Yash Machine Tools, headquartered in Ahmedabad, Gujarat, India, is a renowned manufacturer and exporter of high-quality sheet bending machines and metalworking equipment. The company offers a diverse range of products, including press brakes, shearing machines, hydraulic presses, bus bar machines, and other sheet metal machinery.

Don't wanna be here? Send us removal request.

Text

Different Types of Sheet Bending Machines: A Comprehensive Guide

Sheet bending machines play a crucial role in metalworking and fabrication, allowing industries to shape and cut metal sheets with precision. These machines are essential in various sectors, including automotive, construction, shipbuilding, and aerospace.

Different types of bending and cutting machines are used depending on the material type, thickness, and desired shape. This guide explores various sheet bending machines, including nibbling machines, power presses, press brakes, riveting tools, shearing machines, and more.

Nibbling Machines

A nibbling machine is a sheet metal working tool that uses a fast-moving punch to cut and shape metal sheets.

How Does Nibbling Work?

The machine moves the sheet under a small punch that makes repetitive cuts.

It allows complex shapes and patterns to be cut with high precision.

Key Applications:

✔ Used for creating perforations, notches, and intricate shapes in metal sheets. ✔ Common in automotive, electronics, and furniture manufacturing.

Power Press Machines

Power press machines apply high force to bend, punch, or shape metal sheets.

Types of Power Press Machines:

Mechanical Power Press – Uses a flywheel to generate force.

Hydraulic Power Press – Uses hydraulic cylinders for higher precision and flexibility.

Industrial Applications:

✔ Metal stamping ✔ Cutting and bending sheet metal ✔ Automotive and appliance manufacturing

Press Brake Machines

A press brake machine used to bend metal sheets into different angles.

Types of Press Brakes:

✔ Mechanical Press Brake – Ideal for mass production.

✔ Hydraulic Press Brake – Offers greater flexibility and control. ✔ CNC Press Brake – Uses computer automation for high precision.

Choosing the Right Press Brake:

✔ Consider material thickness and bend complexity. ✔ Hydraulic press brakes are better for versatile applications.

GP-G-Series Riveting Tools

These are advanced gp series riveting tools designed for fastening sheet metal components.

✔ Used in automotive, aerospace, and construction. ✔ Ensures strong and durable metal joints.

Riveting Machines

A riveting machine is used to join metal sheets using rivets.

Types of Riveting Machines:

✔ Pneumatic Riveting Machines – Operate using compressed air. ✔ Hydraulic Riveting Machines – Provide high pressure for stronger rivet joints. ✔ Impact Riveting Machines – Use mechanical force for joining parts.

✔ Common in shipbuilding, bridge construction, and heavy machinery manufacturing.

Mechanical Under Crank Shearing Machine

A mechanical under crank shearing machine is used for cutting sheet metal.

Advantages:

✔ High precision in metal cutting ✔ Suitable for high-volume production ✔ Low maintenance and easy operation

Shearing Machines

Shearing machines cut metal sheets without producing heat or sparks.

Types of Shearing Machines:

✔ Mechanical Shearing Machines – Best for mass production. ✔ Hydraulic Shearing Machines – Provide better force control.

✔ Used in metal fabrication, shipbuilding, and steel processing.

Bhaiya Cutter Machines

A Bhaiya cutter machine is a specialized cutting tool for sheet metal fabrication.

✔ Cuts metal sheets with high accuracy. ✔ Used in light and heavy-duty industrial applications.

Sheet Metal Bending Machines

Sheet metal bending machines are used to bend and form metal sheets into different shapes.

Common Types of Sheet Bending Machines:

✔ Press Brakes – For large-scale metal bending. ✔ Roll Benders – Used to create curved metal sheets. ✔ Folding Machines – Used for delicate bends in thin sheets.

✔ Industries using sheet bending machines include construction, furniture manufacturing, and aviation.

Conclusion

Sheet bending machines play a vital role in metal fabrication, ensuring precise cutting, bending, and shaping of metal sheets. Whether it’s nibbling, power pressing, riveting, or shearing, each machine offers unique benefits.

As technology advances, modern CNC-controlled machines are revolutionizing the sheet metal industry, improving productivity and reducing labor costs. Choosing the right sheet bending machine depends on factors like material type, production volume, and precision requirements.

youtube

FAQs

What is the difference between a mechanical and hydraulic press brake? A mechanical press brake is faster but less flexible, while a hydraulic press brake offers better control for complex bending.

How does a nibbling machine work in sheet metal fabrication? A nibbling machine creates intricate shapes by making small, repetitive cuts on metal sheets.

What are the advantages of using riveting tools in metalworking? Riveting tools provide strong, durable metal joints without the need for welding.

