metal/ceramic injection moldingmim-supplier.com is your premier destination for metal and ceramic injection molding solutions.

Don't wanna be here? Send us removal request.

Text

Why Understanding MIM Kinetics is Critical to High-Performance Component Manufacturing

In the sector of superior production, each micron is subject. This is particularly relevant in relation to Kinetics Metal Injection Molding, a technique that merges the advantages of plastic injection molding with the energy of metal. If you are aiming to supply high-performance components, overlooking the technology at the back of MIM kinetics can be a pricey mistake.

What Are MIM Kinetics?

Simply put, kinetics refers to the rate at which bodily and chemical modifications arise at some point of the MIM technique, especially in the course of debinding and sintering. It impacts the entirety from particle diffusion to shrinkage, without delaying the final residences of the factor.

Precision Starts with Process Control

When you're producing important elements—whether for aerospace, automobile, or medical devices—the margin for error is razor-thin. Controlling MIM kinetics allows you to excellently track density, porosity, microstructure, and even mechanical overall performance. The extra exactly you can control these variables, the steadier and dependable your components might be.

The Risk of Ignoring MIM Kinetics

Many producers leap into MIM, questioning if it is just like plastic molding—but with metallic powder. That’s a dangerous assumption. Without a thorough knowledge of the Kinetics Metal Injection Molding MIM, you are likely to face troubles like cracking, dimensional inaccuracies, and underperformance in real international applications.

How Kinetics Affects the Bottom Line

Think of it like baking a cake. You wouldn’t crank up the oven and hope for the satisfactory temperature, time, and even the form of your tray all be counted. The identical is going for MIM. If sintering fees or temperature profiles aren’t optimized, you’ll end up with parts that both fail fine assessments or cost more to transform. Understanding kinetics isn’t simply technology—it’s clever enterprise.

Call to Action: Upgrade Your Process Knowledge

If you're critical approximately production elite components, now is the time to invest in training, equipment, or partnerships that help you master MIM kinetics. From simulation software to sessions with MIM professionals, there are resources available that may rework your results.

Conclusion

Kinetics is the heartbeat of metallic injection molding. The more you recognize and manage it, the more predictable, dependable, and excellent overall performance your additives will be. Don’t treat kinetics as an afterthought—make it a concern.

0 notes

Text

Top 5 Emerging Trends in MIM Sintering Technology for 2025

Metal Injection Molding (MIM) sintering is a present process a rapid evolution, and 2025 is shaping up to be a landmark year for innovation. As industries continue to call for smaller, stronger, and more complicated components, MIM Sintering is stepping up with technological improvements that can set new requirements in production precision and performance.

Let’s take a more in-depth take a look at the 5 developments reshaping the destiny of this powerful procedure.

1. AI-Powered Process Optimization

Artificial Intelligence is reworking MIM sintering with the aid of permitting smarter, data-driven management over temperature, atmosphere, and cycle instances. Machines getting to know algorithms can now expect and adapt sintering parameters in real-time, meaning more regular part first-rate and reduced waste. With this degree of precision, producers can improve yield prices and shorten manufacturing cycles.

2. Advanced Materials for High-Performance Applications

2025 will see a surge in the use of advanced materials tailor-made for MIM tactics. From excessive-temperature superalloys to magnetic stainless steels, engineers are pushing the limits of what may be sintered. These new materials are making their way into aerospace, protection, and medical devices, in which failure isn't an option.

3. Sustainability and Energy Efficiency Initiatives

Environmental issues are using innovation in sintering furnace layout and strength intake. Low-electricity sintering techniques and recyclable binders are being developed to lessen the carbon footprint of the process. This is not just going inexperienced—it’s additionally approximately value savings and complying with global regulations, a main difficulty for Sintered Metal Manufacturers seeking to hold compliance and profitability.

4. Micro-MIM for Miniaturized Components

As products come to be smaller and smarter, micro-MIM is gaining critical traction. This fashion specializes in developing extremely small, elaborate parts with unmatched precision, specifically useful in electronics, scientific implants, and wearable tech. Expect similarly breakthroughs in tooling, feedstock components, and submit-processing strategies designed particularly for miniaturized manufacturing.

