Don't wanna be here? Send us removal request.

Text

Top TPM Software Solutions: A Comparative Analysis

Total Productive Maintenance (TPM) is a holistic approach to equipment maintenance, aiming to optimize production processes and minimize downtime. With the growing importance of TPM in today's competitive environment, organizations are increasingly seeking software solutions to manage and streamline their maintenance activities. In this comprehensive analysis, we'll explore the top TPM software solutions available in the market, comparing their features, benefits, and pricing to help you make an informed decision.

Maintenance Connection:

Maintenance Connection is a leading TPM software solution that offers a wide range of features to help organizations manage their preventive and predictive maintenance activities. Its user-friendly interface enables seamless collaboration among all stakeholders involved in total productive maintenance. Some of its key features include:

Asset management: Track equipment history, schedule maintenance, and monitor the lifecycle of assets.

Work order management: Create, assign, and track work orders with ease.

Preventive maintenance: Automate the scheduling of routine maintenance tasks to minimize downtime.

Inventory control: Manage spare parts inventory and streamline the procurement process.

Customizable reporting: Generate detailed reports to gain insights into maintenance performance and costs.

Pricing: Maintenance Connection offers a quote-based pricing model, tailored to the specific needs of each organization.

Fiix Software:

Fiix Software is a cloud-based TPM software solution that focuses on asset management, work order tracking, and inventory control. Its robust feature set and real-time analytics capabilities enable data-driven decision-making for optimal equipment performance. Some of its standout features include:

Mobile app: Access critical maintenance data and manage work orders on-the-go.

Integration: Seamlessly integrate with other enterprise systems such as ERP and EAM.

Predictive maintenance: Leverage machine learning to predict equipment failures and schedule maintenance accordingly.

Customizable dashboard: Monitor key performance indicators (KPIs) and gain insights into your maintenance operations.

Compliance management: Ensure adherence to regulatory requirements and industry standards.

Pricing: Fiix Software offers a tiered subscription model, with plans starting at $45 per user per month.

eMaint CMMS:

eMaint CMMS is a versatile, cloud-based TPM software solution that offers a wide range of features for managing equipment maintenance processes. With its customizable dashboards and automated work order generation, eMaint CMMS caters to organizations of all sizes and industries. Key features of eMaint CMMS include:

Preventive maintenance scheduling: Automate the scheduling of maintenance tasks and ensure timely completion.

Work order management: Streamline the process of creating, assigning, and tracking work orders.

Asset tracking: Keep track of equipment data, maintenance history, and warranty information.

Document management: Store and organize equipment manuals, maintenance procedures, and safety guidelines.

Inventory management: Manage spare parts inventory and optimize procurement processes.

Pricing: eMaint CMMS offers a tiered subscription model, with plans starting at $33 per user per month.

UpKeep:

UpKeep is a mobile-first TPM software solution designed to simplify maintenance management for teams of all sizes. Its intuitive interface and powerful features make it an ideal choice for organizations looking to improve their total productive maintenance efforts. Some of its core features include:

Mobile app: Manage work orders, track assets, and communicate with team members on-the-go.

Barcode scanning: Quickly and accurately identify assets and inventory items using barcode scanning.

Customizable reporting: Analyze maintenance data and generate reports tailored to your organization's needs.

Predictive maintenance: Utilize data-driven insights to schedule maintenance and prevent equipment failure.

Integrations: Connect with other systems such as accounting and inventory management software.

Pricing: UpKeep offers a tiered subscription model, with plans starting at $35 per user per month.

Hippo CMMS: Hippo CMMS is a comprehensive, user-friendly TPM software solution that caters to various industries, including manufacturing, healthcare, and hospitality. It offers a range of features aimed at simplifying maintenance management and improving overall operational efficiency. Key features of Hippo CMMS include:

Interactive site and floor plans: Visualize asset locations and maintenance data with interactive floor plans.

Work order management: Streamline the creation, assignment, and tracking of work orders.

Preventive maintenance: Automate maintenance scheduling and reduce the risk of equipment failure.

Inventory management: Optimize inventory levels, track spare parts usage, and manage vendor relationships.

Customizable reporting: Generate detailed reports to gain insights into maintenance performance and trends.

