Don't wanna be here? Send us removal request.

Text

Devcon Epoxies from ITW Performance Polymers: A Complete Surface Cure

Finding a way to restore a machine's mechanism led to various innovations. The methods to repair and maintain these machines introduced epoxies and adhesives into the equation. Every epoxy manufacturer brings a wide range of solutions to address almost every issue. For instance, manufacturers like Devcon are an integral part of the industry, offering complete solutions.

ITW Performance Polymers is an online distributor platform that brings together every recognized epoxy and adhesive manufacturing brand. You can find top manufacturers under a single roof.

Check out this YouTube video https://youtu.be/eKifDbZC2KI?si=Wturj1XA4uwOySbP for an application demo of Devcon epoxy.

Water-Resistant Adhesives:

Water and moisture exposure have been a concern for almost every technician. The conventional adhesives used for metal and rubber adhesion couldn't last when exposed to water and moisture. The problem was still manageable for indoor equipment. Devcon made sure that it was no longer a concern.

ITW brings the best metal to metal adhesive and rubber adhesives for industries. The Devcon product range from this store ensures excellent adhesion. Moreover, water exposure is no longer a concern when you use these products. Therefore, they are worth trying out. Visit this store and get the finest Devcon products now!

Curing Time:

Industrial epoxies and adhesives evolved with time. The need for these products changed. For instance, former formulas used to take days to cure. The industrial operations were paused for an undefined period due to curing delays. Devcon took a stand against such issues and addressed them using a proven formula. Check the best Devcon products at https://itwperformancepolymers.com/products/devcon

ITW Performance Polymers brings all the Devcon products according to your needs. If you need an adhesive or epoxy for fast curing, you can find the same product in this store. You will no longer need several days to use the product or machine. You can start using it the next day or so.

Durable Adhesion:

Smooth surfaces are always difficult to deal. They fail to stick together and form a strong bond. Metals and rubbers have been a constant concern. In such cases, technicians need a suitable epoxy and adhesive for rubber conveyor belt repair and metal bonding.

ITW Performance Polymers ends their hunt. The store brings the finest products from Devcon that work on these surfaces. Moreover, these adhesives and epoxies are able to create a strong and durable bond.

Get more details at https://itwperformancepolymers.com/

Contact: (978) 774-0516

Email: [email protected]

Original Source: https://bit.ly/3Taoesw

0 notes

Text

Epoxy Resins: A Must-Have Material for Construction and Repair Work

Epoxy resins are special chemical materials that have changed how people build things. They are beneficial in construction because they are flexible, strong, and stick to many surfaces. You can use them as sealants, glue, protective coatings, or to stop rust and water damage. So, if you are searching for the strongest epoxy for metal, you can count on professional brands. They deliver premium quality products with several benefits. One significant advantage of epoxy resins is that they can handle heat, moisture, and chemicals, which makes them perfect for use in complex environments. They are also great for fixing and maintaining concrete structures and making buildings and roads last longer. Let's explore more. For more information related to epoxy products, head to this YouTube video https://youtu.be/eKifDbZC2KI?si=9L37jcUP7Vdr6_DY from a reputable company. What is an Epoxy Resin? Epoxy compounds are a unique type of resin that belongs to a specific class of polymers. These compounds react with curing substances or resin hardliners such as polyamines, phenolic compounds, or amino acids to form a strong material that lasts longer.

Furthermore, if you are looking for the best epoxy plastic putty, you can rely on trusted brands! They deliver premium products at a cost-effective price. Characteristics of Epoxy Resins: Epoxy resins are a popular compound in the construction industry because of its several unique properties, including:

It has a high mechanical strength over other construction material.

Epoxy substances can react with many resins and other compounds.

Epoxy is fine for various electrical devices, like generators, motors, insulators, and bushings.

The Advantages of Using Epoxy for Construction Needs. Many industries can opt for epoxy due to its significant properties. It is strong, long-lasting, and can resist heat, water, and chemicals. To learn more, visit https://itwperformancepolymers.com/products/devcon/metal-rebuilding-repair/devcon-plastic-steel-putty-a

Plus, it sticks well to different surfaces, which makes them very useful in construction. Here are some uses of epoxy:

Epoxy can be perfect for decorative purposes.

It is an excellent option for sealants or coatings.

Epoxy is a popular choice in manufacturing and construction needs.

About ITW Performance Polymers: ITW Performance Polymers is a leading organization that offers the best industrial adhesives worldwide. It also provides an incredible range of industrial products, including epoxy putty, wear-resistant coatings, pipe wrap, choking compounds, and more. You can choose the one tailored to your needs and budget. To get more details, visit https://itwperformancepolymers.com/ Contact: (978) 774-0516 Email: [email protected] Original Source: https://bit.ly/4keBjfs

0 notes

Text

How Epoxy Adhesives Keep Metal Together in Harsh Environments

In the marine, automobile, aerospace, and infrastructure industries, metals face rigorous corrosive chemicals, extreme temperatures, vibrations, and moisture. Moreover, traditional welding or fastening methods fall short in demanding environments, leading to corrosion and material degradation. In such a scenario, epoxy adhesive for metal forms a strong and resilient bond that withstands harsh environments. This YouTube Video https://youtu.be/-lab8jOfWGA?si=qAyky6dC0nw8OudOwill provide you with more details.

