Don't wanna be here? Send us removal request.

Text

What Type Of Products And Services Does Offshore Procurement Companies Supply?

Offshore procurement companies can offer a variety of products and services to meet the needs of investment, management and maintenance of businesses, rigs and more.

Some of the bigger items that can be procured include:

Pipes

Valves and Actuators

Flow Measurement

Fittings

Gaskets

Lifting Equipment

Wire Rope

Electrical Materials

.

.

.

Original source: https://offshoresuppliers.net/

0 notes

Photo

How South Africa Aims To Stop Litter On Our Shores

Dealing with ship chandlers in Cape Town has led to an interest in all things maritime, which makes this exciting news about South Africa’s shores a must share!

The coast of South Africa’s Kwazulu-Natal province looks like it was pulled from a postcard, with wide, sandy beaches stretching for some 600 kilometres. International and local tourists flock here in normal times, drawn to the warm Indian Ocean waters for surfing, relaxation, and glimpses of spectacular wildlife, like loggerhead turtles.

But heavy rains can transform this beautiful coast in a flash. Downpours accelerate the flow of polluted upstream rivers, sending their litter cascading into the sea, including around the city of Durban. After a storm, heaps of plastic bags and bottles pile up on Durban’s shores with the current transporting some rubbish hundreds of kilometres down the coast.

What’s happening to Kwazulu-Natal’s beaches is part of a larger marine litter crisis in South Africa. Every year, between 90,000 and 250,000 tonnes of rubbish enter the oceans that surround the country. This marine litter can damage ship engines and propellers. It becomes entangled in nets and other fishing equipment. It drives away tourists. It’s often ingested by birds, mammals, and fish, causing them to choke or become sick. And it can find its way into the human food chain.

But just where is all this waste coming from?

“Eighty per cent of marine litter originates on land, mediated through flash floods and river inputs,” said Jared Bosire, Project Manager with the United Nations Environment Programme’s (UNEP) Regional Seas Programme. “Therefore, if we want a clean ocean, we must change our behaviour onshore and link the solution to the source, which is upstream.”

A new project driven by the South African Department of Environment, Forestry and Fisheries aims to do exactly that. The department is joining forces with local officials, non-profit groups, like Coastwatch and Durban Green Corridors, and Plastics SA, a privately-owned company, to stem the flow of marine litter in five river systems in Kwazulu-Natal. Through increased litter collection and community-led waste sorting and recycling, the department will reduce litter generation at its source, thereby lessening the amount of pollution that reaches the ocean.

Litter booms, barriers that collect floating debris, will be installed in the uMngeni, uMlazi, uMbilo, uMhlatuzana, and aManzimnyama rivers. Communities will help clean out the booms on a daily basis during the two-year project. The booms have the added benefit of trapping invasive species, like the exotic water hyacinth, before they take root in waterways.

“If we want a clean ocean, we must change our behaviour onshore.”

- Jared Bosire, UNEP project manager

The department will also implement a waste sorting and recycling programme in one community per river. One possibility being considered is the idea of “swop-shops” where community members can trade the recyclable litter for essentials, said Yazeed Petersen, a Project Manager from the South African Department of Environment, Forestry and Fisheries. “Integrating these shops into the project will further encourage communities to become involved in litter collection.”

Douw Steyn of Plastics SA agreed. “We need to ensure that value is given to waste plastic so that it can contribute to the circular economy. Recyclers cannot get enough material, so there is enormous potential for those willing to collect litter.”

The project is designed to help South Africa achieve its targets under Sustainable Development Goal 14.1, under which the country is committed to preventing and reducing marine pollution by 2025, as well as Sustainable Development Goal 6.3 to improve water quality by 2030 through reducing pollution.

The initiative is being funded by the Global Environment Facility through the Implementation of the Strategic Action Programme for the Protection of the Western Indian Ocean from Land-Based Sources and Activities, executed by the Nairobi Convention. This project will reduce land-based stresses on this environment by protecting critical habitats, improving water quality, and managing river flows. The convention, part of UNEP’s Regional Seas Programme, serves as a platform for governments, civil society and the private sector to work together for the sustainable management and use of the Western Indian Ocean.

.

.

.

Original article from https://www.unep.org/

1 note

·

View note

Text

Procurement Teams And Category Management

The benefits it brings and top tips for success

Experienced procurement professionals will no doubt have heard the terms ‘category management’ and ‘category planning’. For some, they may represent an ideal way of working that feels very far from the reality of their day-to-day experience. For others, they may be synonymous with a past attempt to try something new that sadly failed due to lack of momentum, support, resource or internal buy-in.

