Don't wanna be here? Send us removal request.

Text

Stone Cutting Machines For Sale

Looking for high-quality stone cutting machines for sale? Explore a wide range of precision-engineered machines like the Metro B10, B12, B13, B14, B21, and B30, all designed for optimal stone cutting efficiency and accuracy. Whether you’re working with granite, marble, or other types of stone, we have the perfect machine for your business needs.

Why Choose Our Stone Cutting Machines?

At Shri Bhagwati Machines Pvt Ltd, we pride ourselves in offering an integrated range of stone cutting machines. These machines are thoroughly designed to provide high precision, long durability, and efficiency. Our products work with all types of stones like granite, marble, and quartz, making them highly versatile for small-scale workshops as well as large manufacturing units.

Our stone cutting solutions stand out in the market because of their robust construction and advanced technology. Each machine is built using high-quality materials that are meant to ensure long-lasting performance even under demanding conditions. Innovative designs feature CNC controls and laser technology, which enables the possibility of precise cuts to increase the quality of your finished products.

We understand that cost-effectiveness for our customers is very critical. Therefore, our stone cutting machines not only come with reliable performance but also minimize operating costs through energy efficiency and reduced maintenance requirements. This would make them an ideal investment for any business looking to optimize the production process without compromising the quality.

We are committed to excellence and make certain that solutions are tailored to the specific needs of our clients. From manual stone cutting machines for custom projects to fully automated systems for a high volume of production, we have just the right equipment to give your stone processing the next level it deserves.

Our Top Stone Cutting Machines for Sale

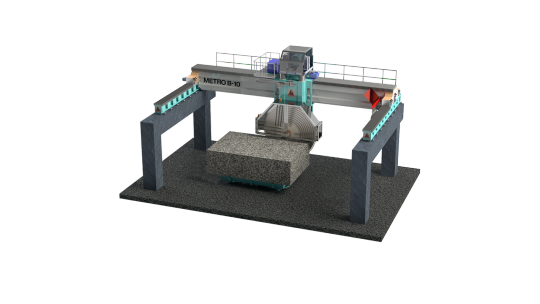

Metro-B10 — Designed for smaller scale operations, the Metro-B10 offers unmatched cutting precision for granite and marble.

Metro-B12 — A versatile machine with advanced features and robust performance for mid-range stone cutting needs.

Metro-B13 — Perfect for large-scale projects, offering high cutting speed and efficiency.

Metro-B14 — A durable machine for precision cutting and high productivity, designed for continuous use in heavy-duty applications.

Metro-B21 — A highly advanced stone cutting solution that integrates automated technology for precise and high-volume production.

Metro-B30 — Our most advanced model, with state-of-the-art technology and high-performance capabilities for the most demanding stone cutting tasks.

Key Features of Our Stone Cutting Machines

High Precision Cutting — Achieve flawless cuts for granite, marble, quartz, and other stone types.

Durable and Long-Lasting — Crafted from high-quality materials to ensure long-term performance.

Affordable Pricing — Cost-effective machines designed to fit within your budget.

Advanced Technology — Featuring CNC controls and laser technology for precise cutting.

High Cutting Speed — Enhance production with faster cutting speeds.

Energy Efficient — Save on operational costs with machines designed to reduce energy consumption.

Robust Build — Durable and heavy-duty construction for long-term reliability in industrial settings.

User-Friendly Interface — Simple control panels that allow for easy operation, even for beginners.

Safety Features — Equipped with multiple safety mechanisms to ensure secure operations.

Applications of Stone Cutting Machines

Marble Processing — Efficiently cuts large marble blocks into slabs of various thicknesses for countertops, flooring, and decorative applications.

Granite Processing — Designed to handle tough granite blocks, producing precision-cut slabs ideal for high-end installations.

Sandstone Cutting — Perfect for slicing sandstone blocks into manageable slabs for construction and landscaping projects.

Quartz Stone Cutting — Specialized machines that cut quartz stone blocks into customized thicknesses for various applications including kitchen countertops.

Custom Thickness Slabs — Our machines are versatile enough to produce slabs in a range of thicknesses tailored to meet specific project requirements.

Ready to upgrade your stone cutting operations? Contact us today at 88549 03444 to get a quote for the best stone cutting machines for sale at affordable prices. We provide machines designed for maximum efficiency and long-lasting performance. Visit us @ https://bhagwatimachines.com

#stone cutting machiens#multiblade cutters#stone block cutting machine#shri bhagwati machines pvt ltd

0 notes

Text

Top Laser Cutting Machines by Indian Manufacturers: Revolutionizing Precision and Performance

Table of Contents

Introduction

Why to Choose Indian-Made Laser Cutting Machines?

Features of the Top Laser Cutting Machines by Indian Manufacturers

Leading Indian Brands Revolutionizing Laser Cutting Technology

How Indian Laser Cutting Machines Compare to International Brands

FAQs

Conclusion

Introduction

India is rapidly establishing itself as a global leader in laser cutting technology, offering innovative and affordable solutions. From metal fabrication to automotive and industrial manufacturing, Indian laser cutting machines are transforming the way industries operate, delivering high precision, speed, and reliability at competitive prices.

This blog dives into the top laser cutting machines produced by Indian manufacturers, their standout features, and how they compare to international brands.

Why to Choose Indian-Made Laser Cutting Machines?

Indian manufacturers are carving a niche in the global market by combining advanced technology with affordability. Here’s why they’re a top choice for businesses:

1. Cost-Effectiveness

Indian laser cutting machines are competitively priced, offering high value without compromising on quality.

2. Cutting-Edge Technology

Incorporating fiber lasers, CNC systems, and IoT integration, Indian machines are equipped with the latest technological advancements.

3. Customizable Solutions

Indian manufacturers excel in offering tailored solutions that cater to diverse industrial needs, from sheet metal cutting to intricate designs.

4. Reliable Support and Maintenance

With localized service centers and responsive customer support, Indian manufacturers ensure smooth operations and minimal downtime.

Features of the Top Laser Cutting Machines by Indian Manufacturers

Indian laser cutting machines are designed to meet the demands of modern manufacturing.

1. High Precision

These machines achieve exceptional accuracy with tolerances, making them ideal for intricate designs.

2. Fast Cutting Speeds

Advanced laser systems enable rapid operations, reducing production time and increasing throughput.

3. Energy Efficiency

Energy-saving designs ensure lower operational costs and support sustainable manufacturing practices.

4. Versatility

They handle a wide variety of materials, including stainless steel, aluminum, brass, and titanium.

5. User-Friendly Interfaces

FAQs

1. What industries benefit the most from laser cutting machines?

Industries such as automotive, aerospace, construction, electronics, and metal fabrication benefit significantly from precision and efficiency in laser cutting.

2. Are Indian-made laser cutting machines durable?

Yes, Indian laser cutting machines are built with robust materials and advanced designs, ensuring long-term durability and reliability.

3. How do I choose the right laser cutting machine?

Consider your material types, required precision, production volume, and budget. Indian manufacturers like Shri Bhagwati Machines Pvt. Ltd. offer tailored solutions to suit your needs.

4. Are Indian laser cutting machines automation-ready?

Absolutely! Many Indian laser cutting machines feature IoT integration, CAD/CAM compatibility, and smart interfaces for automation.

Conclusion

With cutting-edge technology, competitive pricing, and exceptional quality, the top laser cutting machines by Indian manufacturers are transforming industries worldwide.

Get a quote for laser cutting machines — Click Here

0 notes

Text

Granite Cutting Machinery

SEO-optimized suggestion for your blog:https://bhagwatimachines.com/stone-cutting-machines

Table Of Contents

Introduction

Why Invest In Granite Cutting Machinery

Types Of Granite Cutting Machinery

Bridge Saw Machine

CNC Stone Cutting Machine

Block Cutting Machine

Single-Blade Block Cutting Machine

Multi-Blade Block Cutting Machine

Bridge Type Block Cutting Machine

Why Choose Shri Bhagwati Machines Pvt. Ltd.

