PCB Power Inc. is a leading California-based provider of precise and reliable PCB manufacturing services, backed by over 35 years of excellence. As an ITAR, UL, and ISO-certified company, we specialize in PCB design, prototyping, and production, catering to industries such as aerospace, defense, automotive, industrial electronics, educational institutions, R&D, telecommunication, and medical electronics across the USA. By combining our 25+ years of expertise from PCB Power Market in India with a deep understanding of the USA electronics ecosystem, we deliver cost-effective, tested, and tailored solutions.

Don't wanna be here? Send us removal request.

Text

Top 15 PCB Board Manufacturers in USA

When it comes to building reliable electronics, choosing the right PCB board manufacturer in USA is critical. Whether you’re a startup, engineer, OEM, or tech company, having a dependable partner for printed circuit board fabrication and assembly ensures faster production, fewer errors, and better results.

In this blog, we list the Top 15 PCB board manufacturers in the USA known for high-quality PCB fabrication, assembly, and fast delivery. These companies are widely searched and trusted across various industries — from medical to aerospace, IoT, automotive, and industrial applications.

1. PCB Power

PCB Power is one of the most trusted names among PCB board manufacturers USA. With over two decades of industry experience, PCB Power offers quick-turn PCB fabrication, full turnkey assembly, and components sourcing — all under one roof.

As a USA-based PCB company, they focus on delivering high-quality single, double, and multilayer PCBs with fast turnaround and competitive pricing. Whether you’re building prototypes or mass production, PCB Power’s online ordering system makes it easy to get instant quotes, track orders, and communicate with real engineers.

Key Features:

US-based production for fast and reliable delivery

ISO-certified processes for superior quality

Advanced manufacturing for high-density, multilayer PCBs

Turnkey assembly and BOM handling

Expert support for startups, engineers, and OEMs

If you’re looking for a complete PCB manufacturing solution in the USA, PCB Power should be your first stop.

2. Advanced Circuits

Advanced Circuits is one of the largest and oldest PCB manufacturers in the United States. Known for high-quality prototypes and low-to-medium volume production, they serve industries like aerospace, defense, and telecom.

They offer same-day and next-day shipping options and have their own in-house manufacturing for consistent quality.

3. Sierra Circuits

Sierra Circuits is a full-service PCB company specializing in quick-turn fabrication and assembly. They’re well-known for their high-performance HDI PCBs, rigid-flex boards, and support for complex designs. Sierra Circuits is ideal for companies looking for technical precision and tight tolerances.

4. Sunstone Circuits

Sunstone Circuits has built a reputation for delivering reliable prototype PCBs and small-batch orders. Their online design tools and instant quote system are ideal for hobbyists, startups, and small engineering teams. Their US-based manufacturing ensures high quality and fast shipping.

5. Bay Area Circuits

Located in California, Bay Area Circuits serves the Silicon Valley tech community with rapid prototyping, fabrication, and assembly services. They are experts in small-run production and serve various industries including medical, aerospace, and communications.

6. Rush PCB Inc.

Rush PCB Inc. offers full turnkey PCB services, including design, manufacturing, and assembly. They specialize in multilayer, flex, and rigid-flex PCBs with quick-turn options. Their experienced team supports everything from prototypes to volume production.

7. Custom Circuit Boards

Based in Arizona, Custom Circuit Boards provides high-quality PCBs for engineers and hardware startups. They focus on fast production and specialize in multilayer boards, thick copper PCBs, and RF designs.

8. Imagineering Inc.

Imagineering Inc. offers both PCB fabrication and assembly with ISO 9001 and AS9100 certifications. They serve demanding industries like medical and aerospace and are known for excellent quality and fast lead times.

9. Epec Engineered Technologies

Epec is a full-service provider offering custom PCB manufacturing, flexible circuits, and battery packs. With decades of experience, they provide engineered solutions for complex applications and tight deadlines.

10. APCT Inc.

APCT is known for high-speed, high-density interconnect PCBs. They support quick-turn and production-scale manufacturing. Their specialties include aerospace and defense-grade boards with rigorous quality requirements.

11. OnBoard Circuits

OnBoard Circuits offers affordable PCB prototyping, fabrication, and assembly with domestic and offshore capabilities. They are known for great customer support and fast delivery for small to medium volume orders.

12. Millennium Circuits Limited (MCL)

MCL provides reliable PCBs including rigid, flex, and rigid-flex boards. They serve industries like telecom, industrial, and medical, offering fast turnaround times and excellent pricing.

13. TechnoTronix

TechnoTronix offers advanced PCB manufacturing and assembly solutions with a strong focus on precision and fast lead times. They work with both small businesses and large enterprises, offering everything from basic to complex PCB designs.

14. RedBoard Circuits

RedBoard Circuits provides quality PCBs with a focus on customer service and quick delivery. They offer a wide range of PCB types including FR4, aluminum, and Rogers materials.

15. ALLPCB USA

ALLPCB USA offers cost-effective PCB solutions with a quick-turn focus. They provide both prototype and production runs and serve customers looking for affordable yet reliable circuit boards.

Choose the Best PCB Manufacturer for Your Needs

Selecting the right PCB board manufacturer in USA can be the difference between a successful project and costly delays. Whether you need fast prototyping, volume production, or full turnkey PCB assembly, each of these top 15 manufacturers brings something unique to the table.

However, if you’re looking for a complete solution with fast delivery, reliable quality, and competitive pricing — PCB Power is a clear leader. With US-based manufacturing, expert support, and a user-friendly online ordering platform, PCB Power makes your PCB journey seamless from design to delivery.

0 notes

Text

Top Trends in PCB Assembly for 2025

PCBs are the heart of the modern world. Whether it’s household equipment, industrial equipment, or defense ordnance, printed circuit boards are running everything. With new developments, the global scene of PCB manufacturing is changing rapidly. Using the newest technologies is not only a great concept, but staying competitive depends on it as well. From downsizing to AI-driven manufacturing, 2025 promises to bring major breakthroughs along with making advancements in current technologies that will change the way Printed Circuit Boards (PCBs) are manufactured.

This article will walk you through some key industry trends that will sketch the future of PCB assembly.

5 Key Trends in PCB Assembly to Follow in 2025

As the world is moving towards manufacturing more complex products and adopting advanced technologies, the PCB assembly industry is also observing several key trends. Here are a few noteworthy trends to follow.

