Don't wanna be here? Send us removal request.

Text

Digital Diffrential Pressure Gauge

Explore wide range of high-quality products in the Digital Differential Pressure Gauge category. Find the best Digital Differential Pressure Gauge for your needs and enjoy unbeatable prices. Discover more at PARSHVI TECHNOLOGY (INDIA) PRIVATE LIMITED !

Digital Diffrential Pressure Gauge

0 notes

Text

Improving Modern Wellbeing and Effectiveness with Cutting-Edge Switch Advances

In the always-advancing scene of modern innovation, wellbeing and productivity are principal concerns. The requirement for solid and high-level instruments to screen and control different cycles has prompted the advancement of state-of-the-art gadgets, for example, chute jam switches, differential strain transmitters, and flameproof tension switches. The Flameproof Air differential pressure switch and the ATEX Air differential pressure switch are two that stand out as outstanding options for critical applications.

Differential pressure transmitter

0 notes

Text

Upgrading Modern Cycles with State-of-the-Art Strain and Level Control Advancements

In the steadily developing scene of modern robotization, the requirement for exact control and checking of tension and level boundaries is fundamental. As ventures take a stab at expanded effectiveness and dependability, creative arrangements, for example, vacuum pressure switches, gas pressure switches, water level transmitters, water level switches, and computerised differential strain measures have become imperative. In this article, we will investigate how these cutting-edge innovations from parshvitechnology.com are upsetting different modern cycles.

Air Velocity Transmitter

0 notes

Text

Gas Pressure Switch

Adjustable differential pressure switch for measuring the pressure difference between air or other non-combustible, non-aggressive gases and overpressure, vacuum, and differential pressure.

Gas Pressure Switch

0 notes

Text

Upgrading Modern Cycles with State-of-the-Art Strain and Level Control Advancements

In the steadily developing scene of modern robotization, the requirement for exact control and checking of tension and level boundaries is fundamental. As ventures take a stab at expanded effectiveness and dependability, creative arrangements, for example, vacuum pressure switches, gas pressure switches, water level transmitters, water level switches, and computerised differential strain measures have become imperative. In this article, we will investigate how these cutting-edge innovations from parshvitechnology.com are upsetting different modern cycles.

parshvitechnology.com vacuum pressure switches assume a significant part in keeping up with ideal circumstances in vacuum frameworks. The purpose of these switches is to control and monitor the level of vacuum, ensuring that processes that require particular vacuum pressures run smoothly. With their strong development and exact responsiveness, these switches add to the general productivity of vacuum-based applications, forestalling likely harm and guaranteeing wellbeing.

Gas pressure switch are fundamental parts in modern arrangements where exact control of gas pressure is basic. parshvitechnology.com gas pressure switches offer a dependable answer for observing and keeping up with ideal gas pressure levels. Whether it's in assembling, central air frameworks, or other modern cycles, these switches give constant criticism, considering quick acclimations to guarantee the solidness and proficiency of tasks.

Water management is an important part of many different industries, and water level transmitters help keep accurate and constant monitoring going. parshvitechnology.com water level transmitters use progressed sensor advances to give constant information on water levels. These transmitters can be used in a variety of critical systems, including water treatment plants, storage tanks, and other critical systems where precise water level control is necessary for successful operation. They are extremely versatile.

In enterprises where fluid levels should be firmly observed and controlled, Water Level Switches by parshvitechnology.com offer a dependable arrangement. These switches are intended to set off unambiguous activities when a foreordained water level is reached, forestalling floods or insufficient levels that could disturb processes. With their solidness and exactness, water level switches add to the smooth activity of different modern applications, including wastewater executives and substance handling.

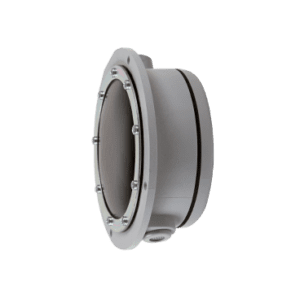

The Digital differential pressure gauge from parshvitechnology.com addresses a jump forward in pressure observing innovation. With a computerised show giving exact and moment readings, these measures are important in applications where keeping a particular strain differential is basic. The digital differential pressure gauge improves the overall efficiency of industrial processes by ensuring precision and dependability in cleanrooms, pharmaceutical manufacturing, and HVAC systems.

