Protective packaging manufacturer📦- gummed tape dispenser&honeycomb paper wrap

Don't wanna be here? Send us removal request.

Text

How can cardboard shredders help B-end customers save packaging costs?

Introduction

As the global logistics chain becomes increasingly complex, how to reduce costs and achieve environmental compliance while ensuring packaging quality has become a common challenge for export-oriented companies, third-party warehousing service providers, and e-commerce sorting centers.

Especially in B-end business scenarios, waste cardboard piles up, buffer material costs are high, and environmental protection requirements are becoming increasingly stringent. These seemingly trivial issues directly affect operational efficiency and customer satisfaction. And a seemingly simple device - the Cardboard Shredder- is becoming a key breakthrough point chosen by more and more companies.

Cardboard shredder: a reversal tool from "discarded materials" to "fillers"

The cardboard shredder shreds the waste corrugated cardboard on site and converts it into a lightweight, durable, and elastic honeycomb paper pad, which is used to fill the internal gaps of the carton or wrap items.

What's special about it?

Typical application scenarios: reducing costs and improving efficiency for B-end warehouses

Scenario 1: Industrial equipment export enterprises

In the export packaging of hundreds of equipment every month, waste paper boxes were originally just garbage. Now they are crushed on site to form cushions to fill the corners of transportation equipment, avoiding transportation shaking and bumps, saving cushion costs and improving packaging quality.

Scenario 2: Third-party warehousing service providers (3PL)

Daily processing of a large number of warehouse-in and return items, using cardboard shredders to crush returned cartons on site and fill other shipping boxes, greatly reducing the purchase of buffer materials, and the packaging area can be operated with electricity without connecting to the system.

Scenario 3: Green brand owners, environmentally friendly e-commerce brands

More and more customers emphasize sustainable supply chains. The filling paper tapes output by cardboard shredders are beautiful and natural, 100% paper, which is not only easier to be accepted by consumers, but can even be used as one of the "brand packaging selling points" in social media.

Equipment highlights: Practicality and durability

1.Applicable cardboard: Maximum width 325mm, cardboard thickness within 6mm, suitable for more than 90% of standard cartons

2.Operation method: Mechanical knob control, forward/backward one-click

3.Applicable cardboard: Three-layer, five-layer, heavy-duty corrugated cardboard can be processed

4.Warranty service: 3-year tool warranty + 2-year machine warranty

5.Compact structure: suitable for all kinds of packaging tables and packaging workstations

6.Easy maintenance: equipped with a paper scraps frame for easy cleaning and maintenance

Learn about product performance now: View What Is Cardboard Shredder product?

Real feedback from customers

"In the past, there were a lot of waste cartons piled up in the warehouse, and the packers could never get bubble film. Since using this cardboard shredder, the warehouse has become tidy, the efficiency has increased, and even customers say that our packaging looks more professional and environmentally friendly." —— Warehousing Manager of a German Auto Parts Exporter

"We do small-batch customization, so there is no need to build a large packaging line. With this equipment, we can pad the returned cartons ourselves, which is very suitable for our business model." —— D.L., founder of an Asian cross-border e-commerce company

Conclusion

The cardboard shredder is not a "cool automated equipment", but it can truly solve many problems faced by enterprises in packaging costs, environmental audits, and warehousing operations.

Today, when sustainable packaging has become a general trend, improvements in every packaging link are a reflection of the company's responsibility to customers, the environment, and its own profits.

#paperindustry#custompackaging#ecofriendlypackaging#sustainablepackaging#paperpackaging#protectivepackaging#3pl logistics#sustainpackaging

0 notes

Text

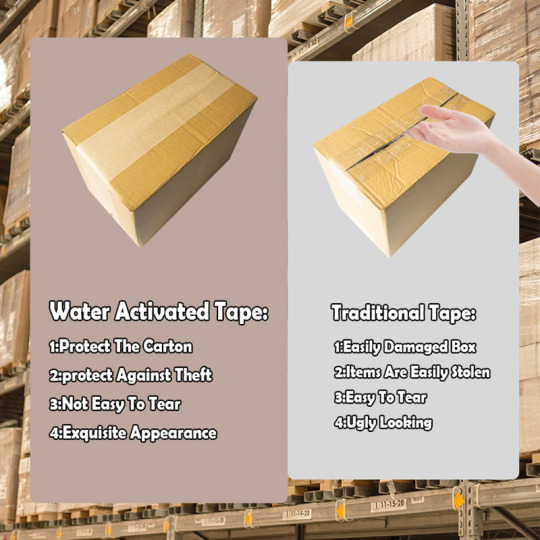

Why Do You Need To Use Kraft Paper Tape?

Putting packaged products into corrugated boxes and sealing them is the last and most important step in packaging, and it will be necessary even in the next few decades. With the continuous development of e-commerce and the increasing demand in the market in recent years, the concern for the safe delivery of products has made this process even more important.

So, let's do a survey. What type do you use to seal the boxes? Scotch tape is the answer we will hear. This tape is widely used throughout the country because of its low cost and simplicity.

However, it also has limitations: such as:

*Safety

*Speed

Many companies in the current market have begun to use kraft paper tape, which can solve many of the shortcomings of traditional scotch tape. Before we start, we should need to understand what kraft paper tape is.

What Is Kraft Paper Tape?

Kraft paper tape, also known as water activated tape, is a natural paper tape based on paper as raw material. It can quickly activate the adhesive after encountering water so that it can produce high-quality and good adhesion with most packaging cartons and product surfaces. Like other types of tapes such as traditional scotch tape, its main purpose is to seal boxes or cartons.

The biggest difference is that it is activated by water and produces a tough, high-strength adhesive, which allows it to maintain optimal adhesion even in wet environments, which also means that it is more difficult to tear by hand than other tapes, which also reflects that it can prevent the risk of theft and tampering. It is a packaging tape approved by the United States Postal Service and UPS.

So, what are the benefits of using kraft paper tape?

1. Water activated tape - high safety factor

According to traditional habits, most of the tape is dispensed by using a tape gun in combination with traditional transparent tape, but the long-term use of this manual tool will cause safety hazards to employees. Repeating an action for a long time to reinforce cartons is very likely to cause shoulder and neck injuries, hand and wrist strain, etc. These injuries may be long-term and difficult to resolve. This will lead to higher medical claims and poor employee retention rates.

The automation function of the water activated tape dispenser is the most common packaging equipment that dispenses tape to the required length, which can easily and safely dispense the tape.

Its strong viscosity can strongly adhere to the carton, making it difficult to tear off, thus avoiding the risk of tampering or theft during transportation.

Because the tearing of kraft paper tape will leave traces, this security can prevent potential theft and ultimately improve your company's reputation and trust in the products delivered to customers.

2. Water activated paper tape - excellent return on investment

Water activated paper tapes provide a stronger seal, requiring only one strip of tape to create a better seal on a carton, and are also reusable and 100% recyclable.

On average, packers use 50% more clear tape than they need to seal a carton. So using paper tapes can eliminate that waste as well.

3.Water activated Tape-increased productivity

Nothing is more significant than increased productivity.

After all, if kraft paper tape can help you seal and prepare more corrugated boxes in less time, then a quick return on investment will be another advantage. It can quickly offset the cost of purchasing dispensers and tape.

Test results show that using a water-activated tape dispenser can increase packaging speed by at least 20% compared to traditional tape guns. It only needs to select the required length of tape, and it will quickly cut and output it, and it can be pasted on the carton, unlike traditional tape guns that need to repeatedly reinforce the tape in the same direction, resulting in reduced efficiency.

