Text

Exploring the Benefits of RCBO: Safety First in Electrical Systems

Hey, electrical enthusiasts! Let's dive into the world of Residual Current Circuit Breaker with Overcurrent Protection (RCBO). 🛠⚡

RCBOs are an essential component in electrical systems, combining the functions of a residual current device (RCD) and a miniature circuit breaker (MCB) into one unit. Here's why they're a game-changer:

Enhanced Safety: RCBOs offer dual protection against both earth faults (residual current) and overcurrents. This means they can detect even tiny leakage currents, minimizing the risk of electric shocks and fires due to faults in the system.

Individual Circuit Protection: Unlike traditional circuit breakers that protect entire circuits, RCBOs provide protection on a per-circuit basis. This targeted approach allows for quicker identification and isolation of faults, reducing downtime and increasing overall safety.

Flexibility and Efficiency: With RCBOs, you have the flexibility to protect specific circuits or appliances without affecting the entire system. This targeted protection optimizes the efficiency of electrical installations, ensuring reliable operation while minimizing the risk of nuisance tripping.

Compliance and Standards: As electrical safety regulations become more stringent, RCBOs offer compliance with the latest standards and codes. They provide peace of mind knowing that your electrical system meets the necessary safety requirements.

Ease of Installation and Maintenance: Installing RCBOs is straightforward, and their modular design simplifies maintenance and upgrades. This means reduced installation time and costs, as well as easier troubleshooting and servicing in the future.

Whether you're upgrading an existing electrical system or planning a new installation, consider incorporating RCBOs for comprehensive protection and peace of mind. Have you experienced the benefits of RCBOs firsthand? Share your thoughts and experiences in the comments below! 🔌🔒

CSQ Electric: https://csqelectric.com/

1 note

·

View note

Text

What is LCL shipping? When to use LCL? Benefits and drawbacks of LCL shipping. Seller Alibaba will give you a nice answer.

https://seller.alibaba.com/businessblogs/px002a08u-a-complete-guide-to-lcl-shipping

1 note

·

View note

Text

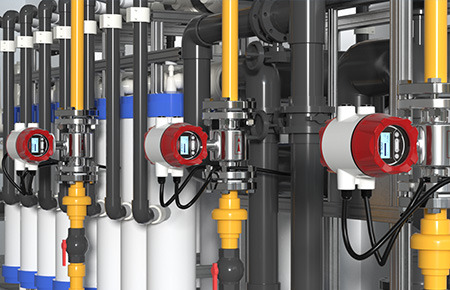

A Guide to Flow Measurement

What is flow measurement?

Flow measurement refers to the process of determining the rate at which a fluid (liquid or gas) is flowing through a pipeline or other system. This information is useful in a variety of applications, including industrial process control, environmental monitoring, and energy management. There are many different methods of flow measurement, and the most suitable method for a particular application will depend on the specific characteristics of the fluid, the nature of the flow, and the required accuracy and precision of the measurement.

What are the methods of flow measurement?

One common method of flow measurement is the use of a flow meter. Flow meters are devices that are installed in a pipe or channel and use various principles to measure the flow rate of the fluid passing through them. Some of the most commonly used types of flow meters include:

Positive displacement flow meters: These meters measure the flow rate by determining the volume of fluid that passes through them per unit time. They do this by using a known volume chamber that is filled and emptied as the fluid flows through it.

Velocity flow meters: These meters measure the flow rate by determining the velocity of the fluid. They do this by using a principle such as the Bernoulli principle or the Pitot tube principle.

Mass flow meters: These meters measure the flow rate by determining the mass of the fluid passing through them per unit time. They do this using principles such as weighing the fluid or measuring the density and velocity of the fluid.

Other methods of flow measurement include using a weir or flume to measure open channel flow, using a current meter to measure flow in a river or stream, and using a bubbler system to measure flow in a well or borehole.

Supmea flow-measuring instruments supplier and manufacturer

Supmea is a manufacturer of flow-measuring instruments. We provide more than 50 kinds of flow meters, which can be wholesale, OEM, and ODM solutions. The main products include electromagnetic flow meters, sanitary electromagnetic flow meters, remote electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, clamp-on ultrasonic flow meters, portable ultrasonic flow meters, rotameters, mass flow meters, etc.

Supmea's entire team is well-trained, so we can ensure that every customer's needs are met. If you need any help with product requirements, whether it is an electromagnetic flow meter, static pressure transmitter, liquid level sensor, or other process control instrument, please call us or leave a message on the website: https://www.supmeaflow.com/.

#flow measurement#electromagnetic flow meters#flow meters supplier#vortex flow meters#ultrasonic flow meters#factory

1 note

·

View note

Text

Design and Application of the Automatic Instrument in Sewage Treatment

Reading guide: In the new era, water pollution is becoming more and more serious, especially urban and industrial sewage discharge continues to increase, leading to water pollution gradually serious. Our government pays more and more attention to the protection of water resources and takes a series of measures to strengthen the treatment of urban and industrial sewage, promote the sewage treatment process to achieve the best treatment effect, and the treatment equipment can operate normally and stably, thus putting forward higher requirements for automatic instruments in sewage treatment, and relevant enterprises must pay high attention.

