Don't wanna be here? Send us removal request.

Text

The manufacturing of PCB Milling Boards

PCB Milling boards

Boards (circuits boards, printed circuit boards, …) can be manufactured in many ways, in this article, there’re two PCB milling ways we would like to introduce. The first way goes like this:

• Making a movie • Exposure of the photosensitive base material • Develop • Etching • Drilling • Decoating • Coating with soldering varnish

PCB Insulation milling

The second way of PCB manufacturing-PCB milling, which at first seems more attractive, is insulation milling. This requires the following steps:

• Generating the milling data, preferably as G-code according to DIN 66025 • Clamping the base material • Milling the contours of the conductor tracks • Drilling the holes for the components in the same clamping • Coating with soldering varnish

The following points speak for the insulation milling:

• The basic PCB material is cheaper • The panic with chemicals falls away • The production of a single PCB prototype is faster

On the other hand, it speaks against:

• You need an appallingly expensive CNC milling machine, along with the necessary control electronics and PCB software. Nothing should go below 2,000,- Euro total costs, even in self-construction. As a PCB manufacturer in China since 2006, MOKO Technology manufactures PCB with advanced CNC milling machines to assure good quality • Expensive carbide cutters are required for milling, which usually last only 1 – 2 European boards • Creating the milling data is not easy • Setting the PCB milling parameters is difficult and usually only works with trial and error • Milling a one-sided European board can take more than an hour • The milling dust (glass fibers!) may be harmful to health

PCB manufacturing procedure

If you still want to mill your printed circuit boards, here is the procedure you can use to produce the board shown above with the dimensions 100 mm x 60 mm. This is the control board of the spindle motor of the milling machine. The board is only one-sided, but the production of double-sided boards is possible according to the same process. It is important that a trace width can be created, which makes it possible to perform a trace between two IC connections. Otherwise, only very simple boards can be milled. The fact that it can be successful in this shows the following cut-out enlargement:

The trace width should be around 0.3 mm, the distance between the traces and soldering eyes about 0.4 mm. This means that the PCB board can also be soldered sensibly without constantly soldering traces with each other. However, this requires a decent soldering iron with a thin, long tip and good soldering wire (0.5 mm).

The software pcb-gcode

Without appropriate software, of course, nothing works. You can use the layout software Eagle to design the printed circuit boards, of course, if you find MOKO Technology, you can get PCB design as free with your PCB manufacturing need. Eagle has a freeware version for trying out and for smaller projects. This is also interesting for people who use a different layout program, as we will see later.

However, creating PCB milling programs for insulation milling is not a standard function of Eagle. But because it is possible to have such functions carried out by so-called “ULPs” (User Language Programs), a man named John Johnson has earned himself to write a suitable ULP.

The ULP can be downloaded from the CadSoft download page. First, look for the “PCB-gcode.zip” ULP. Unfortunately, there is no search function, but the ULPs are sorted alphabetically. Download the zip file and unzip all the files it contains to the c:-programs-EAGLE-4.12-ulp directory.

Now, if you type “run pcb-gcode -setup” in Eagle’s layout view on the command line, the following configuration screen should appear:

Here you set the following parameters:

1.Top Side (top of the PCB board, side of the component)

• Generate top outlines – Generate PCB milling data for the conductor tracks of the top • Generate top drills – Create drilling data for the top • Generate top fills – Create milling data to remove all copper between traces and soldering eyes (usually not required)

2.PCB Bottom Side (bottom of the board)

• How the parameters of the top

3.PCB Board (parameters that apply to the entire board)

• Generate Milling – generates milling data from the mill layer of the board (e.g. outline or larger cutouts) • Isolation Default – this should be a very small value, 0.0025 is OK • Isolation Maximum – the maximum width of the insulation • Isolation Step Size – how much wider the insulation becomes with each pass

4.CB Units (units of measure)

• Microns – thousandths of a millimeter • Millimeters – millimeters • Mils – Thousandths of An inch • Inches – inches (25.4 mm)

Then click on the “Machine” tab. The following window appears:

Here you set the following parameters:

5.Z-Axis (Z-Axis settings)

• Z High – A position that avoids collisions with clamping devices • Z Up — The position on which the Z-axis is driven over the board when positioning in a hurry. Should not be chosen too high to save time • Z Down – Intrusion depth of the cutter • Drill Depth, slightly more than the thickness of the printed circuit board • Drill Dwell – Bore time • Milling Depth – PCB Milling depth for outlines and cut-outs, slightly more than the thickness of the board

6.Tool Change

• Position on which the Z-axis is driven for convenient tool change

Spindle (milling spindle)

• Spin Up Time – Time in seconds to keep the spindle at speed • Etching Tool Size – Width of the engraving stitch for milling the trace outlines (see below)

7.Feed Rates

• XY – Feed speed for the X and Y axes during PCB milling • Z – Immersion speed of the cutter

Then click on the “GCode Style” tab. The following window appears:

Here you can now set for which PC control program the code should be generated. This is what a so-called “post processor” (.pp) does. As a fan of Mach3, I chose “Mach”. If there is no post-processor for the control program you are using, you can create one yourself by doing the following:

• Choose the post-processor that comes closest to the desired one • Then open the gcode-defaults.h file in the directory C:-Programs-EAGLE-4.12-up with the editor • Make the necessary changes • Do not change the format codes such as “%f”, “%d”, etc. • Save the file under a new name, e.g. “Cover.pp”

Then, when you click Accept, the configuration changes are saved. Clicking “Accept and make my board” saves the configuration changes and starts generating the milling and drilling data. Clicking “Cancel” discards all changes.

Generating PCB milling and drilling data in Eagle

Generating the data from Eagle is very easy, but some detail needs to be considered to create a usable circuit board. First, you should set the “Design Rules”. To do this, enter “DRC” on the command line or click on the corresponding icon. The design rules window appears.

First, click on the “Clearance” tab and set all distances to 16mil (0.4 mm). This is, first of all, a good starting point for your own experiments. Then click on the “Sizes” tab.

Set the minimum track width to 16mil (0.4 mm). This is important when working with the Autorouter. Then click on “Restring”.

Set the pads (component connectors) to 16mil. This ensures that they do not become too small. All values are those with which I work and with which I have achieved good results. Of course, you may be able to achieve better results with other values.

Then click “Check”. You will probably get a list of errors that complains of too few distances between the traces. Change the spacing accordingly. However, you can ignore too few distances where traces are performed between IC ports. They should not make the traces narrower there either.

If everything is fine, type “run pcb-gcode” on the command line

The following files are then generated, all of which have the name of your schematic file, to which the following extensions are attached:

• top.nc: the trace outlines for the top of the board • bot.nc: the trace outlines for the bottom of the board • tf.nc: Milling data to remove the remaining copper on the top (usually not necessary) • bf.nc: Milling data to remove the remaining copper on the bottom (usually not necessary) • td.nc: Drilling data, seen from the top. In the beginning there is a table with the required drill diameters. Due to the conversion inch millimeters with partly “crunch” values. Just take the drill that comes closest.

These are to be used in the production of one-sided boards, otherwise, the board would have to be turned over. mt.nc: Milling data for outlines and cutouts, seen from the top. mb.nc: Milling data for outlines and cutouts, seen from the bottom.

These files are written to the same directory as your schematic file.

For a first test, you can now open the top.nc or bot.nc in Mach3 and view the result. Presumably, the display of the milling webs is outside the preview window. Therefore, reduce the size of the display until you see the board. Then move and move them until you have a clear picture:

Click on the image to see it in full size and check the outlines of the traces and component connectors. Particularly critical are the places where traces are carried out between component connections. If there is no milling track between the conductor track and the connection, then you must reduce the width of the milling stitch in the configuration (Etching Tool Size).