5. Hybrid Manufacturing with 3-D Printing Integration

MIM sintering is being incorporated with additive production to release hybrid production workflows. 3-D printing allows for the creation of complex green elements, which are then densified through MIM sintering. This hybrid approach gives extra layout flexibility and the capability to create formerly “not possible” geometries with mass production scalability.

Conclusion: The Future is Sintered, Smart, and Sustainable

From AI to sustainability and hybrid manufacturing, the future of MIM sintering is bright and full of potential. These rising developments are not handiest improving the performance and skills of producers but also opening doors to new programs throughout high-tech industries.

If you’re inside the commercial enterprise of precision manufacturing or factor engineering, now's the time to discover those innovations and adapt. Stay aggressive, reduce waste, and supply greater value with modern-day MIM technology.

Ready to lead the exchange?

Partner with ahead-wondering sintered steel manufacturers and start transforming your manufacturing line these days.

0 notes

Text

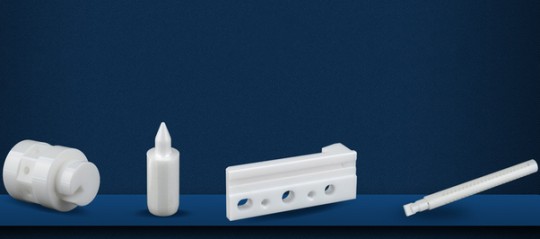

Understanding the Production and Application of CIM

In today’s rapidly growing industry the demand of high performance parts is constantly rising. For industries looking for superior quality and intricate designs – ceramic injection molding emerged as a groundbreaking solution.

This blog aims to highlight Ceramic Injection Molding Process and why is it advantageous to choose CIM supplier for your specific needs.

A Brief Overview

Ceramic injection molding is a versatile manufacturing process to enable production of complex ceramic parts with exceptional precision. By combining plastic injection molding and ceramic powder technology – it allows efficient mass production for intricate ceramic component. The process includes the injection of ceramic powder-filled binder into mold cavity.

The production process is a breakthrough manufacturing process to revolutionize the production of different ceramic parts. CIM indeed orders unparalleled advantages to fabricate high-precision ceramic components with intricate geometries.

Importance of CIM for Ceramic Part Design

The production process has streamlined the fabrication of intricate geometric, thin walls and complex shapes. In addition, it also eliminates the limitation of traditional ceramic manufacturing method. Overall, it enables the production of high-quality parts with enhanced functionality and performance.

What are Ceramic Materials?

It refers to the inorganic, non-metallic compounds with wide variety of properties including high strength, temperature resistance and chemical inertness. The materials comprised of metallic and non-metallic elements that are bonded together through ionic and covalent bonds.

Varied application

CIM Ceramic Injection Molding makes it commercially feasible to manufacture intricate geometries, with features like undercuts, perpendicular holes, screws that were ideally difficult and expensive to fabricate with traditional production process.

By shaping the components in one process combined with the beneficial features of the product – make it a perfect technology to use for various market. CIM components can be used in different medical devices including orthodontics, automotive, vacuum application, consumer products and more.

Benefits of ceramic injection molding

The applications of CIM span a wide range of industries and huge areas of research:

Forming net or net shape parts

Improving productivity and efficiency

Lower manufacturing cost

Improving product performance and high degree reproducibility

Precise surface finish

Tight tolerance

Different Materials Used for Ceramic Injection Molding

Any production powder is suited for the precise manufacturing process; however, nano dimension specializes in:

Alumina

Zirconia

ATZ

ESD (Electrostatic discharge material)

Ceramic Materials Properties

Ceramic materials possess a wide range of properties making them highly desirable for multiple applications. By understanding these properties – it is crucial to select the appropriate ceramic material for the specific requirement.

