Don't wanna be here? Send us removal request.

Text

All about Erp And Cad Integration In 2020

Table of Contents

Get This Report about 10 Ways Machine Learning Can Close Legacy Erp Cad Gaps

The Only Guide to Integrating The Cad/pdm/plm System Into The Usa Business

The Basic Principles Of Why Erp-based Plm - Cad Inside Agnilinks

The 9-Second Trick For 5 Reasons For Erp, Crm And Cad Integration For Business

Manufacturing Management Software - Cad Erp Can Be Fun For Anyone

Get This Report on Manufacturing Management Software - Cad Erp

Everything about Advantages To Integrating Your Cad And Erp Systems

Elmo Solutions is something I've found out through the years working with lots of manufacturers. It can make a significant difference to the time element! Engineers use tools like CAD/Solidworks and so on software to do their design work. Our ERP items have actually a tool called ' CADLINK' that can make a considerable distinction to get design work exported from CAD into ERP.

6 Simple Techniques For Plm Vs Erp - Design Rule

Proofing that all has transformed to ERP takes some time. With CADLINK, the import/export might take simply 20 minutes. The ROI on that tool is like the day prior to yesterday! That's why we can be found in and do what we do.

CAD IntegrationCountless organizations depend upon CAD information and illustrations as the foundation of their product designs, but numerous ERP software application bundles don't integrate well with CAD systems. abas bridges this space through an API-based CAD integration add-on that works with leading CAD software application suites, consisting of SolidWorks and Autodesk Inventor.abas ERP's option allows businesses to deliver build material information directly in between the CAD and ERP systems in simply a few clicks, making it simple to keep items as much as date based upon continuously altering design illustrations.

Top Guidelines Of Cad, Pdm & Plm Applications - Link With Erp

At its most basic, field mapping is a tool that lets companies establish sensible conditions for different values within the system. For instance, if a CAD develop template does not have the appropriate variety of columns relative to the item detail in the ERP system, the field mapping option will flag the concern to make sure the problem gets fixed.

These include: Developing versatile templates: Each engineer can produce develop product design templates that ensure smooth integration in between the CAD and ERP systems - ERP CAD integration. This allows your staff member to rapidly create and change templates within the CAD system and draw up relevant fields for the ERP setup. These criteria are kept locally on the user's maker, but can easily be moved to other workstations by copying an.xml file any way that works for the user Dropbox, Flash drive, Samba share, and so on.

With flexible field mapping meanings in hand, engineers get total freedom to develop their CAD drawings as needed without sacrificing functionality within the ERP systemSimplifying interoperability: abas' field mapping system enables you to establish columns and similar fields within your develop materials structure to ensure the right information winds up in the right location.

10 Ways Machine Learning Can Close Legacy Erp Cad Gaps for Beginners

The outcome is a much simpler environment for develop material list customization. You can likewise utilize partial transfer performance when you simply require to take some construct products from the CAD list to the ERP system. As each upload procedure takes location, the develop products to be moved in between software application platforms are put in a chart with checklists showing they will be moved.

The result is a circumstance in which users need to go into that data by hand in both the ERP system and the CAD platform to guarantee it transitions with a develop material list throughout the integration process. Our field mapping tool allows users to develop preconfigured information sets to make sure that information gets to the right location and users do not require to waste time getting in data.

abas works hard to ensure our customers are able to take full advantage of this performance by ensuring the platform is extremely simple. When engineers have actually developed a product, they just require 3 clicks to get the job done: One click of the mouse to open the combination platform, another to start the transfer, and a third to access the develop material list in abas ERP and ensure it is updated.abas' CAD integration platform likewise simplifies the process of making modifications to drawings, as it instantly updates everything from product master documents to work and sales orders with the right details.

Unknown Facts About What Is Erp And Cad? Enterprise Resource Planning Explained Here

8 Simple Techniques For Integrating The Cad/pdm/plm System Into The Usa Business

Making organisation easyEngineers play an integral function in preserving continuous innovation for an organization. Their capability to change product styles quickly and efficiently plays a necessary role in updating your offerings because of altering market needs. ERP CAD integration. You do not need constraints in information combination to come between your company and a blistering pace for development.

< bas ERP's CAD combination platform is created to assist your people attain at their biggest potential by streamlining and streamlining information sharing between disparate CAD and ERP systems.

