PCBSky is a professional PCBs and flex PCBs company in China, providing full PCB fabrication and assembly services in certified quality standards. We specialize in quick turn PCB & prototypes custom PCB manufacturing.Order from the TRUE PCB manufacturer.

Don't wanna be here? Send us removal request.

Text

Choosing a Vendor for Outsourcing PCB Prototype Assembly

You may either construct the printed circuit board (PCB) prototype yourself or contract out its production to a company that specializes in PCB prototype assembly if you are creating a product and require a rogers PCB prototype. However, creating a PCB prototype in-house would need a PCB manufacturing and assembly facility, which would not be cost-effective if used primarily for extremely limited production runs like PCB prototypes. Subcontracting with a supplier who specializes in producing prototype PCBs makes more commercial sense. The following are the main recommendations for choosing a vendor to contract out prototype PCB fabrication work:

Reduce Your Costs

Making a large batch of PCBs is typically less expensive than making a small batch. Prototype PCBs are nonetheless often made in modest numbers since the circuit architecture is still being improved. To keep the overall cost of producing short runs of PCBs very low, a vendor that specializes in PCB assembly can reduce the expenses of assembly setup and distribute the cost of production by sharing the production task among numerous clients.

Lead Periods

Make sure you are aware of the elements that affect the lead time when picking a vendor to outsource your PCB assembly. There will be fewer clients that have the same criteria as your PCB design, thus it will take longer for the vendor to arrange your production run if your rogers PCB China design includes uncommon materials or measurements (such as thicknesses). Depending on the desired lead time, an online quotation system will adjust the quote's price.

Services for Design and File Formats When choosing a rogers PCB manufacturer, the file types you utilize for your electronic circuit designs matter. If you use different file formats, be sure the vendor can deal with them. The majority of vendors utilize the Gerber format. Due to its technical skills and internal experience, a PCB assembly firm that also provides design services in addition to contract manufacturing services is the best option for handling any issues that may arise during pre-assembly.

Follow our Facebook and Twitter for more information about our product.

0 notes

Text

Get Into the Facts Regarding PCB

Get Into the Facts Regarding PCB

With the use of conductive paths or traces carved from copper sheets that are bonded onto a non-conductive substrate, PCB manufacturing supports mechanically electronic components that are electrically coupled. Standards established by the IPC organization govern a large portion of the assembly, PCB design, and quality control requirements for the electronic industry. An insulator, which is made…

View On WordPress

1 note

·

View note

Text

Advances in the Industry of Printed Circuit Board

Electronic devices have emerged as a result of technological advancements. Technology advancements have produced many of the electronic devices we use every day, including iPods, computers, laptops, radios, and many more. Currently, various electronic firms mix durable materials, high aspect ratio holes, and other qualities to produce devices for the general population.

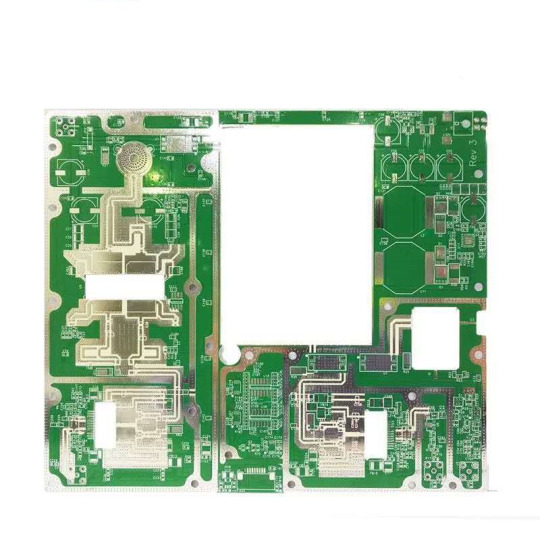

Printed circuit boards (PCBs) are essential for the proper operation of modern electronic devices. Depending on the kind of devices they will be utilized with, PCB manufacturing is done. PCBs are essential to the operation of numerous electrical devices, including computers, radios, guitar effects, and many more.

The printed circuit board industry has developed in modern times. The majority of modern PCBs incorporate added features to improve the performance of electrical devices. PCB manufacturers now provide plates with holes that have a high aspect ratio. High aspect ratio holes allow for a more equal flow of electrolytes to various locations on the panel, which is essential for PCB performance. This enhances the functionality of several board components.

To reduce signal loss when utilizing PCBs, manufacturers have also actively invested in employing high-frequency materials for PCB board manufacturing. The quality of electrical devices is determined by the PCB's material selection. Using the correct materials results in significantly enhanced functioning for radios, oscilloscopes, and other devices that rely on frequency. Contact one of the numerous PCB industry manufacturers if you're seeking high-quality PCBs and components.