Which industries require shearing machines the most? Shearing machines are essential in shipbuilding, construction, and metal fabrication.

How do I choose the right sheet bending machine for my workshop? Consider factors like material thickness, required precision, and production volume.

0 notes

Text

Comprehensive Guide to Sheet Bending Machines

Introduction

Sheet bending plays a crucial role in metal fabrication, enabling the shaping and processing of metal sheets for various industrial applications. From construction and automotive to aerospace and shipbuilding, the demand for high-precision sheet bending machines is growing rapidly.

Yash Machine Tools is a leading provider of technologically advanced sheet bending machines and components designed to enhance efficiency and productivity in metalworking operations. This guide explores different types of bending machines, including bending rollers, hydraulic presses, iron workers, shearing machines, press brakes, and more.

What is Sheet Bending?

Sheet bending is a metalworking process used to deform and shape metal sheets into desired angles and curves. It is a critical step in manufacturing, allowing industries to create structural components with high precision and durability.

Key Sheet Bending Methods:

Press Braking – Uses a punch and die to create precise bends.

Rolling – Forms curved or cylindrical metal parts.

Folding – Bends sheet metal without excessive force.

Stamping and Punching – Used for cutting and shaping metal sheets.

Types of Sheet Bending Machines

Various bending machines are available based on the type of bending process:

Manual Bending Machines – Suitable for small-scale operations.

Mechanical Bending Machines – Offer automation for increased efficiency.

Hydraulic Bending Machines – Provide high force for bending thick metals.

Bending Roller Machines

A bending roller machine is used to bend metal sheets and plates into cylindrical or curved shapes.

Industries Using Bending Rollers:

Construction

Automotive

Shipbuilding

Aerospace

Advantages: ✔ Smooth bending without damage ✔ Handles various sheet thicknesses ✔ Reduces material waste

3 Roll Pyramid Type Mechanical Plate Bending Machine

The 3 roll pyramid type plate bending machine is a widely used mechanical bending tool.

Features:

High precision for metal sheet rolling

Works with different materials like steel, aluminum, and copper

Requires less maintenance and is cost-effective

Profile & Pipe Bending Machines

Profile & Pipe Bending Machines are used to bend pipes, tubes, and structural metal profiles into complex shapes.

Common Applications:

✔ Metal furniture production ✔ Construction framework bending ✔ Automotive exhaust pipe shaping

Bus Bar Bending, Cutting, and Punching Machines

Bus bar bending, cutting, and punching machines are used in electrical and construction industries to shape copper and aluminum bus bars for power distribution.

✔ Performs multiple operations – bending, cutting, and punching ✔ Reduces manual labor and enhances precision

Metal Sheet Bending Machines

These machines are designed for shaping thin and thick metal sheets efficiently.

Hydraulic vs. Mechanical Bending:

✔ Hydraulic bending machines provide higher force and flexibility ✔ Mechanical bending machines are more economical for mass production

Folding Machines

Folding machines are used to bend thin sheets without damage. They are widely used in roofing, HVAC, and cabinet making.

✔ High accuracy in folding angles ✔ Quick operation with minimal labor

Hydraulic Press Machines

Hydraulic press machines use hydraulic force to bend, cut, or shape metal sheets.

✔ High tonnage capacity ✔ Precise pressure control for accurate bending

Hydraulic Iron Worker Machines

A hydraulic iron worker is a multi-functional machine that can: ✔ Cut metal sheets ✔ Punch holes ✔ Bend structural steel

These machines are widely used in fabrication workshops and steel processing plants.

Power Press Machines

Power press machines use mechanical or hydraulic force to punch, bend, or shape metals.

✔ Ideal for mass production ✔ High-speed operation for increased efficiency

Press Brake Machines

Press brakes are used for precise metal bending and shaping.

✔ Available in hydraulic and mechanical versions ✔ Used in automotive, aerospace, and industrial fabrication

Riveting Machines

Riveting machines are essential in sheet metal assembly for joining multiple metal sheets securely.

✔ Strong and durable connections ✔ Used in automotive and aircraft manufacturing

Shearing Machines

Shearing machines are used for cutting metal sheets without producing chips.

✔ High-speed cutting for efficiency ✔ Used in steel fabrication, shipbuilding, and industrial manufacturing

Sheet Metal Machines – Complete Overview

With automation and precision engineering, modern metal sheet Bending Machines have transformed the metalworking industry.