Tips For Maintaining Your Granite Cutting Machinery

Frequently Asked Questions

Conclusion

Introduction

Granite is one of the most durable and versatile natural stones used in construction and design, ranging from kitchen countertops to monumental sculptures. To meet the growing demand for granite products, it’s crucial to have the right equipment for efficient and precise cutting. This is where granite-cutting machinery plays a pivotal role. At Shri Bhagwati Machines Pvt. Ltd., we specialize in providing high-quality, reliable, and innovative granite-cutting machinery designed to boost productivity and ensure precision in every cut.

Why Invest in Granite Cutting Machinery?

Granite cutting is an intricate process that demands accuracy, efficiency, and specialized tools. Manual cutting can be slow, imprecise, and labor-intensive, which is why granite-cutting machinery is a game-changer. These advanced machines not only enhance the speed and quality of the cutting process but also reduce labor costs and material wastage.

Here’s why investing in the right granite-cutting machinery is essential for businesses in the stone industry:

Precision and Accuracy: Modern single-blade and multi-blade granite cutting machines deliver precise cuts, ensuring that every piece fits perfectly. Whether it’s a countertop, tile, or large slab, accuracy is key to avoiding wastage and ensuring high-quality finishes.

Time Efficiency: Granite cutting machinery significantly speeds up production time. This increased efficiency helps businesses meet demand more quickly, saving time and improving overall productivity.

Versatility: These machines can handle different types of granite and other stones, allowing for various applications, from decorative pieces to architectural slabs.

Cost-Effectiveness: Although the initial investment may seem high, the long-term benefits of using automated cutting machinery, such as reduced wastage and higher production rates, make it a cost-effective solution.

Types of Granite Cutting Machinery

At Shri Bhagwati Machines Pvt. Ltd., we offer a range of granite-cutting machines, each designed to cater to specific needs in the stone industry. Here’s an overview of some popular types of granite-cutting machinery:

1. Bridge Saw Machines

Bridge saw machines are the most commonly used for cutting large granite slabs. These machines are designed to make straight, precise cuts across the stone. With the ability to adjust the cutting angle, these machines offer versatility and precision, making them ideal for both straight and curved cuts.

Key Features:

High-speed cutting

Precision cutting for large slabs

Adjustable cutting angles

User-friendly controls

2. CNC Stone Cutting Machines

CNC granite-cutting machines use advanced technology to execute highly detailed and precise cuts. They are ideal for businesses that require intricate designs, such as engraving or custom shapes, in their granite products.

Key Features:

Automated operation

High-precision cuts

Ability to create complex designs

Increased production efficiency

3. Laser Cutting Machines

Laser cutting technology uses a high-powered laser beam to cut through hard granite surfaces with precision. This method is ideal for creating intricate shapes and fine details in granite, offering a clean cut without physical contact with the material. The focused laser beam ensures minimal material wastage and no heat distortion, making it a popular choice for complex, high-precision cutting tasks.

Key Features:

No Heat Distortion: The laser cutting process minimizes the heat-affected zone, preventing any warping or cracking that could occur with other methods.

High Precision for Complex Designs: Laser cutting is ideal for creating intricate patterns and detailed designs with unparalleled accuracy.

Eco-Friendly with Minimal Material Wastage: The precision of the laser ensures minimal waste, making it an environmentally-friendly choice for stone cutting.

Suitable for Cutting Both Thick and Thin Granite Slabs: Laser cutting machines can handle various granite thicknesses, providing consistent, high-quality cuts for both thin tiles and thick slabs.

4. Block Cutting Machines

Shri Bhagwati Machines Pvt. Ltd. (SBMPL) is known for manufacturing a wide range of stone-processing machinery, including block-cutting machines used in the marble, granite, and stone industries. These machines are essential for cutting large stone blocks into smaller, uniform slabs with precision.

Here are some of the types of block-cutting machines offered by Shri Bhagwati Machines Pvt. Ltd. (SBMPL):

Single-Blade Block Cutting Machine

Description: These machines use a diamond wire to cut stone blocks, offering superior performance, precision, and smooth finishes. Diamond wire cutting machines are suitable for delicate cuts and high-quality stone, offering smoother edges with less wastage.

Features:

Diamond wire cutting for smooth and precise finishes

Ideal for cutting fragile or high-value stones

Low material wastage

Suitable for both horizontal and vertical cuts

Reduced cutting stress on the stone

Multi-Blade Block Cutting Machines

Description: Multi-blade block cutting machines allow for the simultaneous cutting of multiple slabs from a single stone block. This machine significantly reduces the time taken to process large stone blocks and is ideal for high-volume production.

Features:

Multiple blades for simultaneous cutting

Increased cutting speed for higher productivity

Ideal for large stone blocks

Can be used for both granite and marble

Precise and uniform slabs

c. Bridge Type Block Cutting Machines

Description: The bridge-type block-cutting machine has a bridge-like structure with a blade that moves along a horizontal beam. This design is ideal for the precise cutting of large stone blocks, ensuring smooth cuts and high-quality slabs.

Features:

Horizontal cutting system with high precision

Suitable for both granite and marble blocks

Can cut large stone blocks with minimal material loss

Robust construction for heavy-duty operations

Capable of making vertical and horizontal cuts

Why Choose Shri Bhagwati Machines Pvt. Ltd.?

At Shri Bhagwati Machines Pvt. Ltd., we understand the unique requirements of the granite industry. Based in Ajmer, Rajasthan, we’ve been providing premium granite-cutting machinery for over 30 Years. Our machinery is known for its precision, reliability, and durability, making us a trusted partner for stone businesses across India.

Here’s why we stand out:

High-Quality Machinery: We offer only the best-in-class granite cutting machines that meet international standards, ensuring superior quality and performance.

Customization: Whether you need a bridge saw machine or a CNC cutting system, we provide customized solutions to match your unique requirements.

Expertise: With years of industry experience, our team of experts is equipped to provide comprehensive support, from machine selection to after-sales service.

Affordable Pricing: We offer competitive pricing, ensuring that you get the best value for your investment in granite-cutting machinery.

Customer Support: We’re committed to providing excellent customer support. From installation to maintenance, we ensure your machinery operates smoothly for years to come.

Tips for Maintaining Your Granite Cutting Machinery

To get the most out of your granite-cutting machinery, regular maintenance is key. Here are some essential maintenance tips:

Regular Cleaning: Keep the machinery clean to avoid any dirt or debris buildup that may affect its performance.

Inspect Cutting Blades: Check the condition of cutting blades regularly and replace them when necessary to ensure smooth and precise cuts.

Lubrication: Ensure that all moving parts are adequately lubricated to prevent wear and tear.

Monitor Calibration: Regularly calibrate your machine to ensure precision and accuracy in cuts.

Frequently Asked Questions

1. What are the benefits of investing in granite-cutting machinery?

Investing in granite-cutting machinery improves precision, increases production speed, reduces material wastage, and cuts labor costs. It also ensures a high-quality finish, making it an essential tool for businesses in the stone industry.

2. How does granite-cutting machinery improve time efficiency?

Granite cutting machines speed up the production process by automating cutting tasks, which allows businesses to meet higher demand quickly while maintaining accuracy and reducing manual labor.

3. What types of granite-cutting machinery are available?

Popular types of granite cutting machinery include Bridge Saw Machines, CNC Stone Cutting Machines, Laser Cutting Machines, and Block Cutting Machines, each offering specialized features for different cutting needs.

4. Why is precision important in granite cutting?

Precision ensures accurate cuts that reduce material wastage and prevent errors, which leads to better product quality, smoother edges, and a more efficient cutting process.

5. How do CNC stone-cutting machines work?

CNC stone-cutting machines use advanced computerized controls to execute highly detailed cuts with high precision, making them ideal for intricate designs and custom shapes.

6. What is the difference between Bridge Saw and CNC granite cutting machines?

Bridge Saw Machines are designed for cutting large granite slabs with high-speed precision, while CNC Machines use automated controls to create intricate designs and custom shapes with extreme accuracy.