Based on their performance and quality, PCBs are divided into a variety of categories. The IPC-6012 Class 3 is now one of the most complex PCB classes. To better function for various complicated circuits of various sorts of devices, it adheres to several IPC requirements. Since the IPC-6012 Class 3 conforms to numerous industrial requirements, complex circuit boards like this one are in demand today. The quality of a PCB is crucial since even a little fault might cause a device's circuitry to short, posing a risk of various dangers and accidents.

All electronic devices, including radios used at home and in businesses, are composed of intricate circuitry that is integrated into printed circuit boards. When making electrical products, manufacturers need to utilize PCBs like the IPC-6012 Class 3 to ensure minimal signal loss and frequency clarity. Electronic device performance is currently being further improved by PCB makers by adding new features to their goods for circuit board manufacturing.

Original source: https://pcbskychina.weebly.com

2 notes

·

View notes

Text

Reduce Manufacturing Costs of PCB with These Considerations

Businesses are constantly seeking ways to save costs. PCB fabrication at the PCB factory is one way for electronics businesses to do this. Cost and quality, however, are never completely equal. There are situations in which sacrificing quality is acceptable and those in which it is not. Here are a few cost-cutting strategies that we have discovered to be effective.

Plan the board's size.

The cost of fabrication may be directly and significantly impacted by the size of a PCB. Engineers may need to increase the board size if routing is constrained. However, when it comes time to penalize the boards, this can provide problems. It's crucial to use as much of the panel material as feasible to save expenses. It will boost yield and cut expenses to use measurements that divide equally into various sizes.

Think about utilizing better materials

Customers frequently ask for less expensive alternatives to materials to save expenditures. The small prototype runs where the boards would be evaluated right away can be suitable for this. However, these less expensive materials frequently start to affect the boards' functioning soon. Despite passing tests in the lab, they will start to malfunction in the field due to the varied environmental circumstances. The operation of the board can be impacted by temperature, vibration, and moisture, especially when employing less expensive materials. When selecting materials from the PCB supplier, it is recommended to take these concerns into account.

Use common forms for printed circuit boards.

Squares and rectangles are the most common PCB shares. These are regarded as standard since they simplify penalizing the boards and produce less waste. However, there are many situations where an enclosure or other feature would necessitate a specific form. The CNC routing method requires more time and tools for more complex forms. Additionally, internal and external cuts raise the price. Once more, it might be advantageous to test prototype boards using standard PCB forms before rebuilding them with a bespoke shape if it is believed that the board has a greater than usual probability of failing in some way. The cost of PCB manufacture at the PCB company is greatly influenced by lead time. This is especially true for more complicated PCBs with features like high-layer courts, blind or buried vias, impedance, and/or dielectrics.

Follow our Facebook and Twitter for more information about our product.

3 notes

·

View notes

Text

Shenzhen Huihe Circuits Co., Ltd. Please visit: https://www.pcbsky.com/

5 posts!

2 notes

·

View notes

Text

Printed Circuit Board Is Quite Beneficial To Use

These PCB circuit boards like the rogers PCB have several benefits. They are the perfect option for companies that make various kinds of equipment, devices, and electrical components. Let's look at some of the main benefits of printed circuit boards.

Small Size

Many small components can be housed on a single simple PCB. Instead of using standard wires to link these components, copper rails are used. As a result, hundreds of components may be connected without concern for the size of the circuit board.

These parts are often tiny. Because of this, ordinary cables cannot link these components to one another. In essence, a basic circuit board offers a foundation for the effective placement of electrical components. This compactness makes it possible to design intricate electrical circuits without taking up much room. This has several advantages.

Diagnostic and repair simplicity

With a PCB, you can quickly diagnose and fix problems. The board is built with labels indicating the polarity of the electrical components. It is simple to check for problems and make replacements.

Conserving time

When it comes to connecting the components, the conventional boards take a long time. However, if you need to put together a circuit quickly, PCBs like rogers PCB China need a lot less time.

Reducing electronic noise

If the components are laid out with sufficient care, a PCB can assist reduce electronic noise. The performance of the circuit board might be harmed by the noise, though, if the arrangements aren't done correctly.

Electronic components are organized on a PCB with a minimum amount of space between them. This drastically lowers the electrical noise. A PCB also aids in reducing electromagnetic pickup and radiation. Less crosstalk between the components on the board is ensured as a result. This is typically a significant issue when developing electrical circuits. Additionally, the circuit boards aid in the discharge of electronic noise in the form of heat, radiation, and flashing sound.

Increased Reliability Because of all the advantages listed above, PCBs from the rogers PCB supplier are far more dependable than conventional boards. These are a few of the main benefits of a printed circuit board, to sum up.

Follow our Facebook and Twitter for more information about our product.

