: Designing piping systems that are both efficient and eco-friendly.

Conclusion:

In every industrial project, Piping Stress Analysis acts as the backbone of safe and efficient operations. Without the vigilance and expertise of a Stress Analysis Engineer, industries would face heightened risks, operational inefficiencies, and regulatory non-compliance.

0 notes

Text

Ensuring Project Success: The Role of Third Party Verification in Piping Engineering

In the world of industrial infrastructure, piping engineering plays a critical role in ensuring the safety, efficiency, and reliability of systems. Whether it's oil & gas, chemical processing, or water treatment facilities, the design and installation of piping systems demand precision and expertise. That’s where a professional piping engineering company becomes indispensable. But even the best engineering efforts benefit from an extra layer of assurance — Third Party Verification (TPV).

What Is Third Party Verification in Piping Engineering?

Third Party Verification refers to the independent assessment of piping systems by a neutral expert or agency. It ensures that all designs, materials, and installations comply with regulatory standards, industry codes, and project specifications. This objective review adds an extra level of quality control and helps identify potential risks before they become costly problems.

Why Choose a Specialized Piping Engineering Company?

A reliable piping engineering company offers a comprehensive suite of services, from conceptual design to final commissioning. Their scope often includes:

Piping layout and stress analysis

Material selection and specification

3D modeling and isometric drawings

Code compliance and safety checks

Fabrication and installation support

However, even with a skilled engineering team, having an independent third party review can significantly reduce risks and boost stakeholder confidence.

Benefits of Third Party Verification in Piping Projects

Improved Quality Assurance TPV ensures that every part of your piping system meets the highest standards. This results in fewer design flaws and installation errors.

Regulatory Compliance Third-party inspectors are well-versed in global and regional piping codes (like ASME, B31.3, and API standards), helping avoid costly fines or delays.

Risk Mitigation Identifying potential issues before commissioning saves time and resources in the long run. TPV acts as an early warning system.

Increased Credibility Projects verified by an independent third party are more likely to gain client and investor trust, especially in large-scale industrial sectors.

Objective Evaluation A third party offers unbiased insight, free from internal pressures or conflicts of interest — ensuring the final result is based solely on engineering merit.

Partnering for Success

For project owners and contractors, the combination of a seasoned piping engineering company and professional third party verification is a winning formula. It not only assures optimal system performance but also protects your investment from avoidable risks.

When selecting partners for your next project, look for companies that embrace transparency, collaboration, and a commitment to engineering excellence. Third Party Verification should be viewed not as an extra cost, but as a strategic safeguard.

Final Thoughts

In today’s competitive industrial landscape, cutting corners can lead to major setbacks. By collaborating with a qualified piping engineering company and incorporating Third Party Verification, you lay the foundation for long-term success, safety, and efficiency.

0 notes

Text

How P.E. Certification and P.Eng. Stamping Boost Engineering Credibility

In the engineering world, credibility is everything. Whether you are designing a skyscraper, developing cutting-edge technology, or consulting on a multi-million-dollar project, clients and employers need assurance that your work meets professional standards. That’s where P.E. Certification and P.Eng. Stamping come into play. These qualifications not only prove your technical competence but also unlock new career opportunities, legal authority, and industry recognition.

What is P.E. Certification?

P.E. Certification, short for Professional Engineer Certification, is a license awarded to engineers who have met the education, experience, and examination requirements established by a state or national board. In the United States, it is governed by individual state licensing boards, and the National Society of Professional Engineers (NSPE) plays a significant advocacy role.

Holding a P.E. license demonstrates that an engineer has the authority to sign and seal engineering documents, offer services to the public, and take legal responsibility for their work. It’s a mark of professionalism and ethical commitment.

Key Steps to Achieve P.E. Certification:

Earn an Accredited Degree: Graduate from an ABET-accredited engineering program.

Pass the Fundamentals of Engineering (FE) Exam: This exam tests basic engineering knowledge and is usually taken shortly after graduation.

Gain Work Experience: Most jurisdictions require four years of supervised work experience under a licensed P.E.

Pass the Principles and Practice of Engineering (PE) Exam: This comprehensive test assesses an engineer’s ability to practice competently.

What is P.Eng. Stamping?

P.Eng. Stamping refers to the use of a Professional Engineer (P.Eng.) seal in Canada. When an engineer earns the title of Professional Engineer (P.Eng.), they are authorized to stamp drawings, reports, and specifications to certify that the work complies with regulatory standards and accepted engineering practices.

Each province and territory in Canada regulates its own licensing body, such as Professional Engineers Ontario (PEO) or Engineers and Geoscientists British Columbia (EGBC).

The P.Eng. title is highly respected and required for:

Signing off on engineering projects

Submitting official documents to governmental authorities

Ensuring public safety and welfare

Steps to Obtain P.Eng. Designation:

Education: Graduate from an accredited engineering program.

Work Experience: Complete four years of engineering experience, with at least one year in Canada.

Professional Practice Examination (PPE): This test evaluates ethics, law, and professionalism.

References and Interviews: Provide professional references and, in some cases, pass an interview process.

Why Are P.E. Certification and P.Eng. Stamping Important?