7. What are the advantages of laser-cutting machines for granite?

Laser-cutting machines offer high precision, minimal heat distortion, and reduced material wastage, making them ideal for cutting complex shapes and fine details in granite.

8. How do block-cutting machines improve granite processing?

Block-cutting machines, such as automatic and hydraulic models, efficiently cut large stone blocks into smaller, uniform slabs, reducing labor costs and increasing production efficiency.

9. What is the role of multi-blade block-cutting machines?

Multi-blade block cutting machines allow for simultaneous cutting of multiple slabs, significantly reducing processing time and increasing productivity for high-volume production.

10. Why should I choose Shri Bhagwati Machines Pvt. Ltd. for granite cutting machinery?

Shri Bhagwati Machines Pvt. Ltd. offers high-quality, customizable granite-cutting machines with over 30 years of experience in the industry. Their machinery is known for its precision, reliability, and affordability, backed by expert support and service.

Conclusion

Granite-cutting machinery is an essential investment for any business involved in the granite processing industry. At Shri Bhagwati Machines Pvt. Ltd., we provide state-of-the-art machines that offer exceptional performance, precision, and efficiency. Whether you are looking for a reliable bridge saw, a versatile CNC machine, or a water jet-cutting solution, we have the right equipment to meet your needs.

Located in Ajmer, Rajasthan, we are dedicated to helping you optimize your granite-cutting operations, reduce wastage, and enhance the quality of your products. Get in touch with us today to explore our range of granite-cutting machinery and find the perfect solution for your business.

Ready to take your granite cutting operations to the next level? Contact Shri Bhagwati Machines Pvt. Ltd. today to learn more about our advanced granite cutting machinery and how we can help your business thrive.

Visit us at https://bhagwatimachines.com or call +91 88549 03444 for inquiries and personalized consultations.

Stone Cutting Machiness

Granite Cutting Machines

Bridge Cutter Machines

Block Cutting Machines

0 notes

Text

Shri Bhagwati Machines Pvt . ltd . : Excellence in Stone Cutting Machinery Manufacturing

I. Introduction

- Brief overview of Shri Bhagwati Machines Private Limited

SBMPL is India's leading manufacturer and exporter of high-quality stone block-cutting machinery. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted name in the industry. Specializing in the production of a wide range of stone-cutting machines, Shri Bhagwati Machines Pvt. Ltd is committed to delivering reliable and efficient solutions to meet the diverse needs of its clients.

The company's manufacturing facility is located in Ajmer, Rajasthan, India, where it operates a state-of-the-art manufacturing facility equipped with cutting-edge technology and a team of skilled professionals. This strategic location allows Shri Bhagwati Machines Pvt. Ltd to efficiently serve both domestic and international markets, ensuring timely delivery of its products and services. Additionally, the company's proximity to key transportation hubs enables seamless logistics operations, further enhancing its reputation for reliability and customer satisfaction.

- Industry focus: Manufacturing and machinery

One of the key reasons for Shri Bhagwati Machines Pvt. Ltd success in the manufacturing and machinery industry is its unwavering commitment to quality and innovation. The company continuously invests in research and development to stay ahead of market trends and meet the evolving needs of its customers. By prioritizing customer satisfaction and delivering high-quality products, Shri Bhagwati Machines Pvt. Ltd has established itself as a trusted leader in the industry.

II. Company Background

- Established in 1995

SBMPL has built a strong reputation for reliability and excellence in the manufacturing and machinery sector. With a history of innovation and a dedication to meeting the needs of its customers, the company has grown steadily since its establishment. Through strategic partnerships and a focus on continuous improvement, Shri Bhagwati Machines Pvt. Ltd has become a go-to provider for cutting-edge stone block cutting and polishing machinery solutions.

- Specializes in the production of granite, marble, sandstone, quartz cutting machinery

SBMPL has established itself as a leader in the industry. The company's commitment to quality and customer satisfaction has set it apart from competitors, earning it a loyal customer base. With a team of skilled engineers and technicians, Shri Bhagwati Machines Pvt. Ltd continues to push the boundaries of innovation in the machinery manufacturing sector. The company's dedication to excellence and continuous improvement ensures that it remains at the forefront of the industry, delivering cutting-edge machinery solutions to meet the evolving needs of its clients.

- Strong reputation in the industry for quality and reliability

It has allowed SBMPL to expand its reach globally, establishing partnerships with leading companies in various sectors. The company's state-of-the-art facilities and advanced technology enable it to deliver custom solutions that exceed customer expectations. By staying ahead of industry trends and investing in research and development, Shri Bhagwati Machines Pvt. Ltd remains a trusted partner for businesses looking to enhance their operations and stay competitive in the market.

III. Company Values and Mission

- Commitment to customer satisfaction

At the heart of Shri Bhagwati Machines Pvt. Ltd. lies a strong commitment to continuous excellence. The company is passionate about delivering exceptional service and innovative solutions tailored to each client's unique needs. With a focus on nurturing long-term relationships, SBMPL aims to be the trusted partner for businesses in search of reliable and efficient manufacturing solutions. Their mission is not just about providing high-quality products; it’s also about driving success for their customers while upholding values of sustainability and social responsibility. By fostering a culture of excellence, Shri Bhagwati Machines ensures that they are always striving to exceed expectations and contribute positively to the communities they serve.

- Emphasis on innovation and continuous improvement

Continuous Improvement & Innovation is at the core of Shri Bhagwati Machines Pvt. Ltd approach to business. By staying ahead of industry trends and constantly seeking ways to enhance their offerings, the company ensures that they are always providing the most cutting-edge solutions to their clients. This dedication to innovation not only sets them apart from their competitors, but also allows them to consistently exceed customer expectations and drive positive results. In addition, SBMPL places a strong emphasis on continuous improvement, constantly seeking feedback from clients and employees to identify areas for growth and refinement. By fostering a culture of learning and adaptation, the company remains agile and responsive to the ever-evolving needs of the market, ensuring that they are always at the forefront of industry advancements.

- Dedication to ethical business practices

Ethical business practices and a commitment to sustainability further distinguish SBMPL as a leader in their field. The company upholds high standards of integrity in all their dealings, building trust and long-lasting relationships with both customers and partners. By prioritizing environmentally friendly practices and reducing their carbon footprint, Shri Bhagwati Machines Pvt. Ltd. demonstrates their dedication to social responsibility and a sustainable future.

IV. Products and Services

- Range of stone cutting and polishing machinery and equipment offered

SBMPL includes state-of-the-art stone-cutting and polishing machines. These products are designed with precision engineering and cutting-edge technology to ensure optimal performance and efficiency. In addition to their machinery, Shri Bhagwati Machines Pvt Ltd also offers a range of services such as installation, training, and maintenance to support their customers throughout the lifecycle of their equipment. Their commitment to quality and satisfaction is evident in every product and service they provide, making them a trusted partner for businesses in the marble, granite, natural stone, quartz, sandstone, and cnc cutting industries.

Here are some popular models of stone multi-cutters and line polishing machines offered by Shri Bhagwati Machines Pvt. Ltd.:-

Stone Multicutters

SBMPL Metro B10

SBMPL Metro B12

SBMPL Metro B13

SBMPL Metro B14

SBMPL Metro B21

SBMPL Metro B30

Line Polishing Machines

1. LPM 1300-96

2. LPM 1300-126

3. LPM 1300-166

4. LPM 1300-206

5. LPM 1600-96

6. LPM 1600-126

7. LPM 1600-166

8. LPM 2200-166

9. LPM 2200-216

- After-sales service and support for customers

It is also a top priority for Shri Bhagwati Machines Pvt. Ltd. We offer comprehensive maintenance programs and technical assistance to ensure that our equipment continues to perform at optimal levels. Additionally, our customer service team is available around the clock to address any issues or concerns that may arise. This commitment to customer satisfaction sets Shri Bhagwati Machines Pvt Ltd apart from the competitors and solidifies its reputation as a trusted partner in the stone block cutting and marble and granite slab polishing industry.