Whichever camp you fall into, we’re here to tell you why category management is key to effective procurement functions, and offer our top tips for successful implementation – whether it’s your first foray into it, or you’re approaching category management the second time around.

What is category management?

In the private sector, businesses may drive revenue as far as they can through sales and expanding into new markets, yet still, struggle to improve their profit margins. In the public sector, there is the ongoing battle to do more with less – to expand and improve services despite budget cuts.

In both cases, a strategic approach to controlling expenditure is vital. Without it, it can be easy to allow costs to spiral in the background.

Where category management comes in is to provide the holistic, 35,000-foot-level view of spending across your organisation.

Instead of procuring different products and services separately, it involves grouping areas or types of spend together for ease of management, and to identify where cost savings and other improvements can be made.

A more modern approach to procurement, done right, and together with effective ship chandler, can make a huge difference to a business’s efficiency and profitability.

The benefits of category management

The benefits of category management can be wide-ranging, and include:

Financial savings

First, and perhaps most obviously, effective category management can be the key that unlocks those bottom-line savings organisations are seeking. Having an overview of your organisation’s entire spend, as well as a closer relationship with the marketplace, will help to show areas where spend may be consolidated, either through standardisation across sites, by combining the buying power of multiple procurement teams, or by merging multiple contracts into one under a particular supplier. Due to the nature of contract management, these savings may not be made overnight – it can take some time to align contract terms for example – but the time and effort invested will be worth it in the long run.

Better value for money

Price is not the only criteria upon which contracts are awarded, and the benefit of category management is that, done well, it provides a much clearer evaluation of what is important to an organisation across different areas of spend, whether that be legal compliance, socio-economic benefit, encouraging SMEs, environmental credentials, or something else. So, category planning may result in a focus on a sub-category that does not drive pure cost savings but drives further benefits to the organisation elsewhere.

Increased innovation

It can be tempting to stick with the safety net of an existing supplier because you know they can do the job, even if it means you miss out on the opportunity to get something better for your money. Moving to a new supplier can feel like a big risk, especially where organisations have goods and services that represent critical spend, or have to be traceable, or 100% compliant. By providing a more holistic view of the marketplace, category management enables organisations to have better visibility of opportunities for split-sourcing to test up-and-coming suppliers who may offer more innovative approaches, as well as providing a better foundation from which to manage those relationships. The result is that your organisation can test the waters and bring in more innovation, with less and manage risk.

Improved job satisfaction

Procurement professionals that successfully transition from buyer to category management lead are likely to experience increased job satisfaction, leading to better staff retention. They will still be doing the deals that give them the ‘buzz’, but with more depth: more diverse evaluation criteria, a wider view of the marketplace, and being closer to the data and stakeholders will make the job more varied – and more interesting. They’ll also be able to clearly demonstrate the value they provide for stakeholders through their work – value that those stakeholders could not achieve themselves.

10-point plan for category management implementation

Determine your categories and sub-categories. Category management depends on an organised, structured approach. By looking at all your areas of spend and breaking them down into themes with relevant sub-categories, you can decide where to focus your category planning energies depending on size, amount of spend or criticality to your operation.

Make sure you have quality data on your expenditure. Many organisations will have a lot of data on the front-end of the business through finance and ERP systems and will focus scrutiny there, but may have a lot less visibility of their costs. Effective category planning relies on quality data on past, current and forecasted expenditure, taking into account what is likely to happen in the next 12, 24 or 36 months.

Don’t forget about capex. The majority of organisations will only apply category planning to operational expenditure, with capital expenditure running separately, using different suppliers and subject to different processes and procedures. This is a missed opportunity, as bringing the two together may offer the opportunity to strengthen supplier relationships, reduce costs and improve efficiency.

Estimate the cost-benefit. Evaluate your current suppliers and contracts. If you grouped them according to your category plan and went out to market in that way, what do you think the potential gross savings could be on your bottom-line expenditure?

Determine your ‘confidence factor’. How much support are you likely to get from employees and other stakeholders to do things differently? Do you have senior-level buy-in and are they committed to removing blockages to implementation? How much time do you and your team have to dedicate to moving across to category management? The answers to these questions will help to determine the level of outside support that may be required to complete the transition to category management.

Evaluate the opportunities for synergies and standardisation. Do you have different suppliers providing the same or similar products to your different offices or sites? Are there opportunities for you to go out to market at the same time with a standardised product or slimmed-down list of options, and benefit from the resulting economies of scale?

