Dongguan Orienson Hardware Electrical Co.,Ltd.was established in 2000,which located inDalang Town,Dongguan City and the self-built factory covers an area of 5000 square meters.https://www.oriensonmetal.com

Don't wanna be here? Send us removal request.

Text

The structured shape, size, precision, materials, and technical requirements of bending parts must be conformed to the requirements of the bending process. Various shapes such as the U-shaped bending and V-shaped bending, cap-shaped parts, arc-shaped parts, etc can be made through the bending process. Orienson can provide solutions with a reasonable process, high precision, and low manufacturing cost according to customer requirements, we always commit to reducing the production cost, improving quality, and improving product yield, welcome your consultation.

Types of Custom Metal Bending Stamping Parts

2mm Thickness SPCC Metal Stamping with High Quality Precision2mm Thickness SPCC Metal Stamping with High Quality Precision

2mm Thickness SPCC Metal Stamping with High Quality Precision

Material:0.2mm-5mm Steel(SPCC-SD/SPCC-SB/DC01/SPCE/1075/DT4E) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

0.6mm Thickness OEM H65 Copper Metal Stamping Bending Parts0.6mm Thickness OEM H65 Copper Metal Stamping Bending Parts

0.6mm Thickness OEM H65 Copper Metal Stamping Bending Parts

Material:0.1mm-5mm Copper Alloy(C10100/C11000 /C22000/C26000/C26800/C36000/C7025/C51000/C17200) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

1.5mm Thickness Steel Stamping Bending Parts1.5mm Thickness Steel Stamping Bending Parts

1.5mm Thickness Steel Stamping Bending Parts

Material:0.2mm-5mm Steel(SPCC-SD/SPCC-SB/DC01/SPCE/1075/DT4E) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

0.8mm Thickness OEM Copper Alloy Punch Forming Bending Components0.8mm Thickness OEM Copper Alloy Punch Forming Bending Components

0.8mm Thickness OEM Copper Alloy Punch Forming Bending Components

Material:0.1mm-5mm Copper Alloy(C10100/C11000 /C22000/C26000/C26800/C36000/C7025/C51000/C17200) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings, and other surface treatment.

0.65mm Thickness H65 Copper Metal Parts for Electrical Accessory0.65mm Thickness H65 Copper Metal Parts for Electrical Accessory

0.65mm Thickness H65 Copper Metal Parts for Electrical Accessory

Material:0.1mm-5mm Copper Alloy(C10100/C11000 /C22000/C26000/C26800/C36000/C7025/C51000/C17200) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

0.46mm Thickness Custom Steel Bending Part0.46mm Thickness Custom Steel Bending Part

0.46mm Thickness Custom Steel Bending Part

Material:0.2mm-5mm Steel(SPCC-SD/SPCC-SB/DC01/SPCE/1075/DT4E) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

What is Metal Bending?

Metal bending is a manufacturing process that involves deforming a metal workpiece to create a specific shape or angle. The process is used to produce a wide range of metal products, including brackets, frames, enclosures, and other components.

Metal bending can be performed using a variety of techniques, including press braking, roll bending, and tube bending. Press braking involves pressing a metal sheet or plate between a punch and die to create a bend. Roll bending uses a set of rollers to gradually bend a metal workpiece into a specific shape. Tube bending involves bending a metal tube using a mandrel and a set of rollers.

Metal bending is often used in conjunction with other manufacturing processes, such as metal stamping, welding, and machining, to produce complex metal parts with high precision and accuracy. It is a versatile process that can be used with a wide range of metals, including steel, aluminum, copper, and brass.

At Orienson, we specialize in custom metal bending services and can provide you with the right solution for your specific application requirements. Our team of experts works closely with customers to understand their needs and develop customized solutions that meet their exact specifications. We use the latest equipment and techniques to ensure that every metal bending part we produce meets the highest standards of quality and durability.

Bending Parts Design

For the shape of simple bending stamping parts, such as V-shaped, U-shaped, L-shaped, Z-shaped, etc., we can adopt bending once-forming. For bending parts with complex shapes, it is generally necessary to adopt multiple bending forming.

As deformation will affect the shape accuracy of multi-angle bending parts, we generally bend the outer angle first and then bend the inner angle. The first bending should be set aside some reliable positioning for the next bending to ensure the first bending shape would be not destroyed by the next bending.

The work blank of bending parts with asymmetric structure is prone to deviation during the bending process, we should try to adopt the technique by curving in pairs and then cutting apart.

