OLLITAL focuses on one-stop service in the cleaning industry. Its main business is: dry ice making machines, dry ice cleaning machines, and other industrial machinery.

Don't wanna be here? Send us removal request.

Text

How does a dry ice granulator machine work?(working principles)

This paper provides an in-depth exploration of the working principle of Dry ice granulator machine, their wide range of applications, and the key factors to pay attention to during use. Through a detailed analysis of this technology, it aims to provide practitioners in related fields with a deep understanding, At the same time, we will promote the key product of this article —— Dry Ice Granulator.

With the continuous advancement of industrialization, dry ice, as a unique non-toxic, odorless, colorless and non-conductive substance, is increasingly used in various fields. As a key tool for producing dry ice, dry ice granulator machine is of great significance. This article aims to fully understand the working principle and application fields of dry ice granulator through in-depth study.

The core of the dry ice granulator lies in its efficient cooling system. By analyzing how it works, we can gain insight into how it rapidly cools liquid carbon dioxide to extremely low temperatures to form solid dry ice particles.

Cooling system:

The core of the dry ice granulator lies in its efficient cooling system. By analyzing how it works, we can gain insight into how it rapidly cools liquid carbon dioxide to extremely low temperatures to form solid dry ice particles.

Compression system:

On the basis of the cooling system, the compression system plays a key role. This article will detail how this system achieves efficient compression of liquid carbon dioxide so that it can reach a solidified state during cooling.

Molding system:

The molding system is an indispensable part of the dry ice pelletizer. This article will explain how it can accurately mold the cooled liquid carbon dioxide into solid dry ice pellets of various specifications.

① Liquid carbon dioxide supply: First, liquid carbon dioxide is delivered to the granulator. Liquid carbon dioxide is usually stored at high pressure and transported to the pelletizer through a piping system.

② Pressure relief and expansion: After entering the granulator, the liquid carbon dioxide passes through a pressure relief valve, causing it to rapidly release pressure and expand in an instant. This process causes the temperature of the carbon dioxide to drop dramatically, causing it to change directly from a liquid to a solid state.

③ Granulation head injection: The expanded carbon dioxide gas is injected at high speed through the injection head or nozzle of the granulator. During this process, the velocity and temperature of the gas are very high.

④ Condensation: At the moment when the spray head leaves the nozzle, due to the expansion of high-speed gas and the drop in temperature, part of the carbon dioxide gas immediately solidifies into solid particles. The size of these particles can be controlled by adjusting the parameters of the spray head.

⑤ Separation and Collection: The formed dry ice particles tend to naturally fall to a Collection area due to their high density. Here, dry ice pellets are separated and collected for subsequent use.

⑥ Recirculation: Carbon dioxide gas that is not captured is often recycled back into the system to increase efficiency and reduce waste.

Generally speaking, the dry ice granulator generates a high-speed gas flow by rapidly depressurizing and expanding liquid carbon dioxide, and ejects the gas through the injection head, thereby condensing the gas into solid particles in an instant. This process is very fast, allowing dry ice to be prepared in an efficient manner for a variety of applications, including cleaning, transportation, storage, and more.

Dry ice is widely used in many fields, and its unique physical and chemical properties make it excellent in a variety of applications. Here are some of the main application areas:

- Cleaning and decontamination: Dry ice cleaning machines are widely used to clean mechanical parts, production equipment, molds, engine parts, etc. Since it is water-free, residue-free and chemical-free, it is suitable for industries with high cleaning quality requirements such as food processing, pharmaceuticals, and electronic manufacturing.

- Food and pharmaceutical industry: used for cleaning production equipment, conveyor belts, containers, etc. Since there is no chemical residue, it will not cause contamination to food and medicine.

- Electronics industry: Dry ice is used to clean electronic components, printed circuit boards (PCBs), chips, etc. because no moisture or residue is left after cleaning.

- Automotive repair and manufacturing: Cleans engine parts, wheels, brake systems, etc. to effectively remove grease and dirt.

- Aerospace industry: used for cleaning aircraft engine parts and spacecraft parts. No need to disassemble to avoid impact on the equipment.

- Construction and Coating Cleaning: Clean walls, concrete surfaces, remove paint and more.

- Oil and gas industry: Used to clean oil well equipment, drill bits, etc. to reduce environmental impact.

- Entertainment and Stage Effects: Dry ice is used to create smoke and special effects because it creates unique smoke effects during the sublimation process.

- Refrigeration and Transportation: Dry ice is widely used as a coolant and refrigeration medium for transporting temperature-sensitive commodities such as food and pharmaceuticals.

- Laboratory and scientific research: Dry ice can be used for cryogenic experiments and preparations, such as preparing cryogenic samples in the laboratory or cryopreserving biological samples.

When working with dry ice, there are some safety and operational considerations to keep in mind to ensure safe and effective use. Here are some common considerations:

· Protective measures: Users should wear appropriate personal protective equipment, including gloves, goggles, and long-sleeved clothing, to prevent direct contact with dry ice.

· Ventilation: When performing operations such as dry ice blasting, make sure the work area is well ventilated to remove carbon dioxide gas. Carbon dioxide is a colorless, odorless gas that can cause suffocation with prolonged exposure.