The Science Behind Superior Adhesion When you mix polymers, they undergo a chemical reaction, forming a rigid plastic material. The resin and hardener system build a strong bond that surpasses the metal's strength. For metal applications, an epoxy is strong enough to create mechanical interlocking and chemical adhesion. Furthermore, this adhesive seeps into the pores of the metal surface, creating a physical lock. Resilience against elements Here are a few factors that make epoxy a structural adhesive resistant to harsh environments. Corrosion resistance: The traditional fasteners can result in galvanic corrosion. Meanwhile, epoxy prevents metal contact by serving as an insulating barrier. Furthermore, it reduces the risk of corrosion, the primary reason behind failures in marine and chemical processing. Chemical resistance: When you use cured epoxy, the metal becomes highly resistant to acids, solvents, oils, and alkalis, making it a beneficial property in chemical plants and gas pipelines. Temperature extremes: All epoxies are not the same. Some specialized formulations can withstand extreme temperature fluctuations from lows to scorching highs. Hence, these epoxies are invaluable in the aerospace industry and outdoor infrastructures in changing climates. Vibration and fatigue: Epoxy adhesives distribute the high pressure and temperature over a broad surface area, unlike bolts or rivets. As a result, there is a significant reduction in fatigue resistance. Moreover, it makes bonded metals highly durable under constant use and dynamic loads. Therefore, epoxies are vital for machinery and vehicles. To learn more, visit https://itwperformancepolymers.com/products/plexus. Moisture resistance: There are epoxies for metal that are highly resistant to water, humidity, and saltwater immersion, preventing rust and deterioration of the components. Get additional information at https://itwperformancepolymers.com/blog/explaining-the-epoxy-cure-cycle-of-chockfast-epoxies.

About ITW Performance Polymers: ITW Performance Polymers has the strongest methacrylate adhesive. You can also find the best acrylic adhesive, grouting or choking compounds, syntactic materials, and water-resistant epoxies in the store. Furthermore, you get the highest-quality adhesives and epoxy with exceptional strength and protection, and this brand is a part of the Fortune 200 companies. Contact them now for the best putty for metal and other products. To get more details, visit https://itwperformancepolymers.com/ Contact: (978) 774-0516 Email: [email protected] Original Source: https://bit.ly/4kTL6bO

0 notes

Text

Investing In Industrial Adhesives For Different Purposes

Have you ever thought of choosing industrial adhesives for your business? Do you always get confused about which type of industrial adhesives will suit your needs? This can happen to everyone. When it is your first time choosing these adhesives, you may feel confused about how to start shopping. The aim should be to shop for the perfect option that caters to your preferences. So, let’s discuss more about it. To learn more about adhesives, check out https://youtu.be/5t7WYwLqQ_E?si=V9ukNsu8gKbOimcO. Considering the surfaces When you are shopping for industrial adhesives, you must first consider the surfaces that you want to bond. For instance, if you want to bond simple surfaces like glass or plastic, your needs may be different. However, if you are planning on bonding metals, you may have different requirements.

Determining the temperature Do you want to shop for adhesives that can be used for bonding different types of surfaces? You must also consider if they will be able to withstand difficult conditions. For instance, there may be extreme heat or cold in the area of adhesion. Hence, when you are searching for the best types of solutions, you must consider if they can cater to the requirements of industries like aerospace or more. Understanding the application process When you are choosing the perfect industrial adhesive for your requirements, you must also consider the application process. Some adhesives can be applied by hand. Others may need to be applied by a machine or a spray. When you keep this in mind, you can choose the one that can be applied seamlessly by your team. To learn more about it, visit https://itwperformancepolymers.com/products/plexus.

Ensuring the durability of the bond When you use adhesives in industrial settings, you would surely want the bond to be durable. When shopping for industrial adhesives, consider the bond strength. These adhesives should form long-lasting bonds. If you are planning to shop for adhesives, you must research depending on the type of business and your specific adhesive requirements. It will help you make an informed decision. About ITW Performance Polymers: ITW Performance Polymers is one of the most reliable companies that can provide you with an acrylic adhesive. At this company, you can shop for different types of adhesives crafted for specific applications. So, these adhesives can help you form long-lasting bonds. These adhesives provide an outstanding performance. To get more details, visit https://itwperformancepolymers.com/ Contact: (978) 774-0516 Email: [email protected] Original Source: https://bit.ly/3HXgDLv

0 notes

Text

A Quick Guide on Aluminum Repair Epoxy: Applications and Usage

The toughest materials to deal with were always metals. Their smooth surface often led to unwanted concerns. For instance, it seemed impossible to glue two metal surfaces. However, the introduction of modern epoxies and adhesives changed the equation. Specialized materials, like aluminum repair epoxy, take good care of aluminum parts and structures. This YouTube video https://youtube.com/shorts/8Wo19vj_QMM?si=gcO6XOJVinPewPq1shares the strength and durability of these aluminum repair compounds.