3 notes

·

View notes

Text

Manufacturing Process of the Printed Circuit Board

Manufacturing Process of the Printed Circuit Board

A printed is made up of a self-contained module coupled with electronic parts. A thin layer of conducting material, either printed on the surface board or conducting material is used in PCB manufacturing. A printed circuit assembly is the term for a PCB that has been made with electronic components already installed (PCBA). PCB manufacturing must adhere to a strict process while taking into…

View On WordPress

#circuit board manufacturing#pcb board manufacturing#pcb manufacturing#printed circuit board manufacturers

1 note

·

View note

Text

Know About the Prototype of Printed Circuit Board

When used to mechanically support and electrically link electric components utilizing conductive pathways, signal lines carved from copper sheets bonded onto a non-conductive substrate, PCBs (Printed Circuit Boards) are very useful. PCBs like quick turn PCB are utilized for high-volume manufacture in addition to being affordable and dependable, despite having a greater starting cost than wire-wrapped circuits.

The design of a printed circuit board is typically left up in the air. The functioning of mechanical and electrical items is defined in this way. A PCB prototype is crucial in the design and production of printed circuit boards at this point. This gives the user the chance to examine, test, and, if necessary, modify the PCB design before mass manufacturing.

Extreme conditions are put on the PCB prototype process, and even the traces and leads are examined as the board is being manufactured. The printed circuit board is made, the holes are drilled using specialized tools, and then the prototype at prototype manufacturing factory is tested to ensure its effectiveness and functioning. However, if the prototype fails in any way, a new, updated prototype must be constructed. The prototype is monitored until it meets the requirements.

There are several unknown hazards and inefficiencies associated with the mass manufacture of printed circuit boards in the absence of a prototype. In complicated systems, these modifications may take a long time and be expensive. Additionally, it takes time to isolate any issues with a circuit that are discovered.

In PCB prototype and manufacturing, various PCB requirements and processes call for the usage of various PCB materials.

A PCB can be made or designed to achieve various outcomes and results using:

Using polyimide for flexibility - polyimide is best suited for use in electrical insulation applications because it can withstand high temperatures.

Arlon materials are helpful for the PCB fabrication of high-performance and frequency-sensitive printed circuit manufacture. Arlon is for Longer Life at Higher Temperatures.

The high-performance pre-peg system Isola Range is used for PCB prototypes and PCB fabrication. Its low dissipation factor and low dielectric constant contribute to making it the best material for constructing broadband circuits.

Follow our Facebook and Twitter for more information about our product.

2 notes

·

View notes

Text

Peep Into the Depth of Rogers PCB

Any PCB created by the Rogers Corporation is referred to as a rogers PCB. The Rogers Corporation makes sure the PCB is made of high-frequency PCB material as a result.

In case you were unaware, all over the world, Rogers Corp. is one of the top IT companies. They are pioneers in cutting-edge technological solutions. But most crucially, they create high-frequency PCBs of excellent quality.

Additionally, Rogers Corp is the finest in the business for cutting-edge PCB components. As a result, they create products that link our world, provide protection, and boost power.

After all, the business has been around for many years. And at this point, they have concentrated on providing essential solutions that satisfy the needs of their clients.

Additionally, Chandler, Arizona, USA, serves as the company's primary location.

What Distinguishes the Rogers PCB?

Rogers Corp is distinctive due to three factors. And here are what they are:

The first swear to innovate with the market in mind. Second, the business takes the lead in mission-critical instances. Finally, they are passionate about providing incredible value to their client's success.

The company also provides a wide range of goods that assist in resolving problems in many industries.