Check if you can make life simpler. Whether through automation, disruptive technology, streamlining processes, or removing unhelpful blockages, investigate the means by which you can improve efficiency in your organisation. What is currently wasting your staffs’ time, and how can you change that?

Ascertain your opportunities for continuous improvement. Where can you innovate and improve? Can you use products that are more environmentally friendly? Where can you improve compliance, or offer new socio-economic benefits to the community?

Establish a risk matrix. Draw up a list of the key products and services you need to ensure business continuity, and to meet security and compliance requirements. Use this to put together a risk matrix and business continuity plan that considers the impact on your organisation of a lack of supply in any of these areas.

Consider what you want from your suppliers. Supplier relationship management is a key part of successful category management. A buyer-supplier relationship should have a mutual respect that drives benefits on both sides. So, it can be helpful to establish at the outset what you want your supplier relationships to look like, including how often you should be meeting at the operational and strategic level, and the sort of tangible benefits you expect from a long-standing relationship with a preferred supplier.

.

.

.

Article from https://www.exceeding.co.uk/

0 notes

Photo

The National Disaster Management Guidelines For Boat Safety

On river Brahmaputra, the Dhubri ferry tragedy on April 30, 2012, accounted for the loss of over 250 lives. The increase in the number of boat accidents was brought to attention after the incident. The tragedies were due to overloading and other related factors. It was necessary to avoid the risk of loss of lives which are the result of poor training, dangerous work practices, shortage of marine safety equipment at Cape Town and other ports, inadequate regulation, and near non-existent enforcement.

Thus a need was felt to formulate guidelines on boat and navigation safety in consultation with the concerned states and stakeholders. The National Disaster Management Guidelines for Boat Safety is an effort to sensitize boat operators, passengers, local authorities and stakeholders about the dangers of unsafe navigation practices.

.

.

.

Article from https://www.shmgroup.com/

0 notes

Photo

Shipbuilding Projects Success - How

Unprecedented complexity “Watch the little things; a small leak will sink a great ship,” said Benjamin Franklin. And a small oversight will sink a great shipbuilding project, one might add.

Building a product as complex as a ship, with its hundreds of thousands of parts, and its constellation of OEMs, design offices, suppliers and subcontractors is a challenging endeavour indeed. It takes an average of two years to build an offshore support vessel, and five to seven years to build an aircraft carrier. In comparison, it takes less than 3 months to build a Boeing 777 and 17 to 18 hours to make a Toyota. In addition, no two ships are ever the same. Even sister ships have differences, and these differences in design mean that each shipbuilding project is unique.

Recent years have seen a growing demand for high-tech and high value-added vessels. Navies are asking for adaptable, multirole vessels that can deal with military operations other than war, for example, providing humanitarian relief and emergency medical care after natural disasters or establishing a helicopter platform for replenishment or evacuation. At the other end of the spectrum, the yachting and cruising industries demand versatile vessels that can operate in a wide range of conditions, from the Galapagos to Antarctica. Those vessels require high-tech equipment and systems onboard. They need more sensors, more cables, more automation, and more controls. This increased level of complexity translates into unprecedented risks in the design and build processes. If shipbuilders want to remain competitive in today’s saturated market, they must identify risks as early as possible in the project and find ways to keep those risks under control to deliver on time, on budget and on quality.

Costing: dilemma vs reality In his M.Sc. Thesis – Marine Systems Design at The Department of Marine Technology at the Norwegian University of Science and Technology (Trondheim), “Shipbuilding Cost Estimation”, Haakon Shetelig describes the shipbuilder’s dilemma as follows:

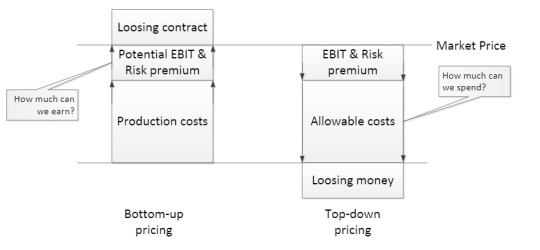

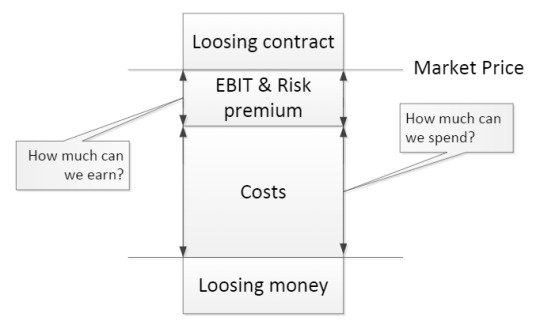

“The dilemma of the shipbuilder is to decide which starting point to choose to find the newbuilding price; the expected costs of a certain vessel or the expected market price for the same vessel. If a shipbuilder chooses to find the price for a new building with bottom-up pricing [also called costing, which is when the price is decided based on the costs], there is a risk of overpricing and then losing a contract. On the other hand, if a shipbuilder uses the market price as the basis [bottom-down pricing, or target costing], the main risk is that the price is too low to cover the expenses.”