Advantages of These Compounds: Aluminum is a widely used material often found in automobiles, construction, electrical systems, appliances, and electronics. This metal plays a crucial role in a product's mechanism and operability. However, damaged or broken aluminum parts can impact their operability. Using epoxy for cast aluminum ensures better results. These epoxies bond the surfaces brilliantly and benefit technicians and users. These products assure a durable bond. Moreover, this cost-efficient solution saves people from massive expenses. Therefore, this easy-to-use product is widely used. Applications: Epoxies for aluminum can solve many problems. For instance, holes and cracks may appear in aluminum structures over time. These epoxies can fill those cracks and holes. Aluminum may get corroded after a point due to high moisture and water exposure. This epoxy can prevent corrosion from worsening. Constant usage can wear and tear the aluminum's surface. The system can fail to function. In such cases, these epoxies can restore their functionality by promoting quick repair. These epoxies can be used to bond broken parts. Usage: Aluminum repair epoxy is pretty easy to use. First, you need to clean the surface and prepare the epoxy mix as instructed. Next, apply the putty on the surface and let it cure. Ideally, you may have to wait for at least 24 hours.

The material is again ready for use. However, you can restore its aesthetics if needed. For instance, sanding can polish the surface and make it smoother. It can enhance functionality. Applying paint on the joint will make it look better and add a protective layer. About ITW Performance Polymers: ITW Performance Polymers is among the highly rated online stores for epoxies and adhesives. If you are looking for an epoxy for aluminum, this store has covered it for you. The products from Devcon can serve the purpose and deliver the required results. So, explore its wide range of metal epoxies and benefit from the repair and maintenance process. Check more about it at https://itwperformancepolymers.com/ Contact: (978) 774-0516 Email: [email protected] Original Source: https://bit.ly/44ijW7h

0 notes

Text

ITW Performance Polymers: Your Partner For All Adhesive Needs

Does your business often require adhesive for different purposes? If so, you may feel confused about where you can find top-notch adhesives that will match your preferences. One company that offers an outstanding collection of adhesives suitable for different purposes is ITW Performance Polymers. To know more about it, visit here. It is a leading adhesive distributor that will surpass your expectations by providing quality products. So, you can trust its products for all your industrial needs. Let’s discuss more about it.

Offering long-term durability

All the products available at ITW Performance Polymers are highly durable. These products will last for a long time. So, when they are used on any part or assembly, they will last for their entire life. You will not have to worry about investing in the adhesives again.

Suitable for harsh climatic conditions

When you are planning on investing in adhesive or aluminum repair epoxy, you may want something that can be suitable for all types of climatic conditions. At ITW Performance Polymers, you can shop for exceptional options that are perfect for all conditions. These products can easily withstand stress, shock, or even impact.

Providing quality solutions

At ITW Performance Polymers, you can find products of the most premium quality. The company values consistency. Hence, you will find consistent quality in all its products. These products are only introduced in the market after thorough research and development. When the expert team of professionals approves the products, you can shop for them on its website. To know more about it, click here.

A trusted global business

ITW Performance Polymers is a well-known global business that has been providing industrial strength adhesives, wear-resistant coating, and other products for a long time. These products are suitable for various industries. Thus, you can choose them according to the specific requirements of your industry. If you are confused about which product will match the specific needs you have, you can contact its team. The team will guide you in the right direction.

Whenever you want to purchase epoxy for cast aluminum, you can explore the products from ITW Performance Polymers. The overall shopping experience will be convenient. The team focuses on delivering outstanding customer service every single time. Therefore, all your adhesive needs will be fulfilled with these extraordinary products.

To get more details, visit https://itwperformancepolymers.com/

Original Source: https://bit.ly/3HgpSWO

0 notes

Text

Understanding the Safety Tips while working with Industrial Adhesives

Are you looking for a high-performance industrial adhesive but unsure about the safety precautions you need to take to prevent any mishaps? If this is your concern, then you are in the right place! By reading this article, you will learn all the essential safety tips to keep in mind while working with industrial adhesives. So, without further delay, let’s start exploring it in more detail.

Ensure Proper Ventilation

Did you know that exposure to fumes and vapors can pose serious health complications? You must be well aware of maintaining a good ventilation system to ensure no build-up of harmful fumes in your workplace. You can use fans and effective exhaust systems to improve the circulation of air and reduce the harmful effects of the chemicals emitted by these adhesives.