The Single Strategy To Use For Why Erp-based Plm - Cad Inside Agnilinks

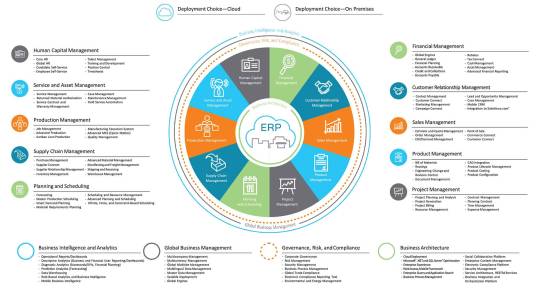

ERP is accepting a new world of consumerized innovation focused on the employees as enterprise' resource experts. Explore how an enterprise-first ERP can utilize social, mobile and cloud innovations to offer workers the flexibility and versatility they prefer to drive company productivity. In a smaller sized view, what does Enterprise Software Systems, ERP, use your department or you and your task? ERP, designed and implemented properly, is specified as streamlining performance by incorporating tasks which otherwise are diverse business events.

Some Of 10 Ways Machine Learning Can Close Legacy Erp Cad Gaps

youtube

A case in point is a local service growing 20% year over year. Yet profits are waning to pre-growth levels; volume is up, profits are down. Enterprise info (big data) and choice support do not always go together. The majority of what an ERP system can do for a company needs extensive understanding, open mindedness and new proficiencies for continual success.

According to Aberdeen, top enterprises showed enhancement in the following four essential performance indicators (KPIs) over the previous year with existing outcomes balancing: 97% complete and on-time shipments. 98% stock precision. 51% have a days sales impressive (DSO) rate of fewer than one month, and 80% have a DSO rate of fewer than 40 days.

A Biased View of What Is Erp And Cad? Enterprise Resource Planning Explained Here

What do we have? What do we need? How can we develop or buy it? Why do these things matter? What do they costs in time, money and individuals? What will ERP mean to the organization's future? Bringing your viewpoints plainly to the discussion table in an open frank online forum of cost versus organisation worth.

On this list was an oscilloscope costing nearly $20,000. I seemed like I was taking the company's cash by asking for such a pricey tool be acquired. My supervisor said; "I don't want you thinking this is your personal spending plan, this is a company and we should have what it will take to be effective." That day, I discovered to separate my personal beliefs about spending versus the business requires.

ERP software application, like a business-muscle, requires exercising to be strong and include value to the company. Like a body of processes and functions, these business-muscles are keys to business core strengths, extended capabilities and endurance (CAD ERP). If we only exercise the arms and not the legs, we will be lopsided in our understanding leaving core proficiencies damaged.

Some Known Questions About Cad, Pdm & Plm Applications - Link With Erp.

Strength is relative and understanding ends up being subjective across an enterprise where training is reduced to save cash in the hope that discovering as we go will be enough. Sometimes a service coach or fitness instructor will assist focus the enterprise on building their strengths ensuring lasting success. SYSPRO is an example of ERP software application developed to deliver the very best enterprise results.

0 notes

Text

All About How Does Erp/cad Integration Help Custom Manufacturers?

Table of Contents

The smart Trick of Pdm Technology Brings Cad And Erp Together That Nobody is Talking About

Getting The Advantages To Integrating Your Cad And Erp Systems To Work

More About How Does Erp/cad Integration Help Custom Manufacturers?

Get This Report on Integrating The Cad/pdm/plm System Into The Usa Business

The Greatest Guide To 10 Ways Machine Learning Can Close Legacy Erp Cad Gaps

The business was dealing with an absence of exposure into information throughout the company, time was being lost calling and emailing internally to get updates about jobs, vital info was stored on undated spreadsheets and manual data entry procedures were producing inaccuracies in information. To resolve Inphi Corporation's issues, Razorleaf's team developed an integration scheme that executed a total change management system in PLM 360, enhanced client communication around RMAs, got rid of manual procedures to cut the time being wasted on errant data searches and provided extraordinary visibility into data and operation company wide.

Examine This Report about Best Systems In 2020: Cad To Erp Performance Review

With a robust PLM integration plan in location, service processes can be enhanced and companies can provide themselves greater control of how they develop items now and well into the future. Which point is critical. PLM integration will become a lot more necessary to organisation and product success as more devices are constructed to be part of the Internet of Things ecosystem.