Note: EBIT = earnings before interest and taxes

Bids must be both attractive and accurate – if the price is too high, the shipyard may lose business. If it is too low, it will lose money. As Haakon continues, there are a few other factors impacting the pricing, such as historic deals impacting the market price, marine suppliers’ prices, etc. As a result, the shipbuilder’s reality is a combination of both approaches whereby the shipbuilder must find the sweet spot between pricing and costing to secure the highest possible profit margin.

Mitigating risks

Risks must be kept under control to maximize earnings, avoid schedule delays, and ensure that the customer’s requirements are met. Failure to deliver according to the contract terms may lead to penalties and, in some cases, damage the shipyard reputation.

The only way to manage those risks is to combine cost, schedule and technical requirements in a fully planned, resourced and budgeted end-to-end project management solution. This integrated solution must offer the three following features:

Integrated planning: Typically, in Marine, the work breakdown structure (WBS) forms the basis of the shipbuilding process. At all times the WBS needs to be connected to the technical requirements set by the customer, so shipbuilders can keep track of how any change to the schedule will impact those requirements, and ensure that they are still able to comply with the contract. Having an integrated systems approach to planning and execution is critical for projects as complex as building a ship.

Integrated bid & risk management: Requirements and risks must be connected from the very beginning of the shipbuilding project when the shipyard is responding to an IFB (invitation for bids) or an RFP (request for proposals). This will ensure that risks are accurately assessed and clearly communicated to the customer during the bidding process.

Closed-loop project management: Best practices and lessons learned need to be fed back into the work breakdown structure (WBS) so workflows and processes can be improved continuously.

Conclusion: introducing the IPPE octopus

To remain competitive in today’s uncertain market, a shipyard must deliver bids that are both attractive and accurate. To this end, having a fully planned, resourced and budgeted end-to-end project management solution has become critical. In the previous paragraph, we have highlighted three key features that a true integrated project planning and execution (IPPE) system should offer.

However, the full picture looks a lot more like this:

And just like an octopus, your shipbuilding project management system should be robust, yet flexible and adaptable. If implemented correctly, it will enable you to steer your projects to successful completion, however complex they may be.

Article from https://blogs.sw.siemens.com/marine/

0 notes

Photo

Common Questions About Inflatable Boat Repairs And Maintenance Answered

We’ve noticed, as ship suppliers, the popularity of and demand for inflatable boats has drastically increased over the past few years. New methods of production, stronger materials, and updated models are the main reasons for the popularity of inflatable boats.

Since the use of these boats has increased, it is necessary to know about the repair and maintenance for the same. Here are 10 common questions people ask while considering the repair and maintenance of inflatable boats.

#1 What is the life of an inflatable boat?

On average, the life expectancy of an inflatable boat is 10-15 years. The approximate lifespan can extend or shorten depending on several factors and the use of the inflatable boat. The age of the boat, the material used, it is stored, the amount of UV exposure, method of manufacture such as using a hand-glued machine vs machine-welded seams, are some of the factors responsible in determining the lifespan of the boat.

In ordinary cases, boats made from Hypalon last longer than those made from PVC. However, inflatable boats are the most easily damaged due to lack of maintenance and proper care.

#2 How to clean an inflatable boat?

It is necessary to clean an inflatable boat after each use. If it is not cleaned, dust and grime tend to settle on the surface of fabric or rubber, which makes the boat look filthy. It also starts the process of boat decay. Rinsing the boat after every use is the most important part of cleaning an inflatable boat. The inside of the boat should be rinsed using fresh water.

It helps to invest in a quality Boat Cleaning Solution which will help keep the boat clean and ship-shape.

After the boat is rinsed with water, ensure that the water does not stay on the surface of the boat. Therefore, the boat should be kept upside down to drain out the water. Then, it should be wiped dry with a towel. Areas between the floor and the side tube tend to collect water, thus they must be strictly dried.