✔ CNC-controlled machines for precise bending ✔ Smart automation for higher productivity

Conclusion

Sheet bending machines play a crucial role in metal fabrication across multiple industries. Whether it’s a hydraulic press, iron worker, bending roller, or press brake, choosing the right equipment ensures precision, efficiency, and productivity.

youtube

0 notes

Text

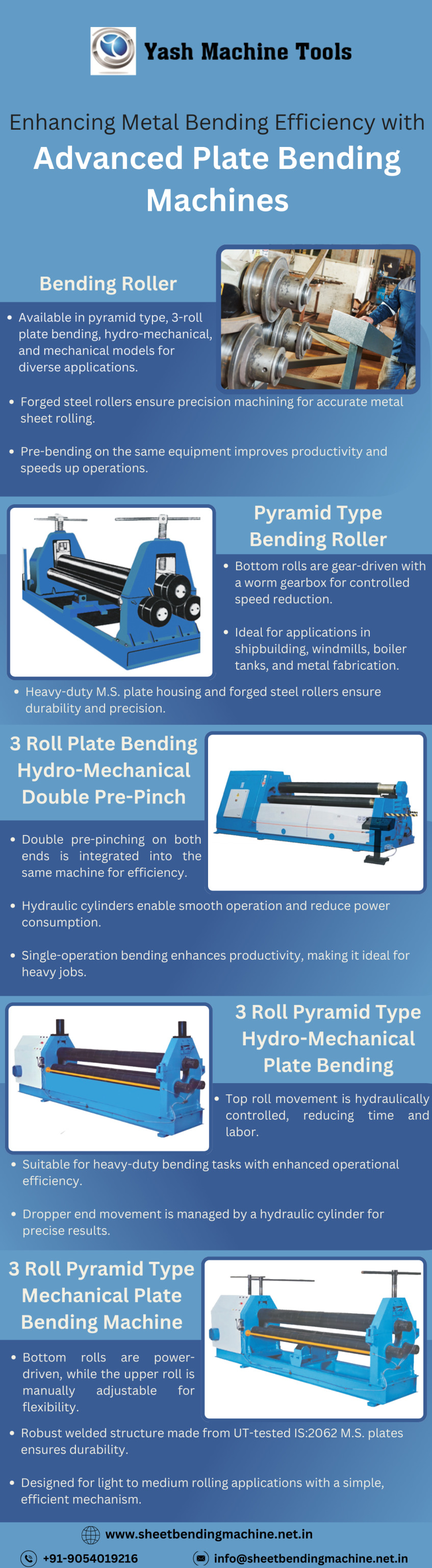

Enhancing Metal Bending Efficiency with Advanced Plate Bending Machines

Achieve precision and efficiency in metal bending with advanced plate bending machines! In this video, we explore how modern plate bending technology enhances productivity, reduces material waste, and delivers high-quality results in industries like manufacturing, construction, and shipbuilding.

🔹 What You’ll Learn:

✔️ How plate bending machines work ✔️ Types of plate bending machines (3-roll, 4-roll, CNC-controlled) ✔️ Benefits of advanced bending technology ✔️ Key features that improve efficiency and accuracy ✔️ Applications across different industries Whether you’re a fabricator, engineer, or manufacturer, investing in the right plate bending machine can boost your production capabilities and streamline metal forming processes. Watch the full video to see the latest innovations in metal bending technology!

For more details, visit us at - https://www.sheetbendingmachine.net.in/product/bending-roller/

#Sheetbendingmachine#PlateBendingMachine#MetalBending#Fabrication#Manufacturing#IndustrialMachinery#MetalForming#CNCBending#Engineering

0 notes

Text

Enhancing Metal Bending Efficiency with Advanced Plate Bending Machines

Yash Machine Tools presents advanced plate bending machines for efficient metal forming. Models include:

🔹 Pyramid Type Bending Roller – Gear-driven, ideal for shipbuilding & fabrication. 🔹 3 Roll Plate Bending (Hydro-Mechanical, Double Pre-Pinch) – Hydraulic operation for precise, heavy-duty bending. 🔹 3 Roll Pyramid Type Hydro-Mechanical – Reduces labor time with hydraulic control. 🔹 3 Roll Pyramid Type Mechanical – Durable, power-driven for light to medium rolling.

Engineered for precision, efficiency, and industrial durability. For more information, visit us at - https://www.sheetbendingmachine.net.in/product/bending-roller/

#PlateBendingMachines#MetalBending#SheetMetal#Manufacturing#YashMachineTools#BendingRoller#IndustrialMachinery

0 notes

Text

Industries Using Different Types of Sheet Metal Machines and Their Applications

Explore the essential role of sheet metal machines across industries like automotive, aerospace, construction, and manufacturing. This video highlights different types of sheet bending machines—including Press Brakes for precise bends, Hydraulic Bending Machines for heavy-duty tasks, Mechanical Bending Machines for high-volume production, Roll Bending Machines for cylindrical shapes, and CNC Bending Machines for complex, precise bends—each transforming metal into vital components used in countless applications.

