Qingdao Binhai Jincheng Foundry Machinery Co., Ltd. is the leading company of surface cleaning. professional machine manufacturer of industrial shot blasting machine, sand reclamation line, V method production line, dust collector, core shooting machine, and molding machine over 20 years. As one of the leading blasting equipment suppliers, we specialize in research, development, production, sale, and service, always keeping the leading role. https://www.qdbhmachinery.com/

Don't wanna be here? Send us removal request.

Text

QXY Steel Plate Pretreatment Line

Main Components of QXY Steel Plate Pretreatment Line

QXY shot blasting machine consists of automatic load and unloading system (Optional), roller conveyor system (Input roller, output roller and inside roller), blasting chamber (chamber frame, protection linear, shot blasting turbines, abrasive supply device), abrasive circulation system (Separator, bucket elevator, screw conveyor), abrasive collection unit (Customized), dust collection system and electric control system. Variety heating methods for preheating and drying part, high-pressure airless spray for painting part. This whole machine uses PLC control, really reach an international advanced level of large complete equipment in the world.

QXY Steel Plate Pretreatment Line Features

1. The impeller head is composed of a blast wheel, the structure is simple and durable.

2. Segregator is very efficient and it can protect the blast wheel.

3. The dust filter can greatly reduce air pollution and improve the work environment.

4. Abrasion-resistant rubber belt lightens the collision of workpieces, and lower the noise.

5. This machine is controlled by PLC, the operation is easy and reliable.

https://www.qdbhmachinery.com/products/qxy-steel-plate-pretreatment-line.html

0 notes

Text

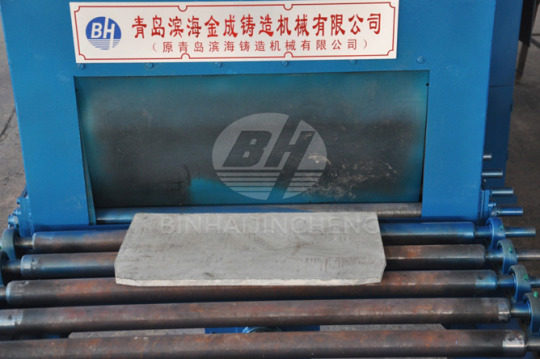

Pavers Shot Blasting Machine

Pavers shot blasting machine is special equipment for pavers roughing which is dedicated designed by our company for the pavers processing industry. It is mainly used to increase the friction coefficient of the surface of the pavers and improve the surface decoration effect. After being processed by the pavers shot blasting machine, the surface of the pavers will show an effect similar to that of the litchi surface. Widely used in the fields of marble wall hanging and anti-skid on the ground. For the moment, more and more ground paving prefers the rough surface, has a board market prospect.

Main features of Pavers Shot Blasting Machine

Simulated shot diagram (including the determination of the model, number and spatial arrangement of the impeller head) and all drawings of the stone shot blasting machine are completely drawn by CAD. And after many times of practical experience optimize, to achieve a more perfect shot effect.

The body of the cleaning room is made of a high-quality Q235A steel plate (thickness 8-10mm). The inner wall is lined with a 10mm thick "Rolled Mn13" protective plate which has the reputation of "the best protective plate" and "lifetime", and adopts the "Block type" protective plate layout.

The Impeller Head is based on fully absorbing Shinto. Japan technology, and after continuously optimized, independently designed and manufactured by ourselves, with the feature of large blasting volume and high shot speed.

Adopting advanced “BE” type full-curtain Separator, and this separator was independently developed by our company on the basis of completely absorbed the technology of Swiss GEORGE FISCHER DISA (GIFA) and American Pangborn company, with perfect separation effect.

Steel shot control system:

The shot gate valve controlled by the cylinder is used to control the supply of the steel shot at a long distance, We can through adjust the bolts on the shot controller to obtain the required shot blasting amount. This technology is independently developed by our company.

The Application of Pavers Shot Blasting Machine

It consists of the following components: Shot blasting room, Front sealed chamber, Rear sealed chamber, Feeding in roller table, Sending out roller table, Longitudinal screw conveyor, horizontal screw conveyor, Bucket elevator, Separator, Platform, Roller in blasting chamber, Dust removal system, Electrical system, Steel shot distribution system, Screw conveyor, etc.

Working Principle of Pavers Shot Blasting Machine

During the cleaning process, the frequency conversion motor drove the roller table to send the work-piece into the shot area of the cleaning room.