· Training: Personnel operating dry ice equipment should receive professional training on the proper use of the equipment and potential hazards. This includes knowledge of starting, stopping, maintaining and handling emergencies of equipment.

· Stay away from sealed containers: Avoid storing or sealing dry ice in sealed containers because subliming dry ice can produce gases that increase pressure within the container and may cause it to rupture.

· Keep away from flammable materials: Dry ice is not flammable, but the sublimation process in a confined space may consume oxygen, so use caution when using it in a confined area.

· Proper handling of dry ice: Dry ice should be handled properly to avoid direct handling. Use dry ice grabbers or gloves when handling to avoid frostbite.

· Avoid direct contact with eyes: Dry ice should not come into direct contact with the eyes as its low temperature may cause eye damage. In case of accidental contact, flush eyes with clean water immediately.

· Storage: Dry ice needs to be stored in a ventilated place and avoid being stored in a closed space for an extended period of time. Dry ice should be placed in a dedicated insulated container to extend its service life.

· Regularly check the equipment: For users who use dry ice equipment, regularly check the working status of the equipment to ensure that the equipment is in normal operation and reduce the risk of potential failure.

· Strictly follow the operating manual: When operating dry ice equipment, carefully read and strictly follow the operating manual and safety instructions of the equipment to ensure correct operation and use.

In the current context of high industrialization and technological development, the dry ice granulator we bring to you is not only a technological innovation, but also a powerful assistant for your business success. By taking a deeper look at our products, you will discover that our dry ice pelletizers play a unique and critical role in various industries. Here are some of the outstanding features and benefits of our products to ensure you stand out in the market:

1. Working principle of high efficiency and energy saving

Our dry ice pelletizer uses advanced cooling, compression and shaping systems to ensure efficient cooling of liquid carbon dioxide and precise shaping of solid dry ice in the shortest possible time. This not only improves production efficiency, but also reduces energy consumption, saving costs for your business.

2. Widely used in many fields

Whether it is food preservation, pharmaceutical industry or industrial cleaning, our dry ice granulator can play an outstanding role in various fields. Not only can it help you maintain the freshness of food and the stability of medicines, it can also be used in industrial cleaning to create more possibilities for your business.

3. Safe and reliable operation

We strictly follow international safety standards to ensure that the operation of the dry ice granulator is safe and reliable. Detailed safety operating procedures and training will keep your staff in a safe working environment and reduce the risk of accidents.

4. Customized services

We understand that each customer's needs are unique, so we offer customized services to meet your specific production requirements. Whether it is throughput, particle size or other special needs, we can tailor a solution for you.

5. Environmental protection and social responsibility

Our dry ice pelletizer uses environmentally friendly materials and energy-saving technology, committed to reducing carbon footprint and fulfilling corporate social responsibility. Choosing our products is not only trust in technology, but also a responsible choice for the environment.

Contact us to start your journey to success!

In this competitive market, choosing our dry ice granulator will be a key step to the success of your business. Please feel free to contact us and our professional team will provide you with detailed product information, solutions and quotations. Let us work together to create brilliance and bring more success and profits to your business!

0 notes

Text

【Cleaning magic��Comprehensive analysis of dry ice cleaning machines and talk about the magical power to dominate the cleaning field!

Hello everyone, welcome to our blog! Today we will introduce to you a magical equipment that leads the field of cleaning-Dry ice cleaning machine. In this article, you will learn more about what dry ice is, its origins, and the detailed features of a Dry ice blasting machine. At the same time, we will also show you the potential of this technology. Finally, if you are also interested in this cleaning technology, we recommend OLLITAL®'s dry ice pellet machine and Dry ice cleaning machine to you. I will also list for you why you should choose OLLITAL®.

1.What is dry ice?

First, let’s understand what dry ice is. Dry ice, also known as carbon dioxide solid (CO2), is the product of compressing carbon dioxide gas into a solid. In the atmosphere, carbon dioxide gas is compressed into a solid form, forming dry ice.

Dry ice is colorless and odorless. It is a non-toxic and harmless cleaning material and is widely used in various cleaning fields. In the atmosphere, carbon dioxide gas is compressed into a solid form, forming dry ice.The temperature of dry ice is usually minus 78.5 degrees Celsius, which is its sublimation point, that is, the temperature at which it changes directly from solid to gaseous state. Dry ice is in a solid state at room temperature and does not pass through the liquid stage. It directly changes from solid to gaseous state when it sublimates.

Dry ice is mainly used in refrigeration, transportation, and cleaning fields. In the field of cleaning, dry ice impacts the surface of objects through high-speed airflow to achieve a cleaning effect. Dry ice produces a large amount of carbon dioxide gas when it sublimates, which may lead to an increase in carbon dioxide concentration in a closed space. While generally not very toxic, the outgassing from it can cause hypercapnia (abnormally elevated carbon dioxide levels in the blood) due to buildup in confined locations Please pay attention to safety.

2.The origin of dry ice

The history of dry ice can be traced back to the 18th and early 19th centuries, and is related to the discovery and research of carbon dioxide.