Click here to know more.

Avoid Contact with Skin and Eyes

While using industrial adhesives, it is essential to avoid contact with the skin and eyes, as it can cause irritation and discomfort. Make sure to cover your eyes with protective goggles and wear personal protection equipment to avoid skin exposure to such harmful fumes and chemicals.

Store Adhesives Safely

To ensure the safety of industrial adhesives, you should store them in a cool, dry place, away from direct exposure to sunlight. Furthermore, you should keep the adhesive containers airtight to prevent them from drying out, by practicing these things you can maintain the longevity of the product.

Visit here to know more.

Be Prepared for Emergencies

Accidents can happen anytime, it is your responsibility to ensure all the safety measures are followed properly. Invest in installing proper eye wash stations and keep spill response kits readily available, in case of an emergency at the workplace.

Seek Professional Advice

If you are unsure about handling industrial adhesives and other chemical products, you should seek professional guidance to handle such products. Contact a reliable company that you trust and start taking their valuable guidance to manage things smoothly.

By following these essential tips you can ensure the safety of your workmen, by providing them a safe and secure work environment.

About ITW Performance Polymers:

ITW Performance Polymers provides a smart way to bond metals with its Plexus® metal-to-metal adhesive, the company also has expertise in creating high-quality pipe wrap. So, what are you waiting for? Start giving your normal adhesives a professional touch!

For getting more information, visit https://itwperformancepolymers.com/

Original Source: https://bit.ly/4dIBzBJ

0 notes

Text

Effective Metal Repairs: How to Use Metal-Filled Epoxy Correctly

Metal-filled epoxy is a repair material that works well on metal parts like brass, aluminium and steel. It is available in two parts: the epoxy resin and a hardener. When you mix them, they form a strong, solid material that sticks well to metal surfaces. You can use the metal patch and fill compound epoxy to fix cracks, holes, broken metal parts, or leaking pipes. Let's understand how metal-filled epoxies work and why they are a significant option for repairing metal surfaces. Uses of Metal-Filled Epoxies: Metal-filled epoxy can be used in many things, including:

It can be used to fill cracks and holes in surfaces to restore them.

To prevent and repair corrosion in metal surfaces.

To repair broken machine parts or other industrial components, metal-filled epoxy can be used.

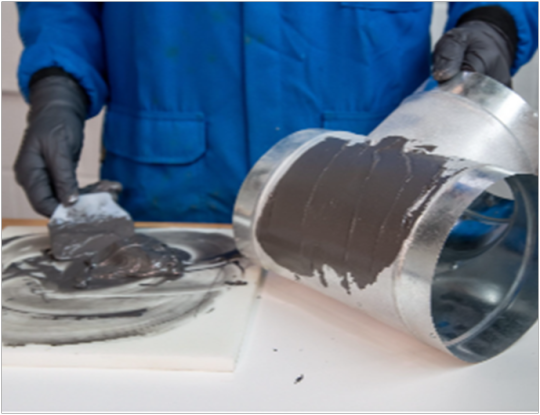

So, these are some common uses of metal-filled epoxy. To know more about this, click here. Further, if you want to buy a metal-filled epoxy or methacrylate adhesive, check these factors and their uses. If it provides these, it will be the best for your project needs. Opt for a professional brand of epoxy to make good-quality surfaces. How to Use Metal Repair Epoxy? There are a few steps to follow if you want to use epoxy on your own. It includes:

Mix the epoxy: Combine the resin and hardener as mentioned in the instructions.

Apply the putty: Use a spatula or knife to spread the putty evenly over the damaged spot.

Let it dry: Leave it alone for 24 hours or follow the drying time on the package.

Paint if needed: Once it is completely dry, paint over the area to make it look nice and smooth.

Now your metal surface is as good as new! Choose the professional firms to hire an expert worker for all your needs. So, if you want to buy a high-quality epoxy, you can count on professional brands! They offer the best and most efficient products that are affordable and deliver results tailored to your needs and preferences. To know more about this, visit here. About ITW Performance Polymers: Are you looking for epoxy putty plastic? ITW Performance Polymers is a leading organisation that provides top-quality epoxy and other adhesives at an affordable rate. It has an expert team of professionals who use high-quality materials to make efficient and durable products. Pick their products and get the most amazing results. For more information, check this out https://itwperformancepolymers.com/ Original Source: https://bit.ly/44ZG48L

0 notes

Text

How to Choose the Right Epoxy for Your Project

Concrete epoxy adhesive is the most reliable and versatile bonding material for industrial repairs. However, not all epoxies are equal. Hence, choosing the right one for your project is essential. Here’s your simple guide to selecting an appropriate epoxy for your project.

Know your materials

Firstly, identify the materials you are bonding. Epoxy works wonderfully on metals, glass, ceramics, wood, and concrete. However, some formulations are suitable for specific materials. For instance, high-strength industry-grade epoxy is ideal for bonding metals. To bond plastics, look for epoxy specifically for thermoplastics or thermosets.