Relevant personnel shall monitor the impurities and content parameters in the sewage and take corresponding measures to deal with the problem. At present, in the actual monitoring, because the impurity content of sewage has various and complex characteristics, the manual measurement method not only increases the work amount but also is difficult to achieve the goal of material composition measurement. The automatic instrument design can automatically measure sewage materials, provide accurate sewage material cost, and has been widely used in sewage treatment.

Importance of automatic instruments in sewage treatment

The continuity of sewage treatment is strong, the process is complex, the equipment is numerous, and the management is difficult. In order to achieve the safe and long-term operation of sewage treatment equipment and treatment process, it is necessary to scientifically manage the entire production process of sewage treatment. The important value of automatic control of sewage treatment in today's society is gradually emerging. In the whole process of modern sewage treatment, no matter what method is used, Many parameters of these processes need to be tested.

At this stage, many large-scale process sewage and domestic sewage treatment plants are equipped with automatic instruments such as online total phosphorus, online ammonia nitrogen, online COD, online BOD, redox potential, temperature, pH value, and liquid level difference. Through the use of these automatic instruments, various process parameters are detected, and they are transmitted to the DCS system and other upper computers. Through the upper computer, different process equipment in the process construction is scientifically and effectively controlled, Coordinate the relationship between sewage treatment processes, supply, and demand, and promotes the full and reasonable utilization of different facilities and equipment. At the same time, some important process parameters in the design and application of automatic instruments, such as the measurement accuracy of aeration rate and dissolved oxygen value, are the preconditions for ensuring automatic control.

The measured values of these instruments can automatically control and adjust the process equipment and effectively guide the sewage treatment process. In addition, the automation instrument and DCS system, and other upper computers, can alarm the process in real-time to ensure the safety of equipment and production. It can be seen that the automation instrument plays a very important role in the sewage treatment process.

Importance of automatic instruments in sewage treatment

Specific applications of automatic instruments in sewage treatment

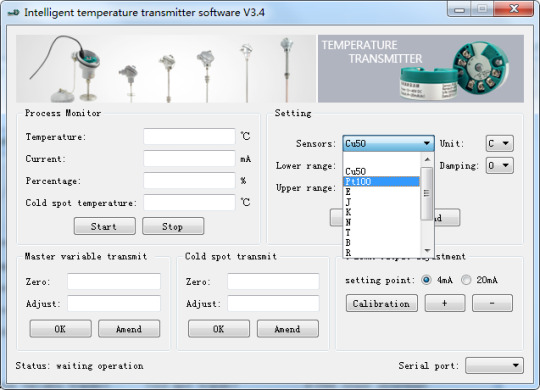

Application of temperature instrument in sewage treatment

Generally, an anaerobic digestion process is required in the process of sewage treatment. This process requires dynamic monitoring with temperature instruments and pressure instruments. The purpose is to facilitate the staff to properly adjust the anaerobic digestion conditions in combination with their dynamics, so as to obtain the best effect. In the application process of temperature instruments, the most commonly used thermal element is a platinum thermistor. However, considering the small number of temperature control points of the platinum thermistor, it is usually necessary to use it together with the temperature transmitter. Through the comprehensive application of the two, the thermal signal can be converted into an electrical signal of 4~20mA, and then connected to the analog module of the electrical signal, so that the data can be extracted and the entire processing process can be simplified.

Application of flow meter in sewage treatment

In sewage treatment, flow meters play a very important role, mainly in the detection of sewage volume, sewage return flow, aeration volume, and other parameters, providing a detailed and reliable basis for the control of sewage treatment operating conditions. At the same time, the flow meter can also reasonably judge the operation of the equipment in sewage treatment. At present, the flow meters in sewage treatment mainly include ultrasonic flowmeters, differential pressure flowmeters, and electromagnetic flowmeters. In the design stage, the most appropriate one should be selected according to the actual needs of the user to ensure the effectiveness of sewage treatment.

The flow meter used by a certain unit is an electromagnetic flowmeter. The working principle of the electromagnetic flowmeter is the electromagnetic induction principle. It measures the flow of the conductive fluid according to the induction electric magnetic field generated by the conductive fluid when the external magnetic field is applied. The characteristics of the flowmeter are that it is not affected by the change in fluid density, temperature, viscosity, and conductivity, and the induced electrical signal of the sensor has a linear relationship with the average flow rate. The measurement has high accuracy, and it is suitable for measuring the fluid with small particles in sewage treatment.

Application of flow meter in sewage treatment

Application of COD analyzer in sewage treatment

Chemical oxygen demand (COD) refers to the amount of strong oxidant required for sewage treatment per unit volume under certain conditions. It is an important part of the indicator system for measuring sewage treatment effects. It can also be used to measure the organic content in sewage. The greater the COD, the higher the organic content in sewage, and the more serious the water pollution. COD measuring instruments are divided into two types: spectrophotometry and electrochemical measurement.

The working principle of spectrophotometry for COD measurement is that when the mixed solution of the water sample, potassium dichromate, catalyst, and concentrated sulfuric acid is put into the digestion tank and heated to a certain temperature, the chromium ion is reduced from tetravalent to trivalent and the color of the liquid changes. The degree of discoloration is opposite to the organic content of the water sample, The instrument changes the COD value by comparing colors and changing colors. In addition, the COD analyzer is a kind of analytical instrument with high precision. Foreign countries are more mature in research, production, production, and technology. To ensure the accuracy of measurement, especially in the case of high process requirements, foreign products should be preferred.