All in all, parshvitechnology.com scope of strain and level control advancements is at the forefront of development in modern computerization. Industries can achieve higher levels of efficiency, dependability, and safety thanks to the digital differential pressure gauge, vacuum pressure switch, gas pressure switch, water level transmitter, and water level switch. These cutting-edge technologies will have a significant impact on the design of automated processes in the future as the industrial landscape continues to change.

0 notes

Text

Improving Modern Wellbeing and Effectiveness with Cutting-Edge Switch Advances

In the always-advancing scene of modern innovation, wellbeing and productivity are principal concerns. The requirement for solid and high-level instruments to screen and control different cycles has prompted the advancement of state-of-the-art gadgets, for example, chute jam switches, differential strain transmitters, and flameproof tension switches.

Improving Modern Wellbeing and Effectiveness with Cutting-Edge Switch Advances

0 notes

Text

Flameproof Air differential pressure switch

Adjustable differential pressure switch for measuring the pressure difference between air or other non-combustible, non-aggressive gases and overpressure, vacuum, and differential pressure.

Flameproof Air differential pressure switch

0 notes

Text

Digital differential pressure gauge

The 990 Display differential pressure gauges are designed to detect differential pressure, overpressure, and vacuum for air and non-aggressive gases. They provide two menu-selectable output signals in addition to one adjustable pressure range.

0 notes

Text

Improving Modern Wellbeing and Effectiveness with Cutting-Edge Switch Advances

In the always-advancing scene of modern innovation, wellbeing and productivity are principal concerns. The requirement for solid and high-level instruments to screen and control different cycles has prompted the advancement of state-of-the-art gadgets, for example, chute jam switches, differential strain transmitters, and flameproof tension switches. The Flameproof Air differential pressure switch and the ATEX Air differential pressure switch are two that stand out as outstanding options for critical applications.

0 notes

Text

The Job of Tension Switches and Transmitters in Present-Day Modern Cycles

In the consistently developing scene of modern innovation, pressure switches and transmitters assume a crucial part in keeping up with the effectiveness and security of different cycles. These gadgets are fundamental for checking and controlling vacuum, gas, and water frameworks, guaranteeing that they function ideally.

Vacuum pressure switch are vital parts in frameworks that depend on vacuum levels for explicit applications. They capability as wellbeing instruments by constantly observing the vacuum pressure and setting off alerts or closing down the framework when tension falls outside the safe working reach. In enterprises, for example, drug assembling, semiconductor assembling, and food handling, these switches guarantee that basic cycles stay stable, forestalling exorbitant free time and likely risks. Gas pressure switches are significant for applications where keeping a particular gas pressure is fundamental. These gadgets are tracked down in many ventures, from air conditioning frameworks to modern heaters and gas pipelines. Gas pressure switches assist with keeping up with the ideal tension inside the framework, subsequently

guaranteeing that ignition processes, gas transport, and security measures are successfully made due. The capacity to answer pressure varieties progressively guarantees the protected and proficient activity of these frameworks.

Water level transmitters are instrumental in enterprises that depend on fluid level administration, for example, wastewater treatment plants, synthetic assembling, and power generation. These transmitters give consistent criticism about the water level in tanks, supplies, and different holders, permitting administrators to pursue informed choices. With their continuous information, water level transmitters assist with forestalling floods, advance water utilisation, and assure the reliable working of hardware.

Water level changes are correlative gadgets to water level switch, intended to initiate or deactivate hardware in light of predefined water levels. These switches are essential in applications like sump syphons, water cleansing frameworks, and water systems. Via naturally beginning or halting gear, water level switches save assets as well as forestall flooding or hardware harm, adding to a more productive and practical modern climate.