- Discovery of Carbon Dioxide: Chemists Joseph Louis Gay-Lussac and Humphry Davy studied carbon dioxide in the late 18th and early 19th centuries. Joseph Louis Gay-Lussac independently discovered carbon dioxide in 1800, Henry Varnon continued to study it after 1800. They noticed that, through specific experiments, carbon dioxide gas could be compressed and liquefied.However, the discovery of carbon dioxide is usually attributed to Scottish chemist Joseph Black, who first discovered it in the 1750s.

- Liquefying Carbon Dioxide: Experiments to liquefy carbon dioxide were conducted in the 1830s. The French physicist and engineer Adolphe Théodore Brongniart performed experiments related to carbon dioxide in 1835, but he did not successfully liquefy the carbon dioxide. After 1835, French engineer Charles Thilorier completed experiments to liquefy carbon dioxide and successfully achieved this. He used high pressure and the right temperature to convert carbon dioxide gas into a liquid state.The first successful liquefaction of carbon dioxide is usually attributed to the efforts of French chemist Charles Cagniard de la Tour in 1822.

- Discovery of Dry Ice: The discovery of dry ice is attributed to French scientists Louis-Joseph Gay-Lussac and Henri Victor Regnault, They noticed that when liquid carbon dioxide was released into the atmosphere, the surrounding air caused rapid cooling and crystallization of the carbon dioxide into a solid state. They observed that these solid forms were similar to ice, but because they did not pass through a liquid state, they were called "dry" ice. In 1824, they successfully prepared dry ice for the first time.However, the term "dry ice" is most commonly associated with American inventor Thomas Benton, who began producing and selling dry ice on a large scale in the early 20th century.

3. Detailed functions of Dry Ice Cleaning machine

Next, let’s take a closer look at the wonders of dry ice blasting. Dry ice cleaning machine is an efficient and environmentally friendly cleaning equipment. Its working principle is to use high-speed spraying of dry ice particles to quickly freeze and crush dirt and grease through the instantaneous alternating hot and cold effect to achieve the purpose of cleaning the surface. Compared with traditional cleaning methods, dry ice cleaning does not produce secondary pollution and does not require cleaning residues. It is suitable for cleaning various complex surfaces and equipment.

- Efficient cleaning: The dry ice cleaning machine can clean the surface of the object in a very short time by spraying small particles of dry ice at high speed. These small particles hit the surface at high speeds during the blasting process, quickly freezing and breaking up dirt, grease, and other contaminants.

- Non-conductive: The cleaning medium of the dry ice cleaning machine is solid carbon dioxide, and dry ice is non-conductive. Therefore, it can be safely used to clean electronic equipment, electrical components and other static-sensitive equipment without causing short circuits or electrical malfunctions.

- No residue: Dry ice sublimates directly into gas during the cleaning process, leaving no moisture or liquid residue. This makes dry ice cleaning suitable for applications that require high cleaning results and no residue, such as food production lines or medical equipment cleaning.

- Environmentally friendly: Dry ice blasting is an environmentally friendly cleaning method because it does not use chemical cleaners and carbon dioxide is a naturally occurring gas in the atmosphere and does not cause harm to the environment. The waste after cleaning is mainly the removed pollutants, and there is no need to process a large amount of chemical waste liquid.

- Suitable for a variety of surfaces: Dry ice cleaning machines are suitable for cleaning a variety of different materials and surfaces, including metal, plastic, rubber, glass, etc. It can be used in many industries such as cleaning machinery and equipment, automobile parts, building surfaces, food processing equipment, etc.

- Reduced downtime: Because dry ice cleaning requires no drying time, cleaned equipment or surfaces can be put into use almost immediately, reducing production line downtime and improving work efficiency.

- Remove difficult-to-clean dirt: Dry ice cleaning has unique advantages for some dirt that is difficult to clean with traditional methods, such as grease, gelatinous substances, pigments, etc. It can quickly freeze these dirt, making it fragile and easy to remove.

youtube

To sum up, the detailed functions of dry ice cleaning machines cover many aspects such as efficient cleaning, non-conductivity, no residue, environmental protection, suitable for a variety of surfaces, reducing downtime, etc., making it widely used in various industries.

4. What can the dry ice cleaning machine be used for?

Dry ice cleaning machine is a multi-functional cleaning tool suitable for multiple industries and application scenarios. The following are common uses for dry ice cleaning machines:

· Industrial equipment cleaning: Dry ice cleaning machines can be used to clean various types of industrial equipment, including mechanical parts, production line equipment, engines, pumps and valves, etc. It effectively removes grease, dirt and other contaminants without damaging equipment surfaces.

· Car maintenance: Dry ice cleaning machine can be used for car maintenance and cleaning, cleaning engine compartment, wheels, chassis and other parts. Due to the non-conductive nature of dry ice, electrical components and sensors can be safely cleaned without causing electrical malfunctions.

· Food and catering equipment cleaning: Dry ice cleaning is suitable for cleaning food production lines and catering equipment. It can remove residual food particles, grease and bacteria and ensure that the equipment meets hygienic standards.

· Building surface cleaning: Dry ice cleaning machine can be used to clean building surfaces, including walls, floors, beams and columns, etc. It effectively removes paint, coatings, stains and other contamination without causing damage to the surface.

· Electronic Equipment Cleaning: Due to the non-conductive nature of dry ice, dry ice cleaning machines can safely clean electronic equipment, circuit boards, computer equipment, etc., removing dust and dirt and improving equipment performance and reliability.