PLM combination will not, and probably need to not, occur overnight (CAD ERP integration). Phasing in levels of combination enables better business processes to be developed action by action. This phased-in method offers a business much better insight into its everyday operations. As modes of pulling out insight ends up being more sophisticated, extra levels of combination should be adopted to fine-tune decisions at every level of item advancement.

Companies that extend PLM integration across design tools and enterprise software are the most likely to experience efficient innovation and productivity. Although PLM combination can appear to be challenging at the beginning, its benefits can pay dividends. So, why are you waiting? has actually sponsored this post. They have supplied no editorial input besides verification of the technical realities.

The 30-Second Trick For Manufacturing Management Software - Cad Erp

youtube

Capitalizing on new digital organisation designs and the development chances they offer are requiring companies to re-evaluate CAD & ERP's role. Made inflexible by years of modification, legacy ERP systems aren't providing what digital organisation models need today to scale and grow. Tradition ERP systems were purpose-built to stand out at production consistency initially at the cost of flexibility and responsiveness to clients' altering requirements.

Companies require to be able to react rapidly to unexpected, unknown and unexpected problems with clever decisions fast for brand-new digital service models to succeed. That's not possible today with tradition ERP systems. Tradition IT technology stacks and the ERP systems they are built on aren't designed to provide the information required most.

A clear, compelling organisation model and effective execution of its related methods are what all effective Cloud ERP executions share. Cloud ERP platforms and apps provide organizations the versatility they require to focus on development strategies over IT restraints. And numerous have taken an Application Shows Interface (API) technique to incorporate with legacy ERP systems to get the incremental information these systems supply.

Brand-new service models thrive when an ERP system is continuously finding out. That is among the best gaps between what Cloud ERP platforms' prospective and where their legacy equivalents are today - CAD ERP integration. Cloud platforms supply greater integration choices and more flexibility to customize applications and improve functionality which is among the greatest drawbacks of legacy ERP systems.

The Greatest Guide To Manufacturing Management Software - Cad Erp

The following are the 10 ways to enhance Cloud ERP with AI and artificial intelligence, bridging the info gap with legacy ERP systems: Having a cloud-based infrastructure that integrates core ERP Web Providers, apps, and real-time monitoring to deliver a steady stream of data to AI and machine learning algorithms accelerates how quickly the whole system discovers.

Apple's Siri, Amazon's Alexa, Google Voice, and Microsoft Cortana have the prospective to be customized to improve operations jobs and procedures, bringing contextual assistance and instructions to complicated tasks. An example of one job virtual agents are being used for today is assisting production workers to select from the correct product bin as required by the Bill of Products.

The Facts About Advantages To Integrating Your Cad And Erp Systems Uncovered

Amazon has effectively partnered with automobile producers and has one of the most style wins since today. They might easily reproduce this success with equipment makers. Cloud ERP platforms have the possible to capitalize on the huge data stream IoT devices are producing today by creating in support at the information structure level first.

Capgemini has actually provided an analysis of IoT use cases shown listed below, highlighting how production asset maintenance and asset tracking are fast wins waiting to occur. Cloud ERP platforms can accelerate them by designing in IoT support. Producers will welcome the chance to have greater insights into how they can support then normalize OEE performance across their store floors.

Plm Vs Erp - Design Rule for Beginners

Artificial intelligence algorithms stand out at discovering patterns in diverse data sets by continuously using constraint-based algorithms. Suppliers vary commonly in their quality and delivery schedule performance levels. Using artificial intelligence, it's possible to produce a track-and-trace application that might indicate which lot from which supplier is the riskiest and those that are of remarkable quality too.

They're able to ease the disputes between how engineering creates an item with CAD and PLM, how sales & marketing sell it with CRM, and how manufacturing constructs it with an ERP system. AI and artificial intelligence can make it possible for configuration lifecycle management and prevent wasted time and sales, improving CPQ and item setup strategies while doing so.

Oil refineries are using maker knowing designs consist of more than 1,000 variables related to product input, output and procedure boundaries including weather to approximate equipment failures. A regional airplane manufacturer is doing this today by using predictive modeling and machine learning to compare past incident reports. With legacy ERP systems these issues would have gone unnoticed and developed into production downturns or worse, the line needing to stop.