Bending times and working arrangements of bending parts must be considered comprehensively according to the complexity of workpiece shape, material performance, precision requirements, and the size of the production batch. Reasonable bending process can reduce bending times, simplify die structure, improve workpiece quality and productivity.

Application Of Bending Parts

Bending is the most common processing method in the stamping industry. Its metal stamping parts are widely used in the automobile industry, electronic and electrical industry, communication fiber industry, the energy development industry, and so on. Orienson has 20 years of industry experience in stamping, adhering to the manufacturing spirit of stamping craftsmen, In strict accordance with TS16949 standards to develop new product development, quality control, lean production management, and TPM management related production management process. We commit to meeting our customers' requirements with the best quality, welcome customers who need stamping parts to consult more details.

Application Of Bending Parts

What is the Common Defects and Technological Countermeasures of Bending Parts

What is the Common Defects and Technological Countermeasures of Bending Parts

Bending is a common process in stamping parts. In view of bending defects, Orienson adopts corresponding effective process measures through process control and prevention to improve the quality of the workpiece.

1. The size of the pressing parts after bending is not up to standard or the shape of the deviation.

2. The product surface quality is poor. The poor surface quality of bending parts is mainly: scratch, strain, concave and so on.

3. The bending crack, the crack is one of the most common problems of stamping bending part.

0 notes

Text

As one of the main stamping processes, deep drawing is widely used. The cylindrical, rectangular, stepped, round, and square mixed drawing and other irregularly shaped thin-walled parts can be made by the deep drawing process. If it is matched with other stamping forming processes, it can produce more complex-shaped parts. Types Of Custom Deep Drawn Components1.0mm Thickness H62 Copper Punch Forming Deep Drawing Components1.0mm Thickness H62 Copper Punch Forming Deep Drawing Components1.0mm Thickness H62 Copper Punch Forming Deep Drawing ComponentsMaterial:0.1mm-5mm Copper Alloy(C10100/C11000 /C22000/C26000/C26800/C36000/C7025/C51000/C17200) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment. 0.5mm Thickness Steel Customized Deep Drawing Parts0.5mm Thickness Steel Customized Deep Drawing Parts0.5mm Thickness Steel Customized Deep Drawing PartsMaterial:0.2mm-5mm Steel(SPCC-SD/SPCC-SB/DC01/SPCE/1075/DT4E) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment. 1.0mm Thickness H65 Copper Deep Drawing Part1.0mm Thickness H65 Copper Deep Drawing Part1.0mm Thickness H65 Copper Deep Drawing PartMaterial:0.1mm-5mm Copper Alloy(C10100/C11000 /C22000/C26000/C26800/C36000/C7025/C51000/C17200) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment. 2.0mm Thickness T2 Copper Metal Parts for New Energy Resources2.0mm Thickness T2 Copper Metal Parts for New Energy Resources2.0mm Thickness T2 Copper Metal Parts for New Energy ResourcesMaterial:0.

0 notes

Text

Since its establishment, Orienson has continuously provided customers with a full range of support and services from product development to mass production with rich experience and professional technology at present. As a well-known metal stamping parts company, we have been serving many famous international companies such as ABB, Emerson, Amphenol, Finisar, Bourns, etc for many years, and for many years in a row by a number of enterprises as excellent suppliers. The metal stamping service scope covers aviation, automotive, medical, optical fiber, high and low voltage switch temperature control and other industries.

Metal Stamping Service Materials

Metal stamping is a manufacturing process that involves the use of a die and a press to shape and cut metal into various forms. This process is widely used in industries such as automotive, aerospace, and electronics, to name a few. The materials used in metal stamping can vary depending on the specific application, but some of the most commonly used materials include steel, copper, aluminum, and stainless steel.

Steel is one of the most commonly used materials in metal stamping due to its strength and durability. It is a robust and reliable material that can withstand high levels of stress and pressure, making it ideal for use in components that need to support heavy loads. Steel can also be easily machined, welded, and painted, which adds to its versatility and makes it a popular choice for a wide range of applications.

Copper, on the other hand, is an excellent conductor of electricity and heat, making it a popular choice for use in electrical components. Copper is also highly malleable, which means that it can be easily shaped and formed into intricate designs. This makes it a great choice for producing complex components that require high levels of precision and accuracy.

Aluminum is a lightweight material that is also incredibly strong and durable. It has excellent corrosion resistance properties, which means that it is often used in outdoor applications where it may be exposed to harsh weather conditions. Aluminum is also an excellent conductor of heat, making it ideal for use in heat exchangers and other similar components.