· Aerospace industry: Dry ice blasting is also widely used in the aerospace industry for cleaning aircraft engines, aviation parts and ground equipment. It effectively removes oil and residue from engines without causing mechanical wear.

· Art and Relic Protection: Dry ice blasting machines are used for the cleaning and protection of art and relics because of their ability to gently and efficiently remove contaminants from surfaces without causing damage to the artwork.

· Stone and sculpture cleaning: Dry ice cleaning can be used to clean stone surfaces and sculptures to remove surface dirt, algae, moss, etc., and restore the original appearance of the stone.

Overall, dry ice blasters excel at cleaning and removing contaminants and are suitable for use across multiple industries, increasing cleaning efficiency and reducing environmental impact.Now that we have learned about the power of dry ice cleaning machines, are you also interested in this amazing cleaning technology? If you are also interested in this great cleaning technology, I will introduce OLLITAL®’s high-quality products to you!

OLLITAL® has been specialized in the cleaning industry for decades and has become a leader in the cleaning industry. The company has a variety of cleaning equipment such as: dry ice blast cleaning machines, Dry Ice Granulators, Plasma cleaning machines, Laser cleaning machines, Ultrasonic Cleaning Machines, One-stop service R&D, production, sales and service of related supporting equipment such as. OLLITAL® can develop machines according to customer needs and provide one-stop service for dry ice cleaning technology. Dry ice cleaning machine is an efficient, environmentally friendly and safe cleaning method, which is widely used in molds, machinery, circuit boards and other industries. Dry ice cleaning can only be achieved with proper control of nozzle design, pressure control, cleaning agent control and operating techniques. Ice cleaning machine achieves maximum cleaning efficiency. OLLITAL®'s efficient, environmentally friendly, safe and flexible cleaning equipment has won a good reputation in the industry and has been sold to more than 30 countries around the world. As labor management costs and land costs continue to increase, automated equipment will inevitably replace semi-automatic or manual production in the future. This is the trend of social development. In the face of opportunities and challenges, Lingtie will not forget its original intention and keep moving forward.

OLLITAL® is committed to the research, development and application of dry ice technology and has advanced dry ice granulator machinery and efficient dry ice cleaning machines. Choose our products and you will enjoy:

· Environmental protection and energy saving: Our products are committed to environmental protection and energy saving. During the production and cleaning process, we use advanced processes and technologies to minimize energy consumption and reduce waste emissions, making your production more sustainable.

· Customized Solutions: We offer flexible custom designs to meet your unique needs. Whether it is the special requirements of the production line or the personalized needs of the cleaning scene, we can provide you with exclusive solutions to ensure that the product is perfectly adapted to your business.

· Safe and reliable: Our products undergo strict quality control to ensure stability and reliability. During use, you can operate with confidence, reduce the risk of equipment failure, and improve work efficiency.

· Multi-industry applications: Our products are widely used in multiple industries, including industry, automotive, food, medical and other fields. No matter what your business type is, we can provide you with practical solutions to meet your diverse needs.

· Professional training and support: Choose our products and you will receive professional training and support services. Our team will provide you with detailed product training to ensure you fully understand the operation and maintenance of the product, while our after-sales service team will be at your disposal to solve problems and provide support.

· Global Quality Recognition: Our products comply with international standards and have gained a good reputation worldwide. By choosing our products, you will get the guarantee of global quality recognition, providing reliable support for the steady development of your business.

If you want to know more about Dry Ice Pellet Manufacturing Machinery or you want to build a dry ice production line, please refer to [Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers].

In this era of cleaning revolution, choose a dry ice cleaning machine to make cleaning easier, more efficient and more environmentally friendly! Thank you for reading our blog, if you have any questions or cooperation intentions, please feel free to contact us. Let us help the cleaning industry together and create a better future!

0 notes

Text

【8 Disadvantages and Advantages of Dry Ice Blasting】

WHAT IS Dry ice BLASTING ?

In the field of modern cleaning technology, dry ice blasting has become an innovative method that has attracted much attention. This cleaning technology uses solid carbon dioxide (dry ice) particles to blast surfaces through high-speed airflow to remove dirt, oil, and other surface contaminants. Compared with traditional cleaning methods, dry ice blasting has unique advantages in terms of environmental protection and non-abrasiveness.

dry ice abrasive blasting is a cleaning and cooling technology that uses solid carbon dioxide (CO2), or dry ice. Dry ice is the solidification of carbon dioxide under high pressure conditions, with a very low temperature of about minus 78.5 degrees Celsius (minus 109.3 degrees Fahrenheit). Due to its low temperature and special properties, dry ice is used in a variety of applications, including dry ice abrasive blasting.

During the blasting dry ice process, solid carbon dioxide is discharged from special equipment at high speed. Dirt, grease, pollutants, etc. are completely removed from the surface through the force and temperature effect of the spray. This process is widely used in industrial cleaning, equipment maintenance, food processing equipment cleaning, and more. Because dry ice leaves no residue during the cleaning process and produces no waste other than carbon dioxide, it is considered an environmentally friendly cleaning technology.

In addition, because dry ice quickly sublimates into gas after spraying and does not produce liquid waste, blasting dry ice is also used in some water-sensitive applications, such as electronic equipment maintenance, electrical equipment cleaning, etc. This technology is also widely used in some special cleaning occasions, such as hygienic sensitive areas, food production lines, etc.