Conclusion

For packaging companies, improving efficiency and reducing costs is fundamental, and investing in a water-activated tape dispenser and choosing to use kraft paper tape is a positive investment for the company and can also allow customers/consumers to get the most benefits from it.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#sustainability#manufacturing#honeycombpaper#kraft paper#carton#suppluchain#recycling

0 notes

Text

About Honeycomb Paper Roll Making Machine Pros And Cons

In the current situation where many businesses are pursuing sustainability, honeycomb paper making machines are the most advantageous production tools. This article will focus on analyzing the advantages, disadvantages and functions of honeycomb paper roll making machines.

About honeycomb paper roll making machine

Honeycomb paper roll making machines are advanced, innovative and intelligent equipment designed to produce high-quality honeycomb paper rolls on a large scale and in batches. It can be said that honeycomb paper making machines are essential equipment for transportation packaging, because the honeycomb paper it produces has excellent strength protection performance, and is extremely light and extensible and environmentally friendly paper packaging materials.

The production process of the honeycomb paper roll making machine is automatic, efficient and intelligent. The kraft paper is fed into the interior and passed through a series of rollers for bonding, folding and cutting and punching small incisions. Finally, it is continuously pressed to form a flexible panel. After unfolding it, it presents a honeycomb structure, so it is also called "honeycomb paper".

Features:

1. Simple and efficient: capable of mass production of honeycomb paper rolls at a speed of 280m/min

2. Precision engineering: the automatic deviation correction system ensures consistent cell size structure and quality in the honeycomb structure

3. Adjustable parameter settings: the honeycomb paper roll size can be set according to demand, 50cm/38cm/30cm wide

4. User-friendly interface: equipped with a touch and simple control panel for easy operation and monitoring

5. Durable and strong: honeycomb packaging paper is strong, durable and 100% recyclable

What is honeycomb paper?

Honeycomb paper is a lightweight, durable, strong protective, customizable and roadside recyclable paper packaging material. It is a hexagonal structure formed by connecting and pasting three layers of kraft paper on the honeycomb layer. It is also a green material certified by FSC. It has been widely promoted and used in life and packaging and transportation industries, including packaging, padding, pallet wrapping, gift packaging and brand promotion.

Its diverse customization, such as customized logos, colors and specifications, and the characteristics of outer packaging have also attracted many consumers.

Why you need honeycomb paper roll making machine?

1. Eco-friendly packaging: Honeycomb wrapping paper is made of renewable paper and is completely recyclable, which reduces the recycling cost. Consumers do not need to deal with it after receiving the goods.

2. Reduce transportation costs: Honeycomb wrapping paper can be stacked in rolls, which is compact and space-saving, which can reduce storage costs, and is extremely light, which means that transportation costs can be reduced.

3. Enhanced product protection: Honeycomb paper has strong cushioning protection performance and can be stretched at a ratio of 1:1.7, tightly and completely wrapping various shapes of objects to ensure safe delivery of goods.

4. Customizable: Manufacturers can customize the size, color, printed brand information, and outer packaging of honeycomb paper according to the specific protection needs of different products, which not only achieves the role of brand promotion, but also improves the consumer's receiving experience.

5. Operational flexibility: Honeycomb paper making machines can usually be integrated into existing production lines, providing flexibility in the size and configuration of the panels produced. About 150/160 rolls of honeycomb paper are produced a day (premise of 8 hours of work) to meet market supply needs.

6. Reliability: Honeycomb paper making machines are durable, reliable and stable, without unnecessary maintenance procedures, and high-precision manufacturing also ensures production quality.

7. Research and development, innovation: The main purpose of honeycomb paper making machines is to provide an environmentally friendly alternative to traditional plastic packaging. The continuous development of automation technology has improved efficiency and customization options to meet the current market needs.

8. Market expansion: Being able to provide sustainable and customizable packaging solutions can open up new markets, especially local logistics warehouses and companies involved in the packaging and transportation industry, and even Amazon, through these advantages and the price advantage of origin, to cooperate with them.

Pros and cons of honeycomb paper making machine

Pros of honeycomb paper making machine:

Customizable options: Adjustable settings allow customization of different specifications and strengths of honeycomb wrapping paper

Durable: Can withstand rigorous industrial use, ensuring a long service life

Eco-friendly production: The machine uses biodegradable and recyclable kraft paper, reducing the impact on the environment

Multiple uses: Produces honeycomb paper that can be used for protective packaging, filling and cushioning

Eco-efficient: Uses pulp production, reducing energy consumption and increasing productivity

Cros of honeycomb paper making machine:

Initial capital considerations: The initial cost of purchasing a honeycomb paper making machine is high, which can be a hindrance for small businesses with limited resources

Regular maintenance: The machine needs to be maintained for a period of time to ensure optimal operation of the machine

Space challenge: The machine is 4840*2288*2100 (L*W*H) and requires a lot of space to operate and place

Employee training: Initially, employees need to be trained in paper loading and settings to operate safely and effectivel

But for the packaging, transportation and manufacturing industries, being able to stably and reliably produce honeycomb paper packaging materials for a variety of applications is a long-term and stable investment in sustainable packaging solutions:

Buffer protection: Provide shock absorption for fragile and glass products

Filling: Fill the gaps in the package to prevent damage caused by squeezing

Conclusion

Honeycomb paper roll making machine is an advanced and environmentally friendly machine representative, which is both economically and environmentally beneficial. Its automated production system and customizable options can meet the needs of today's technological society, making it one of the best choices for producing paper packaging materials.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#sustainability#manufacturing#kraft paper#carton#honeycombpaper

0 notes

Text

Paper Cushion Machine:Eco-friendly Packaging Revolutionary Pioneer

Introduction:

I believe everyone has witnessed that there are many floating plastic bags and some plastic waste on the beach or somewhere, and these plastic particles penetrate the marine food chain, causing serious pollution to the ocean. In 2024, Amazon issued a new policy that strictly prohibits the use of plastic packaging. Under such background and measures, more and more companies have begun to pursue sustainable green packaging.

Among them, paper cushion machines, which have types that meet the needs of various occasions and industries, have emerged. It is also the starting point of green packaging and provides new ideas for solving the problem of plastic pollution.

The Shadow Of Excessive Use Of Traditional Plastic Packaging

Excessive use of plastic packaging, whether for the environment or for human life, causes visible and multifaceted damage to the ecosystem, including ocean, soil, air, and food pollution. From the production of plastic packaging to the inability to be fully recycled, according to data, 380 million tons of carbon dioxide are generated each year, accounting for about 2% of the world's total emissions. This does not include additional carbon emissions generated during subsequent processing.

The United Nations Environment Program pointed out in its latest report that global plastic pollution is being dumped into the ocean at a rate of nearly 9 million tons per year, and it is expected that by 2050, the weight of plastic in the ocean will exceed that of fish. And these pollutions will also directly threaten human health.

Paper Cushion Machine - Pioneer Of The Green Revolution

The paper cushion machine uses a simple and energy-saving production process and 100% renewable kraft paper as raw material to create and develop packaging materials that are suitable for various industries and have high-quality cushioning and protective performance. The heavy-duty industrial paper cushion machine NP-EC 760 and the cost-effective paper void fill machine NP-P2 3.0 meet the needs of various industries.

The working principle of the paper void fill machine is to press the original ecological kraft paper through the internal gear structure to form a tough and durable kraft paper pad. These paper pads are not only recyclable but also completely recyclable in the natural environment. From the data, the use of recyclable kraft paper pad packaging reduces carbon dioxide emissions by 80%, which is economical and has high-quality protective performance.

Examples: Many well-known companies at home and abroad have also adopted kraft paper cushion packaging materials produced by Paper Cushion Machine, such as Amazon, IKEA, or Muji, which take environmental protection and social responsibility as their core values. According to data, Amazon has successfully reduced packaging volume by 20% through this innovation, while improving customer satisfaction; IKEA has reduced the use of plastic by more than 2,000 tons in one year, demonstrating its firm commitment to environmental protection. The successful practices of these companies have proved the huge potential of Paper Cushion Machine in the field of environmentally friendly packaging.