Some Known Factual Statements About Cad Integration - Automatic Cloud Erp

With legacy ERP systems producers most often rely on an analysis of scrap materials by type or triggered followed by RMAs. It's time to get to the reality about why items stop working, and artificial intelligence can deliver the insights to get there.

Some Ideas on 3 Ways Integrating Erp Software With Cad You Need To Know

How to Select the very best ERP Software Application for Your Little Medium Business in 2020 - Reviews, Features, Pricing, Contrast - PAT RESEARCH: B2B Evaluations, Buying Guides & Finest Practices "cookieName":" wBounce"," isAggressive": false," isSitewide": real," doubt":" 20"," openAnimation":" rotateInDownRight"," exitAnimation":" rotateOutDownRight"," timer":""," sensitivity":" 20"," cookieExpire":" 1"," cookieDomain":""," autoFire":""," isAnalyticsEnabled": real.

I find that individuals tend to blur the lines between ERP, MRP, and PLM. The function of this blog is to summarize the high-level intent of many ERP, MRP and PLM systems. Among the most significant driving factors for the need for an enterprise-class ERP system revolves around finance/accounting. Anything that belongs to income or costs should be tracked in severe detail. ERP CAD integration.

0 notes

Text

Some Known Details About 5 Reasons For Erp, Crm And Cad Integration For Business

Table of Contents

Integrating The Cad/pdm/plm System Into The Usa Business - The Facts

Unknown Facts About Plm Vs Erp - Design Rule

Rumored Buzz on Plm Vs Erp - Design Rule

What Is Erp And Cad? Enterprise Resource Planning Explained Here for Beginners

How Does Erp/cad Integration Help Custom Manufacturers? for Dummies

Not known Incorrect Statements About Erp And Cad Integration In 2020

The Ultimate Guide To Best Systems In 2020: Cad To Erp Performance Review

The Buzz on Cad, Pdm & Plm Applications - Link With Erp

Nevertheless, their offering is limited to a simple export-import procedure that is hardly better than manual data transcription, generally since it lacks the real-time, bidirectional technique that is the only practical way to achieve a failsafe CAD ERP integration whenever. The export/import method leaves the door wide open to data rejection by the target system, partly completed transfers, incorrectly validated data, disparities, and so on.

Effective CAD/PDM/PLM-ERP combinations necessarily require real-time information exchange. It is shown that any other way is destined to failure. Why real-time? Due to the fact that you require a layer of defense, a temporary information object that you will utilize to occupy and verify information prior to the final transfer to the ERP system - ERP CAD integration.

Until then, item data must be frozen till final user verification, thus guaranteeing the quality of the information to be passed to the downstream organisation processes. That is the only method to make sure the accuracy of your files accuracy. For instance, you wish to make sure that everyone will working on the existing version/revision.

Advantages To Integrating Your Cad And Erp Systems - An Overview

One combination being asked for more regularly by making business is the combination of CAD software with ERP systems. This connects an organisation's engineering with its production, helping to improve these processes. stands for computer-aided style, and describes software application that engineers use when developing an item in the design phases prior to it is built.

After an item is designed in CAD, engineers need to send the expense of materials (BOM) to making so they can buy the elements of production and after that develop the product. If a business does not have a CAD-ERP connection, engineers will have to by hand input this data. There are 2 primary difficulties with this.

Your engineers will have to get whatever data they require from CAD, load up ERP, and insert it in the appropriate type. For many companies, this will be a major discomfort point, since engineers are losing a substantial amount of their time. Possibly even worse, nevertheless, engineers can make errors during this process.

Little Known Facts About Erp And Cad Integration In 2020.

At worst, the company might simply have to scrap them, leading to squandered money. Meanwhile, purchasing too few systems implies that production is postponed. The business has to put in a late order, time is lost, and the consumer will be dissatisfied that his products are not arriving as scheduled.

In the first method, CAD files can be published directly onto your ERP system. For instance, Odoo, an open-source ERP software, allows users to submit CAD files directly to its PLM (Product Lifecycle Management) module. After this, staff members can quickly make BOM modifications. In the second method, the CAD software can be directly integrated with the ERP, permitting your organisation to completely automate the procedure from development to production.