Digital differential pressure gauge has changed the manner in which enterprises screen and oversee pressure contrasts in different cycles. They give exact and ongoing information, making them important in basic applications like cleanroom conditions, drug fabricating, and central air frameworks. These measures offer dominant precision and dependability, improving security, quality, and proficiency in businesses where moment pressure differentials can have a huge effect.

Conclusion

All in all, vacuum pressure switches, gas pressure switches, water level transmitters, water level switches, and computerised differential tension measures are fundamental apparatuses in the cutting-edge modern scene. Their importance couldn’t possibly be more significant, as they assume an urgent part in keeping up with the trustworthiness and productivity of a great many cycles.

These gadgets are fundamental for checking and controlling vacuum, gas, and water frameworks, guaranteeing that they function ideally. In the realm of modern innovation, where accuracy and wellbeing are central, pressure switches and transmitters are essential parts that empower enterprises to meet their objectives proficiently, economically, and securely.

As innovation keeps on propelling, pressure switches and transmitters will without a doubt develop to fulfil the consistently expanding needs of industry.

0 notes

Text

Guaranteeing Wellbeing and Productivity With Chute Jam Switches and Differential Strain Transmitters

In the present modern scene, wellbeing and productivity are vital contemplations. Makers and administrators are continually looking for inventive answers to safeguard their gear and workers while improving their cycles.

Chute Jam Switch:

Chute Jam Switch are basic gadgets utilised in enterprises where the smooth progression of materials or substances is of most extreme significance. These switches are intended to distinguish blockages or jams in chutes, transports, or other material dealing with frameworks. At the point when a jam happens, the Chute Jam Switch sets off a caution or starts a programmed closure, forestalling harm to hardware and guaranteeing the security of staff.

In mass material taking care of activities, choke jam switches can deflect expensive margin times and fixes. They help in keeping a consistent progression of materials, in this way further developing effectiveness and diminishing creation disturbances.

Differential Strain Transmitter:

Differential pressure transmitters are vital devices for checking and keeping up with ideal circumstances in different modern cycles. These gadgets measure the distinction in tension between two focuses, giving pivotal information that permits administrators to settle on informed conclusions about framework execution.

In the drug business, for instance, Differential Tension Transmitters assume a crucial part in cleanroom conditions. They guarantee that air quality is kept up with inside determined limits, shielding delicate cycles and item quality.

Flameproof Strain Switch:

Security is foremost in enterprises where dangerous gases or materials are available. Flameproof pressure switch is uniquely intended to work in such unsafe conditions, where the gamble of a blast is a genuine concern. These switches are designed to hold any possible blast inside their nooks, keeping it from spreading to the encompassing environment.

Flameproof pressure switches are fundamental in oil and gas, substance, and petrochemical enterprises, where combustible gases or residue are pervasive. They act as basic parts in security frameworks, guaranteeing that hardware is closed down or secluded in the event of unusual tension circumstances.

Atex Air Differential Strain Switch:

In conditions where touchy climates are a steady danger, the requirement for specific hardware is obvious. The Atex Air Differential Strain Switch is a gadget that adjusts to the ATEX mandate, which directs gear expected for use in unstable climates. These switches are intended to work securely in regions where combustible gases, fumes, or residue is available.

Atex Air differential pressure switch is fundamental in modern areas like mining, synthetic handling, and seaward penetrating.

Flameproof Air Differential Tension Switch:

Like flameproof strain switches, flameproof Air differential pressure switches are designed to work in unsafe places where the potential for blast exists. These switches are utilised in frameworks that include the guideline of pneumatic force, guaranteeing the protected and productive activity of hardware and cycles.

Conclusion

Taking everything into account, the modern scene is continually developing, and security and productivity remain foremost worries. They assume imperative parts in safeguarding gear, guaranteeing the security of the workforce, and improving modern cycles. By utilising these trend setting innovations, businesses can proceed to advance and fulfil the consistently expanding needs for wellbeing and proficiency in this day and age.