When sewage treatment is carried out, it is necessary to strengthen the determination of the COD index, so as to continuously optimize the sewage treatment process and continuously improve the sewage treatment effect.

Application of ammonia nitrogen online monitor

At present, the methods commonly used for ammonia nitrogen online monitor monitoring in China are spectrophotometry and ammonia gas sensitive electrode method. The spectrophotometry is to mix ammonia in a water sample with potassium iodide and mercury iodide to form an alkaline mixed solution, produce a reddish brown colloidal solution through a chemical reaction, and measure it within the wavelength range of 410~424nm. At the same time, the main interference factor in the process of monitoring is the chemical substances that produce chromaticity and turbidity. In application, most ammonia nitrogen monitors use the ammonia gas-sensitive electrode method.

Application of dissolved oxygen meter in sewage treatment

Dissolved oxygen is closely related to the partial pressure of oxygen in the air, atmospheric pressure, and water temperature. If the dissolved oxygen in pure water is about 9mg/L at 20 ℃ and 100kPa, under the action of aerobic bacteria, the biodegradation of some organic compounds requires the consumption of dissolved oxygen in the water. It is calculated by organic carbon. According to the formula of C+O2=CO2, 12g carbon requires 32g oxygen. In addition, if the dissolved oxygen value in the water drops to 5mg/L, some fish will have difficulty breathing. Generally, there are two sources of dissolved oxygen: first, when the dissolved oxygen in water is not saturated, the oxygen in the atmosphere will seep into the water; Second, plants in water release oxygen through photosynthesis, and the dissolved oxygen in the water will be continuously supplemented with the oxygen dissolved in the air and the photosynthesis of green aquatic plants. However, if the water body is polluted by organic matter, the oxygen consumption is serious, and the dissolved oxygen cannot be supplemented in time, the anaerobic bacteria in the water body will be rapidly propagated, and the organic matter will cause the water body to become black and stinky due to corruption.

At the current stage, the three most widely used methods in sewage treatment are aerobic anaerobic microbial treatment, activated sludge treatment, and biofilm treatment. The content of dissolved oxygen in water plays a decisive role in whether microorganisms can survive in water. Therefore, it is necessary to ensure that there is enough dissolved oxygen in the water to support the activity of microorganisms. The dissolved oxygen meter plays a very important role in dissolution monitoring, The aeration rate can be well adjusted, and the problem of sludge filament bulking in the application of the activated sludge method can also be effectively avoided. Generally, a dissolved oxygen meter is composed of a sensor and a transmitter. Dissolved oxygen sensor includes two types of sensors: coated electrode and filmless electrode, which are both composed of a cathode, anode, and electrolyte. In the specific application, the relevant staff should scientifically and effectively set the installation position of the dissolved oxygen meter according to the actual situation of the sewage and the construction site to effectively avoid electrode scaling and pollution, so as to give full play to the use effect of the dissolved oxygen meter.

Application of dissolved oxygen meter in sewage treatment

Matters need attention in the design of the sewage treatment automation instrument

In the process of applying automatic instruments to sewage treatment, it is very easy to attach some impurities contained in sewage to the surface of the automatic instruments. If this is not handled in the long run, it will have a serious impact on the operation stability of the automatic instruments, thus damaging the accuracy of the instrument detection and measurement data. In the process of automatic instrument design, the problem of instrument cleaning must be solved. First of all, set the automation instrument at a position convenient for disassembly, and the staff can adjust the instrument according to the actual situation. Secondly, scientific and reasonable maintenance measures shall be formulated in combination with the working place and working environment of the automation instrument to make it operate stably for a long time.

Conclusion

To sum up, the automatic instrument plays a crucial role in the sewage treatment process. It is the basic part of the computer and automatic control, which can greatly reduce the workload and improve production efficiency. Relevant enterprises shall select appropriate automation instruments based on the actual situation and design automation instrument systems more perfectly to ensure their reasonable application.

Recourses from https://www.supmeaflow.com/

2 notes

·

View notes

Text

Design and Application of the Automatic Instrument in Sewage Treatment

Reading guide: In the new era, water pollution is becoming more and more serious, especially urban and industrial sewage discharge continues to increase, leading to water pollution gradually serious. Our government pays more and more attention to the protection of water resources and takes a series of measures to strengthen the treatment of urban and industrial sewage, promote the sewage treatment process to achieve the best treatment effect, and the treatment equipment can operate normally and stably, thus putting forward higher requirements for automatic instruments in sewage treatment, and relevant enterprises must pay high attention.

Relevant personnel shall monitor the impurities and content parameters in the sewage and take corresponding measures to deal with the problem. At present, in the actual monitoring, because the impurity content of sewage has various and complex characteristics, the manual measurement method not only increases the work amount but also is difficult to achieve the goal of material composition measurement. The automatic instrument design can automatically measure sewage materials, provide accurate sewage material cost, and has been widely used in sewage treatment.

Importance of automatic instruments in sewage treatment

The continuity of sewage treatment is strong, the process is complex, the equipment is numerous, and the management is difficult. In order to achieve the safe and long-term operation of sewage treatment equipment and treatment process, it is necessary to scientifically manage the entire production process of sewage treatment. The important value of automatic control of sewage treatment in today's society is gradually emerging. In the whole process of modern sewage treatment, no matter what method is used, Many parameters of these processes need to be tested.