Mechanic Properties

Ceramic material exhibits exceptional mechanic properties including high strength, hardness and stiffness. The production finish is known for unparallel wear resistance and its ability to withstand high compressive force.

Thermal Performance

Ceramic materials have outstanding thermal properties that includes high thermal conductivity and resistance to thermal shock. It can withstand extreme high and low temperature. with these characteristics ceramic becomes more suitable for applications requiring thermal insulation.

Wrapping Up

If you are in the search of top-notch ceramic injection molding solution, look no further. MIM Suppliers offers cutting-edge ceramic injection molding services tailored to your specific needs.

0 notes

Text

Reasons to Choose Metal Casting

Nowadays many engineers and metal fabricators are considering Powder Casting Process in order to streamline productivity and improve production quality. If you are still unaware of powder casting production and don’t believe it holds a competitive candle – this blog is for you.

Honestly, not all die casting applications are a good fit for powder metallurgy – there are some specific cases when powder casting serves the purpose.

An Overview

Powder casting entails filling a die or mold to form the desired shape. Then the formed part releases and processed for the final finish. When the die is full – the upper tool comes down to compact the powder – then the die is opened and the part is ejected.

After that, many powder metal parts go through sintering that fuses the mix into a full hardened piece.

How Does Metal Casting Work?

Metal casting falls into the two broad category based on whether the mold is reusable. Metal casting is simply done by heating the metal until its liquid state and pouring it into the mold. Then it is allowed to cool then the mold is opened and the final cast is removed. It involves heating and molding the metal that helps to differentiate the casting metal from forging.

Metal Casting Processes come with high strength and excellent fatigue property that doesn’t break easily. Manufacturers can achieve tighter dimensional tolerance than machined products. In addition, casting also offers good surface finish with less machining required.

Benefits of Metal Casting

It is a highly specialized process that involves pouring molten metal into the mold – consisting three steps:

Preparation of the mold

Melting and casting

Removing the final product

Weight Reduction

When weight maintenance is crucial, metal casting is probably the best option to try. While selecting the proper alloys or metal – you can reduce the weight of application. It definitely makes metal casting an ideal choice for larger components.

Cost

Metal casting also offers a cost-effective solution when it comes to low-volume manufacturing. Also, it enhances the production speed and ease the process of complex geometries. It also offers a simple process to produce parts that can be done without machining.

Rapid Manufacturing

Time is a very crucial factor during manufacturing. Since metal castings are poured, they hardly require any tooling. Parts can be produces quickly and in minimal quantities – making it a perfect choice for low-volume manufacturing.

Complex Structure

Metal casting is a great choice for complex parts as it offers design flexibility and can be offered in various sizes and shapes. Casts can be very small or even incredibly huge – the process never compromised the quality and structure of the mass.

Even the most complex part can be achieved that may be time-saving and cost-effective than machine.

Wrapping Up

If you are looking for fast production process without compromising the quality of the product – metal casting is arguably the finest option for you. Companies like Mim Suppliers have been producing fast turn metal casting for years. They have a dedicated team to enhance product quality and maintain perfect casting every time. For more information, please get in touch with us.

0 notes

Text

How Alumina Ceramic Injection Molding Enhances Industrial Precision

Introduction

In in recent rapid-paced industrial panorama, precision and durability are non-negotiable factors. Manufacturers throughout sectors name for high-overall performance additives capable of withstanding immoderate situations even as preserving accuracy. This is where alumina ceramic injection molding comes into play. As a cutting-edge generation, it gives high-quality electricity, put on resistance, and dimensional balance, making it the proper solution for industries that prioritize precision.

In this text, we’ll find out how Alumina Injection Molding enhances commercial precision, its blessings, and its packages in the course of various sectors.

What is Alumina Ceramic Injection Molding?

Alumina Ceramic Injection Molding (ACIM) is a manufacturing manner that consists of injecting a ceramic-based feedstock right into a mildew hollow space below excessive pressure. The feedstock consists of first-class alumina powder combined with a thermoplastic binder. After the molding stage, the component undergoes a debinding technique to remove the binder, discovered by way of sintering to achieve its final, strong ceramic shape.