Understand the environment

Where will you use the bonded product? Will you expose it to moisture, extreme conditions, or chemicals? Epoxy varies in resistance to water, corrosion, and heat. To learn more about it, click here. For instance, marine-grade epoxy perfectly holds up in wet or submerged conditions. In contrast, the heat-resistant epoxy is vital for engine components and appliances.

Cure time and work time

Some projects require quick bonding, while others need time to align or assemble. Hence, you must consider epoxies like pipe wrap with different work and cure times. Fast-curing epoxy is excellent for quick fixes, while slow-curing options offer stronger long-term bonds.

One-part and two-part epoxy

One-part epoxies are easier to use as they are pre-mixed and typically cure with heat. Meanwhile, two-part epoxies involve mixing resin and hardener before application. Furthermore, they offer slightly stronger bonds and better resistance to harsh conditions. Therefore, choose based on your comfort level and the strength required. To learn more about it, visit here.

Load and stress requirements

Does your bonded material tend to face constant pressure or movement? Opt for an epoxy that offers flexibility alongside strength. Rigid epoxies crack easily under vibration or shifting, while flexible formulations absorb impact and allow slight movement without breaking the bond.

Read the technical data sheet

Every quality epoxy product comes with a technical data sheet (TDS). This document provides details on bond strength, chemical resistance, and shear resistance.

About ITW Performance Polymers:

ITW Performance Polymers offers the strongest epoxy for metal. It offers methacrylate adhesive, sprayable syntactic materials, acrylic adhesives, repair compounds, grouting and choking compounds, and wear-resistant coatings. Furthermore, the company provides high-quality adhesives, delivering exceptional durability and protection. It is also a part of the Fortune 200 companies. Contact them now to get the best putty for every product industry.

To get more details, visit https://itwperformancepolymers.com/

Original Source: https://bit.ly/4kCCh5z

0 notes

Text

The Need for Weatherproof Adhesives and Epoxies

Structural adhesives have revolutionized the industrial sector with their diverse and comprehensive applications. These compounds have helped industries maintain consistency in their procedures, irrespective of conditions. Plexus brings exceptional structural adhesive and epoxy collections that serve every purpose superbly. The most commendable aspect of these compounds is their weatherproof characteristics.

Epoxy and Adhesive Compounds:

Adhesives and epoxies have served industries for long enough. They have ensured industrial operations do not encounter any halt due to machine and equipment failure. These epoxies and adhesives are here to restore mobility and functions by joining parts and surfaces as needed.

Epoxies and adhesives support surfaces to remain intact. Their contribution makes general industrial repairs more convenient. Therefore, they are widely used even after innumerable advancements and technologies. Click here to explore more about these products and their applications.

Distinct Surface Issues:

It is easier to deal with rough and coarse surfaces using adhesives and epoxies. The problem arose with smooth and granulated surfaces. Metals and rubbers were difficult to stick together due to their slippery textures. Regular adhesives and epoxies failed to serve the purpose.

Therefore, brands like Plexus came up with epoxy adhesive for metal, rubber, and other similar materials. They even brought compounds for concrete and granules that help solidify the surface better. Such introductions allowed industries to combat the situation and eliminate the concerns. Plexus makes sure none of these problems exist to restrict the industry's abilities.

Weatherproof Compounds:

Industries realized a drawback while using strong adhesives and epoxies. The regular products failed to withstand distinct weather conditions. For instance, moisture and water exposure made them lose their strength and stability. As a result, the machine parts get damaged again. Industries needed a solution that could beat moisture, heat, water, humidity, etc. Visit here for more details.

Modern epoxies and adhesives give you an edge to tackle these situations better. These modern solutions from brands like Plexus make sure that the weather is not a concern anymore. Therefore, industries blindly trust these weatherproof compounds for industrial repairs and operations.

About ITW Performance Polymers:

ITW Performance Polymers has been a top distributor of acrylic adhesive and epoxy. The online platform serves various industries, irrespective of their sectors, with the best epoxy and adhesive compounds. You can explore weatherproof structural adhesives that ensure better results. Check out products and top brands at this online store.