For more details, visit us at - https://www.sheetbendingmachine.net.in/

#SheetMetal#MetalBending#PressBrake#HydraulicBending#MechanicalBending#RollBending#CNCMachines#Manufacturing#IndustrialMachinery#AerospaceIndustry#ConstructionIndustry#MetalFabrication#MachineTools

0 notes

Text

Industries Using Different Types of Sheet Metal Machines and Their Applications

Explore the essential role of sheet metal machines across industries like automotive, aerospace, construction, and manufacturing. This video highlights different types of sheet bending machines—including Press Brakes for precise bends, Hydraulic Bending Machines for heavy-duty tasks, Mechanical Bending Machines for high-volume production, Roll Bending Machines for cylindrical shapes, and CNC Bending Machines for complex, precise bends—each transforming metal into vital components used in countless applications.

For more details, visit us at - https://www.sheetbendingmachine.net.in/

#SheetMetal#MetalBending#PressBrake#HydraulicBending#MechanicalBending#RollBending#CNCMachines#Manufacturing#IndustrialMachinery#MetalFabrication#MachineTools

0 notes

Text

Comprehensive Guide to Power Presses, Riveting, and Shearing Machines for Industrial Applications

Introduction

In industries like metalworking, automotive, and construction, machines that can efficiently cut, press, and assemble metal components are indispensable. Among the most common and crucial types of machinery are power presses, riveting machines, and shearing machines. Each serves a distinct purpose, helping manufacturers achieve precision, durability, and consistency in their products. In this article, we'll take a closer look at these machines, explore their variations, and discuss their industrial applications.

Power Press

A Power Press is a mechanical tool used for bending, cutting, punching, and pressing metal sheets. It uses high pressure to shape metal into specific forms. Power presses are highly efficient and can be used in a range of industries, from automotive manufacturing to metal fabrication.

Cross Shaft Power Press

The Cross Shaft Power Press features a cross shaft design, which helps distribute the pressing force more evenly. This design is ideal for heavy-duty applications where high force is needed for deep drawing, blanking, or punching operations. It is commonly used in large-scale metal stamping and forming industries.

Pneumatic Power Press

A Pneumatic Power Press operates using compressed air to generate the pressing force. These presses are highly versatile and are particularly useful in environments that require fast, repeatable pressing operations. They also allow for better control over the force applied, making them suitable for delicate tasks.

Pneumatic Type Power Press

https://www.youtube.com/watch?v=jOohrqxPLloThis variation of the pneumatic press is built for operations where precise control over the air pressure and force is crucial. Pneumatic Type Power Presses are frequently used in the electronics and light metal industries, where materials can be easily damaged if the force is too strong.

H Power Press

An H Power Press has a solid, robust "H" frame structure, providing exceptional stability during operations. This makes it ideal for applications that require high-force pressing, such as forging and stamping thicker materials. Its design ensures a uniform distribution of pressure, reducing the likelihood of damage to the material.

H Type Power Press

Similar to the H Power Press, the H Type Power Press is specifically designed for operations that demand heavy-duty, consistent performance. The H-frame allows for greater control and precision in high-force operations, making it a favorite in industries like automotive and aerospace manufacturing.

C Power Press

A C Power Press has a "C" shaped frame, allowing easy access to the work area. This design is typically used for lighter pressing operations, where high precision is necessary but the material doesn't require as much force. C Power Presses are used for punching, forming, and bending tasks.

C Type Power Press

The C Type Power Press offers many of the same benefits as its H-type counterpart, but with a more compact, accessible design. Its open frame makes it easy to load and unload materials, which is especially useful in small to medium-sized manufacturing operations.

Press Brake

A Press Brake is a machine used for bending sheet metal. It applies force to the sheet metal between a punch and die, forming the metal into a desired shape. Press brakes are essential for creating bends in metal sheets used in construction, automotive, and appliance manufacturing.

CNC Press Brakes

CNC Press Brakes utilize computer numerical control (CNC) to automate the bending process. These machines are programmed to ensure consistent, precise bends, making them ideal for large-scale production runs. Automation not only improves efficiency but also reduces the risk of human error.

CNC Press Brake

A CNC Press Brake is similar to a CNC Press Brakes machine but often used for more specific or custom bending applications. These machines are widely used in the automotive and aerospace industries, where precision is paramount. The use of CNC technology allows for complex bends and shapes to be produced with minimal setup time.

Hydraulic Press Brake Machine

A Hydraulic Press Brake Machine uses hydraulic fluid to generate the pressing force. This type of press brake is ideal for bending thick, heavy-duty metal sheets and is commonly used in industries like shipbuilding and construction. Hydraulic press brakes offer smooth operation and can handle a wide range of materials.