The drying process is the most important one because if the boat is stored without the water being cleaned off its surface, it becomes susceptible to mould.

Leaving the boat out in the sun over extended periods is inadvisable. The heat of the sun tends to damage the fabric of the boat. Therefore, the boat should be sprayed with UV protectant sprays at regular intervals. If the boat has discolouration or dirt patches on its surface, it should be cleaned with an inflatable boat cleaning solution, sponges and brushes, water and hose sprayer. The stains should be scrubbed with a sponge until they come off the boat.

# 3 How to store an inflatable boat?

For storage, your inflatable boat should be kept out of the water to maintain its good condition. Keeping it on the water will expose it to algae, bacteria and other temperature changes, which will cause degradation.

Inflatable boats can be conveniently stored in a small space. However, before storing, the boat should be thoroughly cleaned. The spot where the boat is to be stored should be away from pests and rodents. The boat should be wrapped in extra layers of plastic cover to keep it safe.

The boat is then to be rolled up and kept in a place where it will remain unaffected by extreme changes in the climate as excessive heat and humidity have a negative impact on the adhesives on the boat.

#4 How to identify the fabric of your RIB or inflatable boat?

To repair an inflatable boat, it is first necessary to know the type of material it is made of, so as to use appropriate tools and measures. In ordinary cases, to manufacture the inflatable collars and tubes of boats, three main types of materials are used: Hypalon, Polyvinyl chloride (PVC), and Polyurethane (PU).

Hypalon is a synthetic rubber coating on the fabric. It can last for up to 20 years and its joints are glued by overlapping of layers which are glued to each other. Hypalon boats are dark grey and black.

PVC is a plastic coating which is not flexible and cracks over time. It is the cheapest material for production and can be welded or glued. Boats made out of this are glossy in colour.

PU is a relatively new material and has superior airtightness and durability, as compared to Hypalon and PVC. It is glossy in colour.

#5 How to repair an inflatable boat?

The environment in which the boat is going to be repaired has to have a relative humidity less than 60%, the temperature should be between 18°C and 25°C and the area should be dry and well ventilated. There should be no open flame in the area.

For Hypalon fabric boats, a suitable adhesive should be used. The purpose of repair requires a lot of materials and tools. Some of them are adhesive glue, fabric patch, piece of polythene, sandpaper, solvent/primer or acetone, glue brush, acetone.

The basic steps for repairing an inflatable boat are as follows:

Identify the fabric with which the inflatable boat is made. The type of fabric determines what the apparatus is to be used for repairing the boat.

Create an ideal environment in which to work and repair.

Repair of tubes and collars of the inflatable boat involves tears up to 55mm long. Small tears can be repaired with a single fabric patch, but the larger patches need fixing both from the inside and the outside of the tube.

Gather all the materials required beforehand.

Locate the tear in the tube. If unsure, apply soap water on the surface and look for bubbles arising.

Cut a fabric patch with round corners including the overlap. For Hypalon and PU patches, abrade the back to achieve a key for the application of adhesives.

Clean the back of the patch with a solvent and wait till it evaporates. Mask the area that needs to be repaired to avoid excess application of adhesive.

Use a 2-part adhesive and apply it on the back of the patches in a thin coat. Wait for it to dry for 20 minutes and apply the second coat.

Place a small piece of polythene over the glued area so the patch can be rolled and placed inside the tear.

Unroll the patch and let the surfaces stick.

Smoothen the patch to ensure there are no air bubbles.

Remove the masking tape along with the excess adhesive.

Place a heavyweight on the repair for 24 hours, to make sure the repair has been successful before relaunching the boat.

#6 How to find a leak in a Rigid Inflatable Boat?

The process for inspecting an inflatable boat to find a leak is as follows:

To locate the leak, you have to inflate the collar or tubes of the boat to the maximum so that it sounds like a drum when tapped on with the flat of your hand.

Inspect all areas of the inflatable collar or tube for signs of wear and tear.

Mix mild Ph washing liquid and warm water in equal parts in a spray bottle.

Spray the solution on one side of the tubes and look for any bubbles forming.

Mark all the areas where bubbles are evident with a marker.

Once the entire area of the boat is covered, rinse the surface thoroughly with water and allow it to dry completely.

Further repairs can be carried out on every part where the leak is found, as mentioned above.

#7 How to fit a replacement screw-in type inflatable boat?

RIBs and many other inflatable boats are fitted with the screw-in type of valves. It is necessary to know about the anatomy of the valves in order to fix them. The next process is:

Once the identification of the male and the female section is done, deflate the tube on a flat surface.