WHAT ARE THE ADVANTAGES OF DRY ICE BLASTING?

① No residue: Dry ice sublimates into a gas after blasting, leaving no moisture or liquid residue behind. This is very beneficial for industries that require high standards of cleaning, such as food production, medical equipment manufacturing, etc. At the same time, the residue-free feature avoids additional cleaning steps and improves work efficiency.

② No chemical cleaners required: Dry ice blasting does not require the use of chemical cleaners, avoiding possible chemical pollution to the environment and equipment. This reduces reliance on harmful chemicals and is in line with environmental protection and sustainable development requirements.

③ No water required: Dry ice blasting does not involve the use of water, which is especially important for some water-sensitive equipment and environments, such as electrical equipment, electronic equipment, precision instruments, etc. Avoid electrical failure or equipment damage that may be caused by using water.

④ Efficient Cleaning: Dry ice blasting uses high speed and energy to quickly remove surface dirt. This increases the speed and efficiency of cleaning and reduces downtime during production or maintenance processes.

⑤ No mechanical wear: Compared with traditional mechanical cleaning methods, dry ice blasting does not involve brushes, scrapers and other parts that are in direct contact with the surface, thus avoiding mechanical wear. This helps extend the life of your equipment.

⑥ Multi-field applications: Dry ice blasting can be used in a variety of industries, including industrial cleaning, food production, electronics manufacturing, aerospace, medical equipment, and more. Its versatility makes it a widely applicable cleaning technology.

⑦ Environmentally friendly: Because dry ice is a natural gas and no waste is produced during the cleaning process, dry ice blasting is considered an environmentally friendly cleaning method. This helps reduce negative impact on the environment.

⑧ Precise cooling effect: Due to the extremely low temperature of dry ice, precise cooling of specific areas can be achieved during the spraying process. This is very useful in some applications where temperature control is required, such as electronic component manufacturing, medical device production, etc.

Dry ice blasting technology brings many advantages and applications. Overall, dry ice blasting provides an efficient and environmentally friendly option for cleaning and maintenance, and is widely used in multiple industries and fields.

WHAT ARE THE DISADVANTAGES OF DRY ICE BLASTING?

While dry ice blasting has significant advantages in many aspects, it also has some potential disadvantages that may need to be considered in specific situations:

① High Cost: The cost of dry ice preparation and blasting equipment is relatively high, which may make the initial investment higher. Additionally, dry ice itself can be expensive, although it is available in some areas through specialized suppliers.

② Noise Level: Dry ice blasting equipment can produce some noise when operating, which can be a problem in some noise-sensitive environments, especially where work needs to be done in a quiet environment.

③ Requirements for workers: Dry ice blasting requires professionally trained operators, as improper operation may pose a risk to worker safety. This may require additional training costs and time.

④ Limited scope of application: Dry ice blasting is not suitable for all cleaning scenarios. In some extreme cases, it may be necessary to combine other cleaning methods to ensure a thorough clean.

⑤ Limitations of meteorological conditions: Dry ice blasting is affected by ambient temperature and humidity. In extremely cold climates, dry ice may be more likely to clump, affecting blasting effectiveness.

⑥ CO2 Emissions: Although dry ice itself does not produce pollution during blasting, its original source is carbon dioxide, which is considered one of the greenhouse gases. Therefore, from an overall life cycle perspective, the use of dry ice will also produce CO2 emissions.

⑦ Not suitable for some surfaces: The high energy and speed of dry ice blasting may not work on some sensitive surfaces, such as some plastics, glass and coated surfaces, and may cause surface damage.

⑧ Energy consumption: Dry ice preparation requires liquefied carbon dioxide and high-pressure mechanical equipment, which involves energy consumption. Although there is no energy consumption involved in the cleaning process, overall energy consumption still needs to be considered.

How to get?

Have you learned about the advantages and disadvantages of dry ice blasting(cleaning with dry ice blasting) through this article? If you also want to have this technology, I recommend OLLITAL’s dry ice blasting solution to you.

In order to better utilize the advantages of dry ice blasting, OLLITAL provides efficient, environmentally friendly, and multifunctional Dry ice blasting machines and dry ice granulators. By choosing OLLITAL equipment, you will experience a faster, safer and more economical cleaning solution. Contact us to learn how you can improve your cleaning efficiency while meeting environmental standards.

Xiamen OLLITAL Technology Co., Ltd. It is specialized in the research, production, sales and service related supporting equipment of one-stop service, dry ice jet cleaner, dry ice granulator, plasma cleaner, laser cleaner, Ultrasonic cleaning and high-temperature steam cleaner in the cleaning industry. We can develop machines according to customer needs and provide one-stop services for Dry Ice Cleaning technology. Dry ice cleaning machines are an efficient, environmentally friendly, and safe cleaning method widely used in multiple industries, including molds, machinery, circuit boards, etc. Only by properly controlling nozzle design, pressure control, cleaning agent control, and operating techniques can dry ice cleaning machines achieve maximum cleaning efficiency. Our efficient, environmentally friendly, safe, and flexible cleaning equipment has earned us a good reputation in the industry and has been sold to over 30 countries worldwide. With the continuous increase in labor management costs and land costs, automated equipment will definitely replace semi-automatic or manual production in the future. This is a trend in social development. Facing opportunities and challenges, Lingtie will stick to its original intention and continue to move forward.