Stainless steel is a popular choice for applications that require a high degree of corrosion resistance. It is commonly used in medical equipment and food processing equipment because of its ability to withstand exposure to harsh chemicals and high levels of moisture. Stainless steel is also a strong and durable material that can withstand high levels of stress and pressure, making it ideal for use in a wide range of industrial applications.

Metal stamping is a cost-effective and efficient way to produce high-quality metal components, and the use of different materials allows for a wide range of customization options. From simple brackets to complex parts, metal stamping services can help to bring your designs to life using a variety of materials to meet your specific needs.

Types Of Metal Stamping Services

Bending Parts

Rapid open mold speed, high quality, mature bending process made us widely welcomed by customers. Bending parts we produced has been widely used in automobiles, sensors, electrical and electronic switches, and the medical equipment industry and we continue to provide quality services for years.

Edge Rolling Parts

Under the guarantee of dimensional accuracy and production efficiency, we are committed to providing smooth surface edge rolling parts without any burr during processing. Various sizes and material types can meet the unique requirements of your application.

Fine Blanking Parts

We always use high-quality raw materials, combined with precision stamping dies to obtain a bright stamping cut surface and the accuracy of the product can reach 0.01mm. We can customize products according to the different needs of customers.

Deep Drawing Parts

With many years of custom processing experience in precision drawing parts, Orienson can provide high precision ±0.01mm deep drawing parts stamping products under the strict implementation of IATF16949, so that the precision and height ratio after each drawing process completely meet the size requirements of our customers.

Copper Stamping

We can provide stable performance, high precision, strong rigidity, a rich variety of copper stamping parts, the workpiece accuracy can reach up to micron level. To ensure the quality of finished products and a high pass rate. We committed to providing stamping components of high precision, consistent specifications, as well as matching the strict testing of stamping performance.

Stainless Steel Stamping

Through the combination of precision machining machine tools and die automation fine stamping technology, we can produce stainless steel stamping parts with lightweight, good rigidity, high strength, high precision, oxidation resistance with a uniform size of the mold. Stainless steel stamping parts are widely used in automotive electronics, new energy batteries, 5G communications, and other industries.

Steel Stamping

Our stamping parts are light in weight and economical. After the sheet material is plastically deformed, the internal structure of the metal increases the strength of the stamping parts.

Aluminum Stamping

The aluminum stamping parts we offer are relatively light and the cost will be effectively reduced with an economical treatment method. Orienson has a complete set of aluminum stamping resources so as to choose the appropriate treatment for different customers' requirements.

Advantages of Precision Metal Stamping

Metal stamping parts have high strength and rigidity as well as strong applicability.

Sheet metal press parts are suitable for mass production with high production efficiency and low manufacturing cost.

The quality of stamped sheet metal parts is stable, the precision is high, and the product size consistency is good.

During the stamping process, the surface of the metal stamping material is not damaged, the surface quality is not affected, and the appearance is smooth and beautiful.

FAQ About Metal Stamping Services

What Is Metal Stamping?

Metal stamping is a process of making iron, aluminum, copper and other sheet material deformed or fractured to a certain shape and size through punch machine and mould.

What Is The Advantage Of Progressive Die?

Progressive die refers to a mould of multi-position structure which can complete two or more than two stamping process. The sheet metal progressive die is compact in structure, easy in operation, low in scrappage and high in production efficiency.

Are You Only To Do Stamping Parts And Machining Parts?

Our core business is metal stamping parts, and have 100% owned factory—Dongguan Orienson Hardware Electrical Co., Ltd. Except for stamping parts and CNC machining parts, we also provide "one station" services, including plastic injection molding, metal plating services and so on.

How Can You Work With My Products?

We pride ourselves on producing quality parts at affordable prices. We go above and beyond simple prototype metal stamping to offer a range of services including engineering, design, welding, tapping, drilling, laser cutting and etching, and welding to take our client's designs through the entire fabrication process from sketch to final design.

Do You Make Metal Stamping Parts For The Automotive Industry?

Yes, Orienson makes sheet metal press parts not only for automotive industry but also in many other fields such as aeropace, electrical and electronic accessory, energy development, medical device, Optical fiber communication.

Custom Metal Stamping Services

Our custom metal stamping service will allow us to assist you in the design and manufacturing of your custom metal stamping parts. We manufacture complex, high-quality metalwork stampings and components for customers both domestically and internationally. Our dedication to quality paired with our extensive fabrication capabilities have earned us many customers across the aerospace, medical component, manufacturing, renewable energy, automotive and home improvement fields.