Clamping the board

To be able to mill the board, you must first clamp it. It makes a significant difference whether you work with an engraving depth controller or not. The engraving depth controller ensures that the PCB milling stitch always has the same immersion depth at all points of the board. Because the Stichel is V-shaped, the depth determines the width of the insulation, i.e. the milled web. If this becomes too wide, then your traces disappear into the nirvana, it becomes too narrow, copper stops and leads to short circuits. The depth controller on my machine looks like this:

The short pipe at the front is the connection for the vacuum cleaner, the micrometer screw is used for height adjustment. I will describe how the depth controller works and is built elsewhere.

Because the engraving depth controller presses the board firmly on the underlay, it does not need to be secured against lift-off. Instead, it is important to secure the board against slipping. For this purpose, I have built a frame consisting of 1.0 mm rigid aluminum sheets on a wooden plate.

Two sheet metal strips form an angle into which the board is pressed by two wedges of the same material. The image should make the principle understandable. This type of fastening has the advantage for series production that the boards are always clamped in the same position. So I can first mill all the boards and drill them in one pass without having to constantly change the program and the tool.

The PCB milling tool

You can use engraving stitches for milling, which are parts made of carbide round rods, in which half is ground away in the lower area. These are then sanded at different tip angles. The grinding angle is always half the size of the tip angle. The tip is slightly sanded, resulting in a cutting edge. Cutting width and tip angle can be selected when ordering. So far, I have achieved the best results with 0.1 mm cutting width, a tip angle of 40° and a milling depth of 0.2 mm. The drawing shows a trick:

The shaft diameter should be 3 mm, which also fits with Proxxon collets. There are also stitches with 1/8 inch shaft diameter, which do not fit properly into the 3.2 mm collet and tend to “egg”. Take a look at eBay, there are several vendors. Make sure that you get stitches with a finished cut edge, you have to grind stitches without cutting with a stitch grinding machine yourself.

Workpiece zero point

The workpiece zero points is located on the left front edge of the PCB board in the milling data for the top. At the bottom, however, it is located on the right, front edge. All coordinate values of the X-axis are negative!

Height

If you work with an engraving depth slider, you know how to adjust the height. Otherwise, the easiest way is to clamp a cutter and drive it over the board for a short time. Then loosen the chuck and drop the cutter onto the board. Then tighten the feed again and set the Z-axis to zero. Don’t forget to drive the Z-axis up a bit again!

Immersion depth

The immersion depth is very critical because this results in the width of the PCB milling web. The formula for this is:

Cutter 40°: Width = Immersion Depth * 0.7279 Cutter 60°: Width = Immersion Depth * 1,1547

You need a certain minimum immersion depth (0.15 – 0.2 mm in my experience), otherwise, a ridge will be created at the milled webs. Since inaccuracies of the machine also play a role, I advise trying some of the pieces of waste.

Spindle speed

The speed of the milling spindle should be as high as possible in order to achieve a burr-free cut. Spindle speeds from 20,000 rpm are OK. However, on my machine with 6,000 rpm also quite clean boards are available.

Milling

Now it’s time to start! Also pay attention to the necessary safety distance of the cutter and that there are no clamping means in the way. Don’t forget to turn on the spindle! You probably won’t be satisfied with the first result and will have to experiment a bit.

Drilling

One of the charms of the process is that you can drill the board immediately. To do this, you need the drilling data on the respective page. The holes go through the whole board in any case but are mirror-image at the bottom to the top, i.e. also with the drilling data the zero points of the bottom is the right front. As soon as a drill change is required, the PCB milling program stops and moves the spindle to the position you specified for the tool change.

Double sided PCB

As already mentioned, the production of double-sided boards is also possible. To do this, place a separate, small hole in the layout of the board and note the coordinates. To do this, enter “info” on the command line and click on the hole. You will then see a small window

The first coordinate (52.07) is the X-axis, the second is the Y-axis, seen from the top. If you turned the board after milling and drilling the top, position the center of the milling spindle exactly over this hole and enter the coordinate values as the X and Y positions in the controller. You have to enter the X-coordinate as a negative value!

Other PCB layout programs

If you are working with a different layout program, you can read the Gerber and Exelon data using the Eagle Power Tools and then generate the milling data from it, and as per a PCB manufacturer that you can trust, MOKO Technology can be a good choice as we’re professional in manufacturing and assembling printed circuit boards since 2006, we’re also open to answer any of your questions on the issues of your PCB boards!

0 notes

Text

What is High Tg PCB

High Tg PCB Board

Tg means glass transition temperature. There are also a lot of different High Tg PCB materials that are not listed here, other countries, other companies prefer different materials. If without special notification, we will normally use SYL’s S1170.

6 layers high TG FR4 PCB with blinded holes

Board thickness: 1.6 mm

Minimum. Hole diameter: 0.3 mm

Minimum. Line width: 5.0mil

Minimum. Line spacing: 4.8mil

Surface treatment: immersion gold

Were they from high-TG materials?

The access to a high high-TG material is that it is possible to increase the continuous operating temperature and thus also to higher currents. The continuous operating temperature is the temperature at which the circuit board can be operated continuously without being damaged. Gold plated as a rule of thumb that the TÜV is at about 20 ° C below the specified TG. This difference should serve as security because that means that loading on the TG definitely leads to the destruction of the circuit board.

High-TG material certainly feels like a “special technology”. In the automotive industry, this material is in demand due to the higher temperature resistance – with increasing authorizations and ever-increasing settings. TGs around 130 ° C is the lowest limit of FR4 materials today, but many many multilayers will become TG150 ° C. The temperature of the glass transition The temperature at which the material initially softens because the glass fiber fabric softens.

Exactly from high-TG material one speaks practically from a TG of 170 ° C. This high-TG material up to TG170 ° C becomes like normal FR4 based on epoxy resin and how it should be like a normal circuit board. The exceptions in the process are a drilling parameter because the material contains special fillers. A high TG material can be taken care of, taken care of one eye and taken care of more.

How are the high-TG materials ordering rights?

At Bittele Electronics we offer complete solutions for PCB assembly for all types of requirements related to the production of high-quality PCBs and PCB assembly. One of the most common special requirements for PCB manufacturing is the requirement for high-temperature tolerance to withstand the demanding operating conditions and/or environments.

Our customers often have questions about the temperature requirements for the PCB assembly process itself and whether a certain material selection is required for the lead-free PCB assembly or not.

High TG PCB manufacturer and manufacturing ability

Moko Technology can produce high-Tg circuit boards with a Tg value of up to 180 ° C.

The following table lists some of our commonly used materials for manufacturing high-temperature circuit boards.

Material TG

(DSC, ° C) Td (Wt., ° C) CTE-z (ppm / ° C) Td260 (Minimum) Td288 (Minimum) S1141 (FR4) 175 300 55 8 / S1000-2M (FR4) 180 345 45 60 20 IT180 180 345 45 60 20 Rogers 4350B 280 390 50 / /

One can refer to our direct relationship table as a guideline:

Material TG TÜV FR4 standard TG 130 ° C 110 ° C. FR4 medium TG 150 ° C 130 ° C. FR4 high TG 170 ° C 150 ° C. Polyimide super high TG material 250 ° C 230 ° C.

The properties of high Tg materials are listed below:

Higher heat resistance Lower the CTE of the Z-axis Excellent thermal resilience High resistance to temperature changes Outstanding PTH reliability Pcbway offers some popular high tg materials S1000-2 & S1170: Shengyi materials IT-180A: ITEQ material TU768: TUC material

Types of PCB board material

There are many types of PCB board material, each board specification is different, its material, price, parameters, etc. are also different.