1. Shrinking is in High-Density Interconnections: HDI and Miniaturization

Think about our daily gadgets, such as wearables, Internet of Things devices, and sophisticated medical electronics. These devices need robust and small PCBs, and therefore, in these spaces, High-Density Interconnect (HDI) technology excels. HDI lets electronic gadgets be more powerful despite their compact stature. In what manner? For high-speed applications, it increases signal integrity, lowers component spacing, and permits smaller trace lengths, hence enhancing electrical performance. And it will change the entire PCB manufacturing market.

According to a forecast [1], the HDI PCB market is expected to rise rapidly and, by 2032, will reach almost $40 billion. That makes the direction in which things are heading quite obvious.

2. Smart Factories: Artificial Intelligence and Automation

Like in every other industry, PCB assembly is becoming significantly faster, smarter, and more efficient. Industry 4.0 and manufacturing driven by artificial intelligence lead the push. Think about robotic soldering and pick-and-place robots for fast, more perfect component installation. Artificial intelligence and machine learning have found their way into quality control, that is, for error reduction and flaw detection done automatically. Imagine the Internet of Things, connected production lines, allowing real-time monitoring and predictive maintenance.

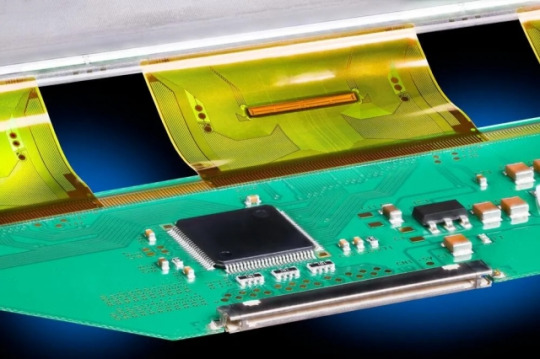

3. Bendable and Adaptable: Rigid-flexible PCBs

Flexible and rigid-flex printed circuit boards are becoming more popular in industries such as transportation, aircraft, and healthcare electronics. But you may think, why so? Because of their small size and lightweight nature, they are ideal for manufacturing small, portable electronic devices. They can withstand significant external force and resist bending and vibration. They endure longer with fewer interconnect failures, making them more reliable.

4. Green is Good: Manufacturing Sustainable Circuit Boards

Growing worries about e-waste and carbon footprints force sustainability to the front stage in PCB production. Lead-free soldering, biodegradable and reusable substrates, recyclable materials, and energy-efficient manufacturing procedures will become the focal points in the near future. It’s about matching global laws and customer demand as much as it is about environmental responsibility.

5. Printing the Future: 3D Printing in PCB Assembly

Additive manufacturing is revolutionizing PCB manufacturing and streamlining complex multilayer design construction. From this, faster prototyping, reduced material waste, and more customization for specific uses follow. This is a breakthrough for design and development; it will only get more so.

The Final Thought

There are a lot of exciting new possibilities in the PCB assemblyand PCB manufacturing industries. Miniaturization, automation, sustainability, and developments in AI-driven manufacturing will enable you to produce premium printed circuit boards (PCRs) that satisfy future electronics needs. Survival in a dynamic industry depends on keeping ahead of the competitors. By following these trends and wise technology investments, you could set yourself up for success in 2025 and beyond.

Know More : https://www.pcbpower.us/blog/top-trends-pcb-assembly

0 notes

Text

All About Materials for Printed Circuit Boards USA

Printed circuit boards (PCBs) in the US are mostly a flat laminated composite. PCB manufacturers use non-conductive substrate materials along with layers of copper circuitry on the external surfaces and buried in internal layers.

Printed circuit boards may be simple, with one or two layers of copper on the substrate, or complex, such as in high density applications, with more than fifty layers. Manufacturers use a flat composite surface, as this is ideal for mounting components that are ultimately attached to the copper layer by soldering. The copper traces interconnect the components electrically.

Basic Components and Materials of a Standard PCB

A standard PCB usually has six basic components:

Prepregs

Laminates

Copper Foil

Soldermask

Silk Screen

Surface Finish

Prepreg is made from a thin fabric of glass and coated with resin. Manufacturers cure the resin in special treaters. The glass fabric forms the basic mechanical support for holding the resin in place. The resin can be of various materials, like FR-4 epoxy, Teflon, Polyimide, and others. Initially, the resin is in a liquid form when coated onto the glass fabric. The combination moves through the treater, and the epoxy begins to dry as it travels through the oven section. Once it exits the treater, the epoxy is dry to touch.

When exposed to higher temperatures, usually above 300 °F, the resin in the prepreg begins to soften and melt. The resin soon reaches its thermosetting point, where it rehardens to become rigid again and very strong. Manufacturers use prepreg sheets to build the second component of a PCB — the laminate.

When laminated together with heat and pressure, sheets of prepreg and copper foil form the copper clad laminates for PCBs. Once the resin hardens, these PCB laminates with copper foil on both sides establish the basic structure of which PCB manufacturers make printed circuit boards.

To produce the circuitry on the laminate surface, the PCB fabricator must image and etch away the unwanted copper from the copper foil. These copper circuits create the tracks or conductors on the internal and external layers of the board. Once the fabricator images and etches each internal layer to constitute the circuits, they laminate them together using the prepreg.

Solder Mask is another epoxy coating on the board to cover the copper tracks on its outer layers. The coating protects the copper tracks on the external layers from oxidizing and corroding over time. As the internal circuitry remains buried within layers of prepreg, they do not need additional protection. Copper pads, where components will be soldered, are not covered by the soldermask.

Silk screen or nomenclature, forms the lettering on the PCB surface showing component numbers, their location, and their orientation. They can also show additional mounting information or handling precautions.

Besides the common green and white colors for the solder mask and silkscreen, manufacturers often use other colors also, in consultation with their customers.

Surface finish protects the copper pads left exposed by the soldermask. Fabricators use various types of surface finishes such as silver, tin/lead solder, lead-free solder, gold, nickel and others. Apart from protecting the exposed copper pads, surface finishes also provide a surface suitable for good solderability.

Selecting Materials for Printed Circuit Boards

Printed circuit board manufacturers offer a variety of materials for making the substrates and other components of PCBs. PCB designers select materials depending on the application requirements. Different material choices provide the PCB with varying qualities, facilitating the optimum performance for specific applications.