V. Market Presence

- Client base includes domestic and international customers

Shri Bhagwati Machines Pvt. Ltd. has established a solid reputation for delivering high-quality stone-cutting solutions that meet the specific needs and requirements of their diverse clientele. The innovative approach to product development and commitment to customer satisfaction has helped them build long-lasting relationships with clients around the world. With a growing market presence and a dedication to excellence, SBMPL is well-positioned to continue leading the way in the stone-cutting and polishing industry for years to come.

- Strong distribution network across regions

It allowed Shri Bhagwati Machines Pvt. Ltd. to reach customers in every corner of the globe. The company ensures that their products are readily available and easily accessible to clients in various markets. This extensive distribution network not only expands their reach but also strengthens its reputation as a trusted and dependable stone-cutting and polishing solutions provider. As a result, SBMPL. has been able to consistently meet the growing demands of its customers and maintain its position as a leader in the industry.

- Participation in industry events and trade shows

The continuous participation in all stone-cutting machinery events has also played a crucial role in solidifying SBMPL's presence in the market. By showcasing its innovative products and networking with industry professionals at these events, the company has been able to stay ahead of the competition and stay informed about the latest trends and developments in the stone-cutting and polishing industry. This proactive approach to industry engagement has not only helped them stay relevant in a rapidly evolving market but has also allowed them to establish valuable partnerships and collaborations with other key players in the industry. In addition, their participation in trade shows has provided them with a platform to launch new products, generate buzz, and attract potential customers, further contributing to their success and growth.

VI. Future Plans and Growth Strategies

- Expansion of product line

SBMPL is continuously expanding to meet the increasing demand for sustainable stone-cutting solutions is a key focus for the company moving forward. By investing in research and development. Additionally, plan to explore new markets and territories, leveraging their existing partnerships and networks to expand their reach and customer base. Collaborating with like-minded businesses and organizations to promote sustainability and social responsibility will also be a priority as they continue to grow and evolve in the stone-cutting and polishing industry.

- Investment in technology and infrastructure

By modernizing the operations and implementing cutting-edge solutions, the company can improve efficiency. This strategic approach will not only benefit the company's bottom line but also help customers for future generations. Additionally, fostering a culture of innovation and continuous improvement among employees will be essential for driving success and staying ahead of the curve in the ever-evolving stone-cutting industry.

VII. Conclusion

- Recap of Shri Bhagwati Machines Private Limited's key attributes

As Shri Bhagwati Machines Pvt. Ltd continues to prioritize innovative initiatives, it will not only benefit the stone-cutting and polishing industry but also strengthen its brand and attract consumers. By setting ambitious goals, implementing effective monitoring and reporting systems, and engaging with customers, the company can truly make a positive impact and lead by example in the industry.Shri Bhagwati Machines Pvt. Ltd is well-positioned to embrace this shift towards innovation and reap the rewards of a more responsible and ethical approach to business.

- Emphasis on the company's commitment to excellence

Shri Bhagwati Machines Pvt. Ltd has always prided itself on its commitment to excellence in all aspects of its operations. This dedication to quality and innovation has set the company apart in the industry, earning it a reputation as a leader in its field. As the company looks towards the future, it recognizes the importance of not only maintaining its high standards of excellence but also of embracing a more sustainable and ethical approach to business. By prioritizing corporate social responsibility, Shri Bhagwati Machines Private Limited can further solidify its position as a forward-thinking and responsible industry leader.

Frequently Asked Questions

1. What type of machines does Shri Bhagwati Machines Pvt. Ltd. manufacture?

Answer: SBMPL specializes in manufacturing a wide range of stone processing machines, including block cutting machines, slab polishing machines, cnc machines, laser cutting machines, cranes, and other stone cutting and polishing machines for marble, granite, and stone industries. They also manufacture different types of Cranes, laser cutting machines, press brakes, and laser cutting machines.

2. Do you offer fully automatic block-cutting machines?

Answer: Yes, SBMPL offers fully automatic block-cutting machines. The automatic machines are ideal for high-volume production and are even suited for smaller-scale operations or budget-conscious clients.

3. What are the key features of your block-cutting machines?

Answer: SBMPL block-cutting machines are known for their precision, durability, and ease of use. Key features include hydraulic lifting mechanisms, high cutting capacity, multi-blade configurations, and automated controls for consistency and high-efficiency cutting.

4. How long has Shri Bhagwati Machines Pvt. Ltd. been in the business?

Answer: SBMPL has been in the stone machinery manufacturing business for more than 30 years, establishing a strong reputation for delivering high-quality and reliable equipment to clients in the stone industry.

5. Are your machines customizable for specific production needs?

Answer: Yes, many of our machines can be customized based on customer requirements. We offer flexibility in machine specifications, such as cutting capacity, blade configurations, and other features based on the type of stone or specific project needs.

6. What type of maintenance do your machines require?

Answer: Regular maintenance of SBMPL machines includes checking the cutting blades, cleaning the hydraulic systems, lubricating moving parts, and ensuring that the electrical and automated components are functioning correctly. We also provide maintenance services for our customers.

7. Do your machines come with a warranty?

Answer: Yes, SBMPL offers a warranty on it’s machines, covering defects in material or workmanship. The warranty period depends on the type of machine and the specific agreement with the customer.

8. Can I get spare parts for SBMPL machines?

Answer: Yes, we provide spare parts for all our machines. You can order genuine parts through our service team to ensure that your machinery operates at peak performance.

9. What is the production capacity of your block-cutting machines?

Answer: The production capacity depends on the model and machine configuration. Our automatic block-cutting machines are designed for high-volume production, capable of cutting multiple blocks per day, while manual machines are more suited for lower-volume, smaller-scale operations.

10. Are your machines energy-efficient?

Answer: Yes, SBMPL focuses on producing energy-efficient machines that reduce operational costs and minimize energy consumption. Our automatic machines, in particular, are designed to optimize power usage without compromising performance.

11. Where are SBMPL’s machines manufactured?

Answer: All SBMPL machines are designed and manufactured in India. We use high-quality materials and advanced technology to produce machines that meet international standards.

12. How can I place an order for SBMPL machines?

Answer: You can place an order by contacting our sales team directly via phone, email, or through our website. We will assist you with the product selection, provide a quote, and guide you through the ordering process.

13. Do you export your machines to other countries?

Answer: Yes, SBMPL exports its machines to various countries around the world. We have established a strong presence in international markets, supplying machinery to clients in the stone processing industry globally.

14. What industries do you serve with your machines?

Answer: SBMPL’s machines are primarily used in the marble, granite, and stone industries. We provide machinery for cutting, polishing, and processing various types of natural stones used in construction, flooring, countertops, monuments, and decorative purposes.

15. Can I get a demo of your machines before purchasing?

Answer: Yes, we can arrange a demonstration of our machines at a facility where our machines are already being installed or in our manufacturing facility, depending on location and availability. This allows you to evaluate the machine’s performance firsthand.

16. How do I contact SBMPL for technical support?

Answer: You can contact SBMPL’s technical support team by phone, email, or via our website’s support page. Our team is available to assist with any machine-related issues or queries regarding installation, operation, or maintenance.

17. What sets SBMPL apart from other manufacturers of stone machinery?

Answer: SBMPL stands out for its focus on high-quality, durable machines that are designed to meet the specific needs of the stone processing industry. We offer customized solutions, efficient after-sales support, and a commitment to innovation, ensuring that our machines deliver optimal performance for all types of stone processing.

NOT TO BE USED. Do you provide installation and commissioning services?