0 notes

Text

Using Precision Instruments from Parshvi Technology to Become an Expert in Control and Monitoring

In today’s hectic industrial environment, control and accuracy are crucial. The maintenance of operational efficiency and safety is contingent upon the availability of dependable instruments, whether for gas system management, water level monitoring, or pressure differential gauges. We’ll go into the importance, adaptability, and ways in which these tools may improve your operations in this blog.

Gas Pressure Switch - Parshvi Technology’s Gas Pressure Switch is a lifesaver in businesses where gas pressure management is essential. To guarantee accurate management and safety in gas systems, these switches are painstakingly constructed. When it comes to ensuring the best possible control and dependability, these switches are used in gas pipelines, industrial burners, and HVAC systems to maintain the ideal pressure.

Water Level Transmitter - Water is essential to many industrial activities, including wastewater treatment facilities and cooling systems. Accurate water level monitoring is crucial to avoiding shortages, overflows, and system malfunctions. The Water Level Transmitters from Parshvi Technology provide real-time water level monitoring and management, assuring the seamless and effective operation of your operations. These transmitters are perfect for a variety of applications since they are also very resilient to adverse environmental conditions.

Water Level Switch - For anyone looking for a simpler but no less efficient way to regulate water level, Parshvi Technology’s Water Level Switches are the ideal choice. These switches provide an additional degree of protection against overflows and equipment damage by being made to initiate certain actions when water levels exceed a predefined threshold. Because of their adaptability, they may be used in industrial tanks and sump pumps, among other uses.

Digital Differential Pressure Gauge - The Parshvi Technology Digital Differential Pressure Gauge is a great tool for measuring pressure differentials precisely. With their cutting-edge digital technology, these gauges provide precise, real-time pressure fluctuation monitoring for a range of industrial applications. These gauges provide you with the exact information you need to guarantee maximum performance and safety, whether you’re in the pharmaceutical production, cleanroom operations, or HVAC maintenance industries.

https://www.parshvitechnology.com/wp-content/uploads/2023/04/990-Frei-Srgb-1-300x300.png

Overall, the foundation of contemporary industrial processes is precise instrumentation. The extensive line of instruments from Parshvi Technology, which includes Digital Differential Pressure Gauges, Gas Pressure Switches, Water Level Transmitters, and Water Level Switches, enables enterprises to stay in control, guarantee safety, and maximize productivity. These tools help you save money and comply with industry standards while also improving the dependability of your operations. Explore the precision instruments from Parshvi Technology to take control and monitor your industrial environment to new levels of safety and efficiency.

0 notes

Text

Employing Specialized Pressure Switches to Ensure Safety and Efficiency

Maintaining productivity and safety in a variety of industrial settings is critical. Precision and dependability are essential for servicing machinery and procedures. One method for doing this is by using specialty pressure switches.

Chute Jam Switch: Chute jams may be a frequent and expensive problem in sectors that deal with material handling, such as mining or bulk material processing. Parshvi Technologies' Chute Jam Switch offers a solution to this issue. By detecting obstructions in chutes or conveyor belts, this specialized switch enables prompt intervention to avoid equipment damage and production disruptions. It enhances material handling activities' efficiency and safety.

https://www.parshvitechnology.com/wp-content/uploads/2023/08/process-industry-services.jpeg

Differential Pressure Transmitter: In many industrial operations, precision is essential, particularly when it comes to pressure differential monitoring. The Differential Pressure Transmitter provides precise and dependable measurement of pressure fluctuations for a range of applications. This transmitter is essential for preserving efficiency and product quality, whether it is for maintaining ideal filter conditions in manufacturing processes or making sure that airflow in HVAC systems is sufficient.

Flameproof Pressure Switch: Safety is the first concern in any area where combustible gases or liquids are present. The Flameproof Pressure Switch is made to the strictest safety regulations. It is perfect for usage in dangerous areas since it reduces the possibility of explosions by trapping any possible fire or explosion within its cage. Chemical facilities, oil refineries, and other businesses where safety is of utmost importance often include these switches.

Atex Air Differential Pressure Switch: Maintaining the proper air pressure differentials is crucial in spaces like cleanrooms and pharmaceutical production plants where air quality and cleanliness are crucial. Atex Air Differential Pressure Switch makes sure that these differentials stay within predetermined bounds. This is essential for maintaining product quality, avoiding contamination, and abiding by industry rules.