Mechanical Press Brakes

A Mechanical Press Brake uses a mechanical system to exert force on the sheet metal. While they are faster than hydraulic press brakes, they are typically used for lighter tasks. They offer less flexibility in terms of force application but are still valuable in industries requiring rapid, repetitive bending tasks.

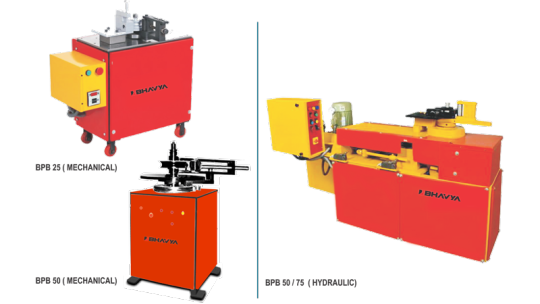

Riveting Machines

A Riveting Machine is used to permanently join two or more pieces of metal by inserting and deforming a rivet. These machines are essential in industries like aviation, shipbuilding, and construction, where secure, durable joints are needed. There are various types of riveting machines, including pneumatic, hydraulic, and manual models.

Pedestal Type Riveting Machine

A Pedestal Type Riveting Machine is mounted on a pedestal, offering stability and ease of operation for high-volume riveting tasks. This type of machine is commonly used in industries like automotive manufacturing, where the assembly of large components requires consistent riveting.

Riveting Machine Manufacturer

When selecting a Riveting Machine Manufacturer, it’s important to consider the reputation of the manufacturer, the type of riveting machine you need, and the after-sales support offered. Top manufacturers provide high-quality machines that can withstand the demands of large-scale production.

Bench Type Riveting Machine

The Bench Type Riveting Machine is designed for smaller, more precise riveting tasks. It is compact and ideal for applications such as electronics manufacturing or small metal assembly tasks. Despite its size, it provides the same level of precision and strength as larger models.

Shearing Machines

A Shearing Machine is used for cutting metal sheets. It works by applying a high-pressure tool to a metal sheet, cutting it along a straight line. These machines are essential for cutting materials to size before they undergo further processing in bending or forming operations.

Hydraulic Shearing Machine

A Hydraulic Shearing Machine uses hydraulic power to exert the cutting force. These machines are highly efficient and capable of cutting through thicker materials than mechanical shears. They are used in industries that require heavy-duty metal cutting, such as shipbuilding and heavy machinery manufacturing.

Mechanical Shearing Machine

A Mechanical Shearing Machine operates using mechanical systems and is typically used for lighter cutting tasks. They offer fast cutting speeds and are ideal for applications where thinner materials are processed at high volumes.

Mechanical Over Crank Shearing Machine

The Mechanical Over Crank Shearing Machine features an over-crank design, offering greater cutting precision and power. These machines are typically used in large-scale metal cutting operations, such as in sheet metal fabrication.

Under Crank Mechanical Shearing Machine

The Under Crank Mechanical Shearing Machine is designed for precise cutting of medium to thick metal sheets. Its under-crank design allows for smoother operation and consistent results in high-volume applications.

Mechanical Under Crank Shearing Machine

This variation of the Under Crank Mechanical Shearing Machine is built for durability and precision. It's used in industries like automotive and appliance manufacturing, where consistent, high-quality cutting is required.

Hydraulic Hand Pipe Bending Machine

The Hydraulic Hand Pipe Bending Machine is a portable tool used for bending pipes. It offers flexibility and power, allowing operators to bend pipes on-site with minimal setup. This machine is ideal for construction and plumbing tasks that require quick, accurate bends.

Motorised Pipe Bending Machine

A Motorised Pipe Bending Machine automates the bending process, making it faster and more precise than manual methods. These machines are used in industries where a large number of pipes need to be bent accurately and consistently.

Cutting Machines

Cutting machines, such as the Angel Cutter, Rod Cutter, and Bhaiya Cutter, are used for slicing through various materials. These machines are vital for ensuring that metal components are the correct size before they are further processed. Each cutter is designed for a specific material or application, ensuring precision in every cut.

Conclusion

In the ever-evolving world of industrial manufacturing, power presses, riveting machines, and shearing machines continue to play a critical role. Whether you’re working with sheet metal, pipes, or small components, the right machine can enhance efficiency, precision, and productivity. Understanding the different types of machines and their applications will help you make informed decisions and choose the best equipment for your manufacturing needs.

youtube

0 notes

Text

Comprehensive Guide to Bending Machines and Presses for Industrial Applications

Introduction

In the world of metalworking, precision, power, and reliability are key. Whether it’s bending profiles, shaping pipes, or pressing metal sheets, having the right tools can make all the difference. Bending machines and hydraulic presses are integral to industries like construction, automotive, aerospace, and electrical manufacturing. These machines allow for seamless and accurate manipulation of metal components, ensuring that complex designs and specifications are met efficiently. Let’s dive into the different types of bending machines and presses and explore how they’re used in various industrial applications.