Depending on the grade from low to high:

The details are as follows:

94HB: ordinary cardboard, without fireproof (the lowest material, punch, can not make PCB power).

94V0: flame retardant cardboard (punched holes).

22F: one-sided half-glass fiber plate (punched holes).

CEM-1: single glass fiber plate (must be drilled by the computer, holes cannot be punched).

1. The quality of the flame retardant properties can be divided into four types: 94V-0 / V-1 / V-2/94-HB

2. Prepreg: 1080 = 0.0712 mm, 2116 = 0.1143 mm, 7628 = 0.1778 mm.

3. FR4, CEM-3 are all for material type, FR4 is fiberglass and CEM3 is the composite substrate.

4. Halogen-free is a substrate that does not contain halogen (elements such as fluorine and iodine), since bromine produces toxic gases when burned, it is not harmful to the environment.

5. Tg is the transition temperature of the glass, namely the melting point.

Moko Technology has been a professional circuit board manufacturer for many years, can provide customers PCB solution for most types of circuit boards from one source, just contact us freely.

We are one of the leading Chinese manufacturers focused on the manufacture of FR4 circuit boards. If you are interested in our PCB solution for the high TG fr4 board, please contact our factory. We are certain that we can offer you the best quality products on time and excellent service from a single source. Hot Tags: PCB solution for high TG fr4 board, china, factory, manufacturer, manufacturing

Why is none of the TG specified in the datasheets?

With some common high-frequency materials, the TG is not taken into account in datasheets. This is due to the technical origin of the importance of the TG concentration since this is the “glass transition temperature”. In principle, this is also the case for polyimide material. In general, with ceramic or PTFE material you can usually have a “TG” of 200 ° C or more.

What should you think about flexible polyimide boards?

Rigid flex circuit board

With flexible printed circuit boards, it should be noted that despite a polyimide, they are usually also equipped with an epoxy component. Even with adhesive-free material, an adhesive would come into play when the cover film or stiffeners were stuck on, as a result of which the TG of the flexible circuit, despite polyimide as the main component, lies in the area of the epoxy.

What can a solder resist withstand?

Conventional solder resists sometimes have a load limit well below the material’s TG. For high TG material for applications above these areas, we, therefore, recommend either manufacturing without solder resist and, if necessary, protecting the entire assembly with appropriate high-temperature protective lacquers. Alternatively, discoloration of the paint at very hot temperatures should be expected.

Then please contact us and we will be happy to supply prototypes from Asia so that the later series material can be correctly qualified.

“Tg” refers to the glass transition temperature from a printed circuit board, indicates the point at which the board material begins to transform. We manufacture standard printed circuit boards with materials offering a TG value of 140 ° C, which can withstand a moderate operating temperature of 110 ° C. Incidentally, PCBonestop also offers high TG printed circuit boards to online customers.

If the Tg of PCB substrate is increased, the heat resistance, moisture resistance, chemical resistance and stability of printed circuit boards will be improved as well. The high Tg applicates more on top free PCB manufacturing processes.

Therefore, the difference between general FR4 and high Tg FR4 is, when hot, especially in heat absorption with moisture, high Tg PCB substrate will perform better than general FR4 in the aspects of mechanical strength, dimensional stability, adhesiveness, water absorption, and thermal decomposition.

China high TG PCB supplier

High TG PCB – High-temperature PCB for PCB applications that require high temperatures.

In recent years, more and more customers have asked to produce high Tg circuit boards.

Since the flammability of the printed circuit board (PCB) is V-0 (UL 94-V0), the printed circuit board changes from the glassy to the rubbery state when the specified Tg value is exceeded and the function of the PCB is impaired.

If your product is operating in the range of 130 degrees Celsius or higher, you should use a circuit board with a high TG for safety reasons. The main reason for the Hi TG board is the shift to RoHS boards. Because of the higher temperatures required for the lead-free solder to flow, most of the PCB industry is moving towards Hi-TG materials.

Attempting to reduce heat build-up on your circuit board can affect the weight, cost, performance requirements, or size of your application. As a rule, it is cheaper and more practical to simply start with a high temperature, heat resistant circuit board.

If your application is at risk of exposing your PCB to extreme temperatures or the PCB has to be RoHS compliant, you should consider high TG PCBs.

Multi layer circuit boards with many layers

Industrial electronics Automotive electronics Fineline trace structures High-temperature electronics

Heat dissipation considerations

High TG PCB circuit boards are very important if you want to protect your circuit boards from the high temperatures of the application process or the extreme temperatures of the lead-free assembly. However, you should, of course, consider several methods of pulling the circuit board Extreme heat generated by electronic applications away from your board.

What is FR-4?

FR-4 circuit boards are divided into four classifications, which are determined by the number of copper trace layers contained in the material:

• Single-sided circuit board / single-layer circuit board • Double-sided circuit board / double-layer circuit board • Four or more than 10 layers of PCB / multilayer PCB

High TG PCB advantages

High glass flow temperature (TG) High-temperature resistance Long peel resistance Small expansion of the Z-axis (CTE)

High TG PCB Application:

Automobile

Backplanes

Server and network

Telecommunications

Data storage

Heavy copper application

Main features

Advanced high Tg PCB resin technology

Industry-standard material with multi-functional epoxy resin with high Tg (175 ℃ from DSC) and excellent thermal reliability.

The world is going green – Why are halogen-free base materials the better solution when PCB requirements are high?

According to IEC 61249-2-21: Definition of “halogen-free” the following applies: – maximum 900 ppm chlorine – maximum 900 ppm bromine – a total maximum of 1500 ppm halogen As a result, halogen-free materials predominantly use phosphorus, nitrogen, ATH as halogen-free flame retardants.

Today, modern base materials are classified according to the following UL classification, which also expresses the different nature of the base material in the standardization. FR 4.0 – filled and unfilled epoxy resin systems Tg 135 – 200 TBBPA FR 4.1 – filled and unfilled epoxy resin systems Tg 135 – 200 halogen-free

A new additional classification has been available for two years: FR 15.0 – filled epoxy resin systems TBBPA RTI 150 ° C FR 15.1 – filled epoxy resin systems halogen-free RTI 150 ° C The replacement of the flame retardant TBBPA with halogen-free flame retardants is linked to other chemical properties of the resin systems. The bonding energy of the resin system increases significantly and serves as the basis for the improved thermal properties of the halogen-free materials. This increased binding energy also improves the adhesion problem with the glass fabric, which in turn has a positive effect on the CAF performance. The lecture shows various examples of improved properties such as heat stability and CAF behavior in small HW-HW, which have been proven in practice.

Factors to consider in terms of thickness

Compatibility with components: Although FR-4 is used in the manufacture of numerous types of printed circuit boards, its thickness affects the type of components used.

Space requirements: When designing a circuit board, it is extremely important to save space, especially with USB plugs and Bluetooth accessories.

Design and flexibility: Most manufacturers prefer thicker printed circuit boards. With FR-4, a carrier that is too thin could break if the circuit board is enlarged. Thicker PCBs are flexible and at the same time allow “V-grooves” (notch cuts).

The environment in which the circuit board is to be used must be taken into account. With electronic control units in the medical field, thin printed circuit boards guarantee lower loads. They can bend and deform when the components are soldered.

Impedance control: The thickness of the printed circuit board includes the thickness of the dielectric medium, in this case, the FR-4, which facilitates the impedance control.

If you want to integrate your printed circuit boards in products where the use of components is not easy and which are not very suitable for a rigid printed circuit board, you should also prefer another material: polyimide/polyamide.