Answer: Yes, SBMPL provides installation and commissioning services for all our machinery. Our trained technicians ensure that machines are properly set up and calibrated for optimal performance.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐮𝐬 𝐭𝐨𝐝𝐚𝐲 𝐟𝐨𝐫 𝐚 𝐟𝐫𝐞𝐞 𝐜𝐨𝐧𝐬𝐮𝐥𝐭𝐚𝐭𝐢𝐨𝐧

Send your requirements via WhatsApp using https://wa.me/918854903444Know more about everything we do at Shri Bhagwati Machines Pvt Ltd by visiting: https://bhagwatimachines.com/

0 notes

Text

Understanding Cranes: A Comprehensive Guide for All Types of Cranes

Cranes are essential machinery in various industries, particularly in manufacturing and construction. They play a critical role in lifting, transporting, and arranging heavy objects and machinery. This guide will explore how cranes work, the different types available, and their specific applications, focusing on manufacturers of all types of cranes, including the cranes exclusively manufactured by Shri Bhagwati Machines Pvt. Ltd.

How Do Cranes Work?

Cranes operate on fundamental principles that allow them to lift heavy loads with ease. Here’s a breakdown of the basic operational principles:

1. Mechanical Advantage

Cranes utilize mechanical components such as levers and pulleys to gain a mechanical advantage. This reduces the amount of effort required to lift heavy objects, making it easier for operators to manage large loads.

2. Distribution of Loads

Cranes are designed to distribute weight evenly across their structure. This distribution minimizes structural stress and enhances stability during lifting operations. Key components such as the base, boom, and counterweights work together to maintain balance.

3. Control Systems

Modern cranes are equipped with sophisticated control systems that allow operators to maneuver loads precisely. These systems may include levers, joysticks, or remote controls, enabling smooth operation even in complex environments.

Types of Cranes and Their Purposes

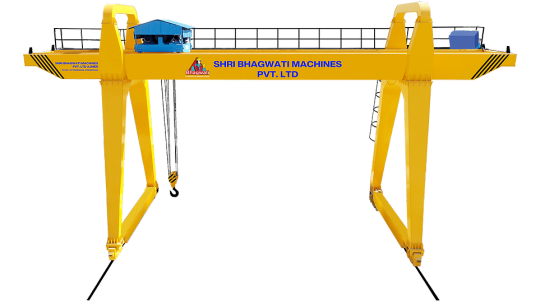

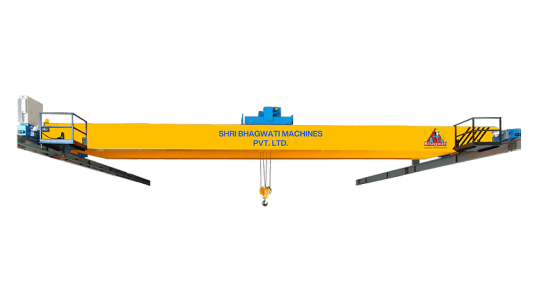

1. Overhead & Gantry Cranes

Shri Bhagwati Machines Pvt. Ltd. is a prominent manufacturer of Electric Overhead Traveling (EOT) cranes, known for their exceptional quality and reliability. EOT cranes are essential in various industrial applications, providing efficient solutions for lifting and transporting heavy loads with ease. Designed to operate on a fixed track, these cranes feature a robust construction that ensures stability and safety during operation. The EOT cranes manufactured by Shri Bhagwati Machines are equipped with advanced control systems, allowing for precise maneuverability and enhanced operational efficiency. Their design maximizes workspace utilization, making them ideal for factories, warehouses, and construction sites. With a commitment to excellence,SBMPL has established itself as a trusted name in the crane industry, delivering high-performance EOT cranes tailored to meet the diverse needs of clients across various sectors.

Visit : https://bhagwatimachines.com/eot-cranes.html

2. Wall Mounted Cranes

SBMPL specializes in manufacturing high-quality wall-mounted cranes, designed to optimize space and enhance efficiency in various industrial settings. These cranes are ideal for environments where floor space is limited, as they utilize overhead areas effectively, allowing for the lifting and moving of loads without occupying valuable ground space.

Visit : https://bhagwatimachines.com/wall-cranes.html

3. JIB Cranes

We are a leading manufacturer of high-quality jib cranes, designed to enhance efficiency and productivity in various industrial applications. Jib cranes are versatile lifting solutions that feature a horizontal arm (jib) mounted on a vertical mast, allowing for flexible load handling within a defined radius.

4. Gantry/Goliath Cranes

We manufacturer high-quality gantry and goliath cranes, designed to meet the diverse needs of various industries. These cranes are essential for lifting and transporting heavy loads, making them invaluable in manufacturing, construction, and logistics.

Visit : https://bhagwatimachines.com/gantry-cranes.html

4. Semi Gantry Cranes

We are a prominent manufacturer of semi-gantry cranes, designed to provide efficient lifting solutions in various industrial applications. These cranes are characterized by their unique design, featuring one leg that runs on a track while the other is fixed to a wall or column. This configuration allows for greater flexibility in confined spaces where traditional gantry cranes may not fit.

Visit : https://bhagwatimachines.com/semi-gantry-cranes.html

5. Additional Crane Types

Mobile Cranes: These cranes offer mobility on job sites and can be driven on highways.

Tower Cranes: Commonly used in urban construction projects due to their height and lifting capacity.

Rough Terrain Cranes: Designed for off-road use with enhanced stability on uneven surfaces.

Crawler Cranes: Feature tracks for mobility and can lift extremely heavy loads.

Floating Cranes: Used in maritime applications for loading and unloading cargo from ships.

Operational Procedures for Planning and Setup

Preoperative Planning: Engineers and operators assess the site, calculate load weights, and plan the lifting procedure to ensure efficiency and safety.

Tower Cranes: Commonly used in urban construction projects due to their height and lifting capacity.

Lifting Procedure: Operators use control systems to raise the load while counterweights help maintain balance

Weight Shifting: Once lifted, the operator carefully moves the load horizontally using the boom or gantry system while ensuring precise synchronization to avoid obstructions.

Positioning: The operator gently lowers the load into place, often guided by signals from ground crew members to ensure accuracy.

Frequently Asked Questions regarding types of manufacturing and construction cranes

How do cranes work? Cranes used in manufacturing and construction are essential for lifting, transporting, and arranging large objects and machinery.

What is the Basic Crane Operation Principles Mechanical Advantage ? Cranes have an edge when lifting large objects because they use mechanical components like hydraulic cylinders, levers, and pulleys. This lowers the amount of work required to move objects.

How cranes helps in Distribution of Loads ? Cranes disperse weight uniformly, reducing structural stress and guaranteeing stability. To balance loads, the base, boom, and counterweights cooperate.

What are System Of Control in Cranes ? Control systems installed on cranes enable operators to precisely move loads. Levers, joysticks and occasionally remote controllers that are manipulated by hand fall under this category.

What are Overhead Cranes ? These tracks-based cranes are commonly observed in production facilities and have the ability to lift and transport objects within a predetermined region. They are very handy when transferring large items between warehouses or assembly lines.

What are wall-mounted Cranes ? ? Wall-mounted cranes serve a specific and valuable purpose in the manufacturing and construction industries. Here’s a detailed overview of their functions and benefits: Wall-mounted cranes allow for lifting and moving loads in areas where floor space is limited. They utilize overhead space, leaving the floor clear for other activities.Their installation against walls helps free up valuable floor space, making them ideal for smaller workshops or factories.

What are JIB Cranes ? Jib cranes are adaptable lifting tools that are frequently utilized in a variety of sectors, such as building, manufacturing, and warehousing. Jib cranes can raise and move big loads both horizontally and vertically, which makes them appropriate for a variety of tasks, including handling commodities and moving industrial parts.

What are the Operating Procedures for Planning and Setup in Manufacturing and Construction ? Engineers and operators arrange the lifting procedure, calculate load weights, and evaluate the site before starting up. Efficiency and safety are guaranteed by a proper setup.

0 notes

Text

The Most Popular Crane Types For Construction And Manufacturing

Because they can lift big objects and equipment to a safe and effective location, cranes are a vital component of the manufacturing and construction sectors. Selecting the ideal crane for your requirements can be made easier if you are aware of the different kinds that are available. The most popular kinds of cranes, such as wall-mounted cranes, jib cranes, semi-gantry cranes, Goliath cranes, EOT cranes, and gantry cranes, will all be covered in this blog.