Before unscrewing the male section of the valve, make sure the new one is handy.

Lay the tube flat and put downward pressure on the valve.

Hold the female valve through the tube to prevent it from moving inside the tube when the male section is unscrewed.

Unscrew the male section and replace it with the new male section.

Ensure that it is in a closed position and re-inflate the test tube to check for leaks and repairs.

#8 How to fix or glue inflatable PVC fabric patches and accessories to Hypalon fabric RIB collars and tubes (and vice versa)?

PVC adhesive and Hypalon fabric, or vice versa, are not compatible but they can be bonded. The first step is to prepare the fabric patch.

For PVC patch –

Clean the side of the fabric or accessory that is to be glued, with solvent or acetone.

Glue PVC patch to Hypalon tube –

After cleaning the patch, apply one coat of adhesive to the side that is to be glued. Allow it to dry and then simply fix it to the Hypalon collar.

For Hypalon patch –

Thoroughly abrade the back of the patch and clean it with a solvent.

Glue Hypalon patch to PVC tube –

After abrading and cleaning the patch with solvent as told in step one, apply a coat of Hypalon adhesive to the back of the patch. Allow it to try and then fix it to the PVC collar.

#9 How to replace an inflatable boat valve?

As required during the repair of inflatable boats, the environment where the valve is to be replaced must be stress-free, relative humidity less than 60%, temperature between 18°C and 25°C. The area should also be ventilated.

The procedure then is as follows:

Deflate the tube and remove the existing valve.

Cut the fabric around it and remove the entire valve assembly.

Fit the new valve to the assembly with valve-doubler.

Lay the assembled valve over the tube and mark the area.

Mask the area with removable masking tape to avoid over-applying of the adhesive.

Abrade the back of the doubler and achieve a key for adhesive (only for Hypalon). Over abrasion must be avoided as it can damage the fabric. PVC does not have to be abraded.

Clean the back of the patch with solvent and wait for it to evaporate.

Apply adhesive using a brush, in a thin coat and leave it to dry for 20 minutes. Apply the patch and the doubler to the cut-out. Smooth down the fabric area to make sure there are no bubbles.

Remove the masking tape along with the excess of solvent and adhesive. Put a weighted object on top of this for 24 hours.

Endnote

That concludes our list of the 10 most common questions people ask when it comes to inflatable boats. For the do-it-yourselfers out there, a word of caution. Repairing and maintaining an inflatable boat is necessary to keep it functioning properly and smoothly.

Even so, it is made mandatory by the IMO to get all inflatable boats inspected once every five years, from a certified manufacturer or service provider. There are several leading inflatable boat manufacturers that offer oar inspection and repair services, which help keep your boat safe and water-worthy for many years.

What are your thoughts about repairing and maintaining inflatable boats? Any questions you would like to ask? Drop a comment to let us know.

Article source: https://www.shmgroup.com/

0 notes

Photo

Ships and installations on South African oceans to report discharge of harmful substances or face a criminal charge’

Here’s an important article from our shipping agents who like to make sure everyone in the industry knows what’s going on IN the industry.

A photo of an incident involving the accidental discharge of oil by a refuelling vessel at sea in South African waters. (SAMSA File Photo)

Seafarers sailing their ships or manning installations across South Africa’s vast three oceans at the tip of the African continent could face fines of up to R25 000, six months in jail or both, should they fail to inform local authorities of such discharges as soon as it is practically possible.

That is according to the South African Maritime Safety Authority (SAMSA) in a Marine Notice (No.55 of 2020) due out this week.

Acting in terms of the Marine Pollution (Control and Civil Liability) Act 6 of 1981, SAMSA said on Friday that should any harmful substance be discharged from a ship, tanker or offshore installation, the involved parties are legally obliged to immediately report the incident to local authorities. These include SAMSA and the Department of Environment, Forestry and Fisheries.

The required report, according to SAMSA also involves any damage to a vessel, a tanker or installation from which a discharge of harmful substances onto the ocean may occur, this regardless of whether such discharge has not actually occurred.

A stricken vessel being towed into a port after suffering damage while traversing South African oceans. (SAMSA File Photo)

The MN No.55 states in part: “…When any harmful substance has been discharged from a ship, tanker or offshore installation the master of such ship, tanker or offshore installation, or any member of the crew of such ship or tanker or of the staff employed in connection with such offshore installation, designated by such master, shall forthwith by the quickest means of communication available report the fact that such discharge has taken place to the principal officer at the port in the Republic nearest to where such ship, tanker or offshore installation is.