The impact of the powerful and dense steel shot in the coordinate direction makes the corroded skin and dirt on the pavers drop rapidly, and the stone obtains a smooth surface with a certain roughness.

The steel shot and rust falling on the top surface of the work-piece is transported to the projectile circulation through the screw conveyor.

Under the operating of the industrial shot blasting machine, the surface of the pavers will quickly erode the flat surface into a three-dimensional litchi surface and fire surface.

This processing method has a fast processing speed, usually each team can handling more than 2000 square meters (according to 8 hours), it is very popular with customers.

https://www.qdbhmachinery.com/products/pavers-shot-blasting-machine/

0 notes

Text

Overhead Rail Shot Blasting Machine

Q38, Q48, Q58 series catenary stepping shot blasting machine are used to remove castings, forgings, structural parts such as the workpiece surface sand, scale, rust and so on. The surface of the workpiece appears metallic luster, and castings surface defects exposed to eliminate the stress within the workpiece, the surface roughness to Ra12.5 requirements GB6060.5 requirements, in line with national JB/ T8355-96 Sa2.5 level.

Specification of Overhead Rail Shot Blasting Machine

Advantages of Overhead Rail Shot Blasting Machine

Improve fatigue resistance and anti-fatigue

Remove the sand of metal surface

Increase service life

Remove metal rust

Remove metal surface oxide skin

Make the surface show metal luster.

Improve adhesive force before painting

Remove the internal stress

Application of Overhead Rail Shot Blasting Machine

Clean Iron Casting

Clean Steel casting

Clean Forging

Clean Stamping parts

Clean LPG cylinder

Other types of metal with very big cleaning efficiency

Features Of Overhead Rail Shot Blasting Machine

1) Rolling manganese 13 protect board,8000-10000 hour longer lifetime.

2) Straight or Y shape track conveyor, loading capacity 500-50000kg

3) High cleaning speed and saving labor.

4) Turbine spare parts are all high chrome

5) Compact and strong structure

6) Dust concentration less than 80mg/m3

7) Can use ABB motor, SEW reducer, SKF bearing

8) Package: wooden box for control cabinet

9) PLC (Siemens or Omron or Mitsubishi brand) control system, and adjust parameter and security

10) The projectile circulation system uses an active monitoring device. When some parts are not running smoothly or are stuck, it will actively alarm and notify the faulty parts, which is convenient for targeted repair

11) Workpieces can be cleaned while walking, or walking after cleaning, etc., with a high degree of initiative, greatly reducing the labor intensity of workers

https://www.qdbhmachinery.com/products/overhead-rail-shot-blasting-machine/

0 notes

Text

Hook Type Shot Blasting Machine

https://www.qdbhmachinery.com/products/hook-type-shot-blasting-machine/Hook type shot blasting machine is suitable for cleaning the foundry part, construction, chemical engineering, machine tools and many other industries of large, medium-size castings and forgings surface cleaning. The hook shot blasting machine is the most popular type cleaning machine.

Machine Usage Of Hook Type Shot Blasting Machine

Hanger shot blasting machine is suitable for cleaning the foundry part, construction, chemical engineering, machine tools and many other industries of large, medium-size castings and forgings surface cleaning.it is the most popular type cleaning machine.

We apply this cleaning technology of hook type industrial shot blasting machine to achieve the purpose of derusting.

Strengthen Eliminate internal stress.

Improve surface adhesion.

Descaling improves fatigue resistance.

Prolong its service life.

Advantages of Hook Type Shot Blasting Machine

PLC (Siemens or Omron brand) electrical control system, can adjust parameter and security assurance, normal standard type usually without PLC.

With the belt connection, centrifugal type turbine, much more stable and uniform rotate speed. High-speed impeller the rotate speed 3000r/min.

High-efficiency dust collector, with filter cartridge, after cleaning the dust consistency can not over 50mg/m3, sure keep the environment clean.

https://www.qdbhmachinery.com/products/hook-type-shot-blasting-machine/

0 notes

Text

Shot Blasting

BH offers various industrial abrasive blasting equipment and parts to customers from all over the world. More than 2000 active customers domestic and abroad prove the ability of shot blasting to deliver the right solution.

Shot Blasting Machine

BH offers various shot blasting machines and parts to customers from all over the world. More than 2000 active customers domestic and abroad prove the ability of shot blasting to deliver the right...

Shot Blasting Room

Shot blasting room well applied to a variety of industries which requires surface preparation and the application of a protective coating. Types of Sand Blasting Machine including Sand Blasting Cabinet, Container Blast Room, Automatic Sand Blasting Machines, all are not expensive but with high quality.