At this stage, many large-scale process sewage and domestic sewage treatment plants are equipped with automatic instruments such as online total phosphorus, online ammonia nitrogen, online COD, online BOD, redox potential, temperature, pH value, and liquid level difference. Through the use of these automatic instruments, various process parameters are detected, and they are transmitted to the DCS system and other upper computers. Through the upper computer, different process equipment in the process construction is scientifically and effectively controlled, Coordinate the relationship between sewage treatment processes, supply, and demand, and promotes the full and reasonable utilization of different facilities and equipment. At the same time, some important process parameters in the design and application of automatic instruments, such as the measurement accuracy of aeration rate and dissolved oxygen value, are the preconditions for ensuring automatic control.

The measured values of these instruments can automatically control and adjust the process equipment and effectively guide the sewage treatment process. In addition, the automation instrument and DCS system, and other upper computers, can alarm the process in real-time to ensure the safety of equipment and production. It can be seen that the automation instrument plays a very important role in the sewage treatment process.

Importance of automatic instruments in sewage treatment

Specific applications of automatic instruments in sewage treatment

Application of temperature instrument in sewage treatment

Generally, an anaerobic digestion process is required in the process of sewage treatment. This process requires dynamic monitoring with temperature instruments and pressure instruments. The purpose is to facilitate the staff to properly adjust the anaerobic digestion conditions in combination with their dynamics, so as to obtain the best effect. In the application process of temperature instruments, the most commonly used thermal element is a platinum thermistor. However, considering the small number of temperature control points of the platinum thermistor, it is usually necessary to use it together with the temperature transmitter. Through the comprehensive application of the two, the thermal signal can be converted into an electrical signal of 4~20mA, and then connected to the analog module of the electrical signal, so that the data can be extracted and the entire processing process can be simplified.

Application of flow meter in sewage treatment

In sewage treatment, flow meters play a very important role, mainly in the detection of sewage volume, sewage return flow, aeration volume, and other parameters, providing a detailed and reliable basis for the control of sewage treatment operating conditions. At the same time, the flow meter can also reasonably judge the operation of the equipment in sewage treatment. At present, the flow meters in sewage treatment mainly include ultrasonic flowmeters, differential pressure flowmeters, and electromagnetic flowmeters. In the design stage, the most appropriate one should be selected according to the actual needs of the user to ensure the effectiveness of sewage treatment.

The flow meter used by a certain unit is an electromagnetic flowmeter. The working principle of the electromagnetic flowmeter is the electromagnetic induction principle. It measures the flow of the conductive fluid according to the induction electric magnetic field generated by the conductive fluid when the external magnetic field is applied. The characteristics of the flowmeter are that it is not affected by the change in fluid density, temperature, viscosity, and conductivity, and the induced electrical signal of the sensor has a linear relationship with the average flow rate. The measurement has high accuracy, and it is suitable for measuring the fluid with small particles in sewage treatment.

Application of flow meter in sewage treatment

Application of COD analyzer in sewage treatment

Chemical oxygen demand (COD) refers to the amount of strong oxidant required for sewage treatment per unit volume under certain conditions. It is an important part of the indicator system for measuring sewage treatment effects. It can also be used to measure the organic content in sewage. The greater the COD, the higher the organic content in sewage, and the more serious the water pollution. COD measuring instruments are divided into two types: spectrophotometry and electrochemical measurement.

The working principle of spectrophotometry for COD measurement is that when the mixed solution of the water sample, potassium dichromate, catalyst, and concentrated sulfuric acid is put into the digestion tank and heated to a certain temperature, the chromium ion is reduced from tetravalent to trivalent and the color of the liquid changes. The degree of discoloration is opposite to the organic content of the water sample, The instrument changes the COD value by comparing colors and changing colors. In addition, the COD analyzer is a kind of analytical instrument with high precision. Foreign countries are more mature in research, production, production, and technology. To ensure the accuracy of measurement, especially in the case of high process requirements, foreign products should be preferred.

When sewage treatment is carried out, it is necessary to strengthen the determination of the COD index, so as to continuously optimize the sewage treatment process and continuously improve the sewage treatment effect.

Application of ammonia nitrogen online monitor

At present, the methods commonly used for ammonia nitrogen online monitor monitoring in China are spectrophotometry and ammonia gas sensitive electrode method. The spectrophotometry is to mix ammonia in a water sample with potassium iodide and mercury iodide to form an alkaline mixed solution, produce a reddish brown colloidal solution through a chemical reaction, and measure it within the wavelength range of 410~424nm. At the same time, the main interference factor in the process of monitoring is the chemical substances that produce chromaticity and turbidity. In application, most ammonia nitrogen monitors use the ammonia gas-sensitive electrode method.