Product category of high TG PCB, MOKO Technology is a specialized manufacturer from China, blank PCB, high TG PCB supplier/factory, wholesale high-quality products of high TG PCB r & d and production, we have the perfect after-sales service and technical support. Look forward to your cooperation!

0 notes

Text

Extremely high density PCB

High density PCB construction

High-density ICs force high density PCB designers to find new design strategies to either have more functionality on smaller plates – in end-user products – or much more function on larger parts.

Another generation of smaller elements on integrated circuits is on the way. This is in the 65 nm range, but some IC manufacturers are already developing prototypes with 45 nm elements. The smallest elements in currently produced ICs, about 90 nm, already conflict with the physical basis of the connection.

Printed connections, or tracks, can only be small until signal integrity and performance distribution problems occur on the disk. The assembly of the new chips on each plate type will require both some new strategies as well as those used in the past.

These problems in the design of printed circuit boards are known: receiving signals from ICs and sending them to ICs, maintaining signal integrity, and distributing power to the components of the disk. Signal integrity means avoiding crosstalk, which occurs when traces are too close to each other, and managing impedance to avoid signal reflections that are more likely to occur in too long a track because they occur on very large high density PCB plates

There is also a new complication: very short rise and fall times. Then, even with very short tracks, potentially additional impedance problems may occur.

Five years ago, a Terabit Internet router was a top product. It contained 52 PCBs and was half a rack or 3 feet high, 2 feet deep and 18 inches wide. Now the router has only one PCB and is only 1.5 inches high. If we had been told at the time that an IC could house billions of transistors and 10 Gbps-compatible tracks, we would have laughed. Now I don’t know if there are any size and speed limits at all.

The signal integrity issues on disks with smaller ICs and tracks can often be handled with familiar techniques: managing track size and separation to minimize crosstalk and construct track connections with appropriate resistors to avoid reflections. We consider thousandths of an inch as minimum track width, and 7 to 8 thousandths of an inch as the minimum distance between them, no matter how many pins a chip has. He prefers a separation of 10-thousandths of an inch.

New PCB Architectures

The design of high density PCB has taken two paths. One leads to the PCBs that are really high-density, used in mobile phones, digital cameras, and other consumer and home electronics devices, where all circuits fit on a thumb nail-sized board and power must be distributed sparingly to extend the service life between individual charges. The other leads to high-performance PCBs in supercomputers, extreme high-speed routers, and similar systems.

On these tiny PCBs, PCB designers don’t have to squeeze components in confined spaces, but performance with low power requirements is everything. Larger PCBs operate at very high speeds. The two types of high-density disks have different problems, while designers scale down to the next generation of ICs with smaller elements.

For high-performance disks with ICs that have 1,000, 2,000, or even more pins, the physical limits imposed by standard connections probably require radically different design techniques.

One example, a self-proclaimed signal integrity evangelist whose company, be The Signal, is located in Olathe, Kansas, is a cube-shaped 3-D PCB.

This is not a collection of stacked layers. It’s an integrated design that’s specific to 3-D, where all important processes run vertically across multiple layers of processors.

Other techniques focus on laminates. Manipulation of laminate material can help reduce signal loss, and very thin plates can support shorter and more connections. Some new production laminates are only 2 thousandths of an inch thick and become thinner. According to Bogatin, these laminates can allow designers to halve the number of layers in a PCB while improving performance provision.

Operating speeds of high density PCB increased from 10 to 20 MHz in the 1980s to gigabit-per-second in the 21st century. In the 1980s, you could design a plate with your eyes closed. Now you have to open both eyes wide.”

Simulation and training

As the panels become more complex and their manufacturers don’t want to waste 1,500-pin ICs due to poor design, simulation and modeling are critical to PCBs. If something doesn’t work, you need to take qualified action, and you can’t get on with tried-and-tested rules of thumb. Disks are increasingly similar to ASICs [Application Specific Integrated Circuits], and now we increasingly need the same type of simulation as for as ICs. Simulation tools that generally do this are now available, but performance integrity toolsets are still missing today.

Extremely high density PCB

MOKO Technology shows the technology platform Dencitec, which allows an extremely high density of integrated functions for printed circuit boards with high throughput.

These options include conductor and spacing widths of up to 25 μm with copper thicknesses of 20 ± 5 μm on all conductive layers, laser via diameter of 35 μm, residual rings with a diameter of 30 μm on the inner layers and 20 μm on the outer layers, copper-filled blind vias with the possibility of via stacking and vias in pads. This leaves more space for the integration of additional options such as energy supply (batteries, etc.). In addition, modern materials enable the manufacture of ultra-thin circuits, such as four-layer flex circuits with a total thickness of fewer than 120 μm. In contrast, commonly used standard processes only deliver good results up to conductor widths and spacings of 50 μm and classic semi-additive processes such as thin-film technology enable conductor widths and spacings of less than 15 μm but are generally limited to production formats.

A simulation of the galvanic copper deposition in the PCB production

Before we produce a high density PCB board, we carefully analyze the data received. This is how we find all potential effects on production, which could impair the quality and long-term reliability.

Until now, electroplating has been a field in which hardly anyone has been able to determine exactly how a particular design will behave. The copper layer thickness that is deposited on the circuit board depends on the layout density. If the density is low, we risk building too much; if the density is high, we risk too little build-up. A copper structure that is too strong means that the holes in the holes become too small. A copper structure that is too low means that the hole walls are too weak so that the plated-through holes can break during assembly and lose their long-term reliability.

The goal is a uniform copper density and a uniform structure over the entire circuit board. We take this into account as much as possible when placing the printed circuit boards on our production benefits. We can place additional copper patterns (so-called compensation surfaces) between and around the circuit board to compensate for the density. Nevertheless, we are limited to these methods because we cannot modify the actual design of the circuit board. Only the developer can do this.

Historically, there have been no developer tools to determine copper density. Today MOKO Technology offers a solution with a color-coded image of the printed circuit board, which shows the potential areas of the superstructure and substructure of copper.

We use special Galvano-simulation software that divides the board into small cells. The copper density of each cell is compared to the average copper density of the entire circuit board and color is then assigned to this cell. A copper density lower than average is colored on a scale from green (average), yellow and orange to red. The more red, the lower the relative density and the higher the risk of excessive copper build-up in this area. Cells with a higher copper density are colored on a scale from green to dark blue. The more blue, the greater the risk of insufficient copper build-up.

Armed with this visual data, the developer can add copper areas in low density areas or reduce large copper areas.

In addition, we will provide a galvano index that measures the uniformity of the copper density on the circuit board. A completely uniform circuit board has an index of 1. This means that no electroplating problems are to be expected. Lower values show less uniformity and are highlighted on the visualized image by red and blue areas. If the index falls to 0.8 or less, special attention is required. In the example shown above, the galvano index is 0.65. The blue area, which is too small, can be clearly seen.

The galvano picture is created when a new order is placed. This galvano picture is part of “PCB Image”, a realistic representation of your printed circuit boards, which we will send you together with the order confirmation. In the near future, this simulation will become part of the price request function. We will do a number of checks and create a report from them. Based on the galvano picture, which was also created, the designer can see whether he can make changes to improve the uniformity of his high density PCB circuit board.

After the modification, the galvano index is 0.95. The picture shows a uniform copper deposition.

Galvano simulation – good galvano index layer pattern – good galvano index

Of course, there may be design restrictions that make a less uniform copper density unavoidable. For this we are preparing another solution to improve the quality and reliability of the finished printed circuit board. The Elsyca Intellitool anode matrix project will further improve the uniformity of the final copper structure.

