🇨🇳PCB Fabrication~PCB Surface ~PCB Design~Supply Chain Service~PCB one-stop Service

Don't wanna be here? Send us removal request.

Text

FR4 circuit board multilayer board lamination process

The parameters such as the total thickness and number of layers of the PCB laminate are limited by the characteristics of the PCB. Special plates generally have a limited variety of plates of different thicknesses, so designers must consider the plate characteristics and PCB processing limitations in the PCB design process.

+More:

1 note

·

View note

Text

HDI PCB board Fabrication

HDI PCB board Fabrication

0 notes

Text

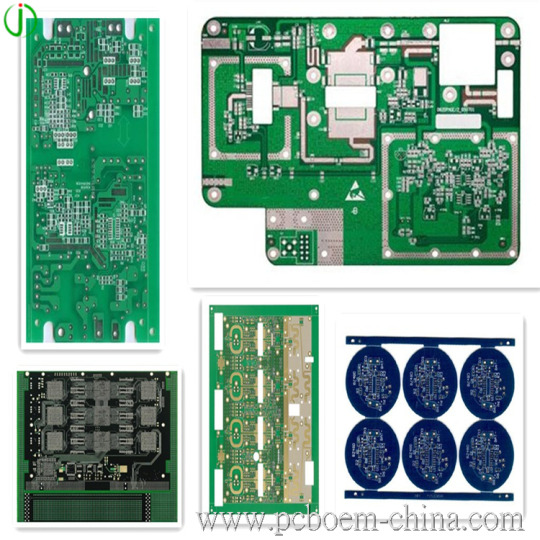

PCB prototype high-end board manufacturing, Juding circuit technology full control quality

PCB prototype production refers to the trial production of printed circuit boards before mass production. The main application is the process of small batch trial production to the factory after the electronic engineer designs the circuit and completes the PCB. This process is before the product design is not completed and confirmed, that is, we understand the "PCB prototype production".

PCB prototyping surface treatment generally adopts hot air leveling spray tin, full plate nickel plating gold, organic solderability protectant (OSP), immersion silver, immersion gold, immersion tin, electroplated hard gold, chemical nickel palladium gold and other processes. To ensure good solderability or electrical performance, these processes need to fully consider the service capacity and service level of the service provider.

+more:

0 notes

Text

Rogers PCB board Fabrication

0 notes

Text

From China: PCB board prototype or mass producer

0 notes

Text

High-temperature mica board PCB manufacturing special process: PCB prototype manufacturing

I. Introduction of high temperature resistant mica board shaped PCB manufacturing productsThe high temperature resistant mica board has excellent high temperature insulation performance and high temperature resistance up to 1000. It has good cost performance in high temperature insulation materials.High temperature resistant mica board has excellent electrical insulation performance, and the resistance to voltage breakdown of common products is as high as20KV/mm.The high temperature resistant mica plate has excellent flexural strength and processing properties. The product has high flexural strength and excellent toughness, and can be processed into various shaped parts without lamination by lathe, milling machine and drill bit.The high temperature resistant mica board has excellent environmental performance. The product does not contain asbestos. It has less smoke and odor when heated, and is smokeless and tasteless

.+MORE:

0 notes

Text

What are the characteristics of the pcb multilayer board manufacturing process?

As the demand for electronic products increases, the structure of pcb boards becomes more and more complex. Due to the space limitations of the PCB circuit board, the circuit board is also gradually "evolving" from a single layer to a double layer to a plurality of layers. So what is the difference between the multi-layer pcb circuit board and the double-layer pcb circuit board in the manufacturing process? The following is a brief introduction from the technicians of Juding Circuit Technology Electronics.

+more:

0 notes

Text

PCB prototype manufacturing ceramic substrate is difficult to make

There are many types of manufacturing techniques for ceramic products in PCB circuit board factories. It is said that there are more than 30 manufacturing methods, such as dry pressing, grouting, extrusion, injection, casting and isostatic pressing, etc., due to electronics. The ceramic substrate is of the "flat" type (square or wafer type), the shape is not complicated, and the manufacturing process using dry molding and processing is simple and the cost is low. Therefore, the dry pressing method is mostly used. There are three main contents in the manufacturing process of dry-pressed flat-panel PCB electronic ceramics, namely blank forming, blank sintering, finishing, and forming circuits on the substrate.

0 notes

Text

PCB prototype multi-layer board manufacturing difficulties

PCB multilayer boards are typically defined as 10-20 or more advanced PCB multilayer boards that are more difficult to machine than conventional multilayer boards and require high quality and reliability. Mainly used in communications equipment, high-end servers, medical electronics, aviation, industrial control, military and other fields. In recent years, the market demand for multilayer circuit boards in communications, base stations, aviation, military and other fields is still strong.

0 notes

Text

Placement of marker points during PCB design

Placement classification of marking points during PCB design

1: Mark point is used for optical positioning of solder paste printing and component placement. According to the role of Mark points on the PCB, it can be divided into jigsaw Mark points, veneer Mark points, and local Mark points (also called device level MARK points).

0 notes

Text

PCB prototyping, flying probe test: PCB surface mount one-stop service provider

In the manufacture of PCB prototypes, flying probe testing is required and quality is guaranteed before delivery to the customer. This test is a relatively effective flying probe test method.

PCB prototyping

0 notes

Text

Juding Circuit Technology PCB one-stop ODM and OEM service provider

The most obvious difference between OEM and ODM is that the OEM is commissioned by the original manufacturer, and the ODM factory commissioned the design.

0 notes

Text

PCB circuit board storage method

The PCB circuit board is a provider of electrical connections for electronic components and plays an important role. After the PCB circuit board is completed, it needs to be stored to avoid damage to the PCB circuit board. So what is the storage method of the PCB circuit board? The following Polytechnics technicians will introduce you:

0 notes