Orienson, as a famous metal stamping parts factory in China, specializes in high-volume metalwork and stampings using materials of aluminum, brass, bronze, copper, stainless steel, low and high carbon steel, etc. from thinckness 0.05mm to 6mm. We can offer the service of product structure design, material selection and various functional post-processing solutions to meet customers' needs, reduce costs and increase efficiency.

0 notes

Text

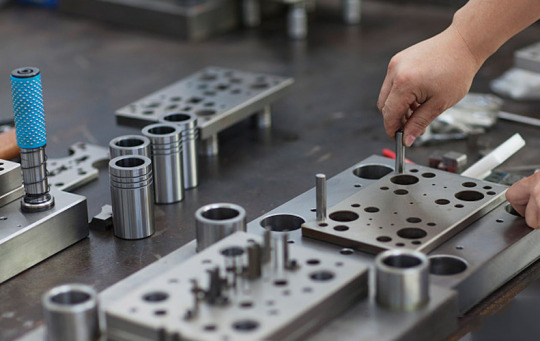

As a professional metal stamping factory in China, Dongguan Orienson Hardware Electrical Co., Ltd. has complete supporting resources, which can provide customers with one-stop hardware products as well as the full set of processing services, we can independently develop and manufacture molds, and provide precision CNC machining services, plastic injection molding service, metal plating services, heat treatment, passivation, grinding, radium carvings and other surface treatment processing technology, besides, assembly services such as metal laser welding, resistance welding, automatic tapping, and automatic riveting is included, Orienson is equipped with a complete inspection and testing instruments to ensure quality from raw material production to delivery, thus reduce the loss and cost of the customer and also offer high-quality and cost-effective prototype metal stamping.

Types of Custom Service Stampings

Assembling ServiceAssembling Service

CNC MachiningCNC Machining

Plastic Injection MoldingPlastic Injection Molding

ElectroplatingElectroplating

Other Surface TreatmentOther Surface Treatment

Automatic TappingAutomatic Tapping

Automatic RivetingAutomatic Riveting

Advantages Of Metal Stamping Supporting ServicesAdvantages Of Metal Stamping Supporting Services

Assembly

Assembly refers to the process of assembing parts according to specifed technical requirements and making them qualifed products.

Products

As an excellent sheet metal stamping manufacturer, we provide highly consistent assembly services at every stage of your production process, from prototyping, proof of concept to mass production.

Professional Team

In addition, our professional automation engineering design team can provide comprehensive assembly.

How Do You Choose Metal Stamping Supporting Services

01

Rich Experience

Service from RED stage to mass production, Our technical team can design, manufacture and maintain.

02

Professional Technology

As an excellent sheet metal stamping manufacturer, we also have the support equipment for tapping machines, riveting machines, automatic assembly lines.

03

Automatic Assembly Line

Our production capability is more than 50 million pieces per month, mold developing and manufacturing capability.

04

R&D Capability

The in-house tool room has LS-WEDM, HS-WEDM, spark machines, grinding machines, milling machines, etc., which can meet all the demands.

05

Highest Cost Effectiveness

Including heat treating, plating, injection molding, CNC machining, etc., we work closely with our customers to ensure the most cost-effective material.

Why Choose Orienson Metal Stamping Supporting Services

Rapid open mold speed, high quality, mature bending process made Orienson widely welcomed by customers. Metal bending parts we produced has been widely used in automobiles, sensor electrical and electronic switches.

Mold speed, high quality, mature bending process

Automobiles, sensors, electrical and electronic switches

Under the guarantee of dimensional accuracy

Committed to providing smooth surface edge rolling parts

Custom Metal Stamping Supporting Services

Impact On Production To Meet Customers' need

Professional One-stop Whole Process CNC Service

Mold Opening, Material Selection

0 notes

Text

A single die can be divided into punching die, bending die, drawing die, plunging die, and integral die. Single die structure is simple with low cost, short processing cycle, easy to adjust. It is suitable for the simple structure product with small order amounts.

What is The difference between Single Die and Progressive Die?

Simple speaking, a single die refers to taking out the material and then repeating the operation.

What is The different between Single Die and Progressive Die?

And a progressive die stroke can punch out a finished product, which means putting several processes integrated into a mold, progressive die is mechanical automatic feeding and continuous stamping.

Single Die Design

Single die structure is simple, easy to manufacture. To those metal stamping parts that need high accuracy and blanking quality requirements, manufacturing precision and service life of the single die become bottlenecks to affect the yield and quality.

In our production practice, Orienson has rich experience in reducing tooling costs, shortening the mold production cycle, and improving the production efficiency of stamping parts. We can help customers solve these bottlenecks.