Designers make a choice of materials depending on:

Electrical performance — high voltage, high speed, high frequency

Mechanical performance — rigidity, flexibility, flame retardant

Thermal performance — ability to survive high temperatures, good thermal conductivity, low coefficient of thermal expansion

Regulatory/Governmental requirements — WEEE, RoHS, UL

For instance, a common popular consideration is complying with UL or Underwriters Laboratories requirements for flame retardation characteristics. Many electronic devices come with a UL rating to show that in the event of the device catching fire, the circuit board will retard the flames and will self-extinguish. This is a critical consideration for several types of consumer and other electronic equipment.

Resins and glass cloth fabrics that make up the laminates, must offer distinct insulating capabilities. Designers use different dielectric materials offering distinctive electrical and thermal characteristics for determining which laminate will best suit a PCB design for a specific application.

When making a material selection for their design, designers must consider various performance features. Most important among these are:

Dielectric Constant and Loss Factor — key electrical factors essential for high-speed performance and signal integrity.

High Glass Transition Temperature — capability to withstand high temperatures during assembly and field operation.

Flame Retardation — for UL qualification

Thermal Conductivity and Coefficient of Thermal Expansion — capability to perform in harsh service environments

Mechanical Strength and Dimensional Stability — mechanical attributes like shear and tensile strength when the PCB is in service, changes in dimension when manufacturing, undergoing thermal cycles during assembly, or when exposed to humidity.

Some Popular Materials for PCBs

FR-4 Prepreg and Laminates

FR-4 is the most popular PCB substrate material and is fire-retardant. The material has good thermal, electrical, and mechanical properties, along with a favorable strength-to-weight ratio as necessary for electronic applications. These are also one of the lowest cost PCB materials available.

Among printed circuit board manufacturers, FR-4 is a popular material for laminates and prepreg made from glass cloth and epoxy resins, for PCBs with low layer counts up to 14 layers. To improve its performance manufacturers often blend the epoxy resin with additives. This significantly improves its electrical, mechanical, and thermal properties, along with its ability to retard flames. Manufacturers use FR-4 laminates and prepregs as they are versatile, adaptable, and offer predictable yields.

Polyimide Prepreg and Laminates

For higher temperature performance compared to FR-4 materials, manufacturers use Polyimide laminates. Costing more than FR-4 materials, Polyimide materials offer better electrical performance, improved capacity to survive in higher temperature and harsh environments. With lower expansion characteristics, Polyimide materials are more stable during thermal cycling. Polyimide is more suitable for higher layer count PCBs.

Teflon Prepreg and Laminates

Bonding materials and laminates made of Teflon offer superior electrical properties, making them suitable for high-speed applications. Although more expensive than Polyimide materials are, Teflon offers designers better signal integrity in their designs. Printed circuit board manufacturers can enhance the characteristics of Teflon with special fillers and additives. Working with Teflon for PCBs requires specialized equipment and processing techniques.

Conclusion

Careful selection of materials for laminates and prepreg is necessary to ensure the Printed Circuit Board has the necessary electrical, dielectric, mechanical, and thermal properties for the end application.

Know More : https://www.pcbpower.us/blog/all-about-materials-for-printed-circuit-boards-usa

0 notes

Text

RoHS Compliant PCB Manufacturing — Essential Resources in USA

RoHS compliant PCBs are common in the PCB industry. RoHS is an acronym for Restriction of Hazardous Substances, and it is a directive from the European Union, which they introduced as 2002/95/EC, in the year 2002. The directive prohibits the use of six hazardous substances, such as:

Lead

Mercury

Cadmium

Hexavalent Chromium

Polybrominated Biphenyl

Polybrominated Diphenyl

The objective of the directive is to focus on the environment-friendly production of components for the electrical and electronic industry. Therefore, for circuit board manufacturers in the USA and elsewhere, making RoHS compliant PCBs means using environment-friendly alternatives for the substances prohibited by the directive. As the demand for RoHS compliant PCB boards increases in the countries belonging to the European Union, circuit board manufacturers supplying to these countries must adhere to the directive.

With rapid replacement of electronic devices, most discarded electronics is ending up in landfills. Hazardous substances like lead, present in conventional PCBs, pose a grave threat to the environment. This is the basic cause for concern that the RoHS directive has set out to address. Most organizations are now preparing to avoid the use of hazardous substances by opting for the RoHS compliance.

Why Opt for Lead-Free PCBs?

There are several reasons that indicate opting for lead-free PCB board is advantageous:

Lead is Harmful to Humans: People manufacturing printed circuit boards must necessarily be in direct contact with solder. As solder contains lead, it enters the human body through eyes, nose, and mouth, as solder fumes. Presence of lead in the human body is hazardous to health, and as a safety precaution, safer products must replace lead.

Lead is Harmful to the Environment: As about 4% of landfill waste consists of electronics, the presence of lead therein has a very wide effect on the environment. At present, many thousands of tons of lead-based electronic products occupy landfills. The presence of acidic rainfall further aggravates the situation by leaching the lead from the electronics into the soil. This contaminates not only the soil, but also the groundwater system that irrigates our crops, and ultimately reaches us.

RoHS Compliance Leads to Lead-Free PCBs: Industries opting for RoHS compliance must use lead-free PCBs for their RoHS compliant products.

With increasing use of electronic products in our lives, it is essential that we protect ourselves from hazardous substances threatening our lives. Therefore, all electronic PCB manufacturers must comply with the RoHS directives to save the environment.

Essential Resources for Manufacturing RoHS Compliant 1–20 Layer PCBs

PCB manufacturers consider manufacturing boards up to 4 layers as convenient. However, with the progress of technology, 20-layer boards are now common, but their design and manufacturing is more complicated. As PCB manufacturers prefer a process with a layer-focus for fabricating boards, making 6+ layer boards falls under a category that the manufacturers call complex multilayer PCBs. The design of these complex multilayer boards can encompass various criteria.

In complying with the RoHS directive, the PCB board designer must consider multiple factors when designing boards. This is apart from the basic requirement that the PCB material must not absorb moisture, and the absence of lead must not lead to a loss of soldering strength. Essentially, the resources necessary for manufacturing RoHS compliant 1–20 layer printed circuit boards includes:

RoHS Compliant PCB Material: Manufacturers must use RoHS compliant PCB materials when fabricating printed circuit boards.