More packing density for complex electronics

The high density PCB boards have to keep up with the advances in microchips. Circuits with a high packing density represent a technological leap, which should have as far-reaching consequences as the transition to surface mounting in the mid-eighties.

Progressive miniaturization of components, chips, and systems will mean a drastic technological leap for printed circuit board manufacture in the coming years as well as due to the introduction of surface mounting (SMT) in the mid-eighties. The highest growth rates are currently to be expected in the field of high-tech circuits because the integration success of the microchips means that the connection technology is also required. The challenge is to produce the finest structures for printed circuit boards with high integration density (High-Density Interconnection – HDI) economically.

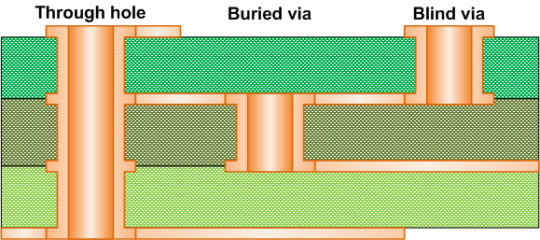

So far, the contacting problems with multi-pole components have been solved by moving some of the connections to one or more additional signal layers. However, the production of multilayer circuits (multilayer) is comparatively complex and therefore costly. However, the number of layers can generally only be reduced by using finer conductor pattern structures or by using smaller hole diameters. In order to electronically connect the individual signal layers of the circuit board to one another, the conductor tracks are so-called vias, i. H. drilled and then metalized holes led to the next level or the underside of the plate. Since a printed circuit board can have several thousand holes, there is enormous potential for savings simply by reducing the hole diameter. Mechanically, however, such micro holes (micro vias) with a diameter of less than 0.1 mm can only be produced with lasers, whereas traditional drilling at 0.2 mm reaches its limits.

However, micro vias are only the first step towards even more complex circuits in fine-wire structuring. The particularly critical work steps here include the entire photo process, with the help of which the copper cladding of the circuit board base material is usually structured. The ultra-fine conductor technology places particularly high demands on the exposure and on the subsequent etching step. If structures with a width and spacing of less than 0.1 mm are to be realized in series production, the production yield drops dramatically in some cases. This can be remedied by new production methods that significantly simplify the entire photo process. This includes direct laser exposure, which describes the photoresist directly with the conductor pattern. The conventional exposure step using a film is completely eliminated.

Technically, direct exposure is superior to previous contact exposure because it offers more flexibility with regard to lot sizes and a higher structure resolution. The number of process steps can thus be significantly reduced. Running costs for clean room, films and masks, photoresists as well as the resulting expenses for the disposal of environmentally harmful materials and residues are also reduced with this procedure. Higher yields can be achieved especially with very fine conductors, since the high coherence of the laser beam enables reliable imaging of the smallest structures with minimal under-radiation. And due to the higher depth of field of the direct imagesetter, even differences in height can be compensated to a certain extent. Automatic optical panel measurement and individual usage indicators are also conceivable as additional functions. Laser direct structuring is even easier, in which the laser mills the conductor pattern directly into the copper cladding, which means that a resist is no longer required.

Chinese companies are also leaders in the development of new connection technologies. “MOV” from the Karlsruhe company Inboard is a new concept and stands for multi-layer surface wiring. This new type of high density PCB circuit board is also called an “integral circuit board” because electronic components such as resistors and capacitors are integrated into the circuit board.

The integrated circuit board not only offers finer conductor track structures and laser-drilled blind holes of less than 80 µm in diameter for contacting the conductor tracks, but the electrical data are also impressive. Compared to conventional multi-layer wiring, the cable length with the same function is reduced by 35%. The number of vias through all layers is even reduced by 80%, the number of signal layers in a reference example from six to only two.

But it is important that you can get by with one-sided assembly technology again. Resistors and capacitors can be included as “printed” components. This new development was triggered by the increasing demands on the working frequency, the number of component connections and ever-smaller designs such as ball grid array and chip size packaging. For example, with 50 printed resistors on a printed circuit board, there is a cost advantage over SMD assembly, according to the inboard.

Moko Technology is working on cost-effective solutions for optical data transmission. A strip-shaped optical fiber made of plastic, which is attached to a so-called backplane, connects hardware components in the computer via very flat, light-conducting plastic strips of up to 50 cm in length. The novel manufacturing process for the strip waveguide is suitable for any carrier materials, in particular for printed circuit board material. We take a different approach and integrates the optical conductors produced by hot stamping into special circuit board layers. This enables passive optical components such as branches to be implemented, which allow optical wiring analogous to electrical circuit board technology. The circuit board is evolving from a simple connecting element to a complex assembly.

0 notes

Text

What is Blind microvia

Increase The Integration Density of PCB by filling blind microvia and through holes using electrolytic copper deposition.

The progressive miniaturization of electronic circuits increasingly requires the use of HDI circuit boards with copper-filled blind microvias. A newly developed copper electrolyte, which is currently being tested under production-related conditions, enables defect-free filling of blind microvias with a small copper layer thickness on the circuit board surface. A copper electrolyte currently in development should also enable the reliable filling of through holes in the future – the current development work is already showing promising results.

Filling of Blind Microvia and Through-holes

Increasing the Packaging Density of PCBs by Filling of Blind Micro-vias and Through-holes by Electrodeposition of Copper.

The increasing miniaturization of electronic circuits makes the use of HDI PCB (HDI printed circuit boards) with copper-filled blind micro-vias, increasingly desirable. A newly-developed copper electrolyte, currently under test in simulated production conditions, will enable defect-free filling of blind micro-vias while at the same time allowing reduced copper deposit thickness on the board surface. This brings with it a more efficient use of materials her and thus a reduction in the cost of PCB manufacture. Another copper electrolyte now under development promises to allow a reliable filling of through-holes.

1 Introduction

In microelectronics, there is still a trend towards miniaturization, that is, towards smaller and more powerful systems that are also supposed to be less expensive than previous systems. The best-known examples of this are smartphones and tablet PCs, the performance of which – in spite of the same or even smaller device size – has increased significantly in recent years.

HDI printed circuit boards (HDI: High Density Interconnect) make a significant contribution to miniaturization. For the electrical connection of individual PCB layers, space-saving blind holes (blind microvias) are used instead of through holes. The integration density can be further increased by filling the blind microvias with electrolytically deposited copper (blind microvia filling). In the meantime, the use of HDI circuit boards is no longer restricted to mobile electronics, but is also increasingly being used in other applications, for example in the automotive sector.

A newly developed electrolyte, which in the Blind Microvia Filling only deposits a very small layer thickness of copper compared to the previous generation of electrolytes, enables the resource, energy and cost-efficient production of HDI printed circuit boards.

Since the integration density of HDI printed circuit boards can be increased even further by using very thin core materials, the development of electrolytes for filling through holes (English: Through Hole Filling) is currently being strengthened. Results of the development work in this area are presented.

2 Miniaturization in the field of microelectronics

The best known representatives of the progressive miniaturization in microelectronics are the very powerful mobile devices such as smartphones and tablets. The high and constantly growing sales figures reflect the great attractiveness of these devices. In 2013, more than 1 billion smartphones were sold for the first time, sales of around 1.2 billion are expected in 2014 and around 1.8 billion in 2017 [2]. In the area of tablet PCs, sales of 271 million devices are predicted for 2014, which corresponds to an increase of almost 40% compared to the previous year [3].

These are installed in processors with very small housing sizes and a very large number of increasingly grid-like connections. The underside of the processor has 976 connections on an area of just under 2 cm², this corresponds to around five connections per square millimeter. The pitch of the connections is only 400 µm.

