Text

Coffee “etch” works great on damascus!

2 notes

·

View notes

Text

Doesn’t look like much now, but each chunk or billet is from 144 to 288 layers of damascus steel. Made myself sick forge welding all this out, but it will be worth it! The largest are 12” long x 2” wide x 3/4” thick.

5 notes

·

View notes

Text

1st blade of the year, 170 layer burl pattern 8” chef.

5 notes

·

View notes

Text

A few silver rings, cast sterling silver.

1 note

·

View note

Text

Went to a Blacksmithing conference, this is Tim Zowda making a razor. He’s the only razor maker I know that makes the whole thing including the steel itself!

2 notes

·

View notes

Text

Did another art fair. Had a little mix of forged things and knives.

2 notes

·

View notes

Text

Filing the slot for the blade tang in a guard blank. Man this gets old, have a stack of blades that need guards!

4 notes

·

View notes

Text

Last weekend the art fair had a lot of interesting people! Sold a lot of knives and forged steel pieces.

0 notes

Text

New blades in progress. I was sick for some time, finally getting back to my favorite activity. These have just been etched in ferric, then coffee.

8 notes

·

View notes

Text

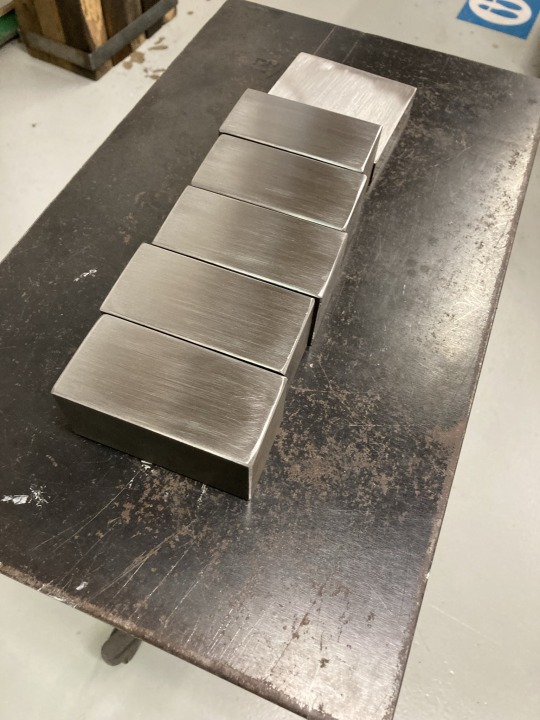

Part of my day job, sanded these jewelry set blocks smooth

1 note

·

View note

Text

Heat treated a few knives

3 notes

·

View notes

Text

Last damascus billet of the year

5 notes

·

View notes

Text

Trying the “ coffee etch”

3 notes

·

View notes

Text

After shutting down the forge I found this, it is burned flux lumps still glowing after welding a bunch of damascus at 2400f!

1 note

·

View note

Text

Of course I rode on the last day of summer!

Was pushing 100 mph (shhh!) not bad for a ‘84 Ironhead.

2 notes

·

View notes

Text

I have been sick. I am getting better, back at work. This is me in my usual safety gear teaching sculpture!

1 note

·

View note