Market Analysis And Data Display

Compared with honeycomb paper machines and tape dispensers, paper cushion machines have higher initial investment costs. Of course, there are also cost-effective models, but in terms of long-term investment, for enterprises, the advantages will be much more than the disadvantages, which can reduce the cost of packaging materials, reduce logistics losses, and enhance brand image. The comprehensive benefits are obvious.

For example, after using a Paper Cushion Machine, an electronic product manufacturer reduced the damage rate of products during transportation by 30%, and the customer return rate by 20%, and finally achieved a significant reduction in overall costs.

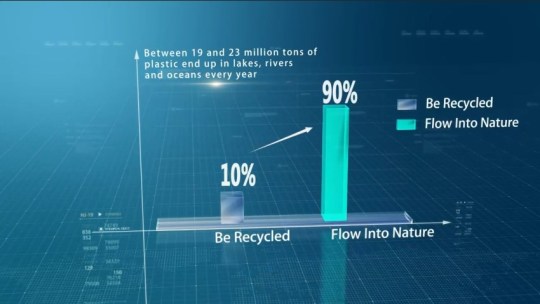

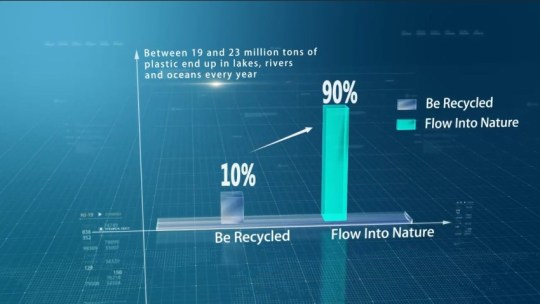

• Market trends: According to the United Nations Environment Programme data in 2023, only 10% of the world's waste can be fully recycled, and most of it still flows into the ocean. The global green packaging material market is expected to expand at a compound annual growth rate of 8% and reach a scale of US$115 billion by 2025. This shows that with the improvement of consumers' environmental awareness and the promotion of policies and regulations, the market demand for green packaging solutions such as Paper Cushion Machine will continue to grow.

Advantages Of Paper Cushioning Solutions

1. Perfect and environmentally friendly packaging material

The tough and durable material of kraft paper provides stronger protection after forming kraft paper pads, and can also be 100% recycled by the soil, improving the recognition of product packaging and brand impression.

2. Diversified applications

Automatic and intelligent packaging equipment can deeply customize logos and colors to meet the unique packaging needs of different industries and products.

3. Promote enterprise reform

Paper Cushion Machines has not only changed the face of the packaging industry but also promoted the green transformation of the upstream and downstream industrial chains and established green packaging standards.

Conclusion

With its unique, stable, and reliable operation and environmental protection concept, Paper Cushion Machine is one of the sustainable choices for various companies to turn to green packaging. It not only solves the environmental problems caused by traditional packaging but also opens up a new path for sustainable development for the packaging industry.

Human beings and nature should coexist harmoniously, effectively utilize environmental resources, and work together to create a clean, healthy, and vibrant home on Earth.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#sustainability#manufacturing#kraft paper#carton#honeycombpaper

0 notes

Text

Automatic Pallet Wrapping Machines: What Can They Do For Your Business?

Introduction:

As society develops faster and more automated, and even AI trends gradually emerge, various industries are looking for ways to improve their core competitiveness. In this online shopping trend and fast-paced packaging environment, efficiency and safety are the top priorities, but simplifying the process at the end of the packaging channel is also necessary.

The automatic pallet wrapping machine is the last step in the entire packaging process and is also the most important and easily overlooked tool. This article will explore the role, advantages, and more of the automatic pallet wrapping machine.

What Is An Automatic Pallet Wrapping Machine?

Imagine that when your goods are neatly stacked on the pallet, the truck goes over to lift the pallet, and the picture that follows is that one of your carton goods tilts and falls from the pallet. Then, what will happen next is conceivable, and the time and labor costs incurred in the middle are incalculable.

At this time, you will need such a simple and fast process. The goods on your pallet are quickly and evenly wrapped and covered with a layer of protective stretch film to ensure that the goods on the pallet can be transported stably and safely. This is also the meaning of the existence of the pallet wrapping machine. It can automatically and quickly wrap the goods together to improve the overall work efficiency at the end of the packaging path.

So, How Does It Work?

Pallet wrapping machines are available in automatic, semi-automatic, and manual models, and the automatic pallet wrapping machine, as the name implies,

is a machine that drives the packaging process through automatic operation. It has an automatic navigation path function that can automatically wrap around the pallet,

and the film bracket can evenly distribute the stretch film according to the background settings and the ratio of 250% of the pre-stretched film and perfectly wrap it on the pallet.

The tight and secure fit fix the goods in place, which can ensure the safety of the transported items and eliminate the risk of the pallet falling and shifting during movement.

Why Do You Need A Pallet Wrapping Machine?

Pallet wrapping machines are generally equipped with stretch film with a pre-stretched film ratio of up to 250%, which means that it can be flexibly stretched and wrapped around the goods, and can apply unparalleled tension effects. No matter how big or small the goods on your pallet are, they can be perfectly adapted and tightly fitted, completely unaffected by the outside world, and can move and transport the goods stably and safely.

This versatility and flexibility make it a key choice for various industries from manufacturing and distribution to retail.

Who Are The Beneficiaries Of Pallet Wrapping Machines?

Whether you are a small retailer a large transportation logistics company or a storage center, a pallet wrapping machine can meet your packaging needs.

It can not only improve the production efficiency at the end of the packaging channel but also simplify the packaging process and benefit from it. It is one of the most beneficial tools for industries that require packaging.

Choose Automation Or Semi-automation?

The biggest difference between the two lies in operation and efficiency. The automated ones have advanced background programming modes and modular design, which reduces manual operation and is not restricted by the site, while the semi-automatic ones require manual installation and disassembly. This process means that more time and labor are needed to produce the same packaging quality, but no matter which one you choose, it should be determined according to your own packaging needs and shipment volume.

Future Trends And Actions

In the current fast-paced packaging environment, manually wrapping a large number of goods will cause packaging stagnation and difficulty, which also represents the importance of automatic pallet wrapping machines. Automatic pallet wrapping machines can also easily and effortlessly handle goods on various pallets and some heavy items, simplifying the packaging process, making the entire work not too stressful for operators, and also improving work efficiency and output.

In summary, investing in an automatic pallet wrapping machine is a positive investment plan for enterprises. Ensuring the safe delivery of products can also reduce the return rate of goods, usher in new business opportunities, and bring new influence. If you are also looking for ways to improve the packaging process, please contact the YJNPACK team immediately, and we will provide you with professional product exchanges and personalized customization services.

#packaging#ecofriendly#packagingmachinery#wrap#paperindustry#sustainability#manufacturing#kraft paper#carton#honeycombpaper#warehouse

0 notes

Text

Paper Cushion Machine:Eco-friendly Packaging Revolutionary Pioneer

The Shadow Of Excessive Use Of Traditional Plastic Packaging

Excessive use of plastic packaging, whether for the environment or for human life, causes visible and multifaceted damage to the ecosystem, including ocean, soil, air, and food pollution. From the production of plastic packaging to the inability to be fully recycled, according to data, 380 million tons of carbon dioxide are generated each year, accounting for about 2% of the world's total emissions. This does not include additional carbon emissions generated during subsequent processing.

The United Nations Environment Program pointed out in its latest report that global plastic pollution is being dumped into the ocean at a rate of nearly 9 million tons per year, and it is expected that by 2050, the weight of plastic in the ocean will exceed that of fish. And these pollutions will also directly threaten human health.