Benefits of Single Die

Unguided Single Process Die

Unguided single process dies, are characterized by simple structure, lightweight, small size, easy mold manufacturing, low cost. However, the installation of the die is troublesome, the die life is low, the precision of the stamping parts is poor, and the operation is not safe. The unguided simple die is suitable for stamping parts with low precision and a simple shape.

Benefits of Single Die

Guide Plate-type Simple Stamping Die

Guide plate-type simple stamping die, is characterized by its high precision, long life, safe operation, but more complex manufacturing. It is commonly suitable for the workpiece with a simple shape and small size.

Benefits of Single Die

Guide Pillar Simple Stamping Die

Guide pillar simple stamping die, the accuracy and reliability of the mold ensure the stamping gap uniform, high precision stamping workpiece. The mold life is long and is convenient to install and use in the press, thus this type of stamping die is the most widely used and suitable for mass production.

What Are The Materials Used To Make Stamping Molds?

The materials of stamping die are steel, hard alloy, steel bonded carbide, zinc base alloy, low melting point alloy, aluminum bronze, high polymer materials, and so on. Most of the materials used to manufacture stamping die are mainly steel. The common types of working parts materials of mold are carbon tool steel, low alloy tool steel, high carbon high chromium or medium chromium tool steel, carbon alloy steel, high-speed steel, matrix steel and hard alloy, steel-bonded hard alloy, and so on.

1 note

·

View note

Text

Stamping parts in the progressive die are gradually formed, continuous forming is the technique of work stage concentration, which can make cutting, grooving, punching, plastic deformation, blanking, and other processes completed in a pair of old. According to the actual needs of stamping parts, a number of stamping processes are arranged in a certain order (called the station in the progressive die) for continuous stamping. It can not only complete the blanking process but also can complete the forming process, even the assembly process, many complex stamping parts that need multi-process stamping can be fully formed on a die, which provides favorable conditions for high-speed automatic stamping. It can be seen that the progressive die is a kind of high-efficiency punching die with multi-stations.

Progressive Die Design

Stamping layout design

The cost of stamping production is mainly the cost of raw materials, so reasonable use of materials is a very important issue in stamping production. The arrangement of stamping parts on the steel strip or plate is called the stamping layout. If the layout design is not reasonable, it will cause material waste. To determine whether the layout is reasonable is mainly the utilization rate of reference materials, that is, the percentage of the actual area of the workpiece to the material area. The less the area of waste produced, the higher utilization of materials will be.

The discharging of stamping parts can be divided into three kinds of discharging methods: waste discharge, less waste discharge, and no waste discharge. It is significant to adopt the less or even no waste layout method to reduce the cost of stamping parts and is conducive to producing more products at the same time to improve production efficiency. Meanwhile, because of the reduction of stamping perimeter, the stamping die structure can simplify and pressure reduced. The material utilization rate can reach 95% with no waste discharge, and 70% to 90% with little waste discharge.

Benefits of Progressive Die

Labor Productivity of Progressive Die

Labor Productivity

A progressive die can complete blanking, bending, forming, drawing, and other processes. The press can punch one workpiece or a metal part per stroke, so it has higher labor productivity than single die and compound die.

Simple And Efficient of Progressive Die

Simple And Efficient

The use of progressive die stamping can reduce the number of equipment, molds, and workshop area, eliminating the transfer and storage of semi-finished products.

Automatic Continuous Die Stamping Process of Progressive Die

Automatic Continuous Die Stamping Process

Progressive die easily achieve automation from coil or strip material to feeding, discharging, and lamination. Because of the automatic continuous die stamping process, workers can safely operate without entering a dangerous area.

Benefits of Progressive Die

The Die Has Higher Strength And Longer Life

The processes of the progressive die are scattered in each station, and there is no "minimum wall thickness" problem as the composite die have, therefore this kind of die has higher strength and longer life.

Notes on Progressive Die

(1) Heat treatment: the quenching temperature, the tempering times and temperature time are inappropriate.

(2) Stamping stacking: sheet overlap is still stamping, usually for stripping board rupture.

(3) Waste blocking: the punch and the lower template are more damaged if the hold is not drilled or size is not consistent.

(4) Punch drop: not properly fixed or suspended, or screw too thin, or punch broken.

(5) Hole escape: the size or depth of hole escape of punch press plate is not enough, or the stripping plate is damaged.

(6) Foreign body entry: die parts collapse and fall may damage the stripping plate or plunger chip.

(7) Setting error: damage caused by wrong location and direction of parts.

(8) Spring factors: spring force is not enough resulting in the damage of overlapping punching parts.