Profile Bending Machines

A Profile Bending Machine is designed to bend metal profiles, such as angles, T-profiles, U-profiles, and more, into curved shapes. These machines are crucial for industries that require specific curved metal components, such as construction and automotive manufacturing. They can handle various sizes and thicknesses of metal profiles, ensuring precision in every bend.

Hydraulic Profile Bending Machine

A Hydraulic Profile Bending Machine utilizes the power of hydraulics to bend metal profiles. The hydraulic system provides more force and allows for smoother, more controlled bending compared to purely mechanical systems. This makes hydraulic bending machines ideal for heavier profiles or materials that require more precision and force during the bending process.

Pipe Bender

A Pipe Bender is an essential tool for industries such as plumbing, HVAC, and automotive, where precise bends in metal pipes are required. Pipe benders are used to create bends without the need for welding, maintaining the integrity of the pipe. They can be manual, electric, or hydraulic, depending on the scale and precision required for the task.

Pipe Bending Machine

Unlike manual pipe benders, a Pipe Bending Machine automates the bending process, ensuring uniformity and precision in each bend. These machines are widely used in industries where high volumes of bent pipes are needed, such as in the production of exhaust systems or frames for heavy machinery.

Fly Press Machines

Fly Presses are manually operated machines used to press or shape materials, typically metals. They are known for their simplicity, reliability, and precision. There are several types of fly presses, each designed for different applications:

Double Body Fly Press

The Double Body Fly Press is a robust machine designed for heavier operations. It provides more stability and power, making it ideal for tasks that require more force, such as stamping or punching thicker metal sheets.

Single Body Fly Press

The Single Body Fly Press is more compact and lightweight compared to its double-body counterpart. It's ideal for light metalworking tasks that don’t require as much force, such as small stamping or light embossing jobs.

Steel Body Fly Press

A Steel Body Fly Press is built entirely from steel, offering superior durability and strength. It’s favored in industries that require prolonged use and consistent performance under demanding conditions.

Mechanical Profile Bending Machine

A Mechanical Profile Bending Machine operates using mechanical systems to bend metal profiles. These machines are typically manual but can be automated in some models. They are suitable for simpler bending tasks where less force is required compared to hydraulic models.

Pyramid Type Bending Roller

A Pyramid Type Bending Roller is a specific type of bending machine where the metal is passed through three rollers arranged in a pyramid formation. This setup allows for gradual bending, ideal for creating smooth curves in metal sheets or profiles.

Hydro-Mechanical Plate Bending Machines

Combining both hydraulic and mechanical systems, Hydro-Mechanical Plate Bending Machines are used for bending thick metal plates. The hydraulic system provides the power, while the mechanical system ensures precision. These machines are commonly used in industries that deal with large, heavy metal sheets.

3 Roll Plate Bending Hydro-Mechanical Double Pre-Pinch

The 3 Roll Plate Bending Hydro-Mechanical Double Pre-Pinch machine offers the advantage of pre-pinch bending, meaning the material is pre-bent at the edges before the final bend is made. This feature allows for more precise control over the shape and prevents unwanted deformation.

Plate Bending Machines

A Plate Bending Machine is designed specifically for bending metal plates. Whether it's rolling, forming, or curving, plate bending machines are critical in shipbuilding, automotive, and heavy machinery manufacturing. These machines ensure uniform bending, reducing the risk of cracks or splits.

3 Roll Pyramid Type Hydro-Mechanical Plate Bending

This machine uses a three-roll pyramid configuration to bend metal plates. The addition of hydraulic systems allows for more precise bending of larger, thicker plates, making it ideal for heavy-duty applications.

Mechanical Plate Bending Machine

The Mechanical Plate Bending Machine is driven entirely by mechanical systems, making it ideal for smaller, less complex bending tasks. It’s typically used for lighter materials where high precision is still required.

Bus Bar Bending-Cutting-Punching Machine

A Bus Bar Bending-Cutting-Punching Machine is a versatile machine that allows for the bending, cutting, and punching of bus bars, which are used in electrical applications to distribute power. This multifunctionality makes it a time-saving solution in electrical fabrication.

Bus Bar in Electrical Applications

Bus Bars are conductive strips used in electrical distribution systems to manage and distribute power. They are essential in industries that require large-scale power distribution, such as manufacturing plants and power stations.

Metal Sheet Bending Machine

A Metal Sheet Bending Machine is used to bend or shape flat metal sheets into various forms. These machines are vital in producing metal housings, frames, and other components used in countless industrial and commercial products.