Key Features of Alumina Ceramics in Injection Molding

High Hardness: Alumina ceramics exhibit exquisite hardness, making them specially proof towards abrasion and put on.

Chemical Resistance: They can resist exposure to harsh chemical substances without corroding.

Thermal Stability: Alumina ceramics maintain stability at high temperatures, ensuring reliability in intense conditions.

Dimensional Precision: The injection molding technique ensures complex shapes with tight tolerances.

Why Alumina Ceramic Injection Molding is Ideal for Industrial Precision

1. Superior Dimensional Accuracy

One of the primary reasons alumina ceramic injection molding is preferred in commercial programs is its superior dimensional accuracy. The molding method allows for the introduction of complicated and miniature components with regular shapes and tight tolerances, important for industries inclusive of electronics, aerospace, and scientific devices.

2. High Surface Quality and Consistency

Alumina ceramics deliver outstanding ground finishes, reducing the need for delivered sprucing or machining. This consistency ensures that additives form precisely into their certain assemblies, improving the overall performance and toughness of the business system.

3. Reduced Component Weight and Increased Strength

Compared to metals, alumina injection molding creates light-weight but strong factors. This weight loss is useful for industries like vehicle and aerospace, in which lighter components make contributions to gas performance and improved average overall performance.

4. Resistance to Wear and Corrosion

Industrial environments regularly expose additives to harsh conditions, together with friction, chemical compounds, and warmth. Alumina ceramics are extraordinarily proof against placed on and corrosion, making them ideal for pumps, valves, and sealing structures that require longevity and minimal renovation.

Applications of Alumina Ceramic Injection Molding in Precision Industries

1. Medical and Dental Devices

In the scientific location, precision is essential. Alumina ceramic injection molding is extensively used to manufacture:

Surgical devices: Durable and evidence against corrosion.

Dental implants and prosthetics: High biocompatibility and put on resistance.

Microfluidic devices: Complex ceramic factors with complicated geometries.

2. Electronics and Semiconductors

With the demand for miniaturized, excessive-precision digital components, alumina ceramics play a key role in generating:

Insulators and substrates: Excellent electric insulation.

Sensor housings: Protect sensitive electronics from outdoor elements.

Heat sinks: Ensuring efficient thermal management in excessive-performance gadgets.

3. Aerospace and Defense

The aerospace enterprise demands additives with excessive put on resistance and dimensional accuracy. Alumina injection molding meets those necessities via producing:

Nozzles and thrusters: Withstanding intense temperatures.

Ceramic bearings and bushings: Reducing friction and placed on.

Radar and communique components: Ensuring reliability and durability.

4. Automotive Industry

Alumina ceramic additives enhance the general performance of numerous automobile structures, such as:

Ignition systems: High-energy ceramic insulators.

Engine sensors: Durable ceramic components for specific readings.

Fuel injectors: Precision-molded ceramic additives for the most appropriate fuel transport.

Key Benefits of Alumina Ceramic Injection Molding for Industrial Precision

1. Exceptional Hardness and Durability

Alumina ceramics have a Mohs hardness of 9, making them simpler than diamonds. This hardness ensures incredible wear resistance, making them ideal for packages related to friction or mechanical pressure.

2. Thermal and Chemical Stability

Alumina ceramics can withstand temperatures up to 1700°C without losing their structural integrity. Their chemical inertness makes them evidence against acidic or simple environments, making sure of balance in chemical processing plants.

3. Reduced Manufacturing Costs

Despite its technical complexity, alumina injection molding reduces manufacturing costs with the aid of allowing:

High-volume production of complex factors.

Reduced need for post-processing.

Minimal cloth waste within the route of production.

4. Improved Product Reliability

Precision-molded alumina elements ensure steady best and reliability, enhancing the overall performance and lifespan of an industrial device.

Challenges and Considerations in Alumina Ceramic Injection Molding

1. Complex Debinding and Sintering Process

The debinding and sintering steps require unique temperature and timing management. Any deviation can result in the deformation or vulnerability of ceramic elements.