Some popular substrate/laminate materials include:

FR370HR

IS410

Polyclad370HR

IsolaFR415

Some important characteristics of lead-free materials used in the preparation of laminates and prepreg include:

T-260

Td

T-288

RoHS Compliant Solder Paste: Also known as lead-free solder material, it typically consists of lead-free solder and flux. Commercial lead-free solder can have various compositions or % weight of metals like Tin (the main element), and Silver, Copper, Antimony, Cobalt, Bismuth, Nickel, Zinc, Indium, Germanium, and other rare-earth elements. The actual composition decides the properties of the solder paste.

For instance, solder paste SAC305 with 96.5% Tin, 3% Silver, 0.5% Copper, offers high strength and thermal fatigue. Although it has a low melting point, it is not eutectic, and rapidly attacks stainless steel in stencils.

Solder paste SN100C with 99.3% Tin, 0.7% Copper, 0.06% Nickel, and 0.005% Germanium, is eutectic with a well-defined melting point.

RoHS Compliant Stencils: It is important that manufacturers use stencils made of material that does not contain any of the six hazardous substances that the RoHS directive prohibits.

RoHS Compliant Surface Finish: Board manufacturers add surface finish to their PCBs for improving their aesthetic value and enhance their shelf-life and soldering capabilities.

Many board manufacturers prefer using SN100CL as lead-free HASL surface finish. SN100CL consists of 99.3% Sn, 0.6% Cu, and a small amount of Ni. The major advantage of using SN100CL is it provides a highly uniform and flat surface, and superior wetting that enables very fine-pitch soldering.

RoHS Compliant Soldermask and Legend Inks: Board manufacturers must use RoHS compliant solder mask and legend inks for solder mask and legend printing on their boards.

Experienced PCB manufacturers typically use the above resources for making RoHS compliant complex multilayer printed circuit boards.

Differences between Leaded Solder and Lead-Free Solder

Leaded solder essentially consists of lead and tin as the major ingredients. That is why it is also known as SnPb solder. However, increasingly, the occupational risk of lead is coming to the fore. Dust and fumes associated with lead soldering have been proven to be toxic when inhaled. All this has made lead solder a documented health hazard.

Solder without lead, or lead-free solder, has now come to replace conventional leaded solder. Lead-free solder comprises many substances, in varying proportions, like:

Tin

Silver

Copper

Nickel

Bismuth

Zinc

Antimony

Major components of some common lead-free solders are:

Tin-Silver: The silver increases the electrical conductivity, while also acting as a catalyst. The presence of tin improves the mechanical strength of the solder, while also acting as a protective agent and reducing corrosion possibilities.

Tin-Copper: Presence of copper increases the mechanical strength and the electrical conductivity

Tin-Zinc: Presence of zinc helps lower the melting point of the solder.

Advantages and Disadvantages of Leaded Solder

Leaded solder offers several advantages:

Strong joint formation

Melts at lower temperature

Good electrical conductivity

Ease of use

Fewer quality problems

Strong wetting

Longer shelf life

Disadvantages of lead solder:

High toxicity

Advantages and Disadvantages of Lead-Free Solder

Advantages of lead-free solder:

Environmentally friendly

Non-hazardous to human health

Good quality of soldering

Disadvantages of lead-free solder:

Higher melting point

Although leaded solder joints look more shiny and clean, and lead-free solder looks rather gray and dull, this is more due to slower wetting in lead-free solder on PCB boards. However, manufacturers using lead-free solder find it to offer better PCB soldering. As lead-free solder does not spread during reflow, it results in better soldering joints. Moreover, lead-free soldering does not lead to the rapid stencil wear that comes from leaded solder use. Use of lead-free solder results in more reliable solder joints as compared to those from leaded solder joints.

Conclusion

In electronic products, reliability is a major issue. Solder joints must be reliable, and they must not act as heat intermediaries. To ensure reliability of solder joints it is necessary to consider the type of solder that works best with the application on hand, while considering factors such as ease of use, wiring requirements, cost, and safety. A reliable circuit board manufacturer can provide RoHS compliant printed circuit boards without sacrificing quality or the time to market.

Know More : https://www.pcbpower.us/blog/rohs-compliant-pcb-manufacturing-usa

0 notes

Text

Choosing the Right PCB Material: A Comprehensive Guide | PCB Power

Choosing the Right Printed Circuit Board Material: A Comprehensive Guide

The choice of materials commonly used for the fabrication of the PCB is extremely important in determining the quality of it. The selection of PCB base material can impact electrical properties, thermal and mechanical behaviour, and reliability of the final product. In this blog, we will learn about the printed circuit board materials which are available to the buyers and their characteristics.

Common Types of PCB Materials

A list of the most common printed circuit board material is given below:

1. FR-4

FR-4 is the most common substrate material for making multi-layer printed circuit boards. It is a fibreglass-epoxy composite, with high dielectric strength. The material FR-4 can retain its stability up to the temperature of 130°C (266°F). It is used in consumer electronics, industrial control, telecommunications and other general application gadgets.

2. Polyimide

Polyimide is famous for its heat resistance and flexibility characteristics. It is commonly applied to flexible PCBs, where the board can be bent or folded. For example, in the case of a smartphone design. Polyimide can work up to a temperature of 260°C (500 °F). It is appropriate for aerospace, automobile, and medical devices where high performance is required.

3. Metal Core PCBs

Metal core PCBs are designed with a metal base material, often aluminum or copper. It offers five times better heat dissipation than FR-4 boards. These boards are popular in areas of heat dissipation which may include LED lighting and power electronics. Metal core PCBs have better thermal management under thermal loads.

4. Rogers Materials

Rogers Corporation produces a range of high-frequency materials that are suitable for advanced applications requiring precise electrical performance. Rogers materials provide low-loss characteristics and stable dielectric constants across varying frequencies.

They are used in telecommunications, aerospace, and military applications.

5. Taconic TSM-DS TLY-5 & DS3

Taconic TSM-DS TLY-5 and DS3 are specialized PCB materials intended for high-frequency applications. They are characterized by low dielectric constants and loss tangents, which keep the signal integrity at RF and microwave frequencies. Taconic materials are used in telecommunications and automotive radar.

Factors to Consider While Choosing PCB Materials

These are some factors one must consider before selecting the material for a printed circuit board:

1. Material Type and Properties

The choice of PCB material significantly impacts its functionality and reliability. Understanding the properties of the materials, such as dielectric constant (Dk), loss tangent (Df), and thermal expansion coefficient (CTE), is important.