1. Electric overhead traveling cranes, or EOT cranes

One of the most popular varieties of cranes in manufacturing and construction are EOT cranes. They are intended to run on a system of tracks that are mounted to a factory or workshop ceiling. With these cranes, loads are raised and lowered by a trolley that can move along a bridge that spans the width of the workspace.

Important Characterstics

Versatility: Fit for a range of uses, such as material handling and heavy lifting.

Space Efficiency: Because they run overhead, they maximize floor space.

Precision Control: Accurate and seamless movements are made possible by electric drives.

2. Gantry Cranes

Important Characterstics

Mobility: Able to relocate to new places with ease.

Height Adjustability: Lifting at different heights is possible thanks to adjustable legs.

Economical: Usually less costly than cranes overhead.

3. Goliath Cranes

Important Characterstics

High Load Capacity: Able to move very heavy objects.

Outside Use: Designed to endure outside environments.

Durability: A long service life is guaranteed by a sturdy structure.

4. Semi Gantry Cranes

Semi-gantry cranes are cranes that combine elements of EOT and gantry cranes. They walk on the ground with one leg and sprint along an overhead track with the other. Because to their special design, they can reach places that full gantry cranes cannot, which makes them especially helpful in spaces that are limited in size.

Important Characterstics

Compact Design: Ideal for spaces with little headroom.

Operation Flexibility: Suitable for a range of environments, such as warehouses and workshops.

Simple Installation: Compared to larger cranes, this one is easier to erect.

5. Wall Mounted Cranes

Important Characterstics

Space Efficiency: Preserves important floor area.

Easy to Use: They are easy to use and may be used for a variety of purposes.

Low Maintenance: Compared to larger cranes, these often require less maintenance.

6. JIB Cranes

Important Characterstics

Versatility: Adaptable to different settings (wall, floor, or portable).

Enhanced Reach: Offers a longer reach for activities involving lifting.

Economical Solution: Perfect for workshops or smaller companies.

In Summary

For maximum productivity and safety in your industrial or construction operation, use the appropriate crane. Every kind of crane has particular benefits and is appropriate for a given set of uses. Knowing your alternatives can help you make an informed choice, regardless matter whether you require the flexibility of a jib crane or the enormous lifting capacity of a Goliath crane. To make sure you choose the ideal crane for your purposes, always seek professional advice and bear in mind elements like weight capacity, workspace configuration, and operational requirements. Happy weightlifting! .

0 notes

Text

An Ultimate Guide to Line Polishing Machines

Who We Are

Shri Bhagwati Machines Pvt. Ltd. is a leading manufacturer of industrial machinery and equipment, specializing in the production of high-quality machines for various industries. With a strong commitment to innovation and customer satisfaction, the company has established itself as a trusted name in the market. Their state-of-the-art facilities and team of skilled professionals enable them to deliver cutting-edge solutions that meet the evolving needs of their clients.

What Are Line Polishing Machines

Line polishing machines are one of the key products offered by Shri Bhagwati Machines Pvt. Ltd. These machines are designed to provide a smooth and flawless finish to marble and granite slabs. The company's line polishing machines are known for their precision, efficiency, and durability, making them a popular choice among manufacturers in the industry. By investing in these machines, businesses can enhance the quality of their products and improve their overall production processes.

Importance Of Line Polishing Machines In Various Industries

Line polishing plays a crucial role in various industries, particularly in the marble, granite, and tiles business, where the quality of the finish can significantly impact the aesthetic appeal and durability of the products. At Shri Bhagwati Machines Pvt. Ltd., we understand that a well-polished surface not only enhances the beauty of natural stones but also ensures their longevity and resistance to wear and tear. Our advanced polishing line machines are designed to deliver exceptional results, utilizing cutting-edge technology to provide consistent and flawless finishes on marble and granite slabs. By focusing on precision and quality, we help our clients achieve the highest standards in their projects, ensuring that every piece of stone reflects the original colors and textures that nature intended. This commitment to excellence in line polishing not only meets industry demands but also elevates the overall value of the finished products in the market.

Features Of Line Polishing Machines

1. High precision and accuracy in polishing

Polishing operations are key features of line polishing machines. These machines are equipped with advanced technology that allows for consistent and uniform polishing across a variety of materials. Additionally, line polishing machines are designed to be highly versatile, allowing for customization of polishing parameters to meet the specific requirements of different industries. With the ability to achieve high levels of precision and accuracy, line polishing machines play a crucial role in ensuring the quality and performance of finished products.

2. Multiple heads for efficient and uniform polishing

By utilizing multiple heads, these machines are able to cover a larger surface area in a shorter amount of time, resulting in more efficient and consistent polishing results. This feature also helps to ensure that the polishing process is uniform across the entire surface of the material, leaving behind a smooth and flawless finish. In addition, the ability to adjust the speed and pressure of each head allows for greater control over the polishing process, making it easier to achieve the desired level of shine and smoothness. Overall, the inclusion of multiple heads on line polishing machines enhances their productivity and effectiveness in delivering high-quality results.

3. Easy to operate and maintain

One of the key benefits of line polishing machines is their user-friendly design, making them easy to operate even for those with limited experience. With intuitive controls on PLC panel and clear instructions, operators can quickly learn how to use the machine efficiently and effectively. Additionally, these machines are designed for easy maintenance, with accessible components that can be easily cleaned and replaced when needed. This ensures that the machine remains in optimal working condition, minimizing downtime and maximizing productivity. Overall, the combination of user-friendly operation and easy maintenance makes line polishing machines a valuable investment for any manufacturing or fabrication facility.

Benefits of Using Line Polishing Machines

1. Increased productivity and efficiency

Line polishing machines offer a wide range of benefits for users. One of the key advantages is the increased productivity and efficiency that comes with using these machines. By streamlining the polishing process and automating certain tasks, line polishing machines allow operators to complete jobs more quickly and with greater accuracy. This not only saves time and labor costs, but also ensures a higher level of consistency in the finished product. Additionally, the user-friendly nature of these machines means that operators can quickly and easily learn how to operate them, reducing the need for extensive training or specialized skills.

2. Consistent quality of finished products

This consistent quality of finished products is crucial for businesses looking to maintain a strong reputation and meet the demands of their customers. With line polishing machines, companies can deliver high-quality results consistently, leading to increased customer satisfaction and loyalty. Furthermore, the precision and uniformity achieved through the use of these machines can also help reduce waste and minimize errors, ultimately improving the overall profitability of the operation. Overall, the efficiency and quality benefits of line polishing machines make them a valuable investment for any business in need of reliable and high-performance polishing equipment.

3. Cost-effective solution for polishing requirements

Line polishing machines offer a cost-effective solution for businesses looking to meet their polishing requirements without breaking the bank. By streamlining the polishing process and reducing the need for manual labor, these machines can help companies save both time and money. Additionally, the consistent results produced by line polishing machines can help minimize the need for rework and touch-ups, further driving down costs and maximizing efficiency. In this way, investing in a line polishing machine can not only improve the quality of finished products but also contribute to the bottom line of the business.

4. Suitable For Marble and Granite industry

Line polishing machines have a wide range of applications, with one of the most common being in the marble and granite industry. These machines are essential for achieving the smooth and glossy finish that customers expect from their countertops, tiles, and other stone products. With the ability to efficiently polish large slabs of stone, line polishing machines are a valuable asset for businesses in this industry looking to meet high demand while maintaining high quality standards.

Customer Testimonials

1. Positive feedback from satisfied customers

It can greatly impact a company's reputation and success. Customer testimonials provide valuable insight into the quality of a company's products and services, helping to build trust and credibility with potential customers. By showcasing positive feedback from satisfied customers, companies can attract new business and retain loyal customers. Additionally, customer testimonials can serve as powerful marketing tools, influencing purchasing decisions and driving sales. In a competitive market, customer testimonials can set a company apart from its competitors and establish a strong brand identity.

