Text

How Are Optical Fibers Made?

Now that we know how fiber-optic systems work and why they are useful -- how do they make them? Optical fibers are made of extremely pure optical glass. We think of a glass window as transparent, but the thicker the glass gets, the less transparent it becomes due to impurities in the glass. However, the glass in an optical fiber has far fewer impurities than window-pane glass. One company's description of the quality of glass is as follows: If you were on top of an ocean that is miles of solid core optical fiber glass, you could see the bottom clearly.

Making optical fibers requires the following steps:

Making a preform glass cylinder

Drawing the fibers from the preform

Testing the fibers

Making the Preform Blank

The glass for the preform is made by a process called modified chemical vapor deposition (MCVD).

In MCVD, oxygen is bubbled through solutions of silicon chloride (SiCl4), germanium chloride (GeCl4) and/or other chemicals. The precise mixture governs the various physical and optical properties (index of refraction, coefficient of expansion, melting point, etc.). The gas vapors are then conducted to the inside of asynthetic silica or quartz tube (cladding) in a special lathe. As the lathe turns, a torch is moved up and down the outside of the tube. The extreme heat from the torch causes two things to happen:

Lathe used in preparing the preform blank

Photo courtesy Fibercore Ltd.

The silicon and germanium react with oxygen, forming silicon dioxide (SiO2) and germanium dioxide (GeO2).

The silicon dioxide and germanium dioxide deposit on the inside of the tube and fuse together to form glass.

The lathe turns continuously to make an even coating and consistent blank. The purity of the glass is maintained by using corrosion-resistant plastic in the gas delivery system (valve blocks, pipes, seals) and by precisely controlling the flow and composition of the mixture. The process of making the preform blank is highly automated and takes several hours. After the preform blank cools, it is tested for quality control (index of refraction).

Drawing Fibers from the Preform Blank

Once the preform blank has been tested, it gets loaded into a fiber drawing tower.

Diagram of a fiber drawing tower used to draw optical glass fibers from a preform blank

The blank gets lowered into a graphite furnace (3,452 to 3,992 degrees Fahrenheit or 1,900 to 2,200 degrees Celsius) and the tip gets melted until a molten glob falls down by gravity. As it drops, it cools and forms a thread.

The operator threads the strand through a series of coating cups (buffer coatings) and ultraviolet light curing ovens onto a tractor-controlled spool. The tractor mechanism slowly pulls the fiber from the heated preform blank and is precisely controlled by using a laser micrometer to measure the diameter of the fiber and feed the information back to the tractor mechanism. Fibers are pulled from the blank at a rate of 33 to 66 ft/s (10 to 20 m/s) and the finished product is wound onto the spool. It is not uncommon for spools to contain more than 1.4 miles (2.2 km) of optical fiber.

Testing the Finished Optical Fiber

The finished optical fiber is tested for the following:

Finished spool of optical fiber

Photo courtesy Corning

Tensile strength - Must withstand 100,000 lb/in2 or more

Refractive index profile - Determine numerical aperture as well as screen for optical defects

Fiber geometry - Core diameter, cladding dimensions and coating diameter are uniform

Attenuation - Determine the extent that light signals of various wavelengths degrade over distance

Information carrying capacity (bandwidth) - Number of signals that can be carried at one time (multi-mode fibers)

Chromatic dispersion - Spread of various wavelengths of light through the core (important for bandwidth)

Operating temperature/humidity range

Temperature dependence of attenuation

Ability to conduct light underwater - Important for undersea cables

Once the fibers have passed the quality control, they are sold to telephone companies, cable companies and network providers. Many companies are currently replacing their old copper-wire-based systems with new fiber-optic-based systems to improve speed, capacity and clarity.

0 notes

Text

A Fiber-Optic Relay System

To understand how optical fibers are used in communications systems, let's look at an example from a World War II movie or documentary where two naval ships in a fleet need to communicate with each other while maintaining radio silence or on stormy seas. One ship pulls up alongside the other. The captain of one ship sends a message to a sailor on deck. The sailor translates the message into Morse code (dots and dashes) and uses a signal light (floodlight with a venetian blind type shutter on it) to send the message to the other ship. A sailor on the deck of the other ship sees the Morse code message, decodes it into English and sends the message up to the captain.

Now, imagine doing this when the ships are on either side of the ocean separated by thousands of miles and you have a fiber-optic communication system in place between the two ships. Fiber-optic relay systems consist of the following:

Transmitter - Produces and encodes the light signals

Optical fiber - Conducts the light signals over a distance

Optical regenerator - May be necessary to boost the light signal (for long distances)

Optical receiver - Receives and decodes the light signals

Transmitter

The transmitter is like the sailor on the deck of the sending ship. It receives and directs the optical device to turn the light "on" and "off" in the correct sequence, thereby generating a light signal.