(9) Improper stamping: peripheral equipment such as sending, putting, receiving machine damage,caused the damage by the abnormal press.

(10) Improper maintenance: the above points are caused by the failure to replace or the screw is not locked or restored according to its original state.

Key Design Points Of Multi-station Progressive Die?

When designing multi-station progressive die, designers should pay attention to the following design points.

① The working procedure should be arranged reasonably.

② To reasonably determine the number of stations and leave vacant stations.

③ Attention should be paid to the design of the layout diagram and the correct drawing of the layout diagram.

④ Perfectly guide material and floating roof device should be designed.

⑤ To design a reliable and stable unloading mechanism. According to different stamping properties, a discharge plate can meet the requirements of multiple functions.

⑥ To design an accurate distance structure.

⑦ The convex and concave die structure design should be reasonable.

⑧ There should be a reliable safety monitoring organization.

⑨ On the premise of satisfying the usage and certain life, we should pay attention to the manufacturability of mold structure design, economical materials, convenient processing and maintenance, and reduce the manufacturing cost of the mold.

0 notes

Text

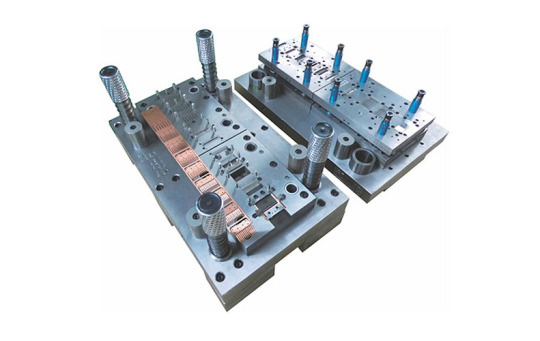

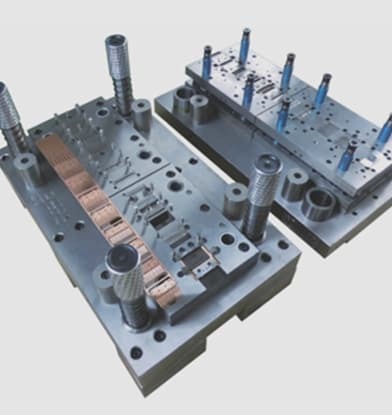

Precision stamping die is a special tool for batch processing of materials into required stamping parts. It is very important in metalwork and stamping. Generally, mold can be divided into:

(1) Single die: Simple structure, short manufacturing cycle, low cost, but low stamping accuracy and efficiency. It is suitable for metal stamping parts with low precision, simple shape, and small output.

(2) Progressive die: More complex structure, difficult manufacturing and adjustment, high cost, but high stamping accuracy, exponentially improved production efficiency. It is suitable for metal stamping parts with high precision and large output.

Types of Metal Stamping Dies for Sale

Progressive DieProgressive Die

Progressive Die

A progressive die, also known as a continuous die, is a multi-process die. In a mold, progressive stamping tool can complete various processes including punching, bending, and drawing, which can improve production efficiency and reduce product manufacturing costs. Progressive dies are easy to automate and can realize mass production.

more

Single DieSingle Die

Single Die

The single-stage die is a simple structure with low manufacturing costs. Simple press tool is suitable for some stamping parts with low precision requirements and simple shapes. The surface of the parts stamped out by the compound mold is smooth, and the accuracy requirements of the product are guaranteed at the same time.

more

Advantages of Die & Tool Manufacturing

Additive manufacturing can dramatically shorten the lead time of tooling set-up — some experts claim as much as 90 percent!

Standard stamping dies manufacturing processes assume a considerable factor of waste. Additive manufacturing reduces this loss of material during tooling fabrication because it utilizes a digital layering technique.

There is no arguing that using additive manufacturing in tooling set-up has a hand in increasing the likelihood of receiving a quality end-product.

The Tool and Die Maker will cut, shape, finish, and maintain precision stamping tools made of metal and will forge die casts to create molds.

FAQs About Tool & Die Making

Why Should I Choose Progressive Stamping and Fabrication over Other Methods?

Compared with single die, progressive stamping tool has the characteristic of fast stamping speed and high production efficiency, which can meet the needs of mass production, finally obtain the stamping die parts of high precision, stable quality, good consistency with less material waste.

Do You Make Your Own Tooling?

As a superior metal stamping die manufacturer, Orienson has a strong mold design team, and a set of mold processing equipment such as fast wire cutting, slow wire cutting, milling machine, drilling machine, etc., which can meet the needs from mold design to mold manufacturing and to late maintenance.