Xiamen OLLITAL Technology Co., Ltd. was established in 2003, with more than 150 employees (as of August 2022). OLLITAL Technology is a company focusing on R&D and specializing in the production of industrial cleaning machinery, dry ice pellet machinery, dry ice cleaning machinery, and Plasma cleaning machines. , Laser cleaning machinery, ultrasonic equipment and other fields of products.

OLLITAL is a professional company with more than 10 years of experience in the cleaning industry. We are committed to providing comprehensive cleaning solutions, covering a series of cleaning equipment such asdry ice cleaning machines, Dry Ice Making Machines, Plasma cleaning machines, Ultrasonic Cleaning Machines, Laser cleaning machines, etc. OLLITAL is a one-stop solution provider for the cleaning industry. We use our excellent technology and professional team to provide customers with efficient and reliable cleaning equipment and services.

OLLITAL has gathered a professional team composed of experts, scholars and other scientific researchers. The company's independently developed dry ice cleaning machines, dry ice making machines, Ultrasonic cleaning machines, plasma cleaning machines, laser cleaning machines and other products have obtained patents and expanded marketing.

OLLITALhas a high reputation in more than 70 countries and regions, providing technical support to tens of thousands of organizations to solve problems in their research, especially universities, research institutes, industries, inspection agencies, etc. We have long-term business partners in more than 130 countries.

OLLITAL always adheres to the mission of "service first, achieving the future" and vigorously promotes corporate culture. OLLITAL is willing to establish win-win business cooperation with dealers around the world with high-quality products and good services.

OLLITALis a testament to excellence in technological innovation and manufacturing. With its commitment to quality and environmental responsibility, OLLITAL was awarded several prestigious Certifications between 2010 and 2022, including ISO 9001, ISO 14001, CE, NSF, EN and FDA. Demonstrates the company's ongoing commitment to meeting and exceeding international standards.

Q1. What is your products range?

• Ollital Technology It is a high-tech enterprise focused on research and development, specializing in the production of industrial cleaning machinery, dry ice particle machinery, dry ice cleaning machinery,plasma cleaning machine, laser cleaning machinery, ultrasonic equipment and other fields of products.

Q2. Are you trading company or manufacturer?

• We are a professional manufacturer of Dry ice cleaning industry, and we have our own factory.

Q3. Do you provide samples? Is it free?

• Yes, we could offer the sample. Considering the high value of our products, the sample is not free, but we will give you our best price including shipping cost.

Q4. Do you have warranty?

• Yes, we offer 1 year warranty for the spare part.

Q5. How long is your delivery time?

• Generally it is within 7 working days after receiving the payment if the goods are in stock. Or it is 15 working days if the goods are not in stock, depending on order quantity.

Q6. What is your terms of payment?

• Payment≤15,000USD, 100% in advance. Payment≥15,000USD, 70% T/T in advance, balance before shipment.

(If you are concerned about payment security for the first order, we advise you can place Trade Assurance Order via Alibaba.We have a flagship store on Alibaba International Station you will get 100% payment refund if we can't meet agreed delivery time.)

OLLITAL(Click the link below to contact directly)

Add.: Haicang District, Xiamen , Fujian , China.

WhatsApp: +8615960821529 Tel.: +86 15960821529 Email: [email protected] Skype: +8615960821529

1 note

·

View note

Text

【The ultimate guide to choosing the perfect Dry Ice Cleaning Machineand dry ice machine for your needs】

UNDERSTANDING YOUR REQUIREMENTS

1. Determine your application area:

Before diving into machine specifications, determine your primary application. Whether it’s industrial cleaning, food preservation, or special effects in the entertainment industry, understanding your specific use case will allow you to more accurately select the machine that’s best for you.Or you can tell us your needs and we will recommend the best solution for you.

2. Dry ice quantity issue:

Consider the amount of dry ice you need. Industrial applications may require high-capacity machines, while smaller equipment can meet smaller-scale needs. Understanding your production requirements is critical.You can refer to 【Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers】and 【How to set up your own dry ice manufacturing factory?】Learn more about dry ice in two articles.

TYPES OF DRY ICE CLEANERS AND DRY ICE PELLETIZERS

1. Dry ice cleaning machine(Dry ice blasting machine):

Compressed air is used to accelerate dry ice pellets to supersonic speeds and spray them onto the surface being cleaned. The high-speed ice particles hit the dirt, and through the freezing and mechanical action of the ice, the dirt is peeled off the surface.It is widely used for cleaning machinery and equipment, production lines, building surfaces, etc. It is especially suitable for the food and pharmaceutical industries because the cleaning process does not require water or chemicals.(Want to learn more about Dry Ice Cleaning?)