The transmitter is physically close to the optical fiber and may even have a lens to focus the light into the fiber. Lasers have more power than LEDs, but vary more with changes in temperature and are more expensive. The most common wavelengths of light signals are 850 nm, 1,300 nm, and 1,550 nm (infrared, non-visible portions of the��spectrum).

Optical Regenerator

As mentioned above, some signal loss occurs when the light is transmitted through the fiber, especially over long distances (more than a half mile, or about 1 km) such as with undersea cables. Therefore, one or more optical regenerators is spliced along the cable to boost the degraded light signals.

An optical regenerator consists of optical fibers with a special coating (doping). The doped portion is "pumped" with a laser. When the degraded signal comes into the doped coating, the energy from the laser allows the doped molecules to become lasers themselves. The doped molecules then emit a new, stronger light signal with the same characteristics as the incoming weak light signal. Basically, the regenerator is a laser amplifier for the incoming signal.

Optical Receiver

The optical receiver is like the sailor on the deck of the receiving ship. It takes the incoming digital light signals, decodes them and sends the electrical signal to the other user's computer, TV or telephone(receiving ship's captain). The receiver uses a photocell or photodiode to detect the light.

0 notes

Text

How Does an Optical Fiber Transmit Light?

Suppose you want to shine a flashlight beam down a long, straight hallway. Just point the beam straight down the hallway -- light travels in straight lines, so it is no problem. What if the hallway has a bend in it? You could place a mirror at the bend to reflect the light beam around the corner. What if the hallway is very winding with multiple bends? You might line the walls with mirrors and angle the beam so that it bounces from side-to-side all along the hallway. This is exactly what happens in an optical fiber.

The light in a fiber-optic cable travels through the core (hallway) by constantly bouncing from the cladding (mirror-lined walls), a principle called total internal reflection. Because the cladding does not absorb any light from the core, the light wave can travel great distances.

However, some of the light signal degrades within the fiber, mostly due to impurities in the glass. The extent that the signal degrades depends on the purity of the glass and the wavelength of the transmitted light (for example, 850 nm = 60 to 75 percent/km; 1,300 nm = 50 to 60 percent/km; 1,550 nm is greater than 50 percent/km). Some premium optical fibers show much less signal degradation -- less than 10 percent/km at 1,550 nm.

Check The Entire Article @HowStuffWorks

0 notes

Text

What Are Fiber Optics?

Fiber optics (optical fibers) are long, thin strands of very pure glass about the diameter of a human hair. They are arranged in bundles called optical cables and used to transmit light signals over long distances.

If you look closely at a single optical fiber, you will see that it has the following parts:

Core - Thin glass center of the fiber where the light travels

Cladding - Outer optical material surrounding the core that reflects the light back into the core

Buffer coating - Plastic coating that protects the fiber from damage and moisture

Hundreds or thousands of these optical fibers are arranged in bundles in optical cables. The bundles are protected by the cable's outer covering, called a jacket.

Optical fibers come in two types:

Single-mode fibers

Multi-mode fibers

See Tpub.com: Mode Theory for a good explanation.

Single-mode fibers have small cores (about 3.5 x 10-4 inches or 9 microns in diameter) and transmit infrared laser light (wavelength = 1,300 to 1,550 nanometers). Multi-mode fibers have larger cores (about 2.5 x 10-3 inches or 62.5 microns in diameter) and transmit infrared light (wavelength = 850 to 1,300 nm) from light-emitting diodes (LEDs).

Some optical fibers can be made from plastic. These fibers have a large core (0.04 inches or 1 mm diameter) and transmit visible red light (wavelength = 650 nm) from LEDs.

Check the Entire article @HowStuffWorks http://computer.howstuffworks.com/fiber-optic1.htm

0 notes

Link

Watch a sinus surgery video showing how ENT doctors use Balloon Sinuplasty to open blocked sinuses for patients suffering from chronic sinusitis.

0 notes

Text

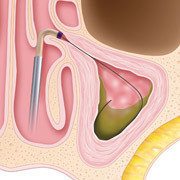

Benefits of Balloon Sinuplasty In-Office

Balloon Sinuplasty technology by Accelarent

Local Anesthesia Balloon Sinuplasty In-Office is an option for patients who decline or are ineligible for general anesthesia.