Check out more at https://itwperformancepolymers.com/

Original Source https://bit.ly/4kficm5

0 notes

Text

ITW Performance Polymers: The Only Adhesive Distributor You Need

Industrial adhesive and epoxy requirements will never come to an end. Even with automation and tech upgrades, industries cannot ignore the need for these compounds. Every machinery and equipment operating in industrial premises needs repair and maintenance, which is impossible without industrial adhesives. ITW Performance Polymers has been more like a partner than a distributor. Industries have relied on it for years and keep doing so. This platform is enough to address every industrial adhesive requirement. Here's why this store is enough for every industrial sector. The Range of Products: Industries need structural stability and machine resources to operate. These structures and equipment pieces serve meticulously day and night. However, after constant operation, their condition deteriorates. As a result, the need for repair, maintenance, and replacements arises. Replacement is usually one of the most financially burdening tasks for every industry. Therefore, these industries focus on repair and maintenance with the help of the best industrial adhesive. ITW Performance Polymers makes sure that it offers every required product to its customers. Whether you need adhesives and epoxies to repair concrete damages or metal surfaces, you can find everything here. This store will make sure that your needs are immediately addressed. Hence, it is an incredible solution for you. Product Description: Every compound available for repair and maintenance serves a unique purpose. Additionally, each product holds unparalleled properties and characteristics based on its application. It might confuse buyers at times. ITW Performance Polymers makes sure that such instances do not waste your time and effort. Before buying every product from this store, you can check the product details which include product applications, directions, and precautions. These details can help you make a better buying decision. So, make sure to choose this store in every case. Essential Details: Usually, technicians have to wait for a few hours or even days for the acrylic adhesive to fulfill its purpose. During this period, operations have to be on hold, affecting industrial functions. It can be daunting at times. ITW Performance Polymers provides essential products to its customers. If you need epoxies and adhesives with low downtime, you can find an ideal option at this store. Otherwise, you can go with the usual options. In both cases, you will end up with the most beneficial products. Check all the details at https://itwperformancepolymers.com/

Original source: https://bit.ly/4j64pNU

0 notes

Text

A Simple Guide to Picking the Right Adhesive for Industrial Use

In industrial work, choosing the right adhesive is very important. Whether you’re working with electronics, car parts, or building materials, an industrial epoxy adhesive must be safe, durable and work well for the job. Picking the wrong one can led to problems, while a good choice helps your project last longer and perform better. Here’s a simple guide to help you choose the best adhesive for your industrial needs. Environmental Conditions: When using adhesives, consider the environmental conditions. Things like changes in temperature, moisture, chemicals, and sunlight can affect how well an adhesive works. For jobs that involve high heat, silicone or epoxy adhesives are usually the best choice. Processing and Curing Time: Processing and curing time can also affect the selection of an adhesive. Always make sure to check the time it takes for the process. Some adhesives require less time to dry, while others like metal epoxy adhesive need more time for quick assembly and optimal performance. Application Method: To select the right adhesive, the method of application is also essential. Check how thick or thin the adhesive is, its viscosity and how easy it is to apply are very important, especially in factories that use machines to do the work. Substrate Compatibility: Compatibility is very crucial when choosing the adhesives for your work. It should bond with the materials you apply. Different types of adhesives work differently with many substrates. For example, silicone, acrylic, and tissue-based adhesives work better for plastics like polycarbonate labels and glass. Epoxy adhesives are great for sticking metal parts. However, these are some factors that people should remember while selecting industrial adhesives. Check for a professional brand before choosing one. They offer the most reliable products or services. Trusted firms have trained and skilled experts who have expertise in the field. They provide the best solutions and also offer guarantees. About ITW Performance Polymers: ITW Performance Polymers is one of the leading businesses. It delivers top-quality epoxy, industrial adhesives, pipe wrap, chocking compounds and more. If you want something for your industrial work, you can count on ITW Performance Polymers. It has skilled professionals who have been working in the industry for years. They give the best solutions at an affordable range. To get more information, visit https://itwperformancepolymers.com/

Original source: https://bit.ly/3E2jNfe

0 notes

Text

Metal-Filled Epoxy Putty: Fixing Cracks and Holes in Machinery

Industrial, automotive, and manufacturing machinery undergo consistent stress, making it prone to cracks and holes. In such a scenario, traditional fixing with welding or replacement is costly and time-consuming. In contrast, metal epoxy putty is a budget-friendly option for repairing machinery and restoring functionality. Why use metal-filled epoxy putty? Metal-filed epoxy putty has steel, bronze, and aluminum particles with superior strength, temperature resistance, and durability. After curing, it forms a solid bond that withstands pressure, chemical exposure, and vibrations. Hence, it is ideal for repairing engine blocks, gearboxes, hydraulic components, and machine housings. Step-by-step guide: fixing machinery cracks and holes

Surface preparation:

You must prepare the surface properly before using the epoxy putty.

Clean the damaged area with a degreaser to remove grease, dirt, or oil.

Roughen the surface with a wire brush or sandpaper to enhance adhesion.

Lastly, dry the surface before putting the putty.

2. Mix the epoxy putty: Metal-filled putty consists of a resin and a hardener. Mix the two in the correct proportion and blend until you achieve a uniform color and texture. Tip: Work quickly as putties set within minutes. 3. Apply the putty After mixing the two components, apply the putty directly to the damaged or damage-prone area.

For cracks: Press the putty in the crack to fill it. Use a gloved finger to smoothen the surface and avoid a bumpy appearance.

For holes: Add layers to match the surrounding surface of the damaged area. For large holes, use a mesh backing with epoxy concrete sealer.