2. High Initial Tooling Costs

While alumina ceramic injection molding offers long-term price financial savings, the preliminary tooling investment may be large. However, it will become cost-powerful for high-quantity production.

3. Limited Flexibility for Large-Scale Components

Alumina ceramic injection molding is nicely suitable for small to medium-sized elements. Larger additives may additionally require opportunity manufacturing techniques.

Conclusion

Alumina ceramic injection molding is transforming industrial production via turning in unequalled precision, sturdiness, and basic overall performance. Its capacity to create complex, high-energy components with tremendous dimensional accuracy makes it a game-changer for the scientific, aerospace, vehicle, and electronics industries. With its resistance to put on, chemicals, and heat, alumina ceramics make certain steady reliability and long-time period cost savings.

If you're seeking to beautify your business additives with modern-day ceramic technology, making an investment in alumina ceramic injection molding is a clever and forward-thinking choice.

0 notes

Text

Property Advantages of the Powder Metal Compaction Process

Compaction and compressibility of powdered metals are considerably better understood in the manufacturing industry now than in the "old days" (around 20 years ago). As a result of this knowledge expansion, opportunities for the industry to develop intricate, structural-grade components have increased.

It is essential to comprehend powder compaction to regulate characteristics such as component density, shape, size, porosity, and hardness. Let's study the Metal Powder Compaction process to help you modernize the performance and cost-effectiveness of your part:

The function of it in the PM process

Overview of die compaction and tooling operations

The die-pressing procedure

Variables that affect compaction

Techniques for increasing compressibility

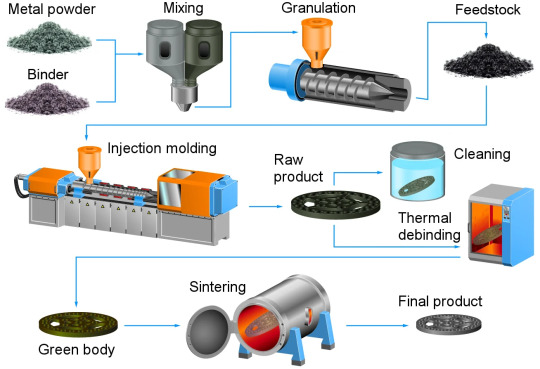

The Function of Compaction in the Process of Powder Metallurgy

Numerous factors affect the performance and durability of your finished component at each stage of the powder metallurgy process. If you are familiar with the entire process, you can better appreciate how compaction is crucial to accuracy and consistency.

There are Four Processes Involved in the Traditional Die-Pressing and Sintering Process:

Blending the Powder:

To create a homogenous material blend, powdered elements or alloy metals are combined with lubricants or binders.

Compacting:

The material is subjected to tremendous pressure in a press to create the required shape of a compressed "green" item.

Sintering:

To create metallurgical linkages, which increase strength and integrity, the powder is heated in a controlled-atmosphere furnace to a temperature lower than the melting point of the base metal.

Secondary Processes:

If required, machining, heat treatment, and surface treatments increase value by further improving performance or dimensions.

Introduction to Die Compaction and Its Tooling Functions

Compaction Methods in Powder Metallurgy involve shaping, distortion, and densification of material under the influence of a tooling set. In die compaction, the most popular method for shaping and densifying powder, a powder is pressed into a "green," pre-sintered compact by applying pressure with upper and lower punches.

A collection of compaction tools is made for every unique part. A basic set of compaction tools consists of upper and lower punches, a core rod, and a die cavity. Tool designers create sets based on press designations, part shapes, and powder parameters.

The Process of Die Compaction

The compaction process is an ongoing cycle in die pressing. The fill position is when tooling motions begin, followed by the compaction and ejection phases.

The finished product is a compacted "green" portion. Green density and strength describe the component's density and strength at this point. The green strengths of these compacts are comparable to those of aspirin tablets and Life Savers candies.