Fast Recovery While recovery time varies with each patient, most patients who undergo the in-office procedure can return to normal activities and work within 2 days.(1)

Comfortable Surroundings Experience the procedure in the comfort of your physician’s office rather than a hospital operating room.

High Patient Satisfaction The majority of patients who had Balloon Sinuplasty In-Office would recommend the procedure to family and friends.(1)

Potential for Significant Cost Savings Some eligible patients may have lower out-of-pocket costs if the procedure is performed in a lower cost of care setting, such as a physician’s office.

Sources

Karanfilov B, Silvers S, Pasha R, Sikand A, Shikani A, Sillers M; for the ORIOS2 study investigators. Office-based balloon sinus dilation: a prospective, multicenter study of 203 patients. Int Forum Allergy Rhinol. 2013;3(5):404-411.

0 notes

Link

Take a quiz to determine if you may be a candidate for Balloon Sinuplasty, a breakthrough sinus procedure used to open blocked sinuses.

0 notes

Link

Watch a sinus surgery video showing how ENT doctors use Balloon Sinuplasty to open blocked sinuses for patients suffering from chronic sinusitis.

0 notes

Video

youtube

Unlike traditional sinus surgery, Balloon Sinuplasty requires no cutting and no removalof bone and tissue.

Balloon Sinuplasty (BSP) uses a small, flexible, balloon catheter to open up blocked sinus passageways and facilitate drainage of the mucus that builds up in patients suffering from chronic sinusitis symptoms.

Sources

Karanfilov B, Silvers S, Pasha R, Sikand A, Shikani A, Sillers M; for the ORIOS2 Study Investigators. Office-based balloon sinus dilation: a prospective, multicenter study of 203 patients. Int Forum Allergy Rhinol. 2012;Nov 7. doi: 10.1002/alr.21112.

Weiss, et al. “Long-term outcome analysis of balloon catheter sinusotomy: Two-year follow-up.” Otolaryngology-Head and Neck Surgery, 2008, Vol. 139, pp. S38-S46.

0 notes

Photo

Karl Storz 28721BWA Arthroscope 30 degree 4 mm ( http://ow.ly/x4hMH ) && Machida ENT-4L Workig Lenght 300mm Diameter 4.3mm (http://ow.ly/x4hH7 )

0 notes

Video

youtube

Working Elements Definition: "...Although the design may vary according to the specific use, all endoscopes have similar working elements. The viewing part (scope) may be a hollow metal or fiber tube fitted with a lens system that permits viewing in a variety of directions. There is also a light source, power cord, and power source. Accessories that might be used for diagnostic or therapeutic purposes include suction tip, tubes, and suction pump; forceps for removal of biopsy tissue or a foreign body; biopsy brushes; an electrode tip for cauterization; as well as a video camera, video monitors, and image recorder." Read More: http://medical-dictionary.thefreedict... Facebook: https://www.facebook.com/proendoscopy Twitter: http://twitter.com/proendoscopy Google+: http://gplus.to/proendoscopy Tumblr: http://proendoscopy.tumblr.com Pinterest: http://pinterest.com/proendoscopy/ Address: 10084 N.W. 53 Street Sunrise, FL 33351 U.S. Phone #954-747-9000 Fax:954-747-9922 Contact Form: http://www.proendoscopy.com/index.php...

0 notes

Link

Looking for a Cystoscope at a GREAT price? Check out what we have!

www.ProEndoscopy.com

0 notes

Quote

The #World couldn't #end on a #friday Come on! Weekend is here! what are you going to do? Our Office hours are M-F 9AM to 5PM. At http://bit.ly/uVWUbU or Facebook! www.facebook.com/proendoscopy

0 notes

Photo

Bom Dia! We got a lovely visit from Brazil! Our IT Department helped us in the translation. We are fluent in Spanish, English, and Portuguese, and will always be here to serve you with any endoscopy issues.

0 notes

Video

youtube

Good Morning! and Great Tuesday from #SouthFlorida & @Proendoscopy Did you know? Our staff recently attended The FIME 2012 Exposition Check it out:http://www.youtube.com/watch?v=UFy47R_tV_w

0 notes

Quote

Good Morning. We're here to help w/ #Flexible & #Rigid #endoscopes till 5PM ET. Lets make a #productive Day! http://bit.ly/uVWUbU Give Us a call @ 1-954-747-9000 or email us: [email protected]

I.G.

0 notes

Quote

#Friday is finally here! Woohoo! @ProEndoscopy will be here to serve you from 9am to 5pm! Give us a tweet! or a click! http://bit.ly/uVWUbU

1 note

·

View note