First of all, this accelerate work. Secondly, engineers spend more of their important time doing engineering rather than clerical work. And lastly, your service is far less likely to make errors, saving you time and money, and likewise causing a greater rate of customer fulfillment. Bista Solutions can integrate different CAD software application with Odoo, allowing a service to end up being even more effective.

The 3-Minute Rule for Cad Integration - Automatic Cloud Erp

We're already doing this for a number of clients. If you desire your business to be next, let us know! You can reach us at 404-631-6219 or leave us a message using our contact type.

CADTalk increases the worth of your SOLIDWORKS investment by allowing you to integrate your engineering information with your ERP (Business Resource Planning) system. We have actually partnered closely with leading ERP suppliers in order to offer complete included, off the shelf combinations. Our combinations are totally supported for future versions of both SOLIDWORKS and your ERP bundle (CAD ERP).

youtube

Aptean deals a variety of consulting, assistance, and service programs to assist you with the execution and use of your Encompix ERP service. Our experienced experts can assist your company through the execution process to minimize danger and attain faster return on investment. Ongoing services consist of technical assistance for customization, data conversion, integration, education, and training.

The Best Strategy To Use For Cad Erp Integration : What To Expect

Decision365 is a commerce efficiency tool that leverages the application most makers already use: Microsoft Outlook. Decision365 permits users to manage orders straight in Outlook with automated integration to your ERP systems. Decision365 connects to more than a lots EDI and e-commerce systems, including SPS Commerce, Conexiom, Shopify, Magento, Volusion, TrueCommerce, B2BGateway, and others.

Among the greatest obstacles for businesses is to connect all of their multi-discipline dispersed systems to one central place. A PLM system should incorporate with other systems, consisting of Business Resource Planning (ERP) systems, Authoring and documents tools, such as CAD, and existing Product Data Management (PDM) systems.

How 10 Ways Machine Learning Can Close Legacy Erp Cad Gaps can Save You Time, Stress, and Money.

Although that might appear like a herculean effort, there's no factor to fret. Bespoke integration doesn't need to be a concern, and furthermore, effective PLM combination can result in greater service success. As Derek Neidling of Razorleaf, a leading PLM combination service company, put it, "In many cases, PLM isn't being thought of on the very first day of incorporation." And that makes sense.

You're drowning in decisions that you may or may not have experience making. PLM isn't on the top of your list. So, by the time your very first couple of items have removed, and you're worrying about staying up to date with supply, you have actually got mountains of information and possibly numerous proprietary design files that you require managed.

What Does Best Systems In 2020: Cad To Erp Performance Review Do?

As soon as PLM has gone into the photo and it's been tied into your CAD system, organisation choices become much easier to make. Your team sees an improvement in process effectiveness, and offered your success, you have actually expanded and even added an ERP system to your company. The issue is, your ERP system and your PLM setup aren't communicating with one another.

The Only Guide to Why Erp-based Plm - Cad Inside Agnilinks

( Image courtesy of Razorleaf.) Although it's totally obvious that having 2 crucial facilities tools that don't talk to one another is less than perfect, integrating PLM with ERP hasn't constantly been the most convenient endeavor. Whether a company feels that it doesn't have the technical knowledge to incorporate, thinks the combination process will take too long or thinks it's too costly, the truth remains that integration has a number of benefits.

Combination can also remove lost effort by keeping everyone on a team appraised of the current status of a project throughout its advancement - ERP CAD. Strong PLM integration can likewise lead to much better business practices that can simplify product advancement and decision-making processes. But, the concern remains, how does a business make what can be a complex combination procedure workable? As it ends up, there are business out there with the expertise to make integration a smooth procedure.

0 notes

Text

Indicators on 3 Ways Integrating Erp Software With Cad You Need To Know

Table of Contents

Some Known Incorrect Statements About 5 Reasons For Erp, Crm And Cad Integration For Business

The Definitive Guide for Plm Vs Erp - Design Rule

The Ultimate Guide To Best Systems In 2020: Cad To Erp Performance Review

Advantages To Integrating Your Cad And Erp Systems Things To Know Before You Get This

The Greatest Guide To Erp Cad Software For Manufacturing

Some Known Facts About Erp Cad Software For Manufacturing.