4. Cure and finish Curing time is different for various products. However, metal-filled epoxies harden within 4-24 hours. Therefore, after curing, sand or drill the putty. Add a protective layer of paint over the repaired area for additional strength. Metal-filed epoxy putty helps repair your machine most durably and cost-effectively. It is the perfect choice for industries looking to avoid costly replacements and decrease downtime. About ITW Performance Polymers: ITW Performance Polymers provides the strongest epoxy for metal. It also offers structural adhesives, grouting and choking compounds, sprayable syntactic materials, wear-resistant coatings, acrylic adhesives, and repair compounds. This company has high-quality epoxy products that deliver exceptional durability and protection. It is also a part of the Fortune 200 company. Contact them today to get the best epoxy putty for every product industry. To get more details, visit https://itwperformancepolymers.com/

Original source: https://bit.ly/43B6jBA

0 notes

Text

Structural Adhesives: A Perfect Guide To Learn About Them

If you have been searching for a structural adhesive, you may feel confused about your choices since there are so many options available in the market. It helps join different types of surfaces. Navigating through different industrial adhesive options can be complicated for anyone. But with the help of correct information, you can make an efficient choice. Let’s discuss more about it. Using structural adhesive Structural adhesive can be perfect for applications where you require some stiffness or strength. If you do not have time to prepare the surface, it can be a versatile choice. Even when the bond lines have gaps, it will be a great option. If you want to fill for sealing and protecting, you can rely on structural adhesives. If you choose epoxy adhesives, they will have exceptional strength. Moreover, they will also have environmentally resistant properties. Things to consider when shopping for structural adhesives Flexibility: Several people think that flexibility is one of the most essential requirements. It is a crucial deciding factor that you may consider when looking for structural adhesives. These adhesives should be suitable even when there are movements. Cure time Adhesives are used in different types of businesses and industries. Therefore, the cure time is an essential factor to consider. In several situations, you may not have a lot of time to spend. So, you must choose adhesives that can cure quickly. It will help you save time. It will also be beneficial for you when you have a large area to take care of. Making the most informed decision Your search for the best methacrylate adhesive may not be as easy as it seems. You should ideally look for the one that offers great strength and flexibility. Moreover, the option should also offer a short cure time. If it can provide you with durable results, it will be even better in the long term. Hence, you can work with trusted companies that offer various options and can easily decide on the most suitable adhesive that matches the application. About ITW Performance Polymers: ITW Performance Polymers is one of the most renowned companies that can help you when you require metal to metal adhesive. On its website, you can find various adhesive options. It focuses on providing complete satisfaction to clients. So, it will be your one-stop destination for all adhesive needs. To get more details, visit https://itwperformancepolymers.com/

Original source: https://bit.ly/4cnuBBy

0 notes

Text

Why do Industries Prefer Plexus Adhesives for Regular Repairs and Maintenance?

Adhesives and epoxies serve a crucial purpose than expected. Their role may be trivial in industrial sectors, but they are the only compounds that step up when needed. Industries have many brands and options when it comes to methacrylate adhesives. Still, several industries go with Plexus adhesives and epoxies. Here's why they prefer this option. Availability: Manufacturing units, warehouses, packaging lines, shipping units, etc., rely on machinery and automated systems. These systems often work day and night, leaving no time to rest. This causes machinery wear and tear. In such cases, technicians work on repairing the damaged parts of the machine. This repair and maintenance task requires compounds to stick the surfaces together. Adhesives and epoxies from Plexus have been an aid to industries. Plexus makes sure that its products are widely available to its customers. There is not even a single instance where it fails to serve the customers in need. Usability: Adhesives and epoxies are no longer tricky to use. Brands like Plexus make sure that its product is perfectly available and convenient to use. Otherwise, it may cause problems. The ease of use makes every MMA adhesive from Plexus an incredible option. Most products are ready to use. All you need to do is clean the surface, apply the compound, stick them together, and that's it. There's no need to mix the product with other sub-products to get the desired outcome. Therefore, it is an excellent option for all. Durability: Why do industries rely on adhesives and epoxies, peculiarly from a brand like Plexus? This specific brand has gained their trust through its products over the years. Therefore, Plexus holds an exceptional position in the market. The adhesives and epoxies from Plexus can help technicians carry out their tasks pretty comfortably. The low downtime does not halt industrial operations for long. All these traits make this brand and its products more reliable. Additionally, the applied adhesives and epoxies can restore the durability of machinery and equipment. Hence, it reduces operational costs for industries. About ITW Performance Polymers: ITW Performance Polymers is among the most prominent market players. This adhesive distributor platform brings top brands and their products together. You can explore every type of compound for different materials and surfaces, including metal and concrete. So, explore its wide range of products now. Check out more at https://itwperformancepolymers.com/