“If, while it is within the prohibited area (E.E.Z [Exclusive Economic Zone]), a ship or a tanker sustains any damage, whether to its hull, equipment or machinery, which causes, or creates the likelihood of a discharge of any harmful substance from such ship or tanker, or having sustained such damage, enters the prohibited area in such damaged condition, the master of such ship or tanker, or any member of its crew designated by the master, shall forthwith by the quickest means of communication available report to the principal officer at the port in the Republic nearest to where such ship or tanker then is the fact that such damage was sustained, the nature and location on the ship or tanker of the damage, the position at sea where the damage was sustained, the name of the ship or tanker, its port of registry, its official number, its position, its course and, if in the Republic, its destination, the quantity and type of harmful substances on board and, in the case of a tanker to which the provisions of section 13 apply, the particulars contained in the certificate.”

Bunkering services on the Indian Ocean near Port Elizabeth (SAMSA File Photo)

On reporting, the MN No.55 indicates that: “SAMSA, DEFF (Department of Environmental, Forestry and Fisheries) and African Marine Solutions (Pty) Ltd AMSOL (the managers of the standby tug “SA Amandla”) are all concerned with the prevention, containment and cleaning up of oil spills at sea. These organizations should be informed as soon as possible whenever there is an oil spill or a threat of an oil spill. SANNCOB (The South African Foundation for the Conservation of Coastal Birds) is dedicated to seabird rehabilitation. SANPARKS (South African National Parks) is the body responsible for managing South Africa’s National Park to develop, expand, manage and promote a system of sustainable National Parks.”

Contact details of all the relevant authorities and contributors to combating of pollution, inclusive of SAMSA regional offices from Port Nolloth on the Atlantic Ocean to Richards Bay near the border of Mozambique on the Indian Ocean, are given in the notice.

In terms of penalties where failure to report occurs, MN No.55 states: “If the master of a ship or a tanker fails to comply with the provisions…. such master shall be guilty of an offence. Any person convicted of an offence …. shall be liable to a fine not exceeding R25 000 or to imprisonment for a period not exceeding six months or to both such fine and such imprisonment..”

According to SAMSA, the marine notice will be on the Department of Transport agency’s website shortly.

Article from: http://www.samsa.org.za/

0 notes

Photo

Is Your Ship’s Safety Equipment in Order?

Lifejackets:

We all know that Lifejackets are the most important piece of safety equipment on any recreational vessel. An approved lifejacket must be carried for each person onboard most vessels. It must be the correct size for the wearer, in good condition and, if an inflatable lifejacket, properly serviced.

Now's a good time in the year to make sure your lifejacket is in good working order.

You can ask your local marine supplier about life jackets and ensuring their up to standard.

Horseshoe Life Buoy:

Additional marine safety equipment that you must have accessible on your boat includes the Horseshoe Life Buoy.

Make sure your Life Buoy isn't suffering from serious wear-and-tear and needing replacing.

Burke's Horseshoe Life Buoy is made from flexible closed foam with zero water retention and offers continuous floatation. It comes with a double coated P.V.C nylon cover, external rope handle, whistle and reflective patches. Complies with AYF special regulations 4.17 and 4.21 when self-ignighting light and drogue are attached.

Retriever Float Lifesling and Stowbag:

An integrated rescue float and lifting sling for man overboard rescue and recovery is not compulsory to have on your vessel, however is highly recommended. Easy to use and store, this low maintenance closed cell foam flotation has retro-reflective patches, wraparound heavy duty webbing straps and 45 mts of 8mm floating line.

Complete with printed instructions and a reinforced PVC stow bag that is easy to attach and remove from boats rail when not underway. Meets YA SR 4.21 Lifebuoy requirement when a self-igniting light fitted.

Throw Bag:

An alternate option for man overboard, is our compact throw bag has 15.2 metres of 3 strand floating line stowed in a nylon bag. Easy to use, simply grasp the hand loop at the draw string end with your non-throwing hand and throw bag at target.

.

.

.

.

.

.

Article source: https://www.burkemarine.com.au/blogs/news/safety-first-is-your-safety-equipment-in-order

0 notes

Photo

NAVIGATING A COVID-19 EFFECTED SHIPPING MARKET

The world is confronting one of the greatest health crises of a generation, one that significantly impacts the worldwide economy, international trade, and global shipping. Our thoughts remain with the communities and individuals, including healthcare workers, first responders, ship chandlers Cape Town and supply chain professionals, who have been affected by the COVID-19 crisis.