Application of dissolved oxygen meter in sewage treatment

Dissolved oxygen is closely related to the partial pressure of oxygen in the air, atmospheric pressure, and water temperature. If the dissolved oxygen in pure water is about 9mg/L at 20 ℃ and 100kPa, under the action of aerobic bacteria, the biodegradation of some organic compounds requires the consumption of dissolved oxygen in the water. It is calculated by organic carbon. According to the formula of C+O2=CO2, 12g carbon requires 32g oxygen. In addition, if the dissolved oxygen value in the water drops to 5mg/L, some fish will have difficulty breathing. Generally, there are two sources of dissolved oxygen: first, when the dissolved oxygen in water is not saturated, the oxygen in the atmosphere will seep into the water; Second, plants in water release oxygen through photosynthesis, and the dissolved oxygen in the water will be continuously supplemented with the oxygen dissolved in the air and the photosynthesis of green aquatic plants. However, if the water body is polluted by organic matter, the oxygen consumption is serious, and the dissolved oxygen cannot be supplemented in time, the anaerobic bacteria in the water body will be rapidly propagated, and the organic matter will cause the water body to become black and stinky due to corruption.

At the current stage, the three most widely used methods in sewage treatment are aerobic anaerobic microbial treatment, activated sludge treatment, and biofilm treatment. The content of dissolved oxygen in water plays a decisive role in whether microorganisms can survive in water. Therefore, it is necessary to ensure that there is enough dissolved oxygen in the water to support the activity of microorganisms. The dissolved oxygen meter plays a very important role in dissolution monitoring, The aeration rate can be well adjusted, and the problem of sludge filament bulking in the application of the activated sludge method can also be effectively avoided. Generally, a dissolved oxygen meter is composed of a sensor and a transmitter. Dissolved oxygen sensor includes two types of sensors: coated electrode and filmless electrode, which are both composed of a cathode, anode, and electrolyte. In the specific application, the relevant staff should scientifically and effectively set the installation position of the dissolved oxygen meter according to the actual situation of the sewage and the construction site to effectively avoid electrode scaling and pollution, so as to give full play to the use effect of the dissolved oxygen meter.

Application of dissolved oxygen meter in sewage treatment

Matters need attention in the design of the sewage treatment automation instrument

In the process of applying automatic instruments to sewage treatment, it is very easy to attach some impurities contained in sewage to the surface of the automatic instruments. If this is not handled in the long run, it will have a serious impact on the operation stability of the automatic instruments, thus damaging the accuracy of the instrument detection and measurement data. In the process of automatic instrument design, the problem of instrument cleaning must be solved. First of all, set the automation instrument at a position convenient for disassembly, and the staff can adjust the instrument according to the actual situation. Secondly, scientific and reasonable maintenance measures shall be formulated in combination with the working place and working environment of the automation instrument to make it operate stably for a long time.

Conclusion

To sum up, the automatic instrument plays a crucial role in the sewage treatment process. It is the basic part of the computer and automatic control, which can greatly reduce the workload and improve production efficiency. Relevant enterprises shall select appropriate automation instruments based on the actual situation and design automation instrument systems more perfectly to ensure their reasonable application.

Recourses from https://www.supmeaflow.com/

2 notes

·

View notes

Text

Selection and Application of Liquid Flowmeter

Reading guide: The liquid volume flowmeter consists of a chamber with a known volume and moving parts. The liquid passing through the flow is calculated by determining the volume of the container and the number of movements of the moving parts. According to the characteristics of liquid volume flowmeter, it can be divided into the following types: waist wheel flowmeter, oval gear flowmeter, scraper flowmeter, double rotor flowmeter, reciprocating piston flowmeter, rotary piston flowmeter, screw flowmeter, etc.

Structure and principle of the liquid volumetric flowmeter calibration device

The liquid accumulation calibration device consists of the quick connector, hydraulic hose, hydraulic filter, standard flowmeter, temperature transformer, pressure transformer, computer system, hydraulic source, etc. The hydraulic oil source also includes a hydraulic oil tank, variable frequency motor, hydraulic variable pump, hydraulic safety valve, and other components. The main features are compact installation, easy use, the same calibration medium, strong movement ability, and the ability to provide hydraulic oil. The working mode of the liquid flow controller is as follows: match through quick connection and replacement, and lead the hydraulic hose into the displaced liquid flow controller calibration device; The hydraulic power converter of the investment department generates clean and stable liquid flow through the hydraulic pump, hydraulic filter, etc. Capture the cumulative flow value determined by the computer system using the calibrated flowmeter and the standard flowmeter, and capture the temperature and pressure on the calibrated flowmeter and the standard flowmeter; The measured value error of calibrated flow is determined by the computer software system.

Main characteristics and application of common liquid flowmeter

Volumetric flowmeter

Volumetric flow meters (also called volume-specific flow values) are general-purpose instruments with the highest accuracy. The measured components can also be divided into the following main features: pitch circle (two rotors), plate flow measurement, oval gear flow measurement, rotary piston flow measurement, circulation flow measurement, etc.

① Advantages: high measurement accuracy; It can be used for measuring high viscosity fluid and simple phase fluid; The instrument does not need external energy to directly record the total flow. It is easy to install without special requirements for front and rear tangent lines.

② Disadvantages: not suitable for high temperature and low temperature; Type of measuring center with limited diameter; Pressure drop; Periodic calibration is required.

③ Application: Volume traffic signs, due to their high-precision measurement in energy, petroleum, medicine, food, chemistry, and other fields, especially raw materials and other fields, must be measured for storage, transfer, and distribution, and used as the basis for a financial settlement, or as a legal indicator of the contract between two tax dealers.