Folding Machines and Trunk Folding Machines

Folding Machines are specialized tools for folding metal sheets along a straight line. Trunk Folding Machines are a subset of these machines designed for more complex folding tasks, such as creating seams or intricate bends in metal sheets used in vehicle trunks or containers.

Hydraulic Presses

A Hydraulic Press uses hydraulic pressure to exert force on a material, making it ideal for tasks that require a lot of power, such as stamping, pressing, or forging metal components. They are more versatile than mechanical presses and can handle a wider range of tasks.

H Type Power Operated Hydraulic Press

The H Type Power Operated Hydraulic Press is a heavy-duty press designed for industrial applications that require significant force. Its H-frame construction ensures stability and precision during operation.

H Type and C Type Hydraulic Presses

Both H Type and C Type Hydraulic Presses are commonly used in metalworking. The main difference is in their construction: H Type presses offer more support and are better suited for larger tasks, while C Type presses are more compact, making them ideal for smaller tasks.

Iron Workers and Hydraulic Iron Workers

Iron Workers are machines used for cutting, punching, bending, and shaping metal. Hydraulic Iron Workers use hydraulic power for these tasks, offering more force and precision, which is essential for thicker or tougher materials.

Nibbling Machines

A Nibbling Machine is used to make small cuts in metal sheets, creating intricate shapes or patterns. These machines are particularly useful for tasks that require precision and detail, such as cutting out complex designs in metal plates.

Conclusion

Choosing the right bending machine or press depends on the specific requirements of your project. Whether you're working with large metal plates, delicate bus bars, or intricate profiles, there is a machine tailored to meet your needs. Understanding the various types of bending and pressing machines available can significantly improve efficiency, precision, and the quality of your final product.

youtube

0 notes

Text

Understanding Sheet Bending Products

Introduction

In manufacturing, the precision and quality of metal bending are vital for ensuring the structural integrity and performance of the final product. Sheet bending machines are indispensable tools in various industries, providing the capability to shape metal sheets into desired forms. This article explores the fascinating world of sheet bending products, their types, and their applications across different industries.

What is Sheet Bending?

Sheet bending exporter is a metalworking process where a metal sheet is deformed along a straight axis, creating a desired angle and shape without altering the sheet's overall thickness. This technique is crucial in manufacturing, allowing the creation of components for applications ranging from automotive parts to household appliances.

Applications of Sheet Bending

Sheet bending is employed across multiple industries, including automotive, aerospace, construction, and electronics. It is used to produce parts like brackets, enclosures, structural components, and decorative items. The precision of sheet bending ensures that parts fit perfectly within assemblies, maintaining structural integrity and aesthetic appeal.

Types of Sheet Bending Machines

There are several types of sheet bending machines, each designed for specific tasks. Press brakes are used for bending large sheets into simple or complex shapes. Bending rollers are ideal for creating cylindrical shapes or large radius bends. Folding machines are specialized for bending thin sheets into various angles.

Profile & Pipe Bending Machines

Profile and pipe bending machines are designed to bend metal profiles and pipes into desired shapes without compromising their structural integrity. These machines are essential for industries that require curved or circular metal components.

Benefits of Profile & Pipe Bending Machines

Profile and pipe bending machines offer several advantages. They provide accurate bends, ensuring consistency in production. They are versatile, and suitable for various materials including steel, aluminum, and copper. They also increase production speed and reduce manual labor. Industries such as construction, automotive, shipbuilding, and furniture manufacturing extensively use profile and pipe bending machine to create components like frames, supports, and railings.

3 Roll Pyramid Type Mechanical Plate Bending Machine

The 3 Roll Pyramid Type Mechanical Plate Bending Machine is used for shaping metal plates into cylindrical and conical shapes. It uses three rollers arranged in a pyramid configuration to apply force to the metal sheet.

Operation of 3 Roll Pyramid Type Mechanical Plate Bending Machine

The machine operates by positioning the sheet metal between the rollers, which are adjusted to apply the necessary pressure to bend the sheet into the desired shape. The top roller moves vertically, while the bottom rollers move horizontally to create the bending force. These machines ensure consistent and accurate bends, have robust construction for long-term use, and are suitable for various materials and thicknesses.

Bending Roller Machines

Bending roller machines are used to roll metal sheets into cylindrical or conical shapes. They are essential in creating components like tanks, drums, and pipes.

Functionality of Bending Roller Machines

These machines operate by passing the metal sheet through a series of rollers that apply pressure, gradually bending the sheet into the desired shape. The rollers can be adjusted to achieve different diameters and shapes. Bending rollers ensure uniform bends, can handle various thicknesses and materials, and reduce waste while increasing production efficiency.