Flameproof Air Differential Pressure Switch: It is designed for dangerous settings, much like the Flameproof Pressure Switch. It ensures safety in potentially explosive environments while offering precise control over air pressure differentials. These switches are essential to the mining and petrochemical industries for preserving operational integrity and safeguarding workers and equipment.

Vacuum Pressure Switch: Industries that use vacuum processes include food packing, medicines, and vacuum furnaces. Sustaining the proper vacuum levels is essential for both process efficiency and product quality. Parshvi Technology's Vacuum Pressure Switchlowers the possibility of defective products and inefficient processes by ensuring that vacuum systems function within predetermined bounds.

https://www.parshvitechnology.com/wp-content/uploads/2023/08/OEM-1024x709-1.jpeg

Overall, specialized pressure switches are essential to preserving efficiency and safety in a variety of sectors. The Chute Jam Switch, Differential Pressure Transmitter, Flameproof Pressure Switch, Atex Air Differential Pressure Switch, Flameproof Air Differential Pressure Switch, and Vacuum Pressure Switch are just a few of the dependable and accurate pressure switches that Parshvi Technology provides. These devices promote process optimization and operational efficiency, which in turn leads to better product quality and increased safety during activities in hazardous areas.

0 notes

Text

Unveiling the Power of Differential Pressure Transmitters

When it comes to business processes and systems, it's veritably important to measure and control effects rightly. The discriminational pressure detector is a crucial piece of outfit that helps achieve this position of delicacy. These bias were made to measure the difference in pressure between two places in a fluid or gas system. They're now used in a wide range of diligence to make sure safety, effectiveness, and responsibility.

How to Figure eschewal Differential Pressure

Differential pressure is the difference in pressure between two places in a system of fluids or feasts. It's frequently used in artificial processes to figure out inflow rates, quantities, and other important factors. Chute jam switch is used extensively. Differential pressure detectors are made to pick up on this difference in pressure and turn it into an electrical affair that can be fluently tracked and added to control systems.

How It Works

A Differential pressure transmitter have four major corridor the detector, the transmitter body, the electronics, and the signal affair. The pressure difference is felt by the sense element, which is generally a diaphragm or a set of diaphragms, which bends as a result. The erected- in electronics also turn this change in stir into an electrical signal that's related to the difference in pressure.

A 4- 20 mama current circle or a digital signal like HART is frequently used to shoot the signal. The operation and the quantum of contact demanded between the emitter and the control system determine which affair signal to use. Flameproof pressure switch has the finest results.

Uses in a number of diligence

Differential pressure detectors are used in a wide range of businesses, each of which benefits from what they can do. Controlling a process in an assiduity DP receivers are used to measure situations in tanks, inflow rates in pipes, and pressure differences between pollutants and partitions in the chemical, petrochemical, and artificial diligence.

HVAC and structure robotization DP receivers are used to control the inflow of air and gas in heating, ventilation, and air exertion( HVAC) systems. This makes sure that the system is comfortable and uses the least quantum of energy. Atex Air differential pressure switch is actually fantastic.

oil painting and Gas In the oil painting and gas assiduity, these receivers are veritably important for keeping track of channel inflow, chancing leaks, and keeping safe pressure differences at different stages of product. Flameproof Air differential pressure switch has been enough good.

https://www.parshvitechnology.com/wp-content/uploads/2023/04/930-8-Hutmutterverschraubung-1-300x300.jpg

Medicinals Differential pressure detectors are used in cleanrooms to control the difference in air pressure and keep sensitive goods from getting defiled.

Water Treatment In water and sewage treatment shops, DP transmitters help measure and control changes in pressure to make sure that the sludge and delivery processes work well.

In the end,

Differential pressure detectors are the retired stars of artificial instrumentation because they make it possible to measure and control effects directly in a wide range of situations. Their capability to turn pressure differences into electrical signals that can be used lets businesses keep their effectiveness, safety, and affair at their stylish. As technology keeps getting better, there is no question that these bias will play an ever more important part in shaping the future of artificial processes and systems, making sure that delicacy and trustability stay at the top of every operation.