· P7X Dry ice cleaning machine: Very suitable for cleaning carbon deposits and oil stains in car engines. It can effectively complete cleaning without damaging engine parts etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· A625i Dry ice cleaning machine: Suitable for cleaning oily molds, motor windings, paint rust cleaning, and printing machine ink residues etc.. (Suitable for rubber factories, shoe factories, factory machine maintenance, etc.)Go to view product details

· P60 Dry ice cleaning machine: Used for car interior renovation and cleaning, car seat cushions, surface glue residue, and oil stain cleaning etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· T6 Dry ice cleaning machine: Used for PCB circuit board renovation and cleaning, soldering residue, surface glue residue, oil stains, PPS material deburring, etc. (Suitable for component factories, component maintenance, factory machine maintenance, etc.)Go to view product details

· B3+ Dry ice cleaning machine: Used for cleaning motor winding dust, printing machine ink, oil sludge, rust stains, heavy oily metal, etc.(Used to clean and maintain a variety of industrial equipment, including engines, pumps, valves, pipes, etc.)Go to view product details

Generally speaking, the dry ice cleaning machine is an efficient, environmentally friendly, and multi-purpose cleaning equipment. Its working principle is based on high-speed spraying of dry ice particles to clean the surface through freezing and mechanical impact. The advantages of this cleaning method include being water-free, leaving no chemical residue, being non-abrasive, suitable for a variety of surfaces and materials, and having a wide range of applications in a variety of industries.

For potential users, when choosing a dry ice cleaning machine suitable for specific needs, factors such as cleaning objectives, working environment, cleaning effect requirements, production capacity and budget need to be considered. Whether in industrial, food, medical or other industries, dry ice cleaning machines have demonstrated their excellent performance in improving cleaning efficiency and protecting equipment surfaces.You can also tell us your needs and our engineers will recommend the most suitable solution for you. Contact an engineer now >>

2. Dry ice pellet machine(Dry Ice Granulator Machine):

Dry ice pelletizer is a piece of equipment specially used to turn liquid carbon dioxide (CO2) into solid carbon dioxide (dry ice) pellets.

Dry ice pelletizers usually deliver liquid CO2 into the machine through a liquid carbon dioxide supply system. Liquid carbon dioxide undergoes a series of cooling and pressurization processes, causing its temperature and pressure to rise. The pressurized liquid carbon dioxide passes through the nozzle or spray head and enters a relatively low-pressure environment. In this environment, liquid CO2 rapidly relaxes and expands, lowering its temperature and turning into a solid state. Because the temperature drops sharply, liquid CO2 turns into a gaseous state and forms tiny CO2 particles, known as dry ice particles.

The Dry ice machine can efficiently convert liquid CO2 into a large number of evenly distributed dry ice pellets. The advanced control system can achieve precise control of parameters such as temperature, pressure and particle size to ensure the production of dry ice that meets requirements. Some Dry Ice Granulator have adjustable mechanisms that allow the user to select different sizes of dry ice pellets. There is no need to add any chemicals during the manufacturing process, and the waste material is CO2 gas, so the dry ice pelletizer is considered a relatively environmentally friendly production method. Most Dry Ice Pelletizer Making Machine are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

3. Dry Ice Block Machine(Dry ice briquetting machine):

A dry ice block press is a piece of equipment specifically designed to compress dry ice pellets or pieces into block form.

Dry ice block presses typically use previously produced dry ice pellets or chips as raw material. These pellets or chips are usually prepared through an overhead dry ice pelletizer or other means. Dry ice raw material is transported to the compression zone and heated to a certain level. The purpose of heating is to cause the dry ice pellets or blocks to begin to soften and melt. After heating, the softened dry ice is placed in a compression zone, where compression machinery or a hydraulic system exerts tremendous pressure to compress the dry ice into blocks. The compressed dry ice blocks pass through the cooling system, where they are quickly cooled and re-solidified to form solid dry ice blocks. The formed dry ice blocks enter the collector through the collection system, and then enter the packaging area through the conveyor system for final packaging.

Go to view product details >>

Main feature:

Efficient production: The dry ice block press can efficiently convert dry ice pellets or fragments into large, solid dry ice.

Uniformity of dry ice blocks: Compression machinery and control systems ensure uniform shape and size of dry ice blocks, suitable for different applications.

Save space: Dry ice in block form is easier to store and transport than in crushed or pellet form, thus saving space.

Energy savings: Previously produced dry ice pellets or crumbs are used as raw material, reducing the need for additional refrigeration and helping to save energy.

Automated operation: Most modern dry ice block presses are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

Application areas:

Food and pharmaceutical transportation: Dry ice blocks are widely used in cold chain transportation to keep food and pharmaceuticals at low temperatures.

Laboratory and scientific research: In laboratories and scientific research fields, dry ice blocks are used to prepare low-temperature environments, such as refrigeration reagents.

Special effects production: Dry ice cubes are often used in film productions and stage performances to create special smoke and cold fog effects.

Environmentally Friendly Cleaning: Dry ice cubes are also used in the cleaning industry for cleaning and removing dirt, especially for electrical equipment cleaning.

Overall, the dry ice block press provides a reliable production method for producing large blocks of dry ice, suitable for the different needs of multiple industries.

RODUCTION CAPACITY

Evaluate the machine's productivity in pounds per hour. Make sure it fits your needs without sacrificing quality. To meet high-volume demand, faster production may be required.