2. Success stories of using line polishing machines

One example of the impact of customer testimonials can be seen in the success stories of using line polishing machines. These testimonials highlight the efficiency and effectiveness of these machines in achieving high-quality finishes on various materials. Customers have praised the durability and precision of these machines, noting the significant improvement in their production processes. By sharing these success stories, companies can demonstrate the value and benefits of their line polishing machines, attracting potential customers who are seeking reliable and innovative solutions for their polishing needs.

3. How the machines have improved their business operations

Customers have reported that the line polishing machines have greatly improved their business operations by streamlining their production processes and reducing downtime. The machines have also increased the overall efficiency of their operations, allowing them to meet tight deadlines and deliver high-quality products to their clients. Additionally, customers have noted that the machines have helped them save on labor costs and reduce waste, ultimately leading to increased profitability for their businesses. Overall, the positive impact of these machines on their business operations has been significant and has solidified their decision to invest in this technology.

Conclusion

1. Recap of the benefits and features of line polishing machines

The line polishing machines have proven to be a valuable asset to the business, providing a range of benefits including increased productivity, improved quality control, and cost savings. The efficiency and reliability of these machines have allowed the company to meet the demands of their clients while also reducing downtime and labor costs. Customers have expressed their satisfaction with the results, noting the consistent quality of the products and the overall efficiency of the operations. As a result, the decision to invest in this technology has been validated, with the positive impact on the business operations clear to see. In conclusion, the line polishing machines have proven to be a wise investment, delivering on their promise of improved efficiency and profitability for the company.

2. Encouragement for businesses to invest in these machines for improved productivity

It also encourages the business due to its cost-effectiveness as an evident, as the benefits far outweigh the initial investment. By incorporating line polishing machines into their operations, businesses can streamline their production processes, reduce errors, and ultimately increase their bottom line. The positive feedback from customers and the tangible results speak for themselves, making it a smart choice for companies looking to stay competitive in today's market. Don't miss out on the opportunity to enhance your business's productivity and profitability with this innovative technology.

3. Contact information for Shri Bhagwati Machines Pvt. Ltd. for inquiries or purchases.

Please feel free to reach out to us at Shri Bhagwati Machines Pvt. Ltd. for more information on how our line polishing machines can benefit your business. Whether you have questions about our products or are ready to make a purchase, our team is here to assist you every step of the way. Contact us today to take your production processes to the next level and see the difference it can make for your bottom line.

0 notes

Text

Tips To Choose Right Stone Cutting Machines

Definition of Stone Multicutter Machines

A stone multi cutter machine is a specialized piece of equipment used in the stone cutting industry to efficiently cut and shape various types of stone blocks. These machines are equipped with multiple cutting blades and tools that can be adjusted to create precise cuts on stones of different thicknesses and sizes. They are essential for cutting stones for construction, such as building facades, countertops, sculptures, and manufacturing stone tiles, slabs, and decorative elements.

Shri Bhagwati Machines Pvt Ltd, we specialize in advanced stone cutting solutions, including single blade, multi-blade stone cutting machines, wire saw machines, and laser cutting machines. These tools are designed to enhance efficiency, accuracy, and productivity in the stone fabrication process.

Importance of Choosing the Right Machine

The right stone cutting machine is essential for maximizing output, ensuring precise cuts, and maintaining long-term equipment durability. At Shri Bhagwati Machines Pvt Ltd, we offer a range of stone cutting machines built to handle a variety of stone types—granite, marble, limestone, and quartz—equipped with durable materials and the latest technologies like computerized PLC controls and laser guidance systems. This ensures precision and consistency in every cut.

Factors to be considered and to be discussed

In this blog, we will explore the factors that should influence your choice of a stone cutting machine, the specific features to look for, and the long-term benefits of choosing a high-quality machine. We will also highlight how Shri Bhagwati Machines Pvt Ltd can provide tailored solutions to meet your stone cutting needs.

a) Type of Stone Being Cut

When choosing a machine, the type of stone granite, marble, limestone or quartz will dictate the type of blades and cutting techniques required. Shri Bhagwati Machines Pvt Ltd offers machines with high-precision blades that can handle all stone types, ensuring you get the perfect cut every time. We provide single blade and multi-blade cutters for different stone thicknesses and sizes, adaptable to your specific project needs.

b) Size and Thickness of the Stone

The size and thickness of the stone also impact the choice of a cutting machine. For thicker stones, our multi blade stone cutter machines and powerful single blade models are ideal for handling even the toughest cutting jobs. For delicate or thinner stones, our laser cutting machines provide the fine precision necessary for intricate designs and finishes.

c) Desired Finish or Shape of the Cut

If your project requires custom shapes, curved edges, or intricate designs, our laser cutting and wire saw machines can offer high accuracy, providing smooth finishes or intricate detail. Shri Bhagwati Machines Pvt Ltd machines are designed to handle complex cuts with precision, ensuring your product is top-quality.

Machine Features

a) Cutting Speed and Accuracy

Cutting speed and accuracy are key considerations. At Shri Bhagwati Machines Pvt Ltd, our multi blade and wire saw machines are designed with advanced features like adjustable speeds, enabling versatility for different stone materials. Whether you’re working on large stone blocks or delicate marble slabs, our machines provide clean, precise cuts that meet the highest industry standards.

b) Safety Features

Safety is paramount in stone cutting. All of our machines are equipped with essential safety features such as blade guards, emergency stop buttons, and automatic shut-off systems to ensure the safety of operators. We prioritize the well-being of your workforce by integrating industry-leading safety mechanisms.

c) Ease of Use and Maintenance

At Shri Bhagwati Machines Pvt Ltd, we understand that ease of use and maintenance are critical. Our machines are designed for user-friendly operation with intuitive interfaces, requiring minimal training. They are also built with durable components that reduce the need for frequent maintenance, saving you time and costs in the long run.

Brand & Reputatation

a) Researching Different Brands

Choosing the right brand can make a significant difference in your overall experience. With a strong reputation in the stone machinery industry, Shri Bhagwati Machines Pvt Ltd has been a trusted name for providing high-quality stone cutting machines. Our commitment to quality and performance ensures you are investing in a machine that will last for years, delivering consistent results.

b) Reading Reviews and Testimonials

Our satisfied clients speak highly of the reliability and efficiency of our machines. At Shri Bhagwati Machines Pvt Ltd, we pride ourselves on offering cutting-edge technology and excellent customer support, making us the go-to brand for stone fabricators across the country.

c) Seeking Recommendations from Other Professionals

Many industry professionals recommend Shri Bhagwati Machines Pvt Ltd due to our ability to meet diverse project requirements. Whether it's precision, speed, or durability, we are the trusted choice for those looking to achieve excellence in stone cutting.

Budget Considerations

a) Initial Cost of the Machine

At Shri Bhagwati Machines Pvt Ltd, we offer a wide range of machines at competitive prices to fit various budgets without compromising quality. While we emphasize value over cost, we also ensure that our machines deliver the best return on investment by enhancing productivity and minimizing downtime.

b) Maintenance and Operating Costs

Our machines are designed for minimal maintenance and maximum operational efficiency. Lower energy consumption, ease of part replacement, and robust performance ensure that long-term operating costs remain manageable, helping you maintain profitability over time.

c) Long-Term Investment Potential

Investing in a high-quality stone cutter from Shri Bhagwati Machines Pvt Ltd is a wise decision for any stone fabricator. Our machines are built to last, reducing the need for frequent replacements or repairs, which translates to significant savings in the long run.

Conclusion

In conclusion, choosing the right stone cutting machine is critical for optimizing your production processes and maintaining a competitive edge in the industry. At Shri Bhagwati Machines Pvt Ltd, we offer a wide range of advanced machines, including single blade, multi blade , wires saw, and laser cutting options, all designed to meet your unique needs. When you invest in one of our machines, you are not just purchasing a piece of equipment but gaining a long-term partner in your stone fabrication success. Visit us at bhagwatimachines.com to explore our offerings and find the right machine for your business today.