Pricing: Hippo CMMS offers a tiered subscription model, with plans starting at $39 per user per month.

Limble CMMS: Limble CMMS is a cloud-based TPM software solution designed to help organizations simplify their maintenance processes, improve communication, and reduce downtime. Its modern, user-friendly interface and powerful features make it an attractive option for businesses of all sizes. Some of the core features of Limble CMMS include:

Mobile app: Access your maintenance data, manage work orders, and receive real-time updates from anywhere.

Asset management: Monitor asset performance, manage warranties, and view maintenance history.

Work order management: Create, assign, and track work orders with ease.

Preventive maintenance: Schedule routine maintenance tasks and monitor their completion.

Customizable reporting: Analyze maintenance data and generate reports to support data-driven decision-making.

Pricing: Limble CMMS offers a tiered subscription model, with plans starting at $40 per user per month.

MPulse CMMS:

MPulse CMMS is a robust TPM software solution that helps organizations streamline their maintenance operations, reduce costs, and improve asset performance. With its extensive feature set and powerful reporting capabilities, MPulse CMMS caters to a wide range of industries. Key features of MPulse CMMS include:

Asset management: Track equipment history, maintenance costs, and lifecycle data.

Work order management: Automate the creation and assignment of work orders, ensuring timely completion.

Preventive maintenance: Schedule routine maintenance tasks and monitor their progress.

Inventory management: Manage spare parts inventory and automate the procurement process.

Customizable reporting: Generate detailed reports to identify trends, inefficiencies, and areas for improvement.

Pricing: MPulse CMMS offers a quote-based pricing model, tailored to the specific needs of each organization.

Conclusion:

Selecting the right TPM software solution is crucial for organizations looking to optimize their total productive maintenance efforts and improve overall operational efficiency. Maintenance Connection, Fiix Software, eMaint CMMS, UpKeep, Hippo CMMS, Limble CMMS, and MPulse CMMS are among the top contenders in the market, each offering unique features and benefits that cater to different organizational needs.

When evaluating TPM software solutions, consider factors such as ease of use, scalability, integration capabilities, and the range of features offered. By carefully assessing your organization's requirements and comparing available options, you can find the right software solution to streamline your maintenance processes and enhance your equipment performance.

0 notes

Photo

Performance management systems help organizations streamline employee evaluations, identify top performers, and set goals for career development. For more info visit : https://www.ribcon.com/performance-management-software/

0 notes

Photo

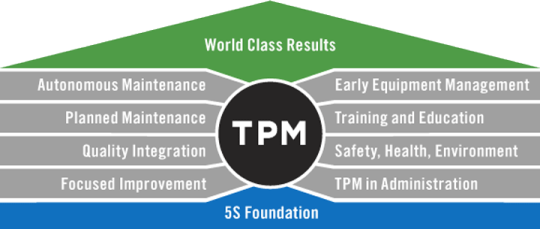

Total productive maintenance is a continuous improvement process that takes place in a plant or facility and includes all activities necessary to ensure maximum effectiveness of the system. The emphasis is on eliminating waste and reducing operating costs by improving efficiency and quality as well as reducing downtime and improving uptime. For more info visit : https://www.ribcon.com/resource-center/total-productive-maintenance/

0 notes

Text

Top Performance Management Software for Your Business

These top-rated performance management software solutions provide comprehensive tools for managing employee performance. Their features include goal setting, performance tracking, and feedback management. Choose one of these expert software solutions for streamlined performance management, enhanced employee productivity, and better business results.

Source Url: https://www.ribcon.com/performance-management-software/

0 notes

Photo

Performance management systems help organizations streamline employee evaluations, identify top performers, and set goals for career development.

For more info visit : https://www.ribcon.com/performance-management-software/

0 notes

Text

Efficient Employee Management with Performance Management Systems

Performance management systems help organizations streamline employee evaluations, identify top performers, and set goals for career development. With automated review cycles, real-time feedback, and analytics, these systems can increase engagement, productivity, and efficiency. Choose the right system to enhance your organization's performance today.