2. Thermal Management

If there is heat involved, then thermal performance is very important, especially for high-power applications. The main thermal properties to study are as follows.

Glass Transition Temperature (Tg): At this temperature, the material would go from being a rigid state to more flexible. Thus, higher Tg materials are better to be used at high temperatures.

Decomposition Temperature (Td): It is the temperature at which the material will begin decomposing. Better indications under very difficult conditions are seen in higher Td.

3. Manufacturing Process Compatibility

The chosen material should also correspond to the manufacturing method employed, i.e., through-hole or surface mount technology (SMT). For example, SMT relies on FR-4 for favourable drillability, while flexible PCBs need materials such as polyimide, which don't crack during bending.

4. Environmental Considerations

Always evaluate the PCB's operational condition since humidity, temperature rise and fall, and exposure to chemicals influence the selection process of materials. Ensure the selected materials can withstand these conditions without degrading.

5. Frequency Range

In an instance where high-frequency signals are involved, it is critical to select materials that have low dielectric loss. High-speed PCBs may require special material under this.

Conclusion

Choose the right printed circuit board material to get the best result in the electronic designs. Designers must know about the properties of various materials such as FR-4, polyimide, PTFE, metal core, and Rogers to satisfy the needs of the projects. Electrical behavior, thermal properties, mechanical strength, cost ,and feasibility of PCB fabrication during manufacturing will help you decide which material is most suitable for your particular project.

At PCB Power, we manufacture high-quality printed circuit boards crafted from a variety of materials, including FR-4, polyimide, and metal core. Whether you are looking for prototype circuit boards or need them in volume, PCB Power can be your trusted partner

Contact our team of experts to discuss your requirements.

Know More: https://www.pcbpower.us/blog/choosing-right-pcb-material-guide

0 notes

Text

Top Trends in PCB Assembly for 2025

Top Trends in PCB Assembly for 2025

PCBs are the heart of the modern world. Whether it's household equipment, industrial equipment, or defense ordnance, printed circuit boards are running everything. With new developments, the global scene of PCB manufacturing is changing rapidly. Using the newest technologies is not only a great concept, but staying competitive depends on it as well. From downsizing to AI-driven manufacturing, 2025 promises to bring major breakthroughs along with making advancements in current technologies that will change the way Printed Circuit Boards (PCBs) are manufactured.

This article will walk you through some key industry trends that will sketch the future of PCB assembly.

5 Key Trends in PCB Assembly to Follow in 2025

As the world is moving towards manufacturing more complex products and adopting advanced technologies, the PCB assembly industry is also observing several key trends. Here are a few noteworthy trends to follow.

1. Shrinking is in High-Density Interconnections: HDI and Miniaturization

Think about our daily gadgets, such as wearables, Internet of Things devices, and sophisticated medical electronics. These devices need robust and small PCBs, and therefore, in these spaces, High-Density Interconnect (HDI) technology excels. HDI lets electronic gadgets be more powerful despite their compact stature. In what manner? For high-speed applications, it increases signal integrity, lowers component spacing, and permits smaller trace lengths, hence enhancing electrical performance. And it will change the entire PCB manufacturing market.

According to a forecast [1], the HDI PCB market is expected to rise rapidly and, by 2032, will reach almost $40 billion. That makes the direction in which things are heading quite obvious.

2. Smart Factories: Artificial Intelligence and Automation

Like in every other industry, PCB assembly is becoming significantly faster, smarter, and more efficient. Industry 4.0 and manufacturing driven by artificial intelligence lead the push. Think about robotic soldering and pick-and-place robots for fast, more perfect component installation. Artificial intelligence and machine learning have found their way into quality control, that is, for error reduction and flaw detection done automatically. Imagine the Internet of Things, connected production lines, allowing real-time monitoring and predictive maintenance.

3. Bendable and Adaptable: Rigid-flexible PCBs

Flexible and rigid-flex printed circuit boards are becoming more popular in industries such as transportation, aircraft, and healthcare electronics. But you may think, why so? Because of their small size and lightweight nature, they are ideal for manufacturing small, portable electronic devices. They can withstand significant external force and resist bending and vibration. They endure longer with fewer interconnect failures, making them more reliable.

4. Green is Good: Manufacturing Sustainable Circuit Boards

Growing worries about e-waste and carbon footprints force sustainability to the front stage in PCB production. Lead-free soldering, biodegradable and reusable substrates, recyclable materials, and energy-efficient manufacturing procedures will become the focal points in the near future. It's about matching global laws and customer demand as much as it is about environmental responsibility.

5. Printing the Future: 3D Printing in PCB Assembly

Additive manufacturing is revolutionizing PCB manufacturing and streamlining complex multilayer design construction. From this, faster prototyping, reduced material waste, and more customization for specific uses follow. This is a breakthrough for design and development; it will only get more so.

The Final Thought

There are a lot of exciting new possibilities in the PCB assemblyand PCB manufacturing industries. Miniaturization, automation, sustainability, and developments in AI-driven manufacturing will enable you to produce premium printed circuit boards (PCRs) that satisfy future electronics needs. Survival in a dynamic industry depends on keeping ahead of the competitors. By following these trends and wise technology investments, you could set yourself up for success in 2025 and beyond.

Know More: https://www.pcbpower.us/blog/top-trends-pcb-assembly

0 notes

Text

Top Quality Control Methods in PCB Manufacturing

Top Quality Control Methods in PCB Manufacturing You Should Know

Circuit boards form the backbone of most modern electronic devices. PCBs must meet the highest quality standards as they are used across various industries, including consumer, medical, and automotive electronics, ensuring reliability and performance. Quality control (QC) in PCB fabrication should be perceived as a compulsory necessity and not just a best practice. Let’s discuss the key aspects of quality control in circuit board manufacturing, including its significance, methods, and benefits.

Why Quality Control is Crucial in PCB Fabrication?

Even the most minor defects in circuit boards may usually lead to a malfunction. It requires strict testing and inspection for flawless production. PCB quality control is important for the following reasons:

1. Reliability of Product

Circuit boards must work perfectly to ensure device reliability. Even microscopic imperfections may cause malfunctioning, data loss, or total system blackout. Such severe results are important in high-value medical equipment or aerospace systems. Implementing quality control actions during the manufacturing process allows for the early detection and elimination of defects.