Original source: https://bit.ly/41UMkN5

0 notes

Text

Impact of ITW Performance Polymers on the Repair and Maintenance of Metals

Metals often suffer relentless attacks. Corrosion eats away at surfaces, abrasion grinds down materials, and too many repairs disrupt operations. The loss of production due to the failure of a metal structure or machinery is commonly an extremely costly consequence in industries such as mining, power generation, and manufacturing. Traditional repair technologies are often insufficiently fast and/or unreliable, or they lack the heavy-duty performance that is needed. ITW Performance Polymers changes this with innovative metal epoxy adhesive technologies created for the rigorous demands of metal repair and maintenance. Epoxy: Revolutionizing Structural Repairs ITW Performance Polymers has been developing solutions for complex needs of repair, one line of products being Devcon®. Such products as Devcon® Aluminum Putty and Devcon® Bronze Putty allow industrial teams to restore the work of equipment effectively. These materials fill gaps, repair damage, and reinforce structural integrity. For example, Devcon® Aluminum Putty provides a smooth solution for aluminum machinery and castings, while Devcon® Bronze Putty serves best in the repair of bushings, shafts, and brass. This high-performance industrial epoxy adhesive provides strength and durability, even in challenging conditions. Unmatched Durability in Harsh Environments ITW Performance Polymers understands extreme environments, and its DevconBrushable Ceramic line of products creates protective barriers against corrosion and chemical attack, keeping equipment in processing plants and offshore facilities safe. DFense Blok offers superior abrasion resistance, extending equipment life where wear can take a toll. DFense Blok Fast Cure reduces downtime with a fast cure, allowing machinery to get back in operation in just two hours. Innovation combined with Accuracy and Versatility. ITW Performance Polymers keeps the leading position in offering innovatively designed products. Various solutions, such as Devcon® Epoxy-Plus 25, ensure outstanding resistance against impacts and fatigue that machinery may undergo, which results from its being exposed to constant vibrations or extreme weights. Advanced formulations glue together a great deal of material variety: from steel, and aluminum to exotic metals. Surfaces, that happen to be regularly exposed either to moist environments or low-temperature conditions, are effectively taken care of with ITW Performance Polymers' pipe wrap epoxies too. Industrial Maintenance With each new development, ITW Performance Polymers enables industries to minimize downtime, improve safety, and reduce costs. ITW Performance Polymers remains at the forefront of changing how industries think about metal repair and maintenance for ongoing success and reliability by providing innovative solutions specifically designed for durability and performance. For more information, visit https://itwperformancepolymers.com/

Original Source: https://bit.ly/4jIfHsK

0 notes

Text

Why Epoxy is Required for Equipment Protection

After a point, every piece of equipment goes through corrosion, wear, and chemical damage. In some situations, this can lead to rust, weakening metal parts and reducing lifespan. The equipment's surface also starts to degrade, causing heat buildup and reducing efficiency in operation. If equipment without the protective coatings is affected by moisture or harsh chemicals, it leads to frequent repairs and breakdowns. The lack of protection also creates maintenance issues that are more costly and time-consuming. To deal with these issues, proper protective coatings are needed. Epoxy coatings are the best solution because they act as a reliable barrier to protect the equipment from wear and tear, corrosion, and other environmental factors. Improving Resistance Equipment in industries that deal with harsh chemicals face many difficulties maintaining equipment. Exposure to various chemical substances can lead to the degradation of surfaces and damage them slowly. By using epoxy protection, the equipment can resist cracks and other issues. Epoxy coatings with chemical-resistant properties help protect the equipment from dangerous chemicals and keep it intact and fully operational. Epoxy coatings protection is essential for industries with heavy machinery or tools to minimize the risk of chemical damage and ensure consistent and safe functioning. Preventing Corrosion Corrosion is a common threat to equipment because of moisture and chemicals. If a protective layer is absent, rust affects metal components, negatively impacting strength and performance. Choosing epoxy coatings provides a strong and resistant shield that prevents the penetration of corrosive substances. This protection supports the equipment's structural integrity, avoids early damage, and reduces the need for frequent repairs. Epoxy coating for steel extends the lifespan of the equipment to support its consistent performance in challenging environments. Advanced Protection The constant friction causes damage to the equipment easily without using a protective solution like epoxy. The internal parts of the equipment slowly get affected, impacting its efficiency. These issues lead to costly repairs and early replacements for the equipment. Epoxy coatings act as a durable barrier for reducing the contact between surfaces to minimize friction and maintain the integrity of the equipment. It provides many benefits, such as prolonged life, smoother operation, and keeping the equipment in working order much longer. Choosing this simple and effective protective measure helps industries save time and money. About ITW Performance Polymers: ITW Performance Polymers is a top company that provides high-quality protective coatings and sealants. It has many years of experience offering reliable solutions for protecting equipment and extending durability. To get more details, visit https://itwperformancepolymers.com/

Original Source: https://bit.ly/3EpGeuM

0 notes