Elements Affecting Powder Compaction

Understanding compressibility is essential to comprehending the factors that affect compaction. Compressibility is the ability of a metal powder to densify in a closed die under applied pressure. Several variables affect a material's compressibility, which the manufacturer can modify to achieve ideal results.

Shape and Size of Particles

A particle is defined as being less than 1 mm. Size counts, even when it comes to minuscule details. The size of the particles affects how well materials may be packed together. During compaction, particle shape affects the material blend's compressibility, flow, and packing. In the traditional pressing process, particles with irregular forms tend to pack together more readily than those with other shapes.

Composition of Chemicals

Compressive behavior tends to vary among alloys and elemental compositions. In contrast to pre-alloyed materials, elemental powder mixes composed of iron, nickel, or copper, for instance, compress more readily.

Hardness

Compressive strength may be affected by the hardness of the material you have selected. More complex materials are less compressible because they are more difficult to distort. During compaction, softer, more ductile particles can deform more readily.

Lubrication

The degree to which particles "slide" past one another during compaction—rather than obstinately remaining in place—depends on the quantity and presence of lubricants. The proper processing and lubrication can:

Increase the power of green

Avoid heating-induced work/strain hardening.

Assist with part ejection from the die while preserving shape integrity and efficiency.

Minimize tooling wear, mainly when compaction pressures are higher.

Make it more compressible.

How to Make Things More Compactible

Compressibility greatly influences the economical and efficient manufacture of powder metal components. The specifications needed to increase compatibility may differ depending on the application or material of your part.

Several parameters can be adjusted for a more seamless pressing process, including particle size and shape, lubrication, hardness, and chemical composition. Your most effective plan can consist of:

Changing Lubricants: A solid lubricant can enhance dimensional control, tool life, and green strength by increasing flowability and decreasing friction between particles and the die.

Base Material Adjustment: Using atomized powder aids in maintaining consistency in particle size and shape in structural elements.

Warm Compaction: This makes the material more malleable by lowering the yield strength of the particles.

Compaction Best Practices for Your Powder Metal Part

Can minor adjustments be made to improve the density and strength of your part? A metal powder compaction specialist can examine your application to determine whether there are chances to enhance the functionality and lifespan of your component.

Go to our blog library and continue learning to get the most out of the powder metal process.

0 notes

Text

What is MIM? Everything You Should Know About Injection Molding!

This blog explores different types molds used in plastic injection molding discussing the ideal applications, strength, weaknesses and lifespan to create effective mold based on the manufacturing requirements.

The creation of the mold of Medical MIM is the first step that demands great precision and accuracy for ensuing the quality and consistency of the final product.

What is MIM?

Well, there are various ways to classify molds in the injection molding that includes plate type, runner type, cavity design and class. Single cavity molds are simple and offer high-quality parts and ideal for low volume production. It also reduces the cost per part for larger volumes.

Different Usage and Type of Injection Molding

Injection mold is categorized in different ways affecting various aspects of production process. Take a look at the detailed look at the categories and significance:

Two-plate molds: it consists of two main parts – cavity and core. They are typically simpler and less expensive.

Three-plate molds: it includes additional plate for separating parts from the runners and improving part ejecting and quality.

Stacked plate mold: utilize multiple levels of cavities and doubling the output without increasing the footprint. They are great for high-volume production that require precise alignment and complicated design.

Mold Cavity Design

It plays a crucial role for production efficiency and part quality that directly influencing the speed, cost and consistency of manufacturing process.

Single-Cavity Mold: it produces one plastic part per injection cycle. It offers single-cavity models and due to the size and relative simplicity they are pretty affordable to produce.

Family Mold: these injection molds come in different parts per production cycle. They are very useful to manufacture multi-part products quickly. Additionally, the SPI classification offers a standardized method for evaluating mold life expectancy and suitability.

Bottom Line

The injection molding molds consist of several components and every type with its own specific function within the molds. The life expectancy of the mold is determined by the number of molding cycle with each cycle of mold opening and closing. Different factors influence the lifespan including the mold class, operating condition, environment and maintenance practices and materials used.