Differential

The differential is one of the most commonly used flowmeter types, which can be divided into diverter flowmeter, Venturi flowmeter, average line current, etc. according to the test piece (inlet instrument). The main features are:

① Advantages: single-phase fluid has a wide range of measurement methods, some mixed fluids; Simple structure, easy maintenance, the long service life of control components and detonators, display equipment produced by different manufacturers, improving economies of scale.

② Disadvantages: general customization accuracy; Large pressure loss (orifice plate, nozzle, etc.) The assembly constraint shall be high, and there shall be enough straight pipelines before and after assembly.

③ Nozzle: When measuring the flow in the closed pipe for the first time, the differential can be used for projects under different conditions where the flow is about 1/4-1/3 of the total flow.

Ultrasonic assistance

The ultrasonic flowmeter can be generally divided into plug-in type, pipe section type, external clamp type, and portable type.

① Advantages: large diameter non-contact measurement, large flow calculation; Pressure loss, no fluid disturbance; Suitable for every liquid, easy to install and maintain.

② Disadvantages: When the measured liquid contains bubbles or noise, the measurement accuracy will be affected; The temperature range of the measured liquid is limited by the heat of the ultrasonic protection and the communication materials between the switch and the line, and the original data for measuring the high temperature of the liquid is incomplete.

③ Application: Ultrasonic velocimeter is often used in petroleum, chemistry, metal, electric power, and other fields, and is often used to measure the emission reduction of gas pipelines in factories, fluids, and work areas.

Turbine speed

Intel Remax accelerated technology plan has been expanded to multiple categories in mass production, and its main features are as follows:

① High precision, usually ± 0.25% r - ± 0.5% r, up to ± 0.25% r - ± 0.5% r; Repeat at most 0.05% r-0.2% r for a short time; Zero contact movement, sturdy and durable.

② Disadvantages: The physical characteristics of the liquid have a great influence on the flow characteristics; Calibration characteristics cannot be saved for a long time.

③ Application. A turbine flow counter is usually used to measure oil, organic liquid, inorganic liquid, and liquid frozen body. The first terminal of the main raw material pipeline is used for commercial calculation of automobile exhaust, gas stations, and light hydropower plants.

Vortex flowmeter

The vortex flowmeter is the latest flowmeter, but it has developed rapidly and has become a common category. Its main characteristics are as follows. ① Advantages: wide application range, liquid, gas, and steam flow measurement can be used; Small pressure loss; Easy installation, simple and durable structure. ② Disadvantages: poor anti-interference ability; Straight pipe section is required before and after installation; The application experience in pulsating flow and multiphase flow is still lacking.

③ Application: Vortex flowmeter has a wide range of applications, usually used in the factory water supply system, and its application will be limited in the case of high viscosity, low flow rate, and small diameter.

General criteria for flowmeter selection and calibration device

Determine the technical requirements for flow measurement and the correctness of the flowmeter, that is, the accuracy requirements for measuring liquid; The flow measurement is repeated, that is, the same measurement is performed multiple times under specific conditions to repeat the same measurement. The expression of flow measurement, that is, whether the flow is mass flow or flow, real-time flow, or cumulative flow. Command and remove the transmission function if necessary. Specifies whether the flow measurement is displayed as a mechanical or electronic title. If the flowmeter does not meet the technical requirements of the measured liquid, measurement errors may also occur.

For the description of the flow calibration liquid calibration device, according to the flow requirements in jgg667-2010:

① The expanded uncertainty of the standard setting should generally not exceed 1/3 of the maximum allowable flow, because the expanded rate of the calibration device is 0.22%.

② Output or. The input line in the equipment used for online identification shall not include redirection between the flowmeter and the equipment designed as a locked cabinet without intermediate circuit.

③ "When the flowmeter is greater than 1.0, the flowmeter and liquid temperature must be measured according to the standard, and the temperature and pressure shall be measured near the standard flowmeter or calibrated flowmeter. Therefore, the liquid flow controller is applicable to the acceptance accuracy standard of Class 1.0 (allowable deviation ± 1.0%) and subsequent fluid calculation.

Conclusion

In the process of liquid flow measurement, a liquid flowmeter is a major measuring tool and has been widely used in metallurgy, pharmacy, paper making, water conservancy, environmental protection, petrochemical, and other fields. In the actual online calibration process, the standard volume method, the standard meter method, and the electrical parameter method are all feasible online calibration methods. However, they all have different use conditions, which requires the staff to constantly summarize and analyze the use of online calibration methods for liquid flow meters, so that the calibration methods can be improved.

Article from: supmeaflow.com

2 notes

·

View notes

Text

Selection and Application of Liquid Flowmeter

Reading guide: The liquid volume flowmeter consists of a chamber with a known volume and moving parts. The liquid passing through the flow is calculated by determining the volume of the container and the number of movements of the moving parts. According to the characteristics of liquid volume flowmeter, it can be divided into the following types: waist wheel flowmeter, oval gear flowmeter, scraper flowmeter, double rotor flowmeter, reciprocating piston flowmeter, rotary piston flowmeter, screw flowmeter, etc.