Paper Cushion Machine - Pioneer Of The Green Revolution

The paper cushion machine uses a simple and energy-saving production process and 100% renewable kraft paper as raw material to create and develop packaging materials that are suitable for various industries and have high-quality cushioning and protective performance. The heavy-duty industrial paper cushion machine NP-EC 760 and the cost-effective paper void fill machine NP-P2 3.0 meet the needs of various industries.

The working principle of the paper void fill machine is to press the original ecological kraft paper through the internal gear structure to form a tough and durable kraft paper pad. These paper pads are not only recyclable but also completely recyclable in the natural environment. From the data, the use of recyclable kraft paper pad packaging reduces carbon dioxide emissions by 80%, which is economical and has high-quality protective performance.

Examples: Many well-known companies at home and abroad have also adopted kraft paper cushion packaging materials produced by Paper Cushion Machine, such as Amazon, IKEA, or Muji, which take environmental protection and social responsibility as their core values. According to data, Amazon has successfully reduced packaging volume by 20% through this innovation, while improving customer satisfaction; IKEA has reduced the use of plastic by more than 2,000 tons in one year, demonstrating its firm commitment to environmental protection. The successful practices of these companies have proved the huge potential of Paper Cushion Machine in the field of environmentally friendly packaging.

Market Analysis And Data Display

Compared with honeycomb paper machines and tape dispensers, paper cushion machines have higher initial investment costs. Of course, there are also cost-effective models, but in terms of long-term investment, for enterprises, the advantages will be much more than the disadvantages, which can reduce the cost of packaging materials, reduce logistics losses, and enhance brand image. The comprehensive benefits are obvious.

For example, after using a Paper Cushion Machine, an electronic product manufacturer reduced the damage rate of products during transportation by 30%, and the customer return rate by 20%, and finally achieved a significant reduction in overall costs.

• Market trends: According to the United Nations Environment Programme data in 2023, only 10% of the world's waste can be fully recycled, and most of it still flows into the ocean. The global green packaging material market is expected to expand at a compound annual growth rate of 8% and reach a scale of US$115 billion by 2025. This shows that with the improvement of consumers' environmental awareness and the promotion of policies and regulations, the market demand for green packaging solutions such as Paper Cushion Machine will continue to grow.

Advantages Of Paper Cushioning Solutions

1. Perfect and environmentally friendly packaging material

The tough and durable material of kraft paper provides stronger protection after forming kraft paper pads, and can also be 100% recycled by the soil, improving the recognition of product packaging and brand impression.

2. Diversified applications

Automatic and intelligent packaging equipment can deeply customize logos and colors to meet the unique packaging needs of different industries and products.

3. Promote enterprise reform

Paper Cushion Machines has not only changed the face of the packaging industry but also promoted the green transformation of the upstream and downstream industrial chains and established green packaging standards.

Conclusion

With its unique, stable, and reliable operation and environmental protection concept, Paper Cushion Machine is one of the sustainable choices for various companies to turn to green packaging. It not only solves the environmental problems caused by traditional packaging but also opens up a new path for sustainable development for the packaging industry.

Human beings and nature should coexist harmoniously, effectively utilize environmental resources, and work together to create a clean, healthy, and vibrant home on Earth.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#sustainability#manufacturing#kraft paper#carton#honeycombpaper#papercushionmachine

0 notes

Text

Paper Bubble:A Perfect Green Protection Package

Today, we are proud to introduce an amazing paper: paper bubble, which is also an innovative and sustainable paper packaging and an alternative to traditional plastic and bubble packaging.

NRTEC, which continues to innovate and develop environmentally friendly packaging products, has introduced and provided a new and innovative and environmentally friendly alternative to traditional bubble cushioning in its paper cushion packaging series based on market demand and usage surveys - paper bubble.

The appearance of Paper bubble paper extends the design of traditional bubbles, with large and small and concave and convex bubbles on the surface. Its excellent, durable, and strong cushioning protection performance is the first choice for many fragile items.

Since NRTEC adheres to the development of environmentally friendly products, and the raw material of Paper Bubble is made of 100% recyclable and renewable kraft pulp, if you tend to use paper packaging, such as honeycomb paper, kraft paper, fanfold paper, or paper bubble, it will be a good choice, but you should choose the right packaging material according to your packaging product.

Environmentally friendly product design is the first driving force for the development of a green environment. Avoid using excessive packaging to ensure the safety of your products. It seems to be successful, but it actually causes endless unnecessary waste of resources.

Innovative and environmentally friendly design

Paper bubbles can be either sheet or integrated, and are produced by paper bubble machines, such as some sensitive and fragile products in life. The sheet-shaped paper bubbles can be directly packaged and are easy to use, fast, and flexible, and even no other filling materials are needed after wrapping the product, ultimately achieving the purpose of safe transportation.

In this way, the packing personnel do not need to wait for the machine production time but can use it directly. There is an obvious tear line in the middle, and the appropriate amount of material can be selected according to the size of the product to reduce material waste. The softness of the paper bubble is strong and durable, and it can fill the gaps in the carton in all directions.

Paper bubbles can be purchased and used separately, which also reduces the cost of purchasing machines and maintenance costs, and can be quickly applied to integrated packaging lines.

Moreover, NRTEC customers can not only transport items safely and reliably, but the function of customizing logos and brand information is also an important measure for brand promotion, and for consumers, it also provides an impressive and unique unboxing experience.

If you are also developing a new packaging strategy, perhaps paper bubbles will be an ideal choice. Please feel free to contact our professional team and we will provide you with a series of packaging solutions.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#sustainability#manufacturing#kraft paper#carton#honeycombpaper#paperbubblewrap

0 notes

Text

How Does a Honeycomb Paper Dispenser Work?

Do you want a super-effective wrapping material that packs your items quickly?

Well, a honeycomb paper machine will do the job effectively. With a perfect packaging environment, this honeycomb dispenser is the best item for your products.

Whether you work in a small store, or in a branded e-commerce office, this machine provides good cushioning protection. The machine has a design with a small footprint that makes it simple to use and operate easily.

So, if you need to unfold the honeycomb paper or stretch it, this packaging material will provide a quick and efficient solution. To see how its whole mechanism works, let’s discuss it in detail below.

The Working Mechanism of Honeycomb Paper Dispenser

To make your packaging simpler, company manufacturers have made a comprehensive model for its users. It not only assists in product packaging but also provides cushioning protection.

The working principle of this honeycomb paper cutting machine is simple and let’s discuss it in a few steps below:

1- Cut the Paper Die

The first step is the cutting of the honeycomb paper. In case you don’t know, the honeycomb paperboard follows the principle of natural honeycomb. Its structure resembles that of the original one.

For cutting purposes, it uses high-quality die-kraft paper along with a tissue interleaf. It makes the material shock-absorbent and gives them highly protective properties.

2- Stick on Both Sides

The paper and the filler are the two main components that make up the honeycomb paper wrap dispenser. After cutting, connect the paper with a three-dimensional hexagon.

With the help of glue, stick the paper on both sides which will make a sandwich-type structure.

3- Wrap the Material

The next step involves wrapping up the cushioning material. You can use honeycomb cardboard to initiate the process. This will also make the material lightweight, strong, heat-absorbent, and recyclable.

Not only this, but it will also consume less energy and make your packaging material environment-friendly.

4- Replace With Foam Packaging

Here comes the final step which is the replacement of the foam package. The paper wrap honeycomb machine resembles a variety of foamed plastic. Replacing it with white foam not only reduces pollution but also makes the machine more user-friendly.

Finally, you’re ready to use your machine as a packaging solution that can perform its services in the industrial and domestic markets.

How Can Honeycomb Paper Machine Benefit You?

Several industry manufacturers are working on modern machine inventions and technological advancements. One of them is the honeycomb paper wrap machine.