0 notes

Text

MIM Sintering

MIM Sintering is a crucial step in the Metal Injection Molding process, where parts are heated to a temperature that causes the metal particles to fuse together. This step is essential for achieving the desired strength and density. Learn about MIM Sintering at mim-supplier.com.

0 notes

Text

Typical Myths Regarding Injection Molding

Making a mold is the first step in the effective and economical process of injection molding plastic parts in large quantities. The most economical and effective method for mass-producing plastic parts is Metal Powder Injection Molding, which can make millions of parts in a surprisingly short period with precise tolerances.

0 notes

Text

Titanium Metal Injection Molding

Experience the precision of titanium metal injection molding at mim-supplier.com. Achieve superior strength and durability in your metal components.

0 notes

Text

Warm Isostatic Press

Warm Isostatic Pressing (WIP) is a technique used to enhance the density and strength of metal and ceramic components. This process applies heat and pressure to reduce porosity and improve material properties. Find more about Warm Isostatic Press at mim-supplier.com.

0 notes

Text

Aluminum Injection Molding

Discover the lightweight versatility of aluminum injection molding at mim-supplier.com. Achieve precision and efficiency in producing aluminum parts.

#Titanium Metal Injection Molding#Powder Metal Manufacturing#Warm Isostatic Press#MIM Injection Molding

0 notes

Text

CIM Ceramic Injection Molding

Experience the precision of CIM ceramic injection molding at mim-supplier.com. Achieve complex shapes and superior performance in ceramic parts.

0 notes

Text

MIM Casting

Discover the versatility of MIM casting at mim-supplier.com. Achieve precise and complex metal parts through our advanced casting techniques.

0 notes

Text

Stainless Steel Injection Molding

Explore the durability of stainless steel injection molding at mim-supplier.com. Achieve corrosion resistance and strength in your metal parts.

0 notes

Text

Mold Your Vision: A Comprehensive Guide to Selecting an Injection Molding Partner

Injection molding is the core of the manufacturing process, which has the significant advantage of very high efficiency with a high precision result. These components are commonly used in many different fields. Not to mention the novel project, favoring the Metal Injection Molding Services can result in success or failure. Below is a detailed step-by-step guide that will assist you in understanding the diverse stages of selection and help you accomplish your dreams with self-assurance.

1. Define Project Objectives: Work by determining what your project is going to be; for example, name the products, rate of production, and deadline. The introduction section could include factors like part complexity, material needs, and desired surface elegance to make your potential injection molding partners perceive a complete picture of your needs.

2. Evaluate Experience and Expertise: Evaluate the experience and skills of potential injection molding providers accordingly to maintain a proper fit with your project objective. Try to find manufacturers that have successfully passed the mark of excellence in your industry and can boast of their experience in projects of a similar magnitude. Acquaintance with material selection, mold shaping, and process enhancement can prove an arsenal impacting the project outcome.

3. Technology and Capabilities: Tough Shot molding technology keeps developing; those advances are beneficial and lead to greater savings of resources. Strive to find injection molding partners that use advanced equipment, cutting-edge technology, and the latest software for production process management and output improvement. Furthermore, they will be asked by the manufacturer about their skills in designing tooling, maintaining molds, and sampling.

Adhering to these key points and considerations, you will be able to suitably select a Powder Injection Molding partner that complements your aspirations for the project and outpaces expectations. Whatever you face and whatever you need, be it in consumer products, automotive components, or medical devices, there is someone you can count on who is known for quality, ingenuity, and customer satisfaction. Be the creator of your vision and innovation by molding with high precision and finding new avenues for your products and business ventures.

0 notes

Text

Ceramic Injection Molding

Ceramic Injection Molding (CIM) is an advanced manufacturing technique that involves blending ceramic powders with binders to create a slurry. This slurry is then injected into molds using high pressure. Once molded, the part goes through a rebinding process to eliminate the binders, followed by sintering to attain the desired ceramic material properties.

1 note

·

View note