Dust Collector

Dust collector, called a dust collector or dust removal equipment, plays a role in filtering out dusts produced by the flue gas. Dust caused by flue gas could have bad influence on workers' health needed to be clean by dust collector.

https://www.qdbhmachinery.com/products/

0 notes

Text

H Beam Shot Blasting Machine

This series belongs to roller shot blasting machine, mainly used for buildings, bridges and other industries with large I-beam, H-beam steel structure such as size pieces of high stress and the elimination of cleaning the surface rust.

Specification of H Beam Shot Blasting Machine

Features of H Beam Shot Blasting Machine

Clean surface rust

Improve corrosion resistance

Improve anti-fatigue performance

Extend steel service lifetime

Make the steel surface craft performance

Remove Internal stress

Reduce labor intensity

https://www.qdbhmachinery.com/products/h-beam-shot-blasting-machine.html

0 notes

Text

Floor Shot Blaster

The Floor shot blasting machine for sale is the shot blasting machine that ejects the shot material (steel shot or sand) at a high speed and a certain angle onto the working surface through a mechanical method.

The shot material fully impacts the working surface to achieve the rough surface and remove residues. At the same time, the negative pressure generated by the dust collector will clean the pellets and the cleaned impurity dust, etc. after the airflow, the intact pellets will be automatically recycled, and the impurities and dust will fall into the dust collection box.

Specification of Floor Shot Blaster

Advantages of Floor Shot Blaster

A high degree of automation, can climb and walk, and the used shot materials can be recycled.

No pollution, this kind of movable type industrial shot blasting machine is equipped with a dust collector, and the dust can be recovered for purification treatment.

Low energy consumption, will greatly reduce the loss cost for enterprises every year.

More convenient, walkable, reasonable and compact design, small footprint, can be taken to the construction site at any time.

Low investment, the investment capital is one-tenth of the traditional investment.

High efficiency. For example, just 550 type, it can clean 260㎡ per hour, SA2.5 level or above.

Application of Floor Shot Blaster

Environmentally friendly products specially developed for various road construction and maintenance, can be dust-free, pollution-free, and the pellets can be automatically recycled during construction operations.

It can be widely used for waterproofing and roughening of concrete bridge deck; cleaning and roughening of asphalt pavement to increase surface roughness; restoration of anti-skid performance of pavement, tunnel and bridge; clearing of asphalt pavement; cleaning of marking line; Anti-corrosion coating treatment; airport road glue and line removal.

Working Principle of Floor Shot Blaster

The Floor blasting machine also called a “movable type" shot blasting machine. It is the floor shot blasting machine that ejects the shot material (steel shot or sand) at a high speed and a certain angle onto the working surface through a mechanical method.

The shot material of the floor blasting equipment fully impacts the working surface to achieve the rough surface and remove residues.

At the same time, the negative pressure generated by the dust collector will clean the pellets and the cleaned impurity dust, etc. after the airflow, the intact pellets will be automatically recycled, and the impurities and dust will fall into the dust collection box.

Main Components of Floor Shot Blaster

Motor, soft starter, frequency converter, imported high-speed bearings, etc .;

Wear-resistant materials are used for the relevant parts of the shot blasting chamber to ensure the service life of the shot blasting chamber.

The wearing parts such as Impeller heads and directional sleeves are precision cast with wear-resistant materials, and life is close to imported parts.

Equipped with steel shot collecting trolley, steel shot or granular steel can be recovered in one second. And this trolley doesn’t need power consumption. (using magnet)

https://www.qdbhmachinery.com/products/floor-shot-blaster/

0 notes

Text

Dust Collector

Shot blasting of casts, forged and pressed parts, remodeled cold or hot, of various complicated forms, springs, etc. (load capacities ranging up to Shot blasting of casts, forged and pressed part, remodeled cold or hot, of various complicated forms, springs, etc.)

Advantages of Dust Collector

High dust removal efficiency: the pulse reverse blow type industrial abrasive blasting dust collector adopts the sub-room stop wind pulse spray dust cleaning technology, and the cleaning efficiency is higher improved the operating conditions of bag changing: the pulse back-blowing dust collector adopts the upper bag drawing method. After the skeleton is drawn out when the bag is changed, the dirty bag is put into the lower part of the box.

Good sealing: The box body is designed with airtightness, good sealing, and the door is made of excellent sealing materials. During the production process, it is detected by kerosene.