0 notes

Text

Accurate Water Level Navigation with the Water Level Switch.

The water level switch is an important device for regulating the flow of fluids and ensuring proper operation in the fields of automation and fluid control. This modest gadget serves a crucial role in providing effective and regulated water management, whether it is in preventing flooding, maintaining water reservoirs, or safeguarding industrial operations. The function, usefulness, and use of the water level switch are explored in this article.

Figuring Out the Float Valve

When it comes to keeping tabs on and regulating the water level in storage tanks, reservoirs, and other containers, nothing beats the simplicity and ingenuity of a water level switch, also known as a float switch. The switch turns on or off dependent on the water level, which is sensed by the movement of a buoyant item (usually a float) that rises and falls with the water level. Digital differential pressure gauge has affordable prices.

Structure and Function

These are the parts that make up a standard water level switch:

First, the object is buoyant, meaning it rises and falls with the water level. Buoyant objects might be composed of foam, plastic, or stainless steel. The float triggers the switch whenever it moves.

When the float reaches a certain height above or below the water's surface, contacts or sensors in the switch mechanism are triggered. These contacts can either fully engage or break an electrical circuit.

The float and the switch mechanism are shielded from the elements and any harm by the enclosure. It also assures a steady and reliable performance.

Positive Effects and Bonuses

There are many benefits to installing water level switches:

Automation: Water level switches eliminate the need for human involvement by automatically sensing and regulating water levels. Vacuum pressure switch is preferred by a lot of people.

These switches assist avoid flooding, damaged equipment, and other possible risks by triggering pumps or alarms when water levels reach critical areas. Gas pressure switch is indeed one of the best.

Thirdly, water level switches improve efficiency by turning on pumps and valves only when they are required, so reducing unnecessary water and power use. Water level transmitter has provided the finest results.

https://www.parshvitechnology.com/wp-content/uploads/2023/04/Level-Transmitters-TLR31TLRG-1-300x300.jpg

Dependability: These switches are built to last in a variety of conditions and may be used in a broad variety of settings.

Savings on water costs, repairs, and maintenance are all possible because to water level switches' ability to detect leaks before they cause harm. You can easily find Water level switch.

Conclusion

In today's sophisticated network of automated and fluid-controlled systems, a seemingly little component known as the water level switch plays an essential role. Because of its precise water-level monitoring and control, it ensures dependable operation in a wide variety of settings, ranging from straightforward domestic sump pumps to complex manufacturing processes. These straightforward tools have proven essential in enhancing water management, cutting down on waste, and raising production across a broad variety of industries, and they will continue to play an important role in these areas as technology continues to advance.

0 notes

Text

What you need to know to get started with differential switch?

To measure and manage the pressure gradient between two locations, engineers have developed differential pressure switches. It functions by monitoring pressure levels in two locations and activating a switch or relay at a threshold that the user specifies. When precise control of pressure is necessary, this switch is frequently utilized in a variety of industrial applications.

Important features of a differential pressure switch include the following:

Function: A differential pressure switch's principal role is to measure and regulate the pressure gradient between two locations. It is typically employed to keep certain pressure differentials for optimal system operation, and it can detect both positive and negative pressure differences.Chute jam switch is used widely.

Components: An adjustable setpoint mechanism, a pressure sensor device, and an electrical switch or relay are the main components of a differential pressure switch. A diaphragm, bellows, or other mechanical or electronic device that senses pressure and translates that change into mechanical displacement or electrical impulses is the pressure detecting element.Differential pressure transmitter will give you good results.

In order to function, a differential pressure switch compares the pressure at two locations inside a system. The switch is activated and the electrical circuit is altered when the pressure differential is greater than a predefined value (setpoint).Flamproof pressure switch is indeed excellent. Depending on the needs of the application, this can be used to set off alarms, turn machines off or on, or initiate other control procedures.