3 Miniaturization in the area of printed circuit boards

Printed circuit boards with a correspondingly high integration density are required for space-saving and reliable electrical connection of processors with extremely high connection densities. The classic multilayer printed circuit board is unsuitable for this, however, since it uses through holes for the electrical connection of individual printed circuit board layers. These have relatively large diameters and, since they are drilled only after the individual layers have been pressed, they extend over the entire circuit board thickness. The consequence of this is that even when directly adjacent layers are connected, the space above and below the actual connection is lost and therefore cannot be used for other structures, for example, conductor tracks. The resulting low integration density of multilayer circuit boards is not sufficient for the requirements described above.

A few years ago, a new, highly integrated generation of printed circuit boards, the so-called HDI circuit board, was therefore developed, which was initially used primarily for the production of mobile phones. When manufacturing HDI printed circuit boards, the individual printed circuit board layers are built up successively (SBU, Sequential Build Up). The electrical connection of adjacent assembly positions is realized using laser-drilled blind microvias. Figure 2 shows schematically the structure of a 2-4-2 HDI circuit board, i.e. the circuit board consists of a four-layer multilayer core and two layers on each side.

4 Blind microvia

Compared to through holes, blind microvias have smaller diameters in the range from 50 µm to 150 µm and they only extend in the z-direction over the thickness of a mounting position (typically 50 µm to 150 µm). They only take up as much space as is actually required for the actual connection. HDI printed circuit boards thus have a much higher integration density than multilayer printed circuit boards and are therefore suitable for the signal unbundling of highly functional electronic components in the smallest space.

4.1 Filling blind microvia

A further increase in the integration density enables stacked blind microvias (stacked blind microvias). If electrolytically deposited copper is used for filling instead of conductive paste, this leads to the following further advantages:

Increased reliability (the blind microvias only contain copper, there is no additional interface) better heat management (heat loss can be dissipated via the highly heat-conductive, copper-filled blind microvias) Further increase in integration density (no additional pads (pads) are required on the circuit board surface for contacting components) The main process steps in the manufacture of HDI circuit boards with copper-filled blind microvias are shown schematically in Figure 4. If a further layer is to be built up, the process sequence must be run through again starting with process step 2.

Stacking copper-filled blind microvias on top of each other means that even non-adjacent assembly positions can be connected in an electrically conductive manner with minimal space requirements (Fig. 5). The use of pad-in-via or via-in-pad designs leads to a further increase in the integration density, since component connections can be soldered directly onto the copper-filled blind microvias, so that no additional connection surfaces are necessary (Fig. 6).

4.2 Previous electrolytes for blind microvia filling

Typically, electrolytes for blind microvia filling contain a relatively high concentration of copper ions in the range from 40 g / l to 60 g / l in combination with a low sulfuric acid concentration in the range from 10 ml / l to 50 ml / l as well as chloride ions. The organic electrolyte additives required to control the coating properties differ from specialist company to specialist company, but mostly the following three components are contained in the electrolyte additives:

Basic additive (inhibitor) Grain Refiner (Activator) Leveler (inhibitor) In addition, the methods of the different providers can also differ in the following features:

System technology (standard vertical system, vertical continuous system, horizontal continuous system) Anode type (copper anode, insoluble anode) Current form (direct current, pulse current, reverse pulse current) applicable current density

The methods previously offered by Schlötter for blind microvia filling work exclusively with direct current in standard vertical systems or vertical continuous systems.

In the early years of blind microvia filling, there were essentially the following additional requirements in addition to the standard requirements for electrolytically deposited copper coatings for printed circuit boards (e.g. ductility, reliability):

defect-free filling of the blind microvias without electrolyte inclusions Minimum filling level or the maximum allowed deepening (dent.

During the filling process, 93 µm copper (B) was deposited in the blind microvia, while the layer thickness on the surface is only 22 µm (C), resulting in the following key figures:

Indentation (A-B): 30.4 µm

Degree of filling (B / A): 75%

Metal distribution (B / C): 426%

It is primarily due to the mode of action of the leveler, by means of which the copper is not deposited on the surface but rather in the blind microvias, i.e. in the areas of low current density and low electrolyte exchange.

To achieve a good filling result, the electrolyte additives must be very well coordinated. Figure 8a shows a blind microvia before the filling process as well as different results, which can only occur through variation of the electrolyte additives – with otherwise the same separation parameters (Fig. 8b – e).

4.3 New electrolyte for blind microvia filling

The integration density of the circuit boards can be increased even further by reducing the track width and spacing. For the etching of such fine conductors, however, the copper layer thickness on the surface must be low, since otherwise severe undercutting and problems with the conductor cross-section can occur.

As shown in Figure 4, the copper layer thickness can be reduced after filling with – possibly repeated – copper thinning, but additional process steps and systems are necessary for this. In addition, copper thinning of copper that was previously deposited is partially removed, which has a negative impact on resource, energy and cost efficiency in the manufacture of printed circuit boards. To completely avoid – or at least to reduce – the copper thinning, in addition to the requirements already mentioned, the requirement to deposit the smallest possible copper layer thickness during the filling process has been added in recent years.

50-70 mg / l chloride

3–10 ml / l additional slotocoup SF 31

0.2–1.0 ml / l additional slotocoup SF 32

0.2–2.0 ml / l additional slotocoup SF 33

The electrolyte is operated at current densities of maximum 2 A / dm² in the temperature range between 18 ° C and 22 ° C.

Compared to the previous generation of electrolytes, the copper layer thickness deposited on the surface could be extremely reduced. This is shown by the metal distribution, which in the laboratory test shown has an extremely high value of over 2000% (Fig. 9b).

Slotocoup SF 30 is currently being tested in cooperation with the Taiwanese Schlötter partner AGES in the PCB Development Center in Taipei opened in 2012 under production-related conditions in a 7200-liter vertical continuous system (Fig. 10).

Deepening: 7.0 µm

Degree of filling: 91%

Metal distribution: 740%

Figure 11b shows another copper-filled Blind Microvia, which comes from the same circuit board as the Blind Microvia in Figure 11a. It is noteworthy that, despite the non-optimal BMV geometry, the filling result is very good.

Slotocup SF 30 also enables defect-free filling of closely spaced blind microvias with a low layer thickness of the copper surfaces.Fig. 12: Slotocoup SF 30 test results when filling closely spaced blind microvias

Very flat blind microvias, which result when extremely thin dielectrics are used, can also be filled defect-free with the new electrolyte, but this results in somewhat higher copper layer thicknesses (Fig. 13).

5 Through Hole Filling

A further increase in the integration density of HDI printed circuit boards can be achieved by replacing the relatively thick multilayer cores that have been used up to now with significantly thinner cores with thicknesses between 100 µm and 200 µm.

Very thin cores can also have through holes instead of blind microvias. Previously, these through holes were first filled with paste after the first copper plating and then copper-plated again to produce the pads. In addition, the use of the paste can lead to reliability problems.

5.1 New electrolytes for through hole filling

Initially, attempts were made to use the copper electrolytes that had already been tried and tested in blind microvia filling in the area of through hole filling. However, it was shown that these electrolytes are not suitable for this application so that further development work was necessary. Some laboratory results from the current development work are shown in Figure 16.

By modifying the electrolyte composition, it was possible to significantly improve the filling of through holes (approx. 85 µm borehole diameter / approx. 110 µm borehole depth). All four depositions shown in Figure 16 were each carried out with direct current with the same deposition time and current density. In addition, only one electrolyte was deposited during the entire deposition period, i.e. there was no electrolyte change in the course of the deposition.