Its high packaging solutions and wrapping qualities provide comfort to its users in a lot of practical applications. So, let’s see how this machine can assist you or what are its advantages?

1- Environment Friendly

The best thing about this honeycomb machine is it avoids pollution. Due to the use of white foam packaging, it has the ability to control polluting agents. Moreover, the cardboard used in its manufacturing made it a recyclable machine.

Have you heard about green packaging solutions?

Yes, the honeycomb machine is one of the top leading solutions that use biodegradable materials and is a green packing machine.

2- Shiny Appearance

Due to the sleek design and high production properties, the honeycomb paper sheet gives a shiny appearance to your products. In addition, it is made for a long life span and thus provides low maintenance properties.

Due to its sustainable development, you can easily solve the quality problems of your products. In addition, it has also surpassed the quality tests on thin cardboard cartons.

3- Multi-Worker

Another attractive property of this machine is its multi-use feature. You can use it for wine box packaging, photo frames, and high-end packaging at the same time.

This machine brings out a special packaging experience for its users and thus values its products. Furthermore, the packaging method this machine uses plays a very effective role in the production of your products.

4- Protection and Safety

One of the most important advantages of the honeycomb machine is the protection and security it provides. Your products will be in a completely secure environment with this machine.

During delivery, the quality of the materials will not be disturbed at all. Moreover, the transportation risks are also very low with this packaging solution. Based on corrugated composite cardboard, this gives excellent results in the paper packaging industry.

5- Efficiency

The highly efficient nature of this machine is shown by the fact that it can wrap the products in no time. With a high inflation speed, it fills the paper quickly so it packs easily. Along with this, it is strong and can manage large products conveniently.

Along with being highly efficient, it is also good moisture resistant. Filling the inner cavity instantly avoids any type of moisture to enter the material. Therefore, manufacturers find it a good packaging solution for the paper industry.

6- Shape of Products

Hence, these technical features guarantee the quality of the honeycomb paper dispenser. The technical qualities also enable its users to pack their packaging materials instantly. You can manufacture your glass products or high-end packaging gifts from this machine.

Not only this, but it also improves the shape of the products without cutting any additional tools. It's easy to operate and its well-managed design provides comfort to its users.

Best of all, it keeps your products in good condition and does not disturb their shape or composition during transport. So, you should not worry at all about the safety and quality of your packaging materials.

Final Thoughts

With plenty of beneficial impacts, the honeycomb wrapping sheet is no doubt a leading step toward paper machinery. The kraft paper buffer material used in the manufacturing of this machine allows for the perfect wrapping of your products.

So, if you ever need a good packaging material for your small retail store or even a large brand, you can go for a honeycomb dispenser. Its unique features and guaranteed quality will never disappoint its customers. You can choose the best according to your company's needs and requirements.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#sustainability#manufacturing#kraft paper#carton#honeycombpaper

0 notes

Text

What is the honeycomb paper making machine?

Are you looking for a packaging machine that requires no complex operations or adjustments? If your answer is yes, then you should consider a honeycomb paper making machine.

It doesn’t need power to operate, so you can use it at any time at any place without an electricity supply. Isn’t it cool to pack your products safely only with a single pull? Of course, it is!

On the other hand, honeycomb paper is super stretchable and flexible. Therefore, it provides excellent buffering to the products and prevents them from scratching.

Moreover, its three-dimensional honeycomb structure provides an eye-catching display; thus offering an excellent unboxing experience to your customers.

This post will let you make a wise decision about buying a honeycomb paper machine. Let’s start!

Honeycomb Paper cutting Machine HP50-D2

If a manual honeycomb paper machine doesn’t satisfy you, go and try the HP50-D2 honeycomb paper dispenser. It is a new invention in packaging that helps you in transporting and protecting fragile products. Fortunately, the automatic operation mode proved to be a golden key for the efficiency of the packaging.

Control Panel

To meet the high demands of packaging productivity by the users, this machine features a speed button. You can change the speed by using the button. In addition, an emergency stop button is also designed in case of any mishap. It will immediately stop the machine.

Great quality

HP50-D2 dispenser frees you from worries after you buy it as it comes with three years warranty. The high-quality and durable materials used for manufacturing the machine let it perform well. However, in case of any difficulty, you can consult the technical sales team 24/7.

Features Smart Operating Modes

There are two smart operation modes on this machine that assist you in reaching your packaging goals efficiently. The one is A and the other is T mode. You can set the machine at A mode in order to run packaging consistently. Whereas, T mode enables you to run packaging at pre-set timings.

Quick and Easy to Use

After following some simple steps to operate the machine you can speed up your packaging. All you need is to place the white paper and honeycomb paper in the rotary rods. Then pull both papers a little out and adjust the required operation mode. Finally, start wrapping your objects as the papers come out of the machine.

Control Panel

To satisfy the customers who demand the packaging machines to operate fast for increasing their productivity, a speed button is designed on the automatic honeycomb machine. You can adjust the speed as per your need. On the other hand, an emergency stop button is there for your safety to immediately stop the machine.

1. 70GSM 80GSM Honeycomb Packaging Paper Machine

70GSM 80GSM honeycomb paper dispenser serves as the best source for protecting your fragile items. Moreover, it allows you to customize the length of the honeycomb wrap. Tear off the length you require and save your budget.

The tissue interleaf is combined with honeycomb kraft paper which as a whole act as an outstanding shock-absorbent material.

Easy Box with Quick Packaging

You don’t need any scissors for cutting the honeycomb paper wrap, instead use your hands to cut the paper. Hence, you can tear the length you need for packaging your item. Further, there is no requirement for any adhesive or tape to stick the paper wrap as its structure has the ability to interlock the cells.

Wide Range of Application

This honeycomb paper machine offers a wide range of applications in various places. Generally, they are suitable for printing supplies industries, e-commerce businesses, electronic and sporting goods, ceramics, etc.

Lowers Shipment Cost

The honeycomb kraft paper weighs much lesser than other traditional packaging materials. Thus, when the products are wrapped in them, it doesn’t increase much weight. You only have to pay for the weight of the item while shipping.

OEM Honeycomb Paper Dispenser HP50-T2

Here comes the new version of the honeycomb paper machine with the addition of the knob aiding the paper to enter the machine. While dealing with the machine you just need to follow three steps;

Pull the paper from the roll.

Wrap the product in it.

Tear off the wrapped paper from the roll.

Fine stability

The HP50-T2 honeycomb paper dispenser consists of four suction cups at the base. As a result, they ensure firm attachment of the machine to the desktop. The increased stability of the machine lets the users operate it easily.

Features Paper Enter Holder

The paper enter holder on this manual machine allows you to enter the paper into the machine. Turning the knob also adjusts the tightening of the honeycomb paper roll resulting in the better wrapping of the objects.

Multiple Options

The honeycomb paper wrap provides you with multiple paper roll holding rods. You can use one rod for installing the honeycomb paper wrap while the other for attaching the white paper roll. Using both papers for packaging your product gives you more strong protection against damage.

Save Storage Space

Honeycomb paper saves storage space due to its structure. As the wrapping paper is present in the form of rolls so you may stack them on one another when not in use. Doing so only occupies a small area of your workstation. Also, the size of the machine is compact, therefore there is no space to worry about at all.

Conclusion

Finally, whether you buy a manual or automatic honeycomb paper machine, both will help you is boosting your business. However, honeycomb paper is a 100% recyclable material that is in line with today's trend of environmental protection. Therefore, adopt this packaging alternative to prevent your environment from non-recyclable packaging materials.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#sustainability#manufacturing#kraft paper#carton#honeycombpaper#honeycombwrap

0 notes

Text

What is the new paper bubble machine PB600A

The industrial paper bubble wrap machine is a new and automated packaging machine that can produce sheet bubble paper on demand. With its simple operation, easy maintenance, and high production capacity, it performs well in the e-commerce, packaging, and transportation industries.