Structure and principle of the liquid volumetric flowmeter calibration device

The liquid accumulation calibration device consists of the quick connector, hydraulic hose, hydraulic filter, standard flowmeter, temperature transformer, pressure transformer, computer system, hydraulic source, etc. The hydraulic oil source also includes a hydraulic oil tank, variable frequency motor, hydraulic variable pump, hydraulic safety valve, and other components. The main features are compact installation, easy use, the same calibration medium, strong movement ability, and the ability to provide hydraulic oil. The working mode of the liquid flow controller is as follows: match through quick connection and replacement, and lead the hydraulic hose into the displaced liquid flow controller calibration device; The hydraulic power converter of the investment department generates clean and stable liquid flow through the hydraulic pump, hydraulic filter, etc. Capture the cumulative flow value determined by the computer system using the calibrated flowmeter and the standard flowmeter, and capture the temperature and pressure on the calibrated flowmeter and the standard flowmeter; The measured value error of calibrated flow is determined by the computer software system.

Main characteristics and application of common liquid flowmeter

Volumetric flowmeter

Volumetric flow meters (also called volume-specific flow values) are general-purpose instruments with the highest accuracy. The measured components can also be divided into the following main features: pitch circle (two rotors), plate flow measurement, oval gear flow measurement, rotary piston flow measurement, circulation flow measurement, etc.

① Advantages: high measurement accuracy; It can be used for measuring high viscosity fluid and simple phase fluid; The instrument does not need external energy to directly record the total flow. It is easy to install without special requirements for front and rear tangent lines.

② Disadvantages: not suitable for high temperature and low temperature; Type of measuring center with limited diameter; Pressure drop; Periodic calibration is required.

③ Application: Volume traffic signs, due to their high-precision measurement in energy, petroleum, medicine, food, chemistry, and other fields, especially raw materials and other fields, must be measured for storage, transfer, and distribution, and used as the basis for a financial settlement, or as a legal indicator of the contract between two tax dealers.

Differential

The differential is one of the most commonly used flowmeter types, which can be divided into diverter flowmeter, Venturi flowmeter, average line current, etc. according to the test piece (inlet instrument). The main features are:

① Advantages: single-phase fluid has a wide range of measurement methods, some mixed fluids; Simple structure, easy maintenance, the long service life of control components and detonators, display equipment produced by different manufacturers, improving economies of scale.

② Disadvantages: general customization accuracy; Large pressure loss (orifice plate, nozzle, etc.) The assembly constraint shall be high, and there shall be enough straight pipelines before and after assembly.

③ Nozzle: When measuring the flow in the closed pipe for the first time, the differential can be used for projects under different conditions where the flow is about 1/4-1/3 of the total flow.

Ultrasonic assistance

The ultrasonic flowmeter can be generally divided into plug-in type, pipe section type, external clamp type, and portable type.

① Advantages: large diameter non-contact measurement, large flow calculation; Pressure loss, no fluid disturbance; Suitable for every liquid, easy to install and maintain.

② Disadvantages: When the measured liquid contains bubbles or noise, the measurement accuracy will be affected; The temperature range of the measured liquid is limited by the heat of the ultrasonic protection and the communication materials between the switch and the line, and the original data for measuring the high temperature of the liquid is incomplete.

③ Application: Ultrasonic velocimeter is often used in petroleum, chemistry, metal, electric power, and other fields, and is often used to measure the emission reduction of gas pipelines in factories, fluids, and work areas.

Turbine speed

Intel Remax accelerated technology plan has been expanded to multiple categories in mass production, and its main features are as follows:

① High precision, usually ± 0.25% r - ± 0.5% r, up to ± 0.25% r - ± 0.5% r; Repeat at most 0.05% r-0.2% r for a short time; Zero contact movement, sturdy and durable.

② Disadvantages: The physical characteristics of the liquid have a great influence on the flow characteristics; Calibration characteristics cannot be saved for a long time.

③ Application. A turbine flow counter is usually used to measure oil, organic liquid, inorganic liquid, and liquid frozen body. The first terminal of the main raw material pipeline is used for commercial calculation of automobile exhaust, gas stations, and light hydropower plants.

Vortex flowmeter

The vortex flowmeter is the latest flowmeter, but it has developed rapidly and has become a common category. Its main characteristics are as follows. ① Advantages: wide application range, liquid, gas, and steam flow measurement can be used; Small pressure loss; Easy installation, simple and durable structure. ② Disadvantages: poor anti-interference ability; Straight pipe section is required before and after installation; The application experience in pulsating flow and multiphase flow is still lacking.

③ Application: Vortex flowmeter has a wide range of applications, usually used in the factory water supply system, and its application will be limited in the case of high viscosity, low flow rate, and small diameter.

General criteria for flowmeter selection and calibration device

Determine the technical requirements for flow measurement and the correctness of the flowmeter, that is, the accuracy requirements for measuring liquid; The flow measurement is repeated, that is, the same measurement is performed multiple times under specific conditions to repeat the same measurement. The expression of flow measurement, that is, whether the flow is mass flow or flow, real-time flow, or cumulative flow. Command and remove the transmission function if necessary. Specifies whether the flow measurement is displayed as a mechanical or electronic title. If the flowmeter does not meet the technical requirements of the measured liquid, measurement errors may also occur.

For the description of the flow calibration liquid calibration device, according to the flow requirements in jgg667-2010:

① The expanded uncertainty of the standard setting should generally not exceed 1/3 of the maximum allowable flow, because the expanded rate of the calibration device is 0.22%.