Differential pressure switches are useful in many different settings. They are widely employed in HVAC systems for the purpose of tracking air velocity, filter condition, and duct pressure. Atex Air diffrential pressure switch is used widely. They are also used to check fluid levels, find leaks, and regulate pump performance in fluid handling systems. Pneumatic systems, industrial procedures, the oil and gas industry, water purification, and so on are all alternative uses.

There are a number of advantages to using differential pressure switches. They keep pressure differentials within acceptable limits by providing precise and dependable monitoring. This aids in the security of systems, the avoidance of faults, and the enhancement of overall system efficiency. Flamproof Air diffrential pressure switch has a reasonable price. Switches that detect changes in pressure can help conserve energy by adjusting system operation accordingly.

Most differential pressure switches include a tunable setpoint that allows users to precisely control the pressure differential at which the switch activates (see also: 4. Because of its customization, the switch may be used in a wide variety of setups and under a variety of scenarios.

In order to prevent damage from extreme pressure differences, many differential pressure switches have built-in safety measures including high and low pressure limits. These restrictions prevent harm to the machine and guarantee its safe functioning.

Finally, a differential pressure switch is an important tool anywhere accurate pressure monitoring and control is required. It improves the system's performance, safety, and efficiency by sensing pressure variations and triggering control actions depending on pre-set settings. A differential pressure switch allows operators to keep pressure differentials at safe and effective levels, protecting machinery and keeping systems operational.

0 notes

Text

Precision Fluid Level Monitoring with a Water Level Switch

One of the most important components of any system that stores or processes liquid is the water level switch. It is essential in a wide range of fields and uses, since it guarantees precise level sensing, prevents overflow and dry running, and sets off actions based on the fluid level. The importance of water level switches in fluid management will be discussed as we delve into their design, many uses, and operation.

Functionality

A water level switch is an instrument used to measure and keep tabs on the volume of liquid in a container. A wide range of sensing technologies, including float switches, conductive probes, capacitive sensors, and optical sensors, are used in its operation. The switch activates, causing an electrical reaction or control action, when the fluid level reaches a predetermined level.Vaccume pressure switch is actually very good.

Water Level Switches and Their Varieties

Float Switches Float switches are quite ubiquitous and widespread. A float with a lever arm or rod attached to it makes up this device. The float follows the fluid's level up or down, and when it reaches a certain point, it triggers a switch. Float switches may be used in a variety of contexts due to their adaptability, dependability, and versatility.Gas pressure switch is used widely.

b) Conductive probes, which measure the fluid's level by measuring its electrical conductivity. They have two or more electrodes at varying heights. The switch mechanism is activated when a conductive route is created between the electrodes and the fluid level.Water level switch is a must have.

Capacitive water level switches operate on the capacitance principle to monitor fluid levels. c. Capacitive Sensors. One of the conductive plates acts as a sensor, while the other acts as a ground for the device. The switch is triggered by a change in fluid level since this causes a shift in capacitance between the plates. You can use Water level transmitter anytime.

Optical Sensors: Water level switches that use infrared or laser technologies to detect liquid use optical sensors. They send out beams of light over the fluid's surface, activating a switch if the beam is broken. Optical switches are commonly utilized when direct contact with the fluid would be unpleasant or impossible.Digital diffrential pressure gauge is indeed fantastic.

Gains

There are several uses for water level switches:

Equipment failure due to dry running or overflow can be avoided with the use of water level switches. Pumps, valves, and other parts that deal with fluids will last longer and function better if you do this.

Water level switches help conserve energy by turning on pumps and other devices only when they're needed. By preventing needless pump usage, they save money and energy.

Water level switches monitor and regulate fluid levels, protecting people and the environment from spills, leaks, and other potential dangers. They help maintain public health and safeguard the environment by stopping waste from piling up or vital supplies from running out.

Conclusion

When it comes to managing the fluid levels in storage facilities, water level switches are crucial. Their advantages include of saving energy, being secure, protecting the environment, being automated, and being adaptable. Industries may reduce dangers associated with poor fluid level control, improve system efficiency, and boost productivity by installing water level switches.

0 notes