2. No Delays and Reduces Costs

It is easier to address and solve problems during production than to deal with failures after manufacturing. If quality control is absent, defective boards will need reworking or replacement, which adds costs and delays to the production schedule. Powerful QC processes will help minimize these risks and the manufacturers can save time and resources.

3. Customer Satisfaction

High-quality circuit boards transform into highly reliable end products that build customer confidence and satisfaction. Brand loyalty is built by customers receiving devices that are perfect in performance. Quality control ensures that manufacturers deliver and exceed customer expectations as much as possible with consistent performance.

4. Regulatory Compliance

Standards such as RoHS (Restriction of Hazardous Substances), IPC (Institute for Printed Circuits), and others are quite specific in electronics. Compliance comes with rigorous quality checks at every stage of production. Thus, the QC processes help manufacturers to detect non-compliance early and avoid legal or financial consequences.

Key Quality Control Methods in PCB Fabrication

Manufacturers of circuit boards have employed various quality control techniques to ensure that they run reliably and perform at required levels. The following are examples of the most common tests performed during circuit board manufacturing:

In-Circuit Testing (ICT): CT is one of the most common test types. ICT tests have open/short circuit checks that measure the performance of integrated circuits via capacitance tests.

Flying Probe Test: The test is performed without power. It detects loose connections, resistance, short circuit, inductance, issues related to the diode, and capacitance by using a probe aligned to a CAD grid.

Functional Test: It ensures that the PCB will work well under the test equipment and fixtures while conforming to the requirements of industry standards such as the UL (Underwriters Laboratories) and MSHA (Mine Safety and Health Administration).

Automated Optical Inspection (AOI): A camera system (or a video camera) and a software program locate missing components, misplaced components, and soldering defects in assembled units.

X-Ray Inspection: It inspects the internal structure of PCBs to check for any missing shorts and openings that often do not appear to the naked eye.

Electrical Testing: The testboard is powered and output signals are checked against performance requirements.

Visual Inspection: A few manual observations are made to check physical damage such as scratches, cracks, and misalignment, which can hinder the performance of that board.

Conclusion

Quality control is a bedrock process for successful PCB fabrication. By using a combination of design validation tools, and advanced inspection technologies like AOI and X-ray testing, the manufacturers ensure the reliability and performance of their PCBs. In the long run, it will reduce costs, and increase customer satisfaction in this competitive market.

PCB Power has been at the forefront of offering high-quality circuit boards with excellent tolerances and reliability. We have strict quality control, from design validation to advanced testing techniques like AOI and X-ray inspection. Connect with us today to get precision-engineered PCBs you can trust.

Frequently Asked Questions

1. What are the top quality control techniques used in PCB manufacturing?

The most common PCB quality control techniques include visual inspection, automated optical inspection (AOI), X-ray inspection, functional testing, and in-circuit testing. These methods help detect defects early and ensure performance.

2. How do you ensure quality in PCB production?

Quality in PCB production is ensured through strict inspections, testing at every stage, using high-quality materials, and following IPC standards. Regular audits and process monitoring are also key.

3. Why is PCB quality control important in electronics manufacturing?

PCB quality control is crucial because even a small defect can lead to device failure. It ensures product reliability, safety, and customer satisfaction—especially in critical industries like automotive and healthcare.

4. What causes PCB manufacturing defects and how can they be avoided?

Common causes of PCB defects include poor soldering, incorrect component placement, or material flaws. They can be avoided through quality checks, using proper design files, and maintaining clean manufacturing environments.

Know More: https://www.pcbpower.us/blog/top-quality-control-methods-pcb-manufacturing

0 notes

Text

What is a PCB Footprint? 5 Things to Know About PCB Footprints

5 Things to Know About PCB Footprints

The process of putting together a printed circuit board is not an easy task. From PCB designing to assembly, different details are involved. Along with this amalgamation of different components, the process of PCB footprint is also a crucial task. In this process, electrical points and physical layouts are allocated to the various elements mounted on a PCB board.

To put it in simple terms, PCB footprints refer to the area that the different components occupy on a printed circuit board. From the pad size and shape to the component outline, all the things come under PCB footprints. This blog will provide various insights into PCB footprints.

1. Information on the Components of PCB Footprints

A circuit board design components come with general information, which are:

Pads: This indicates copper areas where the component leads or pins will be soldered during the assembly process.

Component outline: The area that the components occupy on the PCB is the outline or courtyard. This boundary defines the component shape.

Reference designator: In the PCB layout, you can witness alphanumeric codes. These codes identify the components on the PCB.

2. Libraries for PCB Footprints

An enthusiastic PCB designer would know how important it is to create a PCB footprint library just like its component library. Generally, PCB footprint libraries are available to organizations that are Component manufacturers, third parties, or those who create design software for printed circuit boards. There are various PCB footprints available online. The most popular of them are SnapEDA and Ultra Librarian. The Ultra Librarian is considered to be the world’s largest PCB CAD library. The data of this library can be imported into well-known PCB CAD apps.

3. PCB Footprint Creation

If a PCB footprint library is not available, PCB designers will not have any other choice but to create a PCB footprint on their own. Later, they will upload it to the PCB library database. To create a PCB footprint from scratch, it is essential to have the correct specifications of the concerned components. Start with the general information like pad sizes, hole diameter, pitch and spacing, the component layouts, etc. Ensure the PCB footprint creation is complete otherwise, it can cause problems when you have to define the PCB layout.

4. Specific Standards

To define the PCB layout, its schematic symbol, or 3D model, the PCB footprint should apply to specific international standards:

For PCB footprint, the standard is IPC 7351. The IPC-SM-7351-B version of this standard considers a range of formulas to define the footprint. Many PCB CAD models have been designed, aligning with this standard.

For schematic symbols, the standard is ANSI Y32.2-1975. In electronic and electrical diagrams, certain graphic symbols and designated letters are used. This standard is used to define such elements.

For 3D models, ISO 10303-21 is used. This standard classifies the STEP model file format.

5. Guidelines for PCB Footprints

If a PCB designer wants to create the footprint from the beginning, individuals should follow the guidelines mentioned below:

The component layout on the PCB should be aligned perfectly. The pads of the components on opposite sides should be of similar shapes and sizes to ensure symmetry.

The component outline and the pads should have enough space in between. This would make sure that the desired pins are connected to the right component pads.

To indicate polarized components, integrate polarity indicators.

Don’t use components that are too small, as the automated production process may fail to recognize those parts.