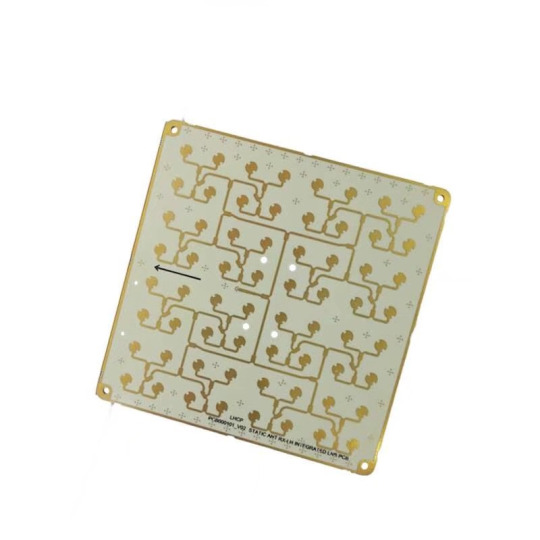

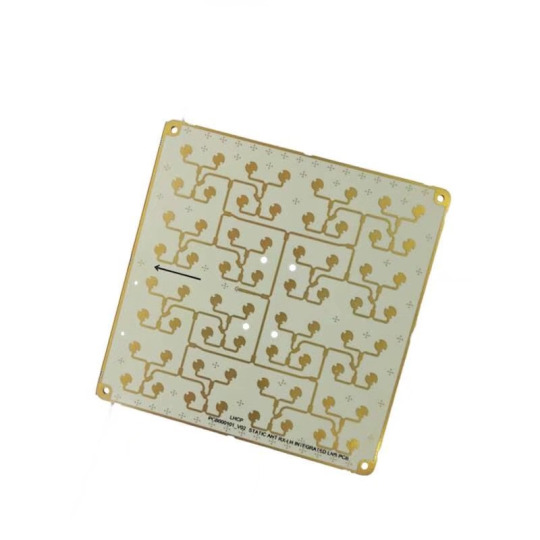

Therefore, it is not surprising that rogers PCB China has top-notch characteristics. These characteristics include outstanding dielectric constant and temperature consistency.

With copper foil, the thermal expansion factor of the dielectric constant on Rogers PCB is relatively stable. As a result, you may utilize Roger PCB to make up for the PTFE substrate's shortcomings.

Additionally, it works fantastically well in high-speed and high-frequency circuits. Additionally, it is useful for applying RF and microwave devices.

Additionally, Roger PCBs absorb little water. They are therefore perfect for situations involving high humidity.

What Kinds of Rogers PCBs Are There?

There are several varieties of Rogers PCB from rogers PCB manufacturer with varying resilience to abrasive environments. The Rogers PCB contains two primary categories as well. They are made of PTFE and thermostats. We will thus mention the three main categories.

Laminates

Modified woven glass reinforced epoxy IMS

Ceramic PTFE

Ceramic/UL 94 V-0 laminated woven glass/Hydrocarbon

Glass-reinforced, cross-plied woven PTFE

Random Glass Fiber PTFE

Weaved Glass, Ceramic, and Hydrocarbon

Modified woven glass-reinforced epoxy laminates

PTFE Composite That's Filled

PTFE antenna grade laminates with woven glass reinforcement

Bonding Supplies

Thermally and electrically conductive (TECA) Woven Glass Prepreg Hydrocarbon Ceramic Thermoset Film

PTFE Ceramic Bond ply

Metal Finishes

Reverse-treated Electrode posited

Adaptive Foil

Electrode posited

Rolled

2 notes

·

View notes

Text

Printed Circuit Board Manufacturing Types as Per Layers and Stiffness

A PCB board manufacturing and design are frequently just as important as the main circuit's design. Compact, flexible PCBs are being used by manufacturers more often to construct and arrange electronic circuits. Printed circuit board production generally involves anything from a single layer PCB to eight (or more) layers, depending on the intricacy of the circuit. This article goes through the various PCB types according to layer count and stiffness.

PCB types according to layers

Your PCB maker would likely advise using a single-sided PCB if your circuit is fairly simple. The whole circuit, including the electrical components and the copper lines, is housed on a single insulating board, making it the simplest PCB of all.

A significantly more complicated circuit may be held on a double-sided board than on a single-sided one. The circuitry components are housed on the substrate's two sides, as the name would imply. When creating double-sided or multilayered PCBs, through hole technology is frequently used.

Multi-layered printed circuit boards (PCBs), which consist of many substrate sheets with insulating layers sandwiched in between each, are used to manufacture complex printed circuit boards.

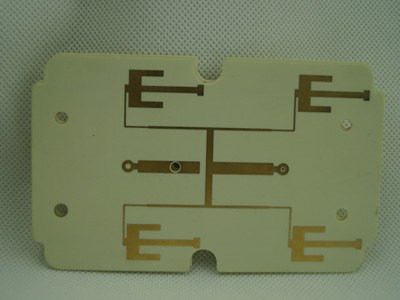

PCB types according to stiffness

Different PCB types offered by printed circuit board manufacturers are required for various purposes. For instance, a rigid PCB is the most common and is present in most consumer electronics used daily, including computers, televisions, mobile phones, and other devices. Such a board will fracture or break if it is bent too much. The flexible PCB is another popular form of PCB that is provided by a PCB manufacturer. In such a PCB, the circuits are put together atop a thin, flexible insulating layer. This makes it possible to bend and curve the PCB as needed without endangering the circuit or the insulating material.

PCBs that combine stiff and flexible PCBs are known as rigid-flex PCBs. When a particularly dense circuit is needed, aerospace and military applications employ these circuits. Electronic items weigh substantially less as a consequence of the space savings provided by rigid-flex PCBs.

It is possible to manufacture printed circuit boards in high volumes or for a small number of circuits. Selecting a PCB manufacturing company with a solid track record is crucial.

Main source: https://pcbskyhuihe.wordpress.com/

#pcb manufacturing#printed circuit board manufacturers#circuit board manufacturing#pcb board manufacturing

3 notes

·

View notes