For more info visit : https://www.ribcon.com/performance-management-software/

0 notes

Photo

Our lean kaizen consulting services by Kaizen consultants in Kaizen consultant India can assist you in achieving savings and increase profits by 25% by eliminating waste and process improvements continuously on journey to excellence. for more info kindly visit : https://www.ribcon.com/services/lean-kaizen-consulting-services/

0 notes

Text

A Brief Introduction to the Kaizen Philosophy

When it comes to business, everything needs to evolve. Whether it is the traditional manufacturing process or the principles of human resource management, the rules need to outpace in the challenging times where hitting the plateau top is not an option.

One such philosophy that is a massive success in the industries is the Kaizen philosophy. Kaizen philosophy does not necessarily mean working on the age-old defined teams and their culture. It is a continuous process where every member of the team plays a pivotal role, whether it is Kaizen HR or Kaizen operations.

So what exactly is Kaizen Philosophy?

The Kaizen (Continuous Improvement) action plan refers to a process in which all the employees of the company work together to achieve increased production efficiency.

The Key Idea - It is a massive incremental process where the growth of each member of the company plays a pivotal role and hence could not be ignored at all costs. To summarize it, it is a collective individual path in which everyone improves the thorough put to get the desired results, that is, increased production capacity.

Steps in the Kaizen Philosophy

The steps in the Kaizen philosophy could be broken down in the following ways.

Set bite-sized, achievable goals, and provide supplementary resources.

Assessment of current state and development of the improvised plan of action.

Implement improvements.

Working together to fix things.

Evaluating results and determine follow-ups

Concluding Remarks

Companies (small or large) need to evolve to survive in the tough marketplace. The principles and ideologies of Kaizen are derived from these and hence could not be ignored at any cost. If implemented rightly, these principles could be game-changer, and hence companies struggle to find efficiencies in the game of manufacturing.

0 notes

Link

0 notes

Link

Lean services have an in-depth history behind in the manufacturing sector. Over the last few decades, The usage of lean has been rapidly increased in the service industry as well.

0 notes

Text

5 reasons why TPM training is beneficial for your manufacturing unit

Corporate environment is broadly establishing the TPM approach to elevate the level and productivity index of their manufactures. The purpose of TPM revolves around raising the asset durability. The usage of this concept results in the elevated efficiency of business, no matter the user is a amateur or well known to this.

So what is Total Productive Maintenance?

A very crucial method of Lean Management, TPM functions in the direction of reduction of malfunction, collisions, and blunders in the production line. The strategy of TPM is based on accomplishment of OEE ( Overall Equipment Effectiveness) in the equipment.

The 3 variables in OEE integrates for its formulation -Performance x Availability x Quality = OEE.

Presented underneath are gains of TPM-

•Increased Equipment Performance - The autonomous maintenance of their equipment by each and every employee brings the dysfunction to 0 %. The quicker availability of spare parts essential for care fortifies the individual. Once in a month the machine is required to be maintained and thoroughly tested.

•Expense Reduction- TPM decreases the equipment failures, flaws and other mishaps to 0 %, so that the costing used in these defects is furthermore brought down to 0. The Sound condition of equipment improves the productivity speed and speedier production. Manufacturing costs results in exemption of cost borne in maintenance of breakdown and flaws.

You may like to read How TPM Training impacts manufacturing productivity.

• Quality index - Quality Improvement is known as a pillar of TPM that looks into maintenance of Quality within services areas. Employing TPM brings the Quality development of surroundings.The work environment owing to minimal accidents becomes more secure place to be worked in.

•Customer Satisfaction- Considering the lowered Manufacturing expenses the company is in the position of delivering its customers a greater portion of value products. The complains of consumers are amended with these changes, bringing in more customer forces.

•Minimized Speed loss- It lowers the gap of nonproductive times and minor stoppages attributable to operator-maintenance interfacing and lower pace of output production.

There comes great number of benefits with the application of TPM. The obligation of employees raises with the maintenance of their hardware, this generates the confidence amongst employees. This strategy is quite useful in relation to equipment productivity, saving time and cost reduction.

Any organization entity considering the objective of maximizing business effectivity and continuous improvement must bring in the TPM strategy to their work premises, or could also hire the TPM consultant.