A service that gets rid of silos of information and includes everyone, is important. Sales has access to essential information to keep in front of client concerns and modifications. Client service can answer order status questions with the customer immediately. Production will have complete insight into the materials and processes for production and can prepare to get rid of product and capability restraints.

When systems are incorporated, separate silos of details are removed, guaranteeing everyone is on the exact same page. Sales can supply true details to customers on the status of orders, how much is owed and see a quote that was sent. Production can see what has been engineered by having bills of product, design files and routings immediately produced and updated from CAD and engineers can see product information, like descriptions and places, by having an ERP solution that updates back to CAD.Because manually keying data into an ERP option requires time and is error-prone, a bidirectional exchange of data between ERP and CRM and CAD systems not only eliminates the requirement to crucial data, however more importantly, guarantees the data equals in all systems.

Salespeople need to see the status of orders from ERP and supply current consumer info to ERP. Store floor employees require existing access to illustrations and work instructions offered by engineering. When integrated, each location will access right details to get rid of questions, traffic jams and delays. A lot of producers have procedures depending on a couple of essential people.

Some Known Incorrect Statements About Why Erp-based Plm - Cad Inside Agnilinks

In a true integrated service, the understanding of key individuals is documented into procedures and less depending on those individuals. This protects the business from staff member turnover and standardizes the procedures so they correspond from one job to the next. In today's world of consumers desiring everything now and done right the very first time, producers require to continually upgrade their systems and procedures to get rid of constraints.

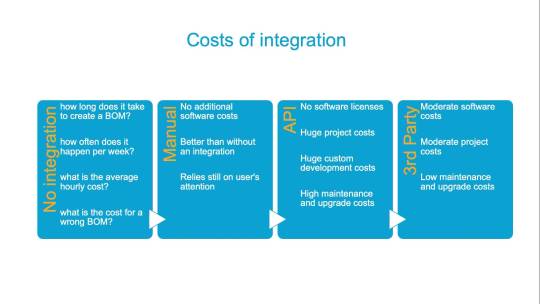

CAD ERP combination decreases the engineering effort, especially in an Engineered-To-Order (ETO) production model. Without it, the transfer of your Bills of Products (BoMs) might take in as much as 20% of your overall engineering time. This includes up to pricey mistakes on the shop floor, as a result of defective information transcription.

Manufacturing Management Software - Cad Erp - The Facts

It will be safe and pleasant, as long as you understand what to look for, and what to expect. The following summarizes what we've learned from our 30+ years in the Expense of Products (BoM) management. It should help you discover what to try to find in an efficient CAD ERP integration software, either homegrown or purchased.

Cad Erp Integration For Manufacturing Companies Things To Know Before You Buy

Our experts will be delighted to discuss your CAD ERP integration needs and requirements (ERP CAD). You can sum up a well-working CAD ERP integration characteristics into either of the following: You desire a fast and effective implementation that will not take forever prior to it's operational You require a bidirectional and real-time metadata exchange.

That usually omits developers from the solution You require a solution that will return benefits over the short-term, ideally a few months Eventually, you will make the grade to PDM or PLM software. You will wish to leverage your past investment, and make the shift as smooth as possible, with optimum results For more than 20 years, Elmo Solutions worked on CAD/PDM/PLM-to-ERP combination.

That is how we have actually established an extensive list of elements forming the core advantages to expect. Those must help you put together your own checklist of what you need to implement a successful CAD ERP combination - CAD ERP. Agni Link's design pillars are the active ingredients for success. Certainly, our CAD ERP solution was designed for services that follow an ETO production design.

Fascination About Plm Vs Erp - Design Rule

Easy to implement: the whole implementation procedure must take no more than 30 days, from starting to end. From the kick-off conference to the final rollout, a normal execution must normally be finished within 20 company days. Easy installation: your CAD, PDM or PLM application get an add-inn set up on specific user environments.

Easy to use and keep: the option you buy ought to require very little training, as there is very little user intervention required: No requirement for an ERP end-user license. You can manage all BoM levels in one single operation. The interface is CAD-vendor independent, and consistent across all CAD/PDM/PLM platforms.

Based on our experience, the only method to attain that is to stay away from any approach or solution that includes custom-made programming, either homegrown or vendor-driven. You wish to be, at all times, in total control, not just of the information combination procedure, however also of the mappings involved in the combination, as well as the habits of these mappings throughout the integration process, and without depending on developers.