1. Legal Authority: Without P.E. Certification or a P.Eng. stamp, engineers cannot legally approve public infrastructure projects, issue reports for government agencies, or offer engineering services directly to the public.

2. Professional Recognition: Clients and employers recognize the stamp as a symbol of trust, reliability, and expertise. It separates you from non-licensed engineers and can lead to senior roles and greater responsibilities.

3. Career Advancement: Many leadership positions in engineering firms require a licensed professional to supervise and approve engineering projects. Holding a P.E. or P.Eng. designation opens the door to promotions and high-profile projects.

4. Ethical Commitment: Both certifications require adherence to a strict code of ethics. Engineers are expected to prioritize public safety, sustainability, and honesty in their work.

Differences Between P.E. Certification and P.Eng. Stamping

While P.E. Certification (U.S.) and P.Eng. Stamping (Canada) serve similar purposes, there are differences worth noting:

Feature

P.E. Certification (U.S.)

P.Eng. Stamping (Canada)

Governing Bodies

State Boards, NSPE

Provincial Regulators (e.g., PEO, EGBC)

Required Exams

FE Exam, PE Exam

PPE Exam, Academic Exams (if needed)

Work Experience

4 years supervised work

4 years, 1 year in Canada

Title Earned

P.E.

P.Eng.

Focus

U.S. Practice, State Laws

Canadian Practice, National Standards

Knowing the differences ensures that engineers migrating between the U.S. and Canada understand local requirements.

How to Prepare for Certification and Stamping

1. Plan Early: Start preparing for certification while still in university. Pass the FE exam and document your work experience meticulously.

2. Choose the Right Mentor: Working under a licensed P.E. or P.Eng. is essential. A good mentor can guide you, verify your experience, and serve as a professional reference.

3. Study Diligently: The exams are tough! Use official study materials, join study groups, and practice using sample exams to improve your chances of success.

4. Understand the Law and Ethics: Both the P.E. and P.Eng. designations require knowledge of professional ethics and legal responsibilities. Review codes of conduct and professional practice guidelines specific to your region.

5. Stay Organized: Keep records of your education, exam results, references, and work experience. Licensing boards require detailed documentation.

Maintaining Your P.E. and P.Eng. Credentials

After earning your P.E. or P.Eng., the journey doesn’t stop:

Continuing Education: Most jurisdictions require ongoing professional development to ensure engineers stay current with industry changes.

Renewal Fees: Licenses must be renewed annually or bi-annually, depending on the region.

Upholding Ethics: License holders must maintain high ethical standards or risk suspension or revocation of their license.

Failing to keep up with these requirements can result in penalties or loss of licensure, so staying engaged with your professional body is crucial.

Conclusion

Achieving P.E. Certification or obtaining a P.Eng. Stamp is a milestone in any engineer’s career. It’s a testament to your skills, professionalism, and commitment to public safety. While the process may seem challenging, the rewards—career advancement, industry respect, and legal authority—are well worth the effort.

0 notes

Text

Obtain P.Eng. Certification for Your Engineering Projects

Obtain professional P.Eng. Certification for your engineering projects with the help of MECS Engineering Inc. Our licensed engineers provide the necessary expertise and verification to ensure your designs meet regulatory and safety standards. With our P.Eng. services, you can confidently move forward, knowing your projects are compliant and built to last.

0 notes

Text

Reliable P.Eng. Stamping for Engineering Compliance

At MECS Engineering Inc., we offer P.Eng. Stamping services to certify the safety and compliance of your engineering projects. Our professional engineers thoroughly review designs, ensuring they meet industry regulations and performance standards. With our certified stamp, you can guarantee that your project adheres to the highest engineering requirements.

0 notes

Text

Professional Stress Analysis Engineer for Reliable Systems

A stress analysis engineer at MECS Engineering Inc. specializes in assessing structural components and piping systems to ensure their reliability under operational stresses. Our engineers apply advanced techniques to predict potential failures, guiding design improvements and ensuring compliance with industry standards. Rely on our team to safeguard the integrity of your systems.

0 notes

Text

Reliable P.E. Stamping Services for Regulatory Compliance

At MECS Engineering Inc., we provide comprehensive P.E. Stamping services to ensure that your engineering designs meet all regulatory standards. Our licensed engineers are experienced in reviewing and certifying your projects, providing you with the assurance of safety and compliance. Trust us for accurate and reliable professional engineering stamps for your documents.

0 notes

Text

Trusted Third Party Verification for Engineering Accuracy

For robust Third Party Verification services, MECS Engineering Inc. is your trusted partner. We offer independent assessments to verify the accuracy and reliability of engineering data and designs, ensuring that your projects meet the highest standards of quality and safety. Rely on our expertise to provide unbiased evaluations for all your engineering needs.

0 notes

Text

Comprehensive Piping Engineering Solutions for All Industries

With a focus on excellence, MECS Engineering Inc. delivers top-tier Piping Engineering solutions tailored to your specific needs. Our team of skilled engineers designs, analyzes, and optimizes piping systems for various industries, ensuring efficiency, safety, and compliance. From conceptual design to detailed engineering, we provide comprehensive piping solutions.

0 notes