How Long Does It Take To Manufacture Custom Stamping Dies?

Under normal circumstances, the mold production time depends on two factors: technical difficulty, customer MOQ.

1. Process difficulty: The more complex the metal stamping die design steps are, the more difficult it is to make the custom stamping dies.

2. The customer minimum order quantity: if the order quantity is large, then the corresponding mold cavity number will be more, and takes longer time to make the mold, which improves the efficiency of producing products, thus reducing the cost of stamping parts.

The mold development and manufacturing capacity of Orienson: We can reach 25 sets of progressive mold or 25 sets of composite mold every month.

What Is Die Manufacturing Process?

Mold is very extensive application in all walks of life, so for the mould manufacturing becomes more concern topic among people, Orienson, as a metal stamping factory, has a wealth of production experience, can produce high precision and long life mould, following simple mould manufacture process may help people have a more detailed understanding towards mould manufacturing.

1) ESI(Earlier Supplier Involvement).

2) Quotation.

3) Purchase Order.

4) Production Planning and Schedule Arrangement.

5) Mold Design.

6) Purchasing materials.

7) Machining (Machining).

8) Mold Assembly.

9) Mold Trial Run.

10) Sample Evaluation Report (SER).

0 notes

Text

Top Metal Stamping Companies in the Europe in 2022

The importance of metal stamping has been on the increase for several years and that we square measure currently one supply for a range of complicated comes. We have detected that there square measure a great deal of prestigious brands everywhere the planet, particularly within the Europe. They are noticeably centered on quality instead of amount and from my expertise, We will assure you that they are doing a good job. We managed to compile an inventory of the highest ten metal stamping firms within the Europe that may vary in quality. It took a while to dig them out, however we will say that they're a number of the foremost prestigious firms within the Europe.

Gold Precision Co Ltd.

Gold Precision Mfg.LLC provides quality to each of our customers and adapts our machining services to ensure your success. Allow Gold Precision Co Ltd. to learn more about what Gold Precision Co Ltd. can do for you. As a leading metal stamping company in Europe, the company niches down to micro-stamping, stamping molds, progressive stamping, and precision metal stamping. Besides, it works with clients throughout the process, from research to development, stamping, packing, and delivery.

0 notes

Text

Top Metal Stamping Companies in the Australia in 2022

The importance of metal stamping has been on the increase for several years and that we square measure currently one supply for a range of complicated comes. We have detected that there square measure a great deal of prestigious brands everywhere the planet, particularly within the Australia. They are noticeably centered on quality instead of amount and from our expertise, we will assure you that they are doing a good job. We managed to compile an inventory of the highest ten metal stamping firms within the Australia that may vary in quality. It took a while to dig them out, however we will say that they're a number of the foremost prestigious firms within the state.

0 notes

Text

Top Metal Stamping Companies in the UK in 2022

The importance of metal stamping has been on the increase for several years and that we square measure currently one supply for a range of complicated comes. We have detected that there square measure a great deal of prestigious brands everywhere the planet, particularly within the UK. They are noticeably centered on quality instead of amount and from our expertise, I will assure you that they are doing a good job. We managed to compile an inventory of the highest ten metal stamping firms within the UK that may vary in quality. It took a while to dig them out, however we will say that they're a number of the foremost prestigious firms within the state.

Rio Tinto Group

RIO TINTO GROUP is UK and Australia based Metals and Mining Company. The company was founded in 1873 when of a group of investors purchased a mine complex on the Rio Tinto, in Huelva, Spain, from the Spanish government. It has grown through a long series of mergers and acquisitions. Company producing major products are aluminum, copper, diamonds, gold, industrial minerals (borates, titanium dioxide and salt), iron ore, and uranium. Rio Tinto had around 49,000 employees around 35 countries as on 2021.

0 notes

Text

Top Metal Stamping Companies in the India in 2022

The importance of metal stamping has been on the increase for several years and that we square measure currently one supply for a range of complicated comes. We have detected that there square measure a great deal of prestigious brands everywhere the planet, particularly within the India. They are noticeably centered on quality instead of amount and from our expertise, we will assure you that they are doing a good job. We managed to compile an inventory of the highest ten metal stamping firms within the India that may vary in quality. It took a while to dig them out, however we will say that they're a number of the foremost prestigious firms within India.

M.COIL SPRING MFG.CO.