Not known Details About 5 Reasons For Erp, Crm And Cad Integration For Business

The ability of defining information validity by your own guidelines. Is simpleness your thing?. No matter the orientation you take, the system should allow you to incorporate and integrate, at a minimum: Part/Component/Assembly information: data's processed, sent out and updated appropriately. Costs Of Products: your edits of assembly or subassembly automatically upgrade to ensure consistency of CAD and ERP data.

Fascination About Cad Integration - Automatic Cloud Erp

When done, an updated routing table is sent out to the MRP system, and a copy is instantly placed into the drawing. There is actually a whole universe of information things that can be shared in between the CAD and ERP environments. The fundamental procedure of your CAD ERP integration should consist of the following steps: Get existing CAD and ERP data from their particular databases.

The Best Guide To Erp Cad Software For Manufacturing

You must have the ability to avoid any redundant information entry. Ah, another thing: although it holds true that 90% of known CAD ERP integrations are about Items and Costs of Materials, there are huge opportunities for other types of combinations, such as flooring layouts, quotes, etc (ERP CAD integration). Here is a non-exhaustive list of possibilities: Assembly/ sub-assembly business Process Management (BPM) data Bills of Materials (BoMs) Parts CRM data document management Estimating Jobs Item catalogs Product configuration parts catalog product information Production orders production schedulesRouting data sales Quotes Supply chain date technical documentation work orders- You may desire to see real case study to compare your scenario.

Little Known Facts About Integrating The Cad/pdm/plm System Into The Usa Business.

As a result, you have every right to anticipate a matching ROI (Return On Investment). Based on our experience, you must expect a relatively fast ROI: As an example, a normal Agni Link implementation pays for itself in 3-6 months. Expect a decrease of your engineering cycle time of 5-20%, as an outcome of the reduction of the time invested in the transfer of BoMs.

However, from our experience, the bulk of the ROI rather originates from savings arising from a remarkable enhancement in BoM accuracy. This, in turn, normally brings a considerable decrease of costly errors on the factory floor: ERP updates it's BoM data whenever a design change is made. The right basic materials utilized at the correct time.

0 notes

Text

The Erp And Cad Integration In 2020 PDFs

Table of Contents

Some Known Factual Statements About Cad Erp Integration : What To Expect

Some Known Factual Statements About Advantages To Integrating Your Cad And Erp Systems

Unknown Facts About 10 Ways Machine Learning Can Close Legacy Erp Cad Gaps

3 Easy Facts About 3 Ways Integrating Erp Software With Cad Explained

An Unbiased View of Best Systems In 2020: Cad To Erp Performance Review

CADTALK was developed to fill the space that exists in between CAD systems and ERP. Both CAD and ERP have assisted organisations greatly to improve their procedures, and automate their data, however if your CAD and ERP can't talk with each other, you are missing out on out. The factor you use CAD and ERP systems is to be more effective, however when those systems don't interact, your business can't reach its complete capacity.

Due to the fact that CADTALK offers a live connection between your CAD and ERP systems, products and parts can be updated in real time without awaiting a manual data re-entry. This suggests your release dates come quicker, and you reduce the time to move to production. Increased production speed suggests your consumers can buy your items faster.

Because our system seamlessly incorporates your CAD and ERP, you are notified to which items you have in stock, and what products you might require. CAD ERP. Knowing part accessibility in the design phase can be exceptionally practical, and eliminate the need for costly redesign later on. Due to the fact that CADTALK integrates your ERP and CAD systems, there are less mistakes in the BOM.

Your information is more accurate, and the single system simplifies how parts are inventoried and shown. CADTALK can notify you to discrepancies between your systems so you can repair them prior to they end up being larger issues. Let CADTALK assist you make your data more dependable. When you reduce your errors and mistakes, you conserve cash.

7 Easy Facts About Manufacturing Management Software - Cad Erp Described

CADTALK can conserve you money with less waste, more accuracy and more performance! You can also construct more complicated products without adding a great deal of cost CADTALK makes it easy!You desire to draw in the finest and brightest engineers to your company who can utilize their skills in style, not information entry.

How Manufacturing Management Software - Cad Erp can Save You Time, Stress, and Money.