Through this special process, the industrial paper bubble machine can feed the kraft paper and produce paper bubbles with a concave and convex surface

or a heart shape (the shape can be customized) and then output it through the cutting process. It is a creative and new type of paper packaging material.

Moreover, the paper bubble machine is very simple to use and has a user-friendly operation interface. Just install the kraft paper start switch and it will

mass-produce paper bubble films at a speed of 30m/min. The rollers inside the machine are made of high-strength metal alloy materials, which can maintain

the performance of the machine for a long time and extend the service life.

For machine maintenance and upkeep, parts can be replaced free of charge during the warranty period. The design of the paper bubble machine makes maintenance simple, and replacement parts can be quickly found locally to minimize losses.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#manufacturing#sustainability#kraft paper#carton#honeycombpaper

0 notes

Text

Factors To Consider for Choosing Right Packaging Material

Do you want to upgrade your business's packaging requirements or are you looking for better packaging materials after having bad customer experiences? It gets annoyed when your brand-new product is damaged due to poor packaging.

Thus, in today's business, it is necessary to switch to packaging materials that not only guarantee the safety of your product but are also economical. Additionally, due to the growing need for sustainable packaging in today's world, more businesses are looking for it

As a result, more and more people are using sustainable materials. We will only discuss materials that are good for the environment.

Therefore, let’s move forward.

What does Packaging Material Mean?

When you run a business that sells valuable goods. You need to ship them across the country on a daily basis and also protect them from damage at all costs. You use a variety of materials to pack your items not only to keep them from getting damaged but also to impress customers with attractive packaging.

List of Sustainable Packaging Material

Before discussing the factors of selecting the appropriate material for your packaging requirements. You need to know about the top sustainable packaging materials that are taking over the market.

Let’s roll in, then!

Kraft Paper Roll

Kraft paper is made up of biodegradable material and is used in a variety of packaging. It is without a doubt the best material for your packaging need. It is easy to use, fully recyclable, and lightweight material that should be a part of your packaging needs.

This kraft paper comes in different varieties and serves a different purpose in every packaging.

Void Fill Paper

A paper cushion machine transforms a simple roll of kraft paper into the packaging material known as void fill paper. The void-fill paper material provides the best layer of protection in packaging boxes. It gives cushioning effect and protects the goods from damage during shipping.

Additionally, the machine utilized for this purpose is user-friendly and affordable for businesses. Machine manufacturers carefully consider your work's viability and create highly efficient machines.

Honeycomb Paper Wrap

Like void fill paper, simple kraft paper is turned into a hexagonal shape like honeycomb paper wrapped through a honeycomb paper dispenser. It wraps the products without any extra taping and packaging. It is not only a better option than bubble wrap but also provides a better-looking appearance.

It is mostly used for fragile products like glass bottles and small packaging can be done effortlessly. Besides, the honeycomb paper dispenser is easy to operate and doesn’t require additional labor. It also increases packaging efficiency by nearly 30%.

Water activated Paper Tape

Water activated paper tape is also made from kraft paper and serves as an adhesive to seal the packaging boxes. The water-activated paper tape dispenser is used to generate the tape according to your packaging requirement. It produces paper tape on demand and saves labor costs. You can even print your company's logo on these tapes to make them unique.

Air Cushion Film Roll

Air cushions or air pillows are the perfect packaging material for providing extra protection in the packaging boxes. They reduce the chances of product damage during shipment. The air cushion machine is used to convert cushion film roll into air cushions. The plastic used in this film rolls is high-density polyethylene HDPE which is a safer and more environmentally friendly option for packaging.

Factors for Choosing Right Packaging Material

We now understand the kinds of packaging materials that are crucial to your packaging requirements. In this section, we will talk about the factors that business owners should keep in mind when purchasing packaging materials.

1. Choose According to Your Business

While making a purchase of packaging materials, this is the first step to consider what type of business you run.

For instance, if you primarily deal with heavy machinery products, you must consider air pillows included in your packaging needs. They are more beneficial than conventional packaging. They provide cushioning effect to your product and fill the void space in the corner of the boxes and reduce the chances of product damage. It will save your shipping cost due to its lightweight. Additionally, the procedure of making air pillows is handy and doesn’t require any training.

Similarly, if your business deals with fragile items like glass material or ceramic products. You must consider honeycomb paper wrap as a packaging material. You don’t need extra taping after using this packaging material. Additionally, due to its adaptability, this wrapping can be used to pack any product shape. It will completely protect your product during transportation and storage.

2. Cleaner packaging

Businesses are not only looking for sustainable but cleaner packaging options as well to gain customer satisfaction. Before sustainable packaging, traditional packaging was harmful to the environment. It also created a lot of mess in the warehouse's packaging stations and a lot of customers complained about having a bad unboxing experience.

Therefore, sustainable packaging manufacturers are coming up with cleaner yet eco-friendly packaging materials. They are creating packaging materials that are suitable for all kinds of businesses.

3. Cost Effective

According to your business requirements, you must ensure what fits best for your product packaging including the size, weight, or shape of your product. To reduce additional costs, the packaging material must be selected in the appropriate size.

4. Find the best supplier

Last but not least, find a supplier that is trustworthy and provides the best packaging material for your company. They will assist you in selecting the best packaging material according to your packaging needs and will provide you with proper customer care services and the best alternatives when needed.

Final Thoughts

At last, it is indeed a crucial step to choose the right packaging material for your business needs. However, keeping the preceding factors in mind can help you resolve the issue.

Before making any purchase, make sure you understand what your product is demanding. In addition, customer satisfaction should remain your top priority.

Hopefully, this blog may help you consider choosing the right packaging material according to your business requirement.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#sustainability#manufacturing#kraft paper#carton#honeycombpaper

0 notes

Text

Cardboard shredder: a green filling solution for efficient logistics

Under the tide of circular economy and sustainable development, cardboard shredder has become a new star in the field of logistics packaging with its unique charm.

This is an innovative device that can turn seemingly useless waste cardboard into valuables, converting it into lightweight, environmentally friendly and efficient honeycomb cardboard filling materials to meet the packaging needs of small warehouses, logistics centers and even individual users.

What is a cardboard shredder?

Cardboard shredder, also known as cardboard box shredder, is a kind of reuse equipment specially designed for waste cardboard. It converts waste cardboard into void-filling material with a honeycomb structure through precision cutting and processing technology.

These materials are not only lightweight and durable but also have good cushioning properties, making them ideal for use as fillers in shipping packages to protect goods from collisions and extrusions during transportation.

Why Do You Need A Cardboard Shredder?

1.Environmental response

Globally, the use of plastic filling materials is facing severe restrictions. The emergence of cardboard shredder provides a sustainable alternative for the packaging industry, reducing plastic waste and promoting resource recycling.

2.Cost savings

Waste cardboard is converted into practical packaging materials within the company, which greatly reduces the cost of outsourced filling materials and reduces waste disposal costs.

3.Space optimization

Compared with traditional fillers, the honeycomb paper produced by the cardboard shredder is small in size and light in weight, which helps optimize storage space and reduce the volume and weight burden of logistics and transportation.

Benefits Brought By Cardboard Shredder

1.Enhance brand image

Use environmentally friendly filling materials to demonstrate corporate social responsibility and enhance consumers' green awareness of the brand.

2.Easy to operate

The compact design makes the cardboard box shredder easy to install in a limited space, and the operation is simple, even non-professionals can get started quickly.

3.Flexible customization

According to actual needs, users can adjust the size and density of cardboard crushing to meet different packaging needs.

4.Enhanced protection performance

The honeycomb structure filling material can effectively absorb impact, protect the integrity of the goods during transportation, and reduce the damage rate.