Conclusion

During the PCB manufacturing process, PCB footprints play a crucial role. They contain information about all the components mounted on the PCB layout. By going through the essential set of information, the soldering process can be done accurately. Usually, PCB footprints are available online, but if a designer wants to create it from scratch, they can do so by following the guidelines.

Frequently Asked Questions:

What is a PCB footprint in PCB design?

A PCB footprint is the physical layout of a component on a circuit board, including pad positions, outlines, and reference markings for accurate placement and soldering.

Why are PCB footprints important?

PCB footprints ensure correct component placement, prevent assembly errors, and improve PCB reliability by following industry standards like IPC 7351.

How do I create a PCB footprint?

PCB footprints can be created using PCB design software by defining pad sizes, hole spacing, and component outlines, or downloaded from libraries like SnapEDA or Ultra Librarian.

What are the best practices for PCB footprint design?

Ensure correct pad alignment, spacing, and polarity marking, and follow IPC standards to avoid soldering defects and improve manufacturability.

Know More: https://www.pcbpower.us/blog/what-is-a-pcb-footprint

0 notes

Text

Custom PCB Assembly for Prototypes and Specialty Projects

Custom PCB Assembly for Prototype and Specialty Needs.

Transforming an electronic product idea into a physical reality can be a significant challenge, especially for small businesses, hobbyists, and researchers. Traditional mass production techniques typically fall short for low-volume or specialized projects, which calls for more tailored solutions. Custom PCB assembly step in to offer the flexibility, expertise, and cost efficiency needed for unique projects.

PCB assembly refers to mounting electronic components onto a printed circuit board so that the device becomes operational. Custom Printed Circuit Board assembly provides customized solutions to fit the needs of the specific project, especially for prototypes and specialized electronic manufacturing needs.

The power of custom PCB assembly is in its flexibility. It serves a wide array of requirements, including startups, DIY enthusiasts, and academic institutions, and even aerospace and defense grade requirements, tackling the specific challenges associated with prototype and niche projects. By optimizing the journey from design to production, these services offer customized solutions that conserve both time and resources.

This guide explores the benefits of custom circuit board assembly and why it’s the ideal choice for specialized or prototype electronic manufacturing.

Key Features of Custom Printed Circuit Board Assembly

Rapid Prototyping: Customized PCB assembly makes it possible for rapid prototyping to quickly test their ideas. Such speed becomes important in the current market to make or break a success.

Quality Assurance: Contracting with an experienced PCB assembly service provider like PCB Power ensures high-quality standards throughout manufacturing. PCB Power makes sure to minimize defects and assure reliability through advanced testing methods like AOI and X-ray.

Cost-Effectiveness: By outsourcing circuit board assembly services, manufacturers can save on factory overheads during in-house manufacturing. This also allows companies to focus on their core competencies. The outsourced specialized provider takes care of the other aspects of PCB assembly.

Flexibility: Custom PCB assembly is flexible for design changes and production volumes. These services can meet any of your demands, whether it is a small test batch or larger quantities for production runs.

Circuit Board Solutions for Prototypes and Specialized Applications

These processes are more than ordinary assembly procedures. It helps to integrate specific parts, meet common testing requirements, and facilitate high-level manufacturing.

1. Integration of Non-Standard Components and Materials

Sophisticated designs, e.g. for space and defense, call for unique products like exclusive sensors and microprocessors. Experienced circuit board assembly companies like PCB Power, possess the knowledge through which they may acquire these elements and interconnect them. They use high-temperature substrate materials, flexible circuits, as well as shielding materials. This assures reliability and performance.

2. Meeting Stringent Testing Requirements

Some industries like aerospace, automotive, and medical electronic industries require such testing and validation. Custom Printed Circuit board assemblyservices provide testing solutions on environmental stress and electromagnetic compatibility (EMC). This is done to meet the requirements of the industry standards and conformity to various certifications. Such services ensure the required performance levels in various extreme conditions.

3. Advanced Manufacturing Techniques

The goals of some products are more demanding than traditional through-hole projects. For intricate enclosures, customized PCB assembly providers use improved processes like 3D printing, chip-on-board, and flip-chip assembly. It is always advisable to use the services of people with experience and excellent tools.

Conclusion

Custom PCB assembly turns innovative electronics into reality. Businesses use these specialized services to bring their products forth. Wherever prototypes or specialty projects are concerned, an experienced provider of PCB assembly services can drastically improve your success.

Discover PCB Power's PCB assembly services for a wide range of industries. PCB Power is one of the most trusted and reliable PCB manufacturing companies, with an experience of 35 years in the USA market Our solutions for bare board manufacturing to component sourcing to circuit board assembly, are best suited for USA manufacturing standards. Our ordering system is a smooth process, ensuring quality PCB manufacturing assemblies and fast turnaround times for your project. Visit our website today to place your inquiry.

Know More: https://www.pcbpower.us/blog/custom-pcb-assembly-prototypes-specialty-projects

0 notes

Text

Top Trends in PCB Assembly for 2025

PCBs are the heart of the modern world. Whether it's household equipment, industrial equipment, or defense ordnance, printed circuit boards are running everything. With new developments, the global scene of PCB manufacturing is changing rapidly. Using the newest technologies is not only a great concept, but staying competitive depends on it as well. From downsizing to AI-driven manufacturing, 2025 promises to bring major breakthroughs along with making advancements in current technologies that will change the way Printed Circuit Boards (PCBs) are manufactured.

This article will walk you through some key industry trends that will sketch the future of PCB assembly.

5 Key Trends in PCB Assembly to Follow in 2025 As the world is moving towards manufacturing more complex products and adopting advanced technologies, the PCB assembly industry is also observing several key trends. Here are a few noteworthy trends to follow.

1. Shrinking is in High-Density Interconnections: HDI and Miniaturization Think about our daily gadgets, such as wearables, Internet of Things devices, and sophisticated medical electronics. These devices need robust and small PCBs, and therefore, in these spaces, High-Density Interconnect (HDI) technology excels. HDI lets electronic gadgets be more powerful despite their compact stature. In what manner? For high-speed applications, it increases signal integrity, lowers component spacing, and permits smaller trace lengths, hence enhancing electrical performance. And it will change the entire PCB manufacturing market.

According to a forecast [1], the HDI PCB market is expected to rise rapidly and, by 2032, will reach almost $40 billion. That makes the direction in which things are heading quite obvious.