With increasing aspect ratio, i.e. decreasing borehole diameter and/or increasing borehole depth, the mass transport and thus the subsequent delivery of copper ions is made more difficult. As a result, defect-free filling of the through holes without electrolyte inclusions is becoming increasingly difficult. Figure 17 shows two filling results of non-preamplified through holes (approx. 50 µm borehole diameter / approx. 160 µm borehole depth).

The electrolyte enclosed in the defect (Fig. 17a) expands when the HDI circuit board is heated and can therefore already lead to a crack in this connection during the soldering of components or when the temperature is subsequently increased, which can lead to a system failure. The focus of the current development work is, therefore, the reliably defect-free filling of through holes with different aspect ratios (Fig. 17b).

6 Inconclusion

Due to their high integration density, HDI printed circuit boards enable reliable unbundling of the high connection densities of these microprocessors in the smallest space.

By filling blind microvias with electrolytically deposited copper, the integration density of HDI printed circuit boards can be further increased. The newly developed electrolyte Slotocoup SF 30, which is currently being tested in Taiwan under production-related conditions, enables defect-free filling with a low copper layer thickness. This leads to a further increase in the integration density and to a more resource, energy and cost-efficient production of HDI printed circuit boards. The first installation at a customer is scheduled for the second quarter of 2014.

The integration density can be increased even further by means of so-called coreless structures, which consist of very thin core materials. Results of current development work show that direct current deposition of copper makes it possible in principle to fill the through holes in these cores. Since the filling result and thus the quality of the connection depends on the aspect ratio of the through-holes, the realization of a reliable defect-free filling with different aspect ratios is currently in the foreground of the development work.

For further info about Blind microvia, you can also visit https://www.mokotechnology.com/blind-microvia/

0 notes

Text

Design, production, and processing of high current PCB

If you want to control currents for electrical drives and power supplies with intelligent electronics, you have to master the balancing act between power and microelectronics. This article describes different variants of a unique and diverse high current PCB technology that are suitable for currents up to 1,000 A. At the heart of this technology are embedded copper bars that protrude from the surface to contact SMDs and other power components.

In order to close the gap between high-current conductors on the one hand and electronic components on the other, a number of cables, mounting materials, and interposers are usually required, especially if SMDs are provided. The aim is to integrate busbars in printed circuit boards in order to save construction volume and assembly effort for systems and to combine the drive and supply currents as well as electronic controls.

There are a number of circuit board technologies that are designed for power applications. These include multilayers with increased copper layer thicknesses of up to 400 micrometers, which can be leveled at higher layers. In addition, several techniques are offered that rely on a selective increase in the copper cross-section, such as the iceberg technique, the wire laid technique and the partial embedding of thick copper laminates.

Drive technology: Optimize high current PCB for motor controls

Three PCB technologies for high-current circuit boards are compared in this article: Dickschicht, Iceberg, and HSMtec. PCB topology and PCB design influence the current carrying capacity and heat dissipation of the power semiconductors.

Suitable technologies are available for combining the load circuit and fine conductor for logic signals on an FR4 circuit board. You save space and avoid the conventional connection technology with separate boards, which increases the reliability of the motor control. The PCB developer can optimize the current carrying capacity and heat dissipation of the power semiconductors according to his task.

From the point of view of the printed circuit board, the specifications of the drive electronics can be summarized in five points: 1) high integration density, 2) reliability of the electronic assembly, 3) fast heat dissipation, 4) high currents combined with control electronics and 5) reduced system costs, e.g. by switching to SMD components, fewer components or assembly processes.

A smart solution is to combine the power section and the control electronics, i.e. the load circuits and the control logic, instead of on two circuit boards on just one circuit board. However, this requires large conductor cross-sections and large insulation distances for the high-current conductors and, at the same time, fine conductor structures for the control on one and the same board. This eliminates expensive plug connections, cables, and busbars, as well as assembly steps and risks that limit reliability. The PCB specialist KSG has three technologies for this: thick copper, iceberg and HSMtec technology. All three processes use the standard base material FR4.

Safe contact with high current PCB

All of these technologies have something in common: There is usually not a sufficient cross-section between the layers of the high current PCB board and the connections for surface-mounted components or screw connections. The vias form a bottleneck for the currents of the desired size. And the press-in plugs, screws, and clamps also do not guarantee reliable contact with the layers. Only the clean soldering of connections forms a continuous connection from the components to all layers. Here, however, the higher the total copper thickness, the riskier is the solder penetration.

In contrast, regardless of the design, the high-current circuit board contacts the components and connections with the maximum conductor cross-section (Figure 2 below). In this way, SM and THT components can be combined with bonded power semiconductors, press-in contacts and screw connections without a bottleneck in the current path. At the same time, the busbar serves as a heat sink. The components are in direct contact with this thermal mass and are therefore optimally cooled.

Design, production, and processing of high current PCB

Compared to conventional busbars known from electrical engineering, individually shaped copper parts are used for the high-current circuit board. The shape and position of the copper parts can be freely defined. This gives the layout designer the freedom to place the components and connections in such a way that a compact module with optimized thermal and electrical functions is created.

Since each high-current project has its own characteristics, it is difficult to lay down general design rules. Depending on the size and shape of the copper parts and insulation bars, the design limits for each project must be checked. Guideline values provide a rough guide for the design.

To manufacture a high current PCB circuit board, the copper parts are first manufactured. Depending on the size, shape, and number of parts, this is done by etching, milling or punching. The copper parts are placed in pre-milled frames and then pressed with prepregs and possibly other layers.

One advantage of the high current PCB is the processing. Because the busbars are embedded, the high-current circuit board – apart from its weight – cannot be distinguished externally from other circuit boards. It can be processed in conventional SMD processes if the profile is set to the higher thermal mass. Experience shows that these soldering processes can be mastered well. A repair process for components that come into direct contact with the high-current rail, on the other hand, is more complex than with conventional flat assemblies.

Technology variants of high current PCB

The full potential of the high current PCB board becomes clear when you consider the possible variations.

The technology offers the greatest benefit if the copper parts are shaped in such a way that they reach the surface and are flush with the other pads on TOP and / or BOT (Fig. 1). This gives you a completely flat circuit board that can be further processed in the subsequent paste printing and assembly process without adjustment. Cable lugs, modules, and screwable components are also easier to connect to the high-current position.

In another version of the technology, the high current layer protrudes laterally from the edge of the circuit board. These contacts can be used directly as plugs or can be contacted like the end of a conventional busbar.

The next two variants of the high current PCB circuit board aimless at high currents than at cooling components.

If the copper parts have SMD connection surfaces both upwards and downwards, they work like conventional printed circuit board inlays, which are pressed into the cutouts in printed circuit boards to conduct heat from power components from TOP to BOT. The embedded copper parts (Fig. 9) differ from conventional inlays in that they are more reliable in manufacture and processing since there is no mechanical stress on the circuit board. In addition, the size and position of the pads can be selected independently of one another. An electrical connection is also possible without additional effort.

The last variant of the high current PCB board is a one-sided version (Figures 10 and 11). Here, raised pads of copper sheet to protrude through the insulation of a thin insulation layer, in order to then be contacted directly as SMD heatsink contacts to the corresponding component connections. In contrast to aluminum substrates made from IMS, this version does not have an insulation layer, so that significantly higher powers can be dissipated here. Such constructions are used, among other things, for high-performance LEDs with up to 10 W.

With the high-current circuit board, MOKO Technology is expanding its range of technologies in the field of thermal management with another important component:

Solid copper is embedded in the circuit board and can be fitted directly to SMD pads that reach the surface.