Positive Impact On The Transportation Industry

•Energy conservation and emission reduction: Reduce dependence and use of plastics, reduce the carbon footprint of the entire supply chain, and conform to the development trend of global green logistics.

•Improve efficiency: produce filling materials on-site, reduce the time waiting for the arrival of filling materials, and speed up logistics turnover.

•Market competitiveness: Provide environmentally friendly packaging solutions to attract more customers who care about sustainable development and enhance market competitiveness.

Conclusion

As an innovation in the field of environmentally friendly packaging, cardboard shredder not only solves the problem of reusing waste cardboard, but also sets off a green revolution in the logistics packaging industry.

It not only reduces the company's operating costs and enhances its brand image, but more importantly, contributes to building a low-carbon and environmentally friendly transportation environment.

In the future, with the increasing awareness of environmental protection, the application prospects of cardboard shredder will be broader and become an important force in promoting the green transformation of the logistics industry.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#sustainability#manufacturing#kraft paper#carton#honeycombpaper

0 notes

Text

Honeycomb Paper Machine-An Eco-friendly Packaging Solution

Are you looking for a packaging machine that requires no complex operations or adjustments? If your answer is yes, then you should consider a honeycomb paper machine.

It doesn’t need power to operate, so you can use it at any time at any place without an electricity supply. Isn’t it cool to pack your products safely only with a single pull? Of course, it is!

On the other hand, honeycomb paper is super stretchable and flexible. Therefore, it provides excellent buffering to the products and prevents them from scratching.

Moreover, its three-dimensional honeycomb structure provides an eye-catching display; thus offering an excellent unboxing experience to your customers.

This post will let you make a wise decision about buying a honeycomb paper machine. Let’s start!

1.70GSM 80GSM Honeycomb Packaging Paper Making Machine

70GSM 80GSM honeycomb paper dispenser serves as the best source for protecting your fragile items. Moreover, it allows you to customize the length of the honeycomb wrap. Tear off the length you require and save your budget.

The tissue interleaf is combined with honeycomb kraft paper which as a whole act as an outstanding shock-absorbent material.

1.Easy Box with Quick Packaging

You don’t need any scissors for cutting the honeycomb paper wrap, instead use your hands to cut the paper. Hence, you can tear the length you need for packaging your item. Further, there is no requirement for any adhesive or tape to stick the paper wrap as its structure has the ability to interlock the cells.

2.Wide Range of Application

This honeycomb paper machine offers a wide range of applications in various places. Generally, they are suitable for printing supplies industries, e-commerce businesses, electronic and sporting goods, ceramics, etc.

3.Lowers Shipment Cost

The honeycomb kraft paper weighs much lesser than other traditional packaging materials. Thus, when the products are wrapped in them, it doesn’t increase much weight. You only have to pay for the weight of the item while shipping.

OEM Honeycomb Paper Dispenser HP50-T2 Here comes the new version of the honeycomb paper machine with the addition of the knob aiding the paper to enter the machine. While dealing with the machine you just need to follow three steps; ●Pull the paper from the roll. ●Wrap the product in it. ●Tear off the wrapped paper from the roll.

1.Fine stability

The HP50-T2 honeycomb paper dispenser consists of four suction cups at the base. As a result, they ensure firm attachment of the machine to the desktop. The increased stability of the machine lets the users operate it easily.

2.Features Paper Enter Holder

The paper enter holder on this manual machine allows you to enter the paper into the machine. Turning the knob also adjusts the tightening of the honeycomb paper roll resulting in the better wrapping of the objects.

3.Multiple Options

The honeycomb paper wrap provides you with multiple paper roll holding rods. You can use one rod for installing the honeycomb paper wrap while the other for attaching the white paper roll. Using both papers for packaging your product gives you more strong protection against damage.

4.Save Storage Space

Honeycomb paper saves storage space due to its structure. As the wrapping paper is present in the form of rolls so you may stack them on one another when not in use. Doing so only occupies a small area of your workstation. Also, the size of the machine is compact, therefore there is no space to worry about at all.

Honeycomb Paper Making Machine HP50-D2

If a manual honeycomb machine doesn’t satisfy you, go and try the HP50-D2 honeycomb paper dispenser. It is a new invention in packaging that helps you in transporting and protecting fragile products. Fortunately, the automatic operation mode proved to be a golden key for the efficiency of the packaging.

1.Control Panel

To meet the high demands of packaging productivity by the users, this machine features a speed button. You can change the speed by using the button. In addition, an emergency stop button is also designed in case of any mishap. It will immediately stop the machine.

2.Great quality

HP50-D2 dispenser frees you from worries after you buy it as it comes with three years warranty. The high-quality and durable materials used for manufacturing the machine let it perform well. However, in case of any difficulty, you can consult the technical sales team 24/7.

3.Features Smart Operating Modes

There are two smart operation modes on this machine that assist you in reaching your packaging goals efficiently. The one is A and the other is T mode. You can set the machine at A mode in order to run packaging consistently. Whereas, T mode enables you to run packaging at pre-set timings.

4.Quick and Easy to Use

After following some simple steps to operate the machine you can speed up your packaging. All you need is to place the white paper and honeycomb paper in the rotary rods. Then pull both papers a little out and adjust the required operation mode. Finally, start wrapping your objects as the papers come out of the machine.

5.Control Panel

To satisfy the customers who demand the packaging machines to operate fast for increasing their productivity, a speed button is designed on the automatic honeycomb machine. You can adjust the speed as per your need. On the other hand, an emergency stop button is there for your safety to immediately stop the machine.

Conclusion

Finally, whether you buy a manual or automatic honeycomb paper machine, both will help you is boosting your business. However, honeycomb paper is a 100% recyclable material that is in line with today's trend of environmental protection. Therefore, adopt this packaging alternative to prevent your environment from non-recyclable packaging materials.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#sustainability#manufacturing#kraft paper#carton#honeycombpaper

0 notes

Text

All You Need to Know About the Honeycomb packing paper

Are you in search of an eco-friendly alternative to plastic bubble wraps?

If yes, then it’s time to say goodbye to bubble wraps and welcome honeycomb packing paper. A sustainable substitute for every kind of plastic packaging. Undoubtedly, using biodegradable alternatives serve to reduce massive plastic global waste issues.

In addition, honeycomb paper is the ideal choice for wrapping your items and strengthening cardboard boxes. Doing so will ensure the safety of your products all through the transporting process. Therefore, a honeycomb packing paper roll is enough to roll a massive amount of daily items.

Further, let’s learn more about the honeycomb paper!

What is Honeycomb Paper?

Basically, the long fibres of conifers make honeycomb kraft paper. These long fibres offer a high stretchability rate to the honeycomb paper. Yet, honeycomb paper is designed after getting inspired by the beehive. The panels of this paper feature a honeycomb core and two covering materials sandwich it.

The hexagonal cells of the honeycomb paper face both sides with a similar composition which makes it strong enough. Furthermore, honeycomb paper provides remarkable cushioning that helps in absorbing maximum shocks during the transition of goods. Thus, it prevents your goods from excessive damage.

However, you may use this kraft paper in various areas, like dunnage, pallets, packaging, and signage displays.

3 Easy Steps to Wrap your Items Using Honeycomb Paper

No doubt, it’s pretty easy to use honeycomb kraft paper for packing the items in your home as well as businesses. Here are 3 simple steps which you may follow for the perfect wrapping of products;

●Step 1

Spread the wrapping paper on a straight surface and place the item on the top of the paper. Then pull the honeycomb kraft paper apart.

●Step 2 Carefully, stretch the paper out in such a way that it comes in a vertical position. Afterwards, start wrapping the object while maintaining the tension.

●Step 3

Once you are done with wrapping, tear off the excessive honeycomb paper and disconnect from the roll. Now, this wrap is enough for shaping and protecting your product.