0 notes

Text

Implementation of TPM In Production

Total productive Maintenance or TPM has developed into trendy technique amidst the business world, when dealing with improving the efficiency and quality index in the firm. This methodology functions with the purpose of improving hardware productiveness in the industry. The use of this concept contributes to the elevated efficiency of business, irrespective of the fact that user is a newbie or familiar to this.

What is TPM?

TPM serves as a tool of Lean Management employed to pull the malfunctions, accidents and defects percentage to minimal. TPM works round accomplishing Overall Equipment Effectiveness (OEE) of plant machines. OEE can be achieved by these three factors- -Performance x Availability x Quality = OEE.

Let’s go through the benefits of TPM -

• Enhanced Asset efficiency-

The elevated efficacy and lessened breakdown of tools is the outcome of autonomous maintenance by employees. The supply of spare parts, components are swift, this enhances the employees help responsible for their machines. Once in a month the Equipment must be repaired and thoroughly checked.

• Reduction in Cost-

The minimised frequency of accidents and flaws in the equipment helps save the cost of correcting those problem areas. The Good condition of equipment improves the productivity pace and quicker production. The part of Manufacturing cost incurred in rectification of damages and complete breakdowns is now conserved.

You may also like to read things to keep in mind before hiring a tpm consultant.

•Quality Enhancement -

Quality Improvement serves as a pillar of TPM that looks into repair of Quality within work premises. Implementing TPM brings the Quality development of surroundings. TPM makes sure that work environment is safer for their employees with reduced problems

• Happy Consumers-

The aid of less manufacturing costs, firms company in satiation of end user values. Consumers issues are resolved gradually, and this alongside brings in more customer for that company.

• Speed Loss Rectification-

It cuts down on the gap of non-productive times and minor stoppages attributable to operator-maintenance interfacing and lower pace of output production.

TPM approach generates several advantages to company when employed appropriately. The obligation of employees raises with the maintenance of their hardware, this brings in the confidence amongst employees. Equipment productivity, Lessened production time, and expense minimization are some of the word alternatives to TPM strategy.

In order to improve your organization performance, together with constant advancement, individuals must imbibe the TPM approach or also can outsource TPM consultants for business procedures.

0 notes

Link

Hoshin Kanri also known as Strategy deployment helps business leaders identify and focus on strategic objectives that will drive Breakthrough performance, also establishes a disciplined process for achieving those objectives. You can get the help for this software from Ribcon Consulting. Visit https://www.ribcon.com/africa/services/breakthrough-hoshin-kanri/ for more information about Hosin Kanri Software

#Hoshin Kanri#kaizen training program#kaizen continuous improvement#lean management#lean manufacturing system

0 notes

Link

Ribcon Consulting brings innovative cost improvement Kaizen tools to increase profitability. Cost reduction using Lean, TPM & Kaizen tools can be achieved without making investment in any new technologies & machines. To reduce the overall cost, first we must identify and reduce cost of all Non-value adding activities. Visit https://www.ribcon.com/ae/services/cost-reduction/ for more information about cost reduction.

0 notes

Link

Ribcon Consulting provides the training of lean manufacturing through the best consultants of lean manufacturing. Lean Manufacturing consultant plays a major role in change management and implementation of Lean Manufacturing program. Visit https://www.ribcon.com/ae/services/lean-manufacturing-consultants/ for more information about lean manufacturing.

#lean manufacturing training#lean manufacturing consultants#lean management training#lean management consulting

0 notes

Link

RIB specialize in Total Productive Maintenance consulting. Our Total Productive Maintenance consulting is directed towards the goal of zero equipment breakdown and zero product defects, which in turn results in improved utilization of production assets and plant capacity. You Can get best tpm training program from our experts. Visit https://www.ribcon.com/resource-center/total-productive-maintenance/ for more details.

0 notes

Link

You can get the best lean manufacturing consultant In Dubai. Ribcon Consulting provides best lean manufacturing consultants in Dubai. Lean Manufacturing consultant plays a major role in change management and implementation of Lean Manufacturing program. Visit https://www.ribcon.com/ae/services/lean-manufacturing-consultants/ for more information about the consultants.

#lean manufacturing training#lean manufacturing#lean management consulting#lean manufacturing consultants

0 notes