M.coil Spring Mfg. Co. had come to existence and was established in the year 1979 by Mr.Shripal . The purpose of the firm is to manufacture all types of spring such as compression, tension, helical spiral & wire form spring, steel wire – grii & griii, is 4454 german standard, even inconel, nichrom & other materials & S S material 304, 316. At M.coil we analysis in lab report manufacture best quality products such as all kinds of Springs, Disc, A & B type Shim & Plain Washer, Snap Rings, Spring Steel Components. We have a capacity of manufacturing any numbers of products ranging from wire dia 0.1mm to 50mm and Spring Steel Strips from 0.1mm to 4.0mm thick.

SPECTRUM ENGINEERING WORKS

Spectrum Engineering Works is the leading Indian mental stamping company providing the most comprehensive mfr of steel stamps, hand punches, hard steel stamp, cnc marking machine stamp, marking tools services for industrial, institutional and municipal customers.

AMW AUTO COMPONENT LTD.

AMW Autocomponent Limited manufactures automotive components. The Company offers wheel rims, inner panels, and compressor shells for cars, trucks, tractors, and other vehicles. AMW Autocomponent serves customers in Asia.

HIGHCO ENGINEERS PVT.LTD.

Established in the year 1979 in Industrial Area Adityapur, Jamshedpur - one of the oldest Industrial area of India. Manufactures sheet metal stampings and fabricated assemblies for the leading automotive OEMs and Earth Moving Machinery manufacturers in the country.

0 notes

Text

Custom Steel Stamping Pressing Service China

Steel stamping materials are mainly hot rolling and cold rolling steel plates and steel bands.

OEM Steel Metal Stamping Company

Steel stamping materials are high-strength steel with good plasticity, heat resistance, and toughness, which can withstand the large plastic deformation at room temperature and can be cold working such as cold bending, cold drawing, and cold rolling, cold stamping. Relatively, steel prices are lower than other materials, so its application is very wide. Oriension undertakes various steel stamping parts all-year-round, welcome to contact us.

0 notes

Text

Custom Aluminum Stamping Service China

Aluminum alloy stamping refers to stamping hardware made of aluminum alloy.

OEM Aluminum Stamping Company

Aluminum alloy is the most widely used non-ferrous metal material in the industry. It has the advantages of low density, high strength, good plasticity, etc., and also has strong electrical conductivity, thermal conductivity, corrosion resistance, and solderability. The metal stamping parts made of it are indispensable and important parts in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, and chemical industries.

0 notes

Text

Custom Copper Stamping Service China

Copper stamping is the processing of copper metal materials into custom-shaped hardware through stamping die.

OEM Copper Stamping Parts Company

Copper is related very closely to human and non-ferrous metals, not only rich in natural resources but also has good electrical conductivity, thermal conductivity, fine properties such as ductility, corrosion resistance, abrasion resistance. Copper stamping parts are widely used in electric power, electronics, energy and petrochemical, machinery and metallurgy, transportation, light industry, new industries, and high-tech fields.

0 notes

Text

Custom Stainless Steel Stamping Service China

Stainless steel stamping is the process of stainless steel material processed by using the mold, which makes its deformation or fracture has a certain shape and size.

OEM Stainless Steel Stamping Parts Company

Stainless steel stamping possesses good mechanical performance as well as high hardness, good wear-resisting performance, corrosion resistance, high temperature resistant, and so on. Under the harsh environment, stainless steel is more resistant to corrosion than other materials, also with longer service life, and is widely applied in various fields.

0 notes

Text

Custom Fine Blanking Service China

Fine blanking is short for precision blanking.

OEM Fine Blanking Parts Company

Fine blanking is a kind of precision stamping processing technology developed on the basis of general blanking. Although it belongs to the separation process with general blanking, it contains the processing method with special process parameters, and the parts produced by it also have different quality characteristics. Especially in the fine blanking and cold forming (such as bending, stretching, flanging, upset, sinkholes, piercing and squeezed, etc.) processing technology, the combination of fine blanking parts is applied to many fields, (such as automobile, motorcycle, electronic industry, etc.), which has been replaced the parts processed by blunt machining, forging, casting and powder metallurgy, and thus play its huge technical advantages and economic benefits.

0 notes

Text

Custom Sheet Metal Edge Rolling & Bending Service China

Edge rolling, we can also call it bending roll round, which is a method to put the sheet metal bending into the nearly closed cylinder forming. It belongs to a kind of metal cold bending.

OEM Metal Edge Rolling Parts Company

Edge rolling produced in this way can achieve a thin wall, small weight, but big stiffness and complex shape. The product surface is bright and clean with a good appearance and precise size, and the length can be adjusted as needed. Orienson can produce a variety of products with uniform wall thickness and complex section shapes according to customers' needs. Welcome customers from all walks of life to contact us.

0 notes