0 notes

Text

MULTICUTTER MACHINES BY SBMPL

I. INTRODUCTION

A. Explanation of granite multi-cutter machines

Granite multi-cutter machines are essential tools in the stone-cutting industry, allowing for precise and efficient cutting of granite materials. These machines are equipped with multiple blades that can make several cuts simultaneously, increasing productivity and reducing labor costs. The use of multi-cutter machines has revolutionized the way stone cutting is done, making it faster, more accurate, and more cost-effective.

B. Overview of Metro-B10, Metro-B12, Metro-B13Pro, Metro-B14, Metro-B21, and Metro-B30

Metro B30

C. Benefits of using these SBMPL Multi-cutters

Multi-cutter machines offer a wide range of benefits for businesses in terms of efficiency, precision, and cost-effectiveness. By investing in a multicutter machine that is tailored to your cutting needs, you can streamline your production process, improve the quality of your cuts, and ultimately save time and money in the long run. These machines are versatile, reliable, and easy to operate, making them a valuable asset for any industry looking to enhance their cutting capabilities.

II. Increased Efficiency

A. Ability to cut multiple slabs in one pass

Multicutter machines have the ability to cut multiple slabs in one pass, which significantly increases efficiency in the production process. This means that you can save time and resources by completing multiple cutting tasks simultaneously, rather than having to switch between different machines or tools. Additionally, the precision and accuracy of multicutter machines ensure that each cut is consistent and high-quality, reducing the need for rework or adjustments. Overall, the increased efficiency provided by multi-cutter machines can help businesses meet deadlines, fulfill orders faster, and ultimately improve their bottom line.

B. Faster cutting speeds compared to manual methods

With the ability to cut through various materials quickly and accurately, businesses can increase their production output without sacrificing quality. This increased speed also allows for more flexibility in meeting customer demands and adapting to changing market conditions. Ultimately, the combination of efficiency and speed offered by multicutter machines makes them a valuable investment for businesses looking to streamline their operations and stay competitive in today’s fast-paced market.

C. Reduces labor costs and time spent on cutting tasks

One of the key advantages of multi-cutter machines is their ability to reduce labor costs and the time spent on cutting tasks. By automating the cutting process, businesses can eliminate the need for manual labor and free up employees to focus on other important tasks. This not only increases efficiency but also helps to reduce the risk of human error, resulting in higher quality products. Additionally, the speed and precision of multi-cutter machines mean that tasks can be completed in a fraction of the time compared to traditional cutting methods, allowing businesses to meet tight deadlines and fulfill customer orders quickly. Overall, the reduction in labor costs and time spent on cutting tasks can lead to significant cost savings and improved productivity for businesses utilizing multicutter machines.

III. Precision Cutting

A. Consistent cuts with minimal errors

Minimal errors are essential in industries such as manufacturing, where precision is key to ensuring the quality of the final product. Multicutter machines excel in this aspect, as they are able to consistently produce accurate cuts with minimal errors. This level of precision is crucial in industries where even the smallest deviation can result in a faulty product or component. By utilizing multicutter machines for precision cutting tasks, businesses can ensure that their products meet the highest standards of quality and reliability. This not only enhances the reputation of the company, but also helps to build trust with customers who rely on consistent and precise products.

B. Ensures uniformity in finished products

Multicutter machines also help to ensure uniformity in finished products, as each cut is made with the same level of precision and accuracy. With multicutter machines, businesses can minimize variations in their products and maintain a high level of quality control throughout the production process. This ultimately leads to cost savings, as fewer defective products need to be discarded or reworked, resulting in higher efficiency and profitability for the company.

IV. Versatility

A. Can be used for a variety of materials such as granite

Multicutter machines are incredibly versatile tools that can be used for a wide range of granite materials. This versatility allows businesses to create intricate designs and shapes with precision and efficiency. Multi-cutter machines can handle a variety of thickness tasks with ease. This flexibility not only saves time and money, but also ensures that finished products have a uniform and professional look. Overall, the versatility of multicutter machines makes them indispensable tools for businesses looking to achieve high levels of precision and quality in their products.

V. Cost-Effectiveness

A. Saves on material waste by maximizing cutting efficiency

With the ability to cut materials with precision, multicutter machines help reduce the amount of wasted material, ultimately saving businesses money in the long run. Additionally, the speed and efficiency of these machines mean that projects can be completed in less time, allowing businesses to take on more jobs and increase their overall productivity. This cost-effectiveness makes multicutter machines a smart investment for any business looking to streamline their production processes and improve their bottom line.

B. Low maintenance requirements and long lifespan

make multicutter machines an even more attractive option for businesses. With proper care and regular maintenance, these machines can last for years, providing consistent and reliable performance. This means that businesses can rely on their multicutter machines for a long time without having to worry about frequent repairs or replacements. This not only saves businesses money on maintenance costs but also minimizes downtime, ensuring that production schedules are not disrupted. Overall, the low maintenance requirements and long lifespan of multicutter machines make them a valuable asset for any business looking to increase efficiency and profitability in their operations.

C. Provides a high return on investment over time

One of the key benefits of investing in multicutter machines is the high return on investment they offer over time. While the initial cost of purchasing a multicutter machine may be significant, the long lifespan and low maintenance requirements of these machines mean that businesses can recoup their investment quickly. By reducing the need for frequent repairs and replacements, multicutter machines help businesses save money in the long run. Additionally, the increased efficiency and productivity provided by multicutter machines can lead to higher profits, further enhancing the return on investment for businesses.

VI. Conclusion

In conclusion, the benefits of multicutter machines such as the Metro-B10, Metro-B12, Metro B-13 Pro, Metro B-14 Pro, Metro-B21, and Metro-B30 are clear. These machines offer significant cost savings through their long lifespan and low maintenance requirements, allowing businesses to recoup their investment quickly. Furthermore, the increased efficiency and productivity provided by multicutter machines can lead to higher profits, further enhancing the return on investment for businesses. Overall, investing in multicutter machines is a smart decision for businesses looking to improve their operations and save money in the long run.

Multi-cutter machines have revolutionized the manufacturing industry by streamlining processes and increasing output. By automating repetitive tasks and reducing human error. Additionally, the precision and accuracy of multicutter machines have led to higher quality output, ultimately enhancing the reputation and profitability of businesses. In conclusion, multi-cutter machines are an invaluable investment for any company trying to remain competitive in today’s market because of their indisputable positive effects on production and profitability.

0 notes

Text

Metro B30: Revolutionizing Efficiency with SBMPL

Overview of the METRO-B30

The METRO-B30 is a sixth-generation multi-blade granite block cutter, engineered using DRSH (Dual RPM Single Housing) technology. This innovation allows the machine to achieve high production levels while minimizing power consumption and reducing cycle times. The design focuses on user-friendliness, featuring a programmed interface that simplifies operation for users.

Key Specifications

Blade Diameter Capacity: Up to 2.4/2.5 meters

Blade Mounting Provision: Accommodates 21 to 22 blades

Useful Cutting Block Size: 3657 mm x 2438 mm x 1066 mm

Power Requirements: Equipped with a 150 HP main spindle motor, ensuring robust performance even with hard density granite materials.

Technological Innovations

The METRO-B30 is distinguished by several advanced technological features that enhance its performance and usability:

Dual RPM Technology — The Dual RPM Technologyallows the METRO-B30 to operate at two different speeds, optimizing the cutting process for various materials. This flexibility results in higher production rates and extended tool life, all while consuming less energy compared to traditional machines.

User-Centric Design — The METRO-B30 features a Siemens 10” HMI (Human-Machine Interface) and PLC (Programmable Logic Controller) machine control. This user-friendly interface simplifies operation, enabling operators to monitor and control the machine with ease. The intuitive design reduces the learning curve for new users, making it accessible for operators of all skill levels.