Let your engineers concentrate on style with CADTALK! The time saved goes toward increased performance, production, and expense savings. CADTALK is easy to use, and our ongoing support ensures that you are constantly able to get the assistance you require. Once CADTALK is installed, the smooth integration permits staff members to get a fast photo of entire processes, from CAD to BOM to production.

If you are utilizing CAD and ERP systems (including SyteLine, SYSPRO and Acumatica ), and wondering how you can increase performance, CADTALK is the answer! Save time, cash, and get your products to production earlier with our combination option. Schedule a demo today to see how CADTALK can assist you!.

3 Ways Integrating Erp Software With Cad Things To Know Before You Get This

Companies operating in the custom production market understand better than anyone that their clients have grown significantly demanding. These customers desire a quality, tailor-made product to be completed in a short timeframe. For the manufacturers who serve these consumers, fulfilling these growing, intricate needs suggests having actually business processes enhanced from the preliminary engineering phase to the minute the end product is shipped to the customer.

About Cad Integration - Automatic Cloud Erp

Enhancing the entire operation can be challenging if the engineering department is utilizing a CAD or item lifecycle management tool that is siloed from the ERP system the production department and other departments are using. Incorporating CAD and production processes is crucial to attaining the dexterity and responsiveness you require to satisfy the dynamic requirements of your requiring consumer base.

The 5 Reasons For Erp, Crm And Cad Integration For Business Diaries

Every savvy magnate today understands that having actually integrated systems that permit you is important in order to drive process improvement and productivity. Incorporating your CAD and ERP systems is essential for customized producers. Absolutely nothing in custom-made production happens up until a consumer shows up with a design and requests a quote.

This information will be gotten in by the custom manufacturer's engineering and style team into their CAD system - CAD ERP. The file output from the CAD system provides the maker with all the essential information about materials, part parts, assembly and subassembly requirements and whatever else required to make the product for the waiting customer.

Absolutely nothing in customized production takes place until a client appears with a design and asks for a quote This is where the integration in between the CAD and the abas ERP system comes into play. The ERP software application can take the CAD file and instantly equate the design and production requirements into practical info for usage in the manufacturing procedure.

The Greatest Guide To Cad Erp Integration For Manufacturing Companies

This is what seamless combination and optimization look like. It's an enormous benefit for your custom manufacturing business and your overall consumer experience, allowing you to deliver quality and do so faster than ever: abas ERP easily integrates with CAD software, permitting custom producers to equate engineering data into monetary and production details that equates into faster delivery times and delighted (even if requiring) consumers.

The ERP system instantly quantifies these and makes it easy to start finding appropriate suppliers. Instead of having your people scratching their heads (a highly-inefficient manual process), your ERP system incorporates with CAD and gets to work instantly solving the challenges. But beyond the production process, abas ERP with CAD combination can translate engineering information into dollars.

Even more, the automatic translation of engineering data into producing guidelines is a major time saver given that it minimizes redundant information entry and the opportunities of human error (due to several manual entries) in between functional areas. ERP CAD integration. Saving time boosts your own and your customer's experience too. Customized makers understands that because every job is an entirely new undertaking, it's not likely that whatever will go precisely as planned as soon as production begins.

Some Known Details About Erp And Cad Integration In 2020

These alterations send out the producer back to the style and engineering stage. Once again, the vibrant interaction between the CAD software incorporated into your ERP system makes this whole modification process much easier. The maker can go back into the CAD file, make the desired changes and let the integrated ERP system immediately upgrade to reflect any changes to the production process and monetary reporting.

Now that's working "wise" and perfectly. Custom producers are constantly searching for ways to meet client expectations on tight due dates while remaining successful. Having an ERP system that incorporates CAD, that also combines different practical locations flawlessly, is an effective way to attain these objectives. The end result of CAD and ERP system integration? Performances that please you, improve your quality and success, and (by the method) please your requiring customers too.

Makers who are engineer-to-order (ETO), design and develop products particular to a customer's requirement, have a huge chance to distinguish themselves in the market. Those ETO manufacturers who win in the market will have a complete Engineered Production Business SolutionTM (EM/ES) or (EMES) that incorporates everything from business resource preparation (ERP), customer relationship management (CRM) and computer-aided-design (CAD). Consumers are anticipating fast turnaround of quotes and orders with high quality, and the procedure of engaging sales, engineering, production and consumer service, all working in harmony, is necessary.

0 notes