Characteristics of kraft paper

Kraft papers show unmatched strength which makes them distinctive from other papers. Let’s see some outstanding features of the kraft paper.

1.Recyclable

Luckily, kraft paper is 100% recyclable. Hence, the more you will replace ordinary paper with kraft paper, there will be a great reduction in the amount of waste paper that mostly ends up in landfills. Yet, this property of the kraft paper is seeking the attention of a lot of customers.

2.All-round and versatile

Kraft paper is multifaceted as it is available in a variety of colours and thicknesses. Additionally, it is present in many varieties such as coated and uncoated versions. In fact, other than packaging means you may use kraft paper for wrapping gifts and paper craft projects.

3.Eco-friendly

One more remarkable feature of kraft paper is its eco-friendly nature. Typically, kraft paper is made up of wood and parts of the plant which constitute resinous pine and bamboo. There are pretty less or no traces of bleach in it.

While manufacturing the kraft paper, it is made sure that all the by-products could be reused in future. So, you may consider it 100% biodegradable.

4.Tear resistant strength

During manufacturing of the kraft paper, a pretty much amount of sulphur is used. This makes the paper exceptionally strong and resistant to tears. However, in the market, you'll come across stronger forms of kraft paper, like virgin kraft paper.

Whereas, when this kraft paper combines with the honeycomb paper and forms honeycomb kraft paper, it features much more excellent properties.

Why should you prefer honeycomb kraft paper?

If still, honeycomb packing paper remains unsuccessful in catching your attention, then surely the following information will greatly help you out. So, let's not waste the time and dive straight in!

1.Cost and Packaging Efficiency

Honeycomb paper packing materials are relatively cost-effective. Also, it is resistant to humidity so there is no obstacle due to weather conditions while transporting the goods.

On top of that, honeycomb paper is pretty efficient, lightweight, and extremely strong. No extra effort is required for its cutting and use which improves the packaging efficiency.

2.Easy to Use

It is super easy to use honeycomb packing paper. You just need to buy a roll of honeycomb paper and wrap it around your items. There is no need to use excessive layers of materials for protecting fragile objects as in the case of bubble wraps.

3.Quite Customizable

Honeycomb kraft paper is not specific for the materials. You may wrap any sort of material using honeycomb packing paper. Ranging from fragile glass objects to wooden objects, you can pack them all using this wrapping paper. This type of packing with honeycomb paper will transport your items safely to their destinations.

Also, you don't need to worry about customizing the size and shape of the honeycomb. It's pretty simple to customise it according to your products.

4.No need for Fumigation

In case, your company deals with exporting the goods, the products wrapped in honeycomb paper don't need fumigation. This is because while production of honeycomb, the manufacturers expose it to microwave or infrared dying. As a result, the packing paper gets sterilized. Therefore, there will be no need to quarantine your goods.

Final words

Most packaging industries are heading towards sustainable packaging means as their customers love environmentally friendly alternatives. In such a situation, honeycomb papers are providing the best services by replacing EP foam, PUF, MDF and bubble wraps.

They are highly efficient and durable for packaging the products. Especially, honeycomb wrappers are ideal for wrapping fragile items. Many auto parts manufacturing industries are relying on honeycomb kraft paper for the safe transit of their products.

So, you may also give a chance to honeycomb packing paper to prove its excellent performance.

#packaging#ecofriendly#wrap#packagingmachinery#paperindustry#sustainability#manufacturing#kraft paper#carton#honeycombpaper#packagingsolutions

0 notes

Text

The Role of Paper Cushion Machine in Packaging Technology

Packaging technology is filled with multiple machines and industries. The global paper cushion machine market is worth more than USD 1577.5 million and is expected to be multifold in the next few years.

If you are looking for a reasonable and energy-saving machine to pack your variety of products, the paper cushion machine is a perfect choice.

However, you should know about its features and working principles before buying it. This article will help you in knowing everything about the packaging industry and its machines.

What is a Paper Cushion Machine?

Being widely used in the manufacturing paper industry, the paper cushion machine has solved multiple packaging issues on one hand. Its void filling system and effective working mechanism have made it one of the finest machines in the market.

A paper cushion machine is also known as a paper pad cutting machine or a pillow machine. From filling the paper to wrapping and squeezing it, the paper cushion machine does the job perfectly. You can use it to pack your airbags, air rolls, or other similar products.

The Working Principle of Paper Cushion Machine

Unlike traditional air packaging machines, the paper cushion machine uses high-quality materials and thus performs better than its competitors. The compositing materials include:

Polyamide/ Polyethylene (PA/PE) co-extrusion plastic material

Peanut

Foam

Paper packing material

To deliver your delicate products safely and sound, the machine has been made eco-friendly and strong enough to easily cope with environmental factors. Let’s have a look at its working mechanism first.

1- Control System

The paper cushion machine works on a control system or precisely the double frequency control system. It operates on a one-way valve that helps in the packaging of air rolls and other air products.

The main purpose of this double frequency control is to save both time and energy when packaging the material. Moreover, the film layer completes in one step and speeds up the packaging process.

2- Automatic Operations

The best thing about a paper cushion machine is you can operate it automatically or manually as per your needs. This functionality makes the working process even more convenient and you can easily identify any fault while operating.

The additional technical features have made the working of the machine even more versatile. This is the reason manufacturing industries rely on paper cushion machines more than anything else.

3- Color Coding

The paper machine can be folded, coiled, and compressed while packaging the products. It works on a mechanism of sealing and cutting. In this way, you can correct the errors in the color code of the machine and solve all your packaging issues. The automatic positioning feature can also be used to adjust faulty color codes.

4- Speed Adjustment

A v-shaped transmission chain is present inside the machine that conveniently adjusts the speed of the packaging products. Depending on the type of material and packaging product, you can increase or decrease the speed of the gearbox. Besides this, the following are some other adjustments you should do with your products:

The shape of the product

Quantity or number of products

Product weight

Size

Shockproof requirements

5- Paper Packaging System

Now comes the most important part of the paper cushion machine and that is packaging the products. With the help of a void filling system, you can easily cut the paper and pack it for the customers. Moreover, the process is economical and manufacturing industries use it to deliver high-quality products to their users.

6- Multi-mode Configuration

The paper voif fill machine has multi-mode configurations that made it highly volatile and smooth. To get precise and accurate products, it is crucial to have a machining setup that not only operates easily but also delivers great results.

Furthermore, the machine comes with recyclable and biodegradable materials that prevent the products from environmental damage. As the disposable material does not contain coated paper it is easy to dispose of it.

Role of Paper Cushion Machine in Packaging Technology

Now, with the advent of technology, different new machines and manufacturing equipment have come into the market. And paper cushion machine is one of them.

With the help of its highly versatile and effective packaging solutions, you can pack your products in a few seconds. Here are some of the advantages of using this machine in the packaging industry:

● Flexible Machine

One of the major advantages this machine provides to the manufacturing industries is its flexible nature. The composition and overall packaging methods are simple and all the products will be delivered with utmost safety and protection.

● Economical

When it comes to saving energy and providing highly reasonable packaging solutions, the paper cushion machine comes on top. It gives the best results with high accuracy and can increase the cushioning volume to more than 35%.

● Sustainable

To deal with emergency packaging products, you need a machine that is sustainable and effective. The paper cushion machine is the one that provides optional integration solutions to the manufacturing industries. Hence, you can rely on this machine in terms of sustainability and environmental stability.

● Space-saving

Being a highly versatile machine, the void-filled air cushion machine saves a lot of time and space by providing quick and effective packaging products. It does not occupy much space and the material used is 99% made of Styrofoam which makes the process even smoother.

Here are some unique features of the paper cushion machine that makes it stand out from the rest:

It produces less garbage

It occupies less storage space

It is highly recyclable

The machine is best for air cushion rolls