Reduced energy consumption for dust cleaning: Since the pulse-reverse-type dust collector for shot blasting adopts the sub-chamber air-stop pulse spraying for dust cleaning, the purpose of complete dust cleaning can be achieved by blowing once, so the dust cleaning cycle is prolonged and the energy consumption for dust cleaning is reduced.

The long life of the filter bag: overhauling and replacing the bag can be carried out in separate rooms under the normal operating conditions of the system fan. The filter bag mouth adopts an elastic expansion ring, which has good sealing performance, firm and reliable. The filter bag keel adopts polygonal shape, which reduces the friction between the bag and the keel, prolongs the life of the bag, and is convenient for unloading the bag.

Improved bag-changing operating conditions: the pulse backflushing dust collector for shot blasting adopts the upper bag-drawing method. After the bag is withdrawn, the dirty bag is put into the ash hopper at the bottom of the box and taken out through the manhole, which improves the bag-changing operating conditions.

Good air tightness: The airtight design of the box body, good airtightness, excellent sealing material for inspection doors, kerosene leak detection during production, the low air leakage rate

It separates the dust from the flue gas is called a dust collector or dust removal equipment. The role of the dust collector will be to filter out the dust. For example, in coal mines, some coal powder will appear during construction. For construction workers, the dust will have a great impact on their bodies, and may also explode. The dust can be filtered out by the dust collector.

Vibrating bag dust collector and pulse dust collector are two commonly used dust collectors for shot blasting.

Comprehensive Comparison of Mechanical Vibration Dust Collector and Pulse Reverse Dust Collector

Mechanical vibrating bag dust collector is generally used for working conditions where the air volume for dust removal is not large and the atmospheric emission requirements are not high. It is a more traditional method of dust removal. One time. Its advantages are small footprint, simple production and installation. During the dust removal process, the dust sticking to the surface of the bag is shaken off by vibrating and sags by gravity.

Pulse back-blowing bag dust collector is used in the working condition with increased dust removal air volume and relatively high atmospheric emission requirements. It is the most widely used dust removal method at present. Use, the bag has special skeleton support, the dust on the surface of the bag is back blown by compressed air, the intake pipe has a special venturi, a special back blowing channel, a pulse controller and a pulse control valve to control the back blowing time and beat , Dust sticking to the surface of the cloth bag is combined with gravity to fall down by blowing back. It has the advantages of high dust removal efficiency, obvious dust removal effect, and less dust emission from the atmosphere; the disadvantage is that the area is slightly larger and the cost is slightly higher.

The principle of the pulse reverse filter cartridge dust collector is the same as that of the pulse reverse bag filter, except that the filter material is the filter cartridge. The filter cartridge is pleated and has a skeleton, so it has a larger filtration area and a smaller volume, The overall cost is not much different from the pulse blowback bag filter. The advantages are: the volume and shape of the equipment are slightly smaller, and the transportation and installation are convenient. It is mostly used in the steel structure industry and workshops, grinding and dust removal industries. If it is used in the casting and forging industry, it needs to be equipped with a cyclone dust collector for primary filtration. The disadvantage is that the cost of replacing a single filter cartridge is slightly higher, but the overall price and the price of the pulse bag filter are moderate

Pulse cleaning cartridge filter and bag filter pulse cleaning principle, in that it is a cartridge filter material, the filter cartridge is due to the fold-shaped, with its own frame, so compared to the filter area, small overall cost and pulse cleaning bag filter is not very different. Advantages are: the volume of the device is slightly smaller form factor, easy to transport and install. Used for the steel industry and workshop, grinding dust and other industries, such as casting and forging industry uses front Cyclones need to be equipped with a preliminary filter. The disadvantages are: single filter cartridge replacement cost is slightly higher, but moderate overall price and pulse bag filter Price

https://www.qdbhmachinery.com/products/dust-collector.html

0 notes

Text

Automatic Molding Machine

Specification of Automatic Molding Machine

Type

BHSD7060

Sand shooting way

From bottom

Sand shooting direction

LEVEL

Productivity

80-400box/hour

Advantages of Automatic Molding Machine

flaskless molding operation

Horizontal or vertical type under customer-tailored, convenient for the core

Fully automatic modeling, one-button operation, no professional workers

Mold hardness: can be adjusted according to different casting requirements, up to 85-90 degrees

The height of the mold is adjustable, saving sand

The mold quality is constant and uniform

With advanced light curtain safety protection device

Sand mold size: 510*610mm, or customized

https://www.qdbhmachinery.com/other-products/automatic-molding-machine.html

1 note

·

View note