Bus Bar Machines

Bus bar machines are specialized tools designed for the bending, cutting, and punching of bus bars, which are crucial components in electrical systems.

Use of Bus Bar Machines

These machines can perform multiple tasks such as bending bus bars into required forms, trimming them to precise lengths, and creating holes or slots for mounting and connection. Bus bar bending-cutting-punching machines are vital in the production of electrical panels, switchgear, and power distribution units, ensuring reliable and efficient electrical connections.

Metal Sheet Bending Machines

There are various metal sheet bending machines catering to different bending needs. Hydraulic press brakes offer high force for thick sheets. Mechanical press brakes provide quick and precise bends. CNC press brakes allow for automated, repeatable bending processes.

Features of Metal Sheet Bending Machines

These machines are known for their precision, accurate angle control, robust construction for long-term use, and user-friendly interfaces and controls. Metal sheet bending machines are used in automotive, aerospace, and appliance manufacturing, producing parts like body panels, brackets, and enclosures.

Folding Machines

Folding machines are used to bend thin metal sheets into various angles, typically for creating precise folds and creases.

Advantages of Folding Machines

These machines offer several advantages including accurate and consistent folds, faster operation than manual bending, and the capability of handling complex folds and multiple angles. Folding machines manufacturers are used in HVAC ductwork, cabinet making, and metal furniture production, where precise bends and folds are essential.

Hydraulic Press Machines

Hydraulic press machines use hydraulic cylinders to generate compressive force, allowing for precise and powerful metal forming.

Working of Hydraulic Press Machines

These machines operate by applying pressure through a hydraulic system, which moves a ram to shape the metal. The pressure can be finely controlled, providing consistent results. Hydraulic press machines can handle thick and tough materials, offer adjustable pressure for accurate forming, and are equipped with safety features to protect operators.

Hydraulic Iron Worker Machines

Hydraulic iron worker machines are multifunctional tools used for cutting, punching, and bending metal sheets and profiles.

Utility of Hydraulic Iron Worker Machines

These machines can perform several tasks, making them highly versatile, including shearing metal sheets and profiles, creating holes and slots, and forming metal into desired shapes. Industries such as construction, shipbuilding, and metal fabrication benefit from the versatility and efficiency of hydraulic iron worker machine.

Nibbling Machines

Nibbling machine use a punch and die to create intricate shapes and patterns in metal sheets by removing small pieces of material. These machines provide high precision and efficiency, making them ideal for detailed and complex metalwork.

Applications of Nibbling Machines

Nibbling machines are used in the aerospace, automotive, and electronics industries to create detailed components and parts that require precise cutting.

Power Press Machines

Power press machines use mechanical force to shape metal sheets, typically for stamping, punching, and forming operations. There are several types of power presses, including mechanical power presses that use mechanical energy for high-speed operations, hydraulic power presses that offer controlled force for precision tasks, and pneumatic power presses that use air pressure for fast and efficient operations.

Industries Utilizing Power Press Machines

Cross soft Power press machines are widely used in the automotive, appliance, and hardware industries to produce parts like brackets, enclosures, and connectors.

Press Brake Machines

A press brake machine is used to bend metal sheets and plates into specific angles and shapes, offering high precision and control.

Types of Press Brake Machines

There are several types of press brake machines, including hydraulic press brakes that offer consistent force for precise bends, mechanical press brakes that provide fast and repeatable bends, and CNC press brakes that are automated for complex and repeatable bending tasks. Press brake machines are crucial for producing precise bends in metal sheets, ensuring that parts fit perfectly in assemblies and maintaining structural integrity.

Riveting Tools

GP-G-Series riveting tools are designed for fastening components together using rivets, providing strong and reliable joints.

Usage of Riveting Tools

Riveting tools are used in various assembly processes, including automotive, aerospace, and construction, where strong and permanent joints are required. Riveting tools create durable and strong joints, offer a fast and efficient fastening process, and are suitable for various materials and applications.

Shearing Machines

Mechanical under crank shearing machines are used to cut metal sheets with precision and efficiency, typically for preparing materials for further processing.

Operation of Shearing Machines

Shearing machines operate by moving a blade in a straight line to shear the metal sheet, providing clean and precise cuts. Shearing machines are used in metal fabrication industries to cut sheets into desired sizes and shapes, preparing them for bending, forming, or welding operations.

Conclusion

Sheet bending products are essential tools in modern manufacturing, enabling the precise and efficient shaping of metal sheets into various forms. They ensure high quality and advanced technology to meet the diverse needs of industries worldwide. Whether you require bending rollers, hydraulic presses, or nibbling machines, sheet bending products provide the perfect solution to enhance your productivity and efficiency.

youtube

1 note

·

View note