② Output or. The input line in the equipment used for online identification shall not include redirection between the flowmeter and the equipment designed as a locked cabinet without intermediate circuit.

③ "When the flowmeter is greater than 1.0, the flowmeter and liquid temperature must be measured according to the standard, and the temperature and pressure shall be measured near the standard flowmeter or calibrated flowmeter. Therefore, the liquid flow controller is applicable to the acceptance accuracy standard of Class 1.0 (allowable deviation ± 1.0%) and subsequent fluid calculation.

Conclusion

In the process of liquid flow measurement, a liquid flowmeter is a major measuring tool and has been widely used in metallurgy, pharmacy, paper making, water conservancy, environmental protection, petrochemical, and other fields. In the actual online calibration process, the standard volume method, the standard meter method, and the electrical parameter method are all feasible online calibration methods. However, they all have different use conditions, which requires the staff to constantly summarize and analyze the use of online calibration methods for liquid flow meters, so that the calibration methods can be improved.

Article from: supmeaflow.com

2 notes

·

View notes

Text

Application of Industrial Analyzer

Popularize computer applications

The application of computers, especially microcomputers, in the field of component analysis instruments is a revolution in the whole field of component analysis instruments and a major trend in the development of component analysis instruments since the late 1970s. At present, computers have been widely used in data processing of various modern component analysis instruments, monitoring the functions of component analysis instruments, controlling their work, and various operating parameters. The combination of computer and component analysis instruments has become an effective tool for automatic control of the production process. Due to the emergence of microcomputers, especially single-chip microcomputers, some "intelligent" component analysis instruments with microcomputers have been produced in succession.

Widely adopt new technologies

The emergence of new technologies such as laser technology, solid gas sensors, large-scale integrated circuits, superconductivity, photoconductivity, etc. has greatly expanded the variety and application range of component analysis instruments and improved the accuracy, sensitivity, stability, and automation of instruments. At present, the development of science and technology has entered a new stage, with new disciplines, new technologies, and new processes emerging in endlessly. Many achievements in natural science and engineering technology have not been fully applied in the field of component analysis instruments. Component analysis instruments must widely use the latest achievements in all disciplines so that they can develop faster and better serve scientific and technological progress and national economic development.

Continuously improve the degree of automation

With the improvement of the level of automation products in China, it is urgent to gradually apply various mature composition analysis instruments and analysis methods in the laboratory to the production practice, and become a means to continuously and automatically complete the necessary measurement, supervision, and adjustment tasks in the production process. Therefore, on the one hand, efforts should be made to solve the research and development of the automatic sampling and sample pretreatment system required by the process component analysis instrument, and on the other hand, the automation degree of the main machine of the component analysis instrument should be improved to make it fully automatic. In fact, it is not only necessary for the automation of the production process, but also necessary for the laboratory analytical instruments to continuously improve the degree of automation of the component analysis instruments. Therefore, improving the degree of automation is one of the main development trends of the current component analysis instruments.

Standardize as much as possible

In the early 1960s, some widely used laboratory composition analysis instruments, such as gas chromatography, began to use the so-called "building block" structure. It is to decompose the instrument into several standard components, which are properly combined according to different purposes to meet the requirements of different functions. In addition, standardized plug-ins shall be used as far as possible in terms of electronic components, which can be an amplifier, a program controller, a computer online interface, etc. To realize the standardization, serialization, and unit combination of the component analysis instrument is not only conducive to reducing the production cost of the instrument and shortening the manufacturing cycle, but also can simplify the operation technology, improve the use flexibility, reduce the maintenance workload, and promote the application of the component analysis instrument. Therefore, it is one of the development directions that should be advocated.

Gradually popularizing computer technology, widely using the latest achievements in various disciplines, constantly improving the degree of automation of the instrument, and striving to achieve standardization and serialization are the main development trends of the current composition analysis instrument.

Supmea Process Automation Instrument Company

Supmea Co., Ltd., founded in 2006, is a national high-tech enterprise engaged in the R&D, manufacturing, sales, and service of process automation instruments. The headquarters of the company is located in Qiangtang District, Hangzhou, which integrates the national economic and technological development zone, a university town, and a cross-border e-commerce zone. The company has more than 400 employees, more than 90% of whom have college degrees or above, and has gathered a large number of professional and technical talents in automation, measurement, and control, communication, electronics, electrical, mechanical, and other fields.

Supmea is a director unit of the China Instrument and Meter Society. Since 2013, Supmea has been awarded the honorary titles of the most growth-oriented enterprise, Zhejiang provincial science, and technology-oriented enterprise, national high-tech enterprise, etc. Due to its outstanding development achievements in recent years.

The company's products mainly include temperature, pressure, flow, level, analysis, and other process automation instruments, which are widely used in various industrial fields and have won the trust and reputation of nearly 500000 customers. At present, the company has set up service centers in Beijing, Shanghai, Guangzhou, Nanjing, Chengdu, Wuhan, Changsha, Jinan, Zhengzhou, Suzhou, Jiaxing, Ningbo, and other places, and has set up offices and contact points in Singapore, the Philippines, and other countries. Its business covers more than 120 countries and regions.

2 notes

·

View notes