TinToll, a part of SINOPCC group established in 1989, dedicated in the developing and sales of polymer additives. We offer the widest range of performance-based polymer additives in the industry; our product portfolio comprises UV absorbers, light stabilizers, antioxidants, photoinitiators, etc. Our goal is to be the most innovative supplier of stabilizer solutions worldwide. Today our products are used successfully throughout the world in the agricultural, automotive&appliances, packaging, artificial grass, coatings, elastomers, wood plastic.https://www.uvabsorber.com/

Don't wanna be here? Send us removal request.

Text

PowerStab™ 3853

CAS No. 167078-06-0

Fatty acids, C12−21 and C18−unsaturated, 2,2,6,6−tetramethyl −4− piperidinyl stearate

PowerStab™ 3853 is a hindered amine light stabilizer (HALS).

Benefits & Applications of PowerStab™ 3853 CAS No. 167078-06-0

PowerStab™ 3853 is a hindered amine light stabilizer (HALS) which is effective in a broad range of polymers and applications, including PP film/tape/injection molding applications, TPO, and PE film/tape/injection molding. The product can also be used for the light stabilization of polyacetals, polyamides, styrenic polymers, and PUR. It is also available in concentrate form for easier handling and dosing in polymer processing operations.

End use applications for which this product is ideal include PP and TPO automotive parts, TPO roofing membranes, PE crates, and PP outdoor furniture.

0 notes

Text

PowerCure™ PAG400

CAS No. 42573-57-9

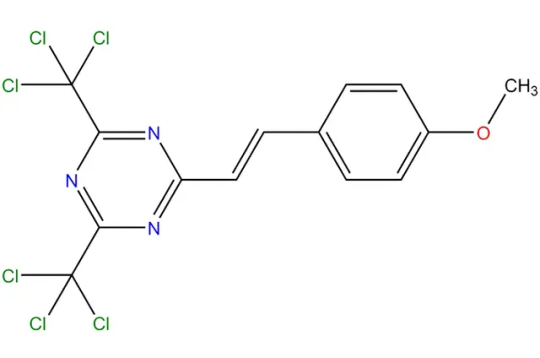

2-[2-(4-Methoxyphenyl-2-yl)vinyl]-4,6-bis(trichloromethyl)1,3,5-triazine

PowerCure™ PAG400 is mainly used for lithographic printing plates. PowerCure™ PAG400 is also widely used in the processing of large-scale integrated circuits.

Benefits & Applications of PowerCure™ PAG400 CAS No. 42573-57-9

PowerCure™ PAG400 is mainly used for lithographic printing plates. PowerCure™ PAG400 is also widely used in the processing of large-scale integrated circuits.

0 notes

Text

PowerSorb™ 3638

CAS No. 18600-59-4

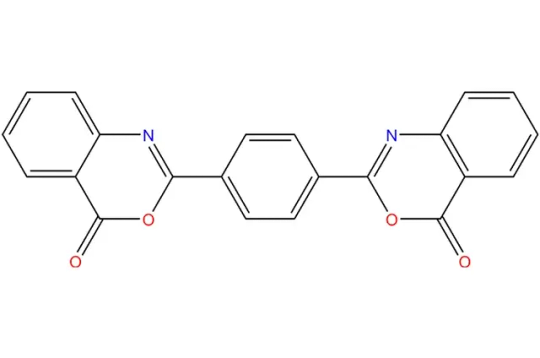

2,2'-(1,4-Phenylene)bis(4H-3,1-benzoxazin-4-one)

Synonym: 2,2'-Benzene-1,4-diylbis(4H-3,1-benzoxazin-4-one)

PowerSorb™ 3638 is a highly efficient and non-staining UV absorber.

Benefits & Applications of PowerSorb™ 3638 CAS No. 18600-59-4

PowerSorb™ 3638 is made to dissolve quickly in PET resin and to give a transparent appearance even with high dosage.

PowerSorb™ 3638 is ideal for film/sheet/plate applications such as solar cell, window film, etc.

PowerSorb™ 3638 is registered on FDA and is approved for food contact applications such as PET bottles and food wrap films.

0 notes

Text

Chemical Application in Fuels & Lubricants

Lubricants:

TinToll's phenolic antioxidants are instrumental in preventing the breakdown of lubricants due to oxidation, which can lead to viscosity changes, sludge formation, and ultimately, reduced lubricating properties. These lubricant antioxidants help maintain the lubricant's stability and integrity over time, extending the lubricant's shelf life and ensuring optimal performance even under high-temperature conditions.

Phosphite antioxidants provided by TinToll, a professional engine oil antioxidants provider, contribute to maintaining the lubricant's resistance to oxidation. They work by scavenging free radicals and inhibiting the chain reactions that lead to oxidative degradation. This helps preserve the lubricant's original properties, reducing the likelihood of viscosity increase and ensuring consistent performance.

Thiosynergists from TinToll serve as co-antioxidants, enhancing the overall effectiveness of the antioxidants in lubricants. They synergistically interact with other antioxidants to provide a more robust defense against oxidation, thus further extending the lubricant's lifespan and ensuring reliable performance.

By incorporating these motor oil antioxidants and thiosynergists into lubricants, manufacturers and end-users can benefit from prolonged engine drain intervals, reduced maintenance costs, and improved lubricant stability.

Fuels:

Incorporating engine oil antioxidants into fuels helps prevent oxidation during storage and combustion. This is crucial because oxidation can lead to the formation of gums and sediments, negatively impacting fuel quality and engine performance. TinToll's motor oil antioxidants ensure that fuels maintain their stability, reducing consumption and enhancing engine performance while upholding engine durability.

0 notes

Text

Chemical Application in Automobile

UV radiation from sunlight can cause degradation of automotive surfaces and materials, leading to fading, cracking, and reduced lifespan. TINTOLL UV absorbers for coatings are incorporated into automotive paints, coatings, and plastics to absorb and dissipate harmful UV radiation, preventing damage. Photoinitiators are added to coating formulations, and upon exposure to UV light, they trigger a chemical reaction that leads to rapid curing.

UV absorbers for coatings absorb UV energy and transform it into harmless heat, protecting the automotive materials from UV-induced degradation.

Light exposure can lead to discoloration, embrittlement, and loss of mechanical properties in automotive parts. Light stabilizers are added to polymers used in interior and exterior parts to prevent degradation caused by light exposure.

Benefits of the application: Maintains color stability, mechanical strength, and overall appearance of automotive components.

Function: Light stabilizers hinder the photochemical reactions that lead to material degradation, preserving the original properties of the materials.

Exposure to heat, oxygen, and other environmental factors can cause oxidative degradation of automotive materials. Polymer antioxidants are mixed into polymers used in various parts to inhibit oxidation and maintain material integrity. Antioxidants inhibit the oxidation process by neutralizing free radicals, thereby preventing the chain reaction that leads to material degradation.

TinToll's polymer additives are essential in the automobile industry to enhance the performance and durability of various automotive components. These additives ultimately contribute to maintaining the aesthetic appeal, structural integrity, and functional properties of automobiles, ensuring that they withstand environmental challenges and maintain their quality over time.

1 note

·

View note