Structure of an SMD high-current circuit board

The high current circuit board can also be contacted with other assembly and connection technologies:

– Reflow / wave soldering SMD / THT – Aluminum wire bonding – Screws: eyelets / threaded holes – Blind holes from the outer layers – Press-fit technology high current connector

In many cases, the additional effort for the production of high current PCB can be reduced partly through specially implemented manufacturing processes and partly through optimized process control of standard processes.

Thick copper PCBs distribute the power losses horizontally

Thick copper technology has been established on the market for many years and is manufactured in large quantities. The PCB industry usually speaks of thick copper for copper structures of ≥105 µm. Thick copper conductors serve the better horizontal heat distribution of high power losses from power components and/or for the transport of high currents and replace stamped and bent constructions for busbars in high current PCB applications. With up to four inner layers, each with 400 µm copper, a current-carrying capacity of several hundred amperes is possible. Ideally, the thick copper conductors are located in the inner layers.

Flexibility for changes in the layout, the compact design, simple processing/assembly and comparably low change costs as well as the standard processes of the PCB industry speak in favor of the thick copper PCB. Although the process steps of a thick copper circuit board do not differ significantly from the standard throughput of a conventional circuit board, the production requires special process experience and management. A thick copper circuit board stays in the etching line 10 to 15 times longer and has a typical etching profile. The etching and drilling processes of the thick copper circuit board determine the design rules for the circuit diagram and must be observed. The PCB manufacturer has a list of suggestions for cost and process-optimized layer construction and design rules.

Important to know: FR4 laminates with a base copper cladding ≥105 µm are more expensive due to the high copper content. Compared to a standard laminate laminated on both sides with 18 µm, the material cost factor is around 1: 8 to 1:10. The PCB developer must pay attention to maximum material utilization. Early coordination with the PCB manufacturer helps to significantly reduce costs. With regard to miniaturization, thick copper technology is limited. Due to the strong undercut, only relatively coarse structures can be created. Another limitation: fine signal wiring is not possible on the same wiring level as the thick copper conductor.

Iceberg: for a uniform surface topography

In a wiring level, there are areas with 70 to 100 µm copper for the logic and areas with up to 400 µm copper for the load. The thick copper is largely sunk in the circuit board. This creates a uniform surface topography across the entire conductor pattern. The iceberg principle can also be combined with thick copper on the inner layers.

Embedding two-thirds of the 400 µm thick copper area in the base material creates a planar printed circuit board surface. Advantage: The conductor flanks can be reliably covered with a solder mask in just one casting process. The subsequent assembly process is possible on one level. Iceberg structures are also suitable as heat sinks for power components and can be combined with plated-through holes (vias) to optimize thermal management.

HSMtec: copper elements in the inner and outer layers Another way to combine load and logic on a circuit board is HSMtec. Here, massive copper elements are selectively installed in the inner layers and under the outer layers of the FR4 multilayer at those points where high currents flow, and ultrasonically bonded to the base copper of the etched conductor patterns. After pressing the layers, the copper profiles are located under the outer layers and/or in the inner layers of the multilayer. The rest of the circuit board remains unaffected.

The multilayer is manufactured in the standard manufacturing process and further processed in the usual assembly and soldering process. With this structure, the electrical specifications for the dielectric strength and insulation classes of machines can be served as well as demanding temperature conditions with limited installation space in vehicles.

The solid copper profiles inside the multilayer also enable three-dimensional constructions. Notch milling perpendicular to the copper profiles allows segments of the circuit board to be bent up to 90 °. In this way, installation space is cleverly used and high current and heat are transported over the bending edge. The construction is laid out as a two-dimensional circuit board, manufactured and assembled in the panel. After assembling or assembling the module, the circuit board is bent into the three-dimensional shape.

The software supports the developers in dimensioning high-current conductor tracks. With just a few entries such as current and temperature, the calculator provides the minimum wire width for HSMtec as well as for 70 and 105 µm copper cladding.

0 notes

Text

Detailed guided on PCB Panel utilization

The PCB Panel benefit

A composite of printed circuit boards, i.e. Printed circuit boards that are not isolated are firmly fixed and the assembly of the printed circuit board also belongs to it, is generally taken as a printed circuit board benefit. The beauty of the layout designs must be the design of the printed circuit board use, in order to be able to use the printed circuit boards at optimal costs and stocks and configurations. The influence of the PCB benefits on the manufacturing costs of the PCB and the cost of assembly. The manufacturing costs of printed circuit boards become clear through the PCB panel inspection control, which is the right regulation of the production panel with the control used by the printed circuit boards.

In the constructed example in Figure 1, the load on panel A (6-fold use) is approx. 50% and the load on panel B (4-fold use) is approx. 70%. With suitable individual printed circuit boards and by cleverly dimensioning the panel and arranging the panels appropriately, panel utilization of up to 85% can be achieved.

Figure 1:PCB Panel utilization

Figure 2 shows the relative cost contributions in the production of printed circuit boards for a standard printed circuit board (100 * 160mm, 8 holes per cm2, 127µm track width/distance, surface: HAL) depending on the number of layers. Essentially, only the costs for drilling, cutting (scoring or milling), the electrical test, packaging and for some material components are directly dependent on the number of printed circuit boards that can be accommodated on a panel. The remaining cost components are independent of the number of printed circuit boards per panel.

Cost components in the circuit board production

Figure 2: Cost components in the production of printed circuit boards

Generally speaking, it can be stated that approx. 70% to 80% of the PCB manufacturing costs are to be regarded as fixed costs, i.e. they are independent of the number of PCBs per panel. For the configurations shown in Figure 1, this means that the 8 circuit boards (Panel B) can be manufactured and purchased almost at the total price of 6 circuit boards (Panel A). The optimal benefit size in terms of manufacturing costs is certainly dependent on the manufacturer. However, considering the commercially available panel cuts of 610 * 530mm or 1070 * 1225mm (standard sheet format) and the mounting margins and spacing required for the manufacturing process, the PCB panel utilization and thus the price formation in the PCB manufacturing for many PCB manufacturers is an optimal benefit size of approx. 245 * 285mm.

The assembly process has cost components that are directly related to the number of components per benefit and thus to the number of printed circuit boards per benefit, such as: Consumption of solder, direct SMD or THD assembly costs per component and AOI cost per component. The costs for packaging the circuit boards, an electrical function test and for separating the circuit boards from the panel are proportional to the number of circuit boards in the panel. Other cost components are almost independent of the number of printed circuit boards in use or the number of components on the printed circuit board:

Throughput time of the benefit in the soldering system, Time for paste printing, The placement machine is idle during retraction/extension or change of use. Assembly costs for PCBs benefit

Figure 3: PCB assembly costs

This reduces the processing costs in the PCB assembly for a benefit with an increasing number of PCBs in the benefit, as shown in principle in Figure 3. The following briefly examines whether maximizing the number of printed circuit boards in terms of use is always technologically sensible.

PCB Benefit Dimensions

The maximum benefit size or PCB size varies depending on the PCB manufacturer and technical equipment. Based on the standard PCB panel size cut 610 * 530mm, which is often processed, there are maximum dimensions of approx. 570 * 490mm for many manufacturers. In electronics production at CAD-UL, the maximum dimensions are specified by the machines used, provided that it is to be carried out completely mechanically:

Paste printer 600 * 600mm SMD pick and place machine 400 * 550mm Vapor phase soldering system 550 * 600mm

The following reasons speak against the processing of benefits with the maximum dimensions:

As PCB panel size increases, this also loses stability, which can also be seen depending on the PCB thickness. There is a risk that the connection points between the circuit boards break due to improper handling.