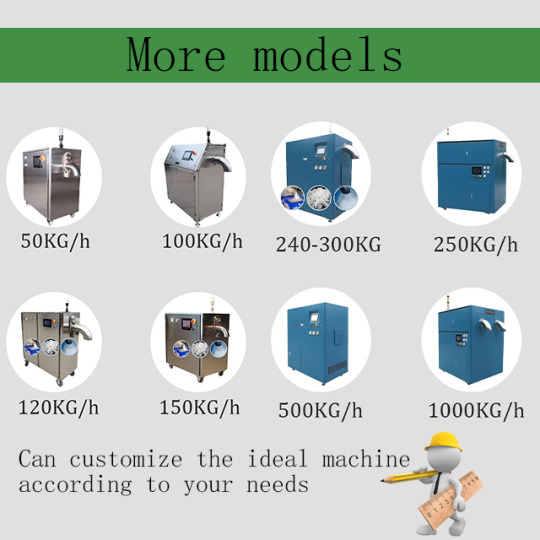

OLLITAL aims to provide customers with more choices in production capacity. Independently developed: 50KG/H (110 lbs/H), 100KG/H (220 lbs/H), 150KG/H (330 lbs/H), 250KG/H (551 lbs/H), 500KG/H (1102 lbs/H), and 1000KG/H (2204 lbs/H) dry ice pellet machine. Or you can tell us your needs and our engineers will customize the most suitable solution for you according to your needs. Contact an engineer immediately for customization >>

TECHNICAL SPECIFICATIONS

1. Size and portability:

Consider the physical size of the machine. A compact, portable unit may be better for versatility and ease of use, especially if you work from different locations or have limited space. If you need to move your cleaning equipment between job sites, choosing a dry ice blaster that is compact and portable may be key. This is important for tasks that require frequent movement or operation in limited spaces.

* Machine size: View the actual dimensions of your dry ice blaster, including length, width, and height. Make sure the machine is sized to fit your workplace and can be easily stored or carried.

* Weight: In addition to size, consider the weight of your dry ice blaster. The lightweight design can improve portability, reduce the burden of transportation, and make the device easier to carry and operate.

* Easy to carry design: Choose a machine with a user-friendly carrying design, such as handles, wheels, or other structures for easy movement. These designs make it easier for operators to move equipment from one location to another.

* Versatility: Some portable dry ice blasters are designed for versatility and can be used in a variety of applications. This flexibility increases the equipment's usefulness and makes it suitable for different types of cleaning tasks.

* Easy to store: Consider the storage needs of the machine when not in use. Some machines may have folding or removable parts to make it easier to store in limited spaces.

* Power and energy requirements: Consider the power and energy requirements of your dry ice blaster. Portable devices are often easier to connect to different types of power sources, such as batteries, generators, or standard electrical outlets.

When selecting a dry ice blaster, considering size and portability can ensure the equipment is better suited to your job requirements, increasing operational flexibility and efficiency.

2. Automation and control:

Automation and control are crucial considerations when selecting a dry ice pelletizer and cleaning machine. Look for user-friendly controls and automation features. An intuitive interface and automation streamline operation, making the machine easier for operators of all skill levels to use.

* Intuitive interface: Choose a dry ice granulator/cleaner with an intuitive interface. An intuitive control panel or touch screen makes it easier for operators to understand and operate the equipment, reducing training time.

* User-friendly controls: Consider choosing a machine with user-friendly controls. Simple buttons, knobs or digital controls allow operators to easily adjust and monitor cleaning parameters.

* Default program: Look for machines with preset cleaning programs. Preset programs improve operational consistency and efficiency, reducing manual setup and adjustments by the operator.

* Automation features: Understand whether the machine has automated functions, such as automatic nozzle adjustment, cleaning trajectory planning, etc. These features simplify the cleaning process and reduce operator intervention.

* Remote control and monitoring: If possible, choose machines that support remote control and monitoring. In this way, operators can monitor and adjust the cleaning process remotely, increasing the operational flexibility of the equipment.

* Fault diagnosis and alarm system: Look for machines with fault diagnosis and alarm systems. These systems can detect and report potential problems in a timely manner, helping to quickly resolve faults and improve equipment reliability.

* Data logging and reporting: Some advanced dry ice cleaning machines have data logging and reporting capabilities that can record key parameters during the cleaning process. This is very useful for quality control and traceability.

* Programmability: If you need to personalize it for a specific application, consider choosing a machine with some programmability to accommodate different cleaning needs.

By choosing a dry ice pelletizer/cleaner with an intuitive interface, automated features, and user-friendly controls, you can increase the ease of use of your equipment, reduce training costs, and ensure consistent cleaning results among operators of different skill levels .

Choosing the perfect dry ice machine requires a thorough understanding of your specific needs, technical specifications, and cost considerations. By carefully evaluating these factors, you will be able to make an informed decision that meets your application requirements and provides long-term value.

Whether you're venturing into a new business or upgrading an existing setup, investing the time in selecting the right dry ice machine is a critical step toward efficiency and success.

If you want to know more about Dry Ice Pellet Manufacturing Machinery or you want to build a dry ice production line, please refer to [Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers].

In this era of cleaning revolution, choose a dry ice cleaning machine to make cleaning easier, more efficient and more environmentally friendly! Thank you for reading our blog, if you have any questions or cooperation intentions, please feel free to contact us. Let us help the cleaning industry together and create a better future!

2 notes

·

View notes