2. Smart Factories: Artificial Intelligence and Automation Like in every other industry, PCB assembly is becoming significantly faster, smarter, and more efficient. Industry 4.0 and manufacturing driven by artificial intelligence lead the push. Think about robotic soldering and pick-and-place robots for fast, more perfect component installation. Artificial intelligence and machine learning have found their way into quality control, that is, for error reduction and flaw detection done automatically. Imagine the Internet of Things, connected production lines, allowing real-time monitoring and predictive maintenance.

3. Bendable and Adaptable: Rigid-flexible PCBs Flexible and rigid-flex printed circuit boards are becoming more popular in industries such as transportation, aircraft, and healthcare electronics. But you may think, why so? Because of their small size and lightweight nature, they are ideal for manufacturing small, portable electronic devices. They can withstand significant external force and resist bending and vibration. They endure longer with fewer interconnect failures, making them more reliable.

4. Green is Good: Manufacturing Sustainable Circuit Boards Growing worries about e-waste and carbon footprints force sustainability to the front stage in PCB production. Lead-free soldering, biodegradable and reusable substrates, recyclable materials, and energy-efficient manufacturing procedures will become the focal points in the near future. It's about matching global laws and customer demand as much as it is about environmental responsibility.

5. Printing the Future: 3D Printing in PCB Assembly Additive manufacturing is revolutionizing PCB manufacturing and streamlining complex multilayer design construction. From this, faster prototyping, reduced material waste, and more customization for specific uses follow. This is a breakthrough for design and development; it will only get more so.

The Final Thought There are a lot of exciting new possibilities in the PCB assemblyand PCB manufacturing industries. Miniaturization, automation, sustainability, and developments in AI-driven manufacturing will enable you to produce premium printed circuit boards (PCRs) that satisfy future electronics needs. Survival in a dynamic industry depends on keeping ahead of the competitors. By following these trends and wise technology investments, you could set yourself up for success in 2025 and beyond.

Know more: https://www.pcbpower.us/blog/top-trends-pcb-assembly

0 notes

Text

Maximizing Electronic Component Reliability in Rigid-Flex PCB Designs

Ever wonder why certain electronic items fail early while others run for years? There are several factors affecting the reliability. And ensuring dependability becomes even more important for rigid-flex PCB designs. For uses where space is constrained and durability is critical, these hybrid printed circuit boards mix the benefits of rigid and flexible circuits and enhance the reliability of the components as well. Without appropriate design procedures, the components may, however, become prone to mechanical stress, thermal expansion problems, and adhesion failures.

Let's explore the main approaches to maximize component dependability in rigid-flex PCB design.

The advantage of rigid-flex printed circuit boards lies in their capacity to adapt to intricate shapes. However, that flexibility, particularly in those transition areas, can pose significant challenges to the component's reliability if not managed properly. Consider it this way: each bend and flex exerts pressure on your components and their connections. Your objective is to reduce the stress on those components.

Effective Strategies to Enhance Reliability

Let's look into practical strategies that can be implemented effectively to enhance component reliability and reduce stress on these components.

Component Placement — Think Strategically:

Avoid placing components haphazardly. Envision the flexibility. Which of the components on the PCB board face the highest stress? Please ensure those areas remain unobstructed and the components can be placed freely.

Consider the various forces influencing your components. Guide them to counteract those forces rather than enhance them.

SMT is a valuable resource in this context. It establishes more robust connections compared to through-hole methods.

Selection of Rigid-Flex PCB Materials — Be Precise:

A flexible material that is capable of withstanding multiple bends is required. As the PCB board holds all the materials,it's essential that the PCB board should not transfer the stress on the components. Polyimide remains a staple for its proven performance, yet it is essential to consider the advantages of newer, specialized materials.

Adhesives play a crucial role in the reliability of the components in a rigid-flex PCB design. An insufficient adhesive leads to delamination. Seek adhesives that have demonstrated reliability in flexible applications.

Adhesiveless substrates offer better thermal stability and reliability.

The thickness of copper requires careful consideration and balance. Excessive thickness compromises flexibility, while insufficient thickness poses risks related to current issues.

Refinements That Create Impact:

Teardrops: While they may seem minor, they play a crucial role in enhancing the integrity of solder joints, thus, of the components as well. Consider them as small support units.

Rounded corners: Rounded corners help to mitigate stress concentration that can occur with sharp corners. Refine those details.

Bend radius: Allow adequate space for your flexible areas to accommodate bending. If there is less bending space, the components in those areas will show reliability issues. Avoid compelling them into narrow, acute angles.

Solder Joints Reliability

Solder joint reliability is a critical aspect of rigid-flex PCB performance, as it directly impacts the longevity and durability of electronic components. Several factors influence the robustness of solder joints in rigid-flex designs.

Avoid Solder Joints in Bending Areas. Placing soldered components too close to a bend zone can lead to mechanical stress and cracking. Components should be placed in rigid sections whenever possible.

Ensuring proper solder paste application and reflow process during the design phase helps create reliable solder joints and prevents connection issues. Here's what to consider for strong solder joints in your design.

Adding conformal coating can protect solder joints from environmental factors.

X-ray analysis helps identify hidden solder joint issues early, allowing for better design decisions before manufacturing

Testing — Don't skip this Step:

Thermal cycling: Expose your boards to temperature variations. If they endure, they are probably going to thrive in the field.

Flex testing: Flexibility is key. Assess the capacity of your boards for cycle endurance. Test the printed circuit boards through cyclic endurance tests.

Automated Optical Inspection (AOI): This modern technology uses high-end cameras and advanced image processing to promptly identify solder joint defects, component placement errors, and pad defects.

Practical Advice for Your PCB Design

Layer stack-up: Visualize your PCB as a multi-layered structure. A well-structured stack-up mitigates the risk of warping.

Flex routing: Navigate those flex circuits with precision and care, as if you are handling a fragile ribbon. Gentle contours without abrupt angles.

Grounding: A reliable ground plane serves as your essential foundation. Ensure you give it the attention it deserves.

Final Thoughts:

Ensuring component reliability in rigid-flex PCBs requires careful planning and precise execution rather than relying on chance. It involves recognizing the distinct challenges and implementing proactive measures to tackle them.

Get in touch with our team of experts by filling out a simple form.

Know More: https://www.pcbpower.us/blog/electronic-component-reliability-rigid-flex-pcb

1 note

·

View note