At MTS Logistics, we understand our duty as an essential provider of transportation and logistics services worldwide. In today’s environment, we are focused on helping our clients navigate the latest shipping challenges, in a smart and effective way, providing the latest shipping tools, services, market data, and specialized shipping expertise.

Thanks to our procedures, cloud-based technical tools and capacity in place, we continue our operations and customer service normally.

Below is an overview of the current issues with air and ocean freight in the market.

With each new day, we provide greater clarity for our clients and customers on how COVID-19 is affecting global shipping, and the ways they can navigate uncertain waters in this volatile times.

OCEAN FREIGHT

COVID-19 is affecting the ocean freight industry differently, but the main themes are inconsistency and changes in demand. Shipping lines and carriers responded to reduced demand by cutting capacity up to 50%. Blank sailings in the Transpacific shipping lane is the new normal. The weekly sailing schedules from China, Malaysia, and Vietnam have been reduced to bi-weekly, and even every 21 days. This makes supply chain planning very difficult for shippers worldwide. Ningbo and Shanghai seem to be affected from this space situation the worst so far. Most of the vessels for Transpacific routes have been overbooked weeks in advance, and premium ocean freight services that guarantee space and equipment are on the rise for shippers that are willing to pay for it. These expedited premium ocean freight services are highly in demand as well for those who cannot afford to risk roll overs, as we even see “subject to roll over” space getting overbooked.

While U.S imports are decreasing on a year-over-year basis, the ocean freight market is experiencing a general rate increase and space crunch because of these factors. One aspect we should keep in mind is that it is advantageous for carriers and shipping lines to sign BCO fixed yearly contract rates while the market is strong, and currently market is very strong. What we see in the ocean freight market in the U.S. is that cargo origin started to gravitate towards southeast Asia, and many shippers are preferring to route shipments via Gulf and East Coast ports as they are better suited and gaining more shares compare to West Coast ports. Thailand, Vietnam, and Cambodia are still experiencing a greater growth in trade to the U.S. compared to China.

AIR FREIGHT

COVID-19 is heavily disrupting the airline industry. IATA is estimating that the airline industry may lose more than $350 billion in revenue. As airlines are one of the most cash flow-dependent industries, they are having a hard time getting through this crisis.

The survival instincts of airlines, and the airline corporate reaction, is a new focus and a potential structural change that centers around flying more commercial cargo rather than passengers. We now see a whole set of passenger airlines carrying more cargo on the upper deck of their airplanes, keeping their fleet in the air, and keeping their employees on their payroll. However, due to the reduced amount of flights, we are experiencing serious space issues and are seeing more airlines focusing on adapting to move more cargo to fulfill the demand for expedited protective equipment shipments all around the world.

Transpacific air freight eastbound rates saw an unprecedented increase over the past month. This increased demand in air freight is also taking a toll on airline terminals that are handling cargo. They are experiencing serious bottlenecks that are affecting transit times worldwide.

THROUGHOUT OUR HISTORY, MTS LOGISTICS HAS BUILT ITS REPUTATION ON BEING THERE FOR OUR CLIENTS, CUSTOMERS, VENDORS, AND COMMUNITIES IN THE MOST CRITICAL, AND VOLATILE TIMES.

This unprecedented environment is no different. We are following the market and global trends in shipping and will continue helping clients understand and plan how the remainder of the year and the recovery in global economy, trade, and shipping will take place. Until then, do not let anyone tell you do not have options. Reach out to us today to learn the ways which we can help you, get the latest information available, and latest shipping services in the market. .

.

.

.

. Article source: https://www.morethanshipping.com/covid-19-navigating-current-shipping-market-and-latest-logistics-issues/

0 notes

Photo

Empowering Women in the Maritime Industry

As maritime enthusiasts, we like to stay up to date on all things maritime - from what’s happening with ship chandlers Cape Town to what the latest maritime innovations are. Enjoy the read!

Every year, the Day of the Seafarer marks an occasion of pride and importance in the maritime world as all across the globe, people express their gratitude to the seafarers for their contribution to the economic and civil structure of the society.

The IMO first started celebrating Day of the Seafarer in 2011, as a way to acknowledge the fact that almost everything in our daily lives is affected directly or indirectly by sea transport. Recognizing this contribution, understanding the risks they take and perils they face is important for us, to completely understand the huge role seafarers play in our culture and society.

Celebrated on June 25 every year, the Day of the Seafarer usually addresses the common problems plaguing the industry that need to be brought into the limelight, thereby paving the road for a better, more aware population.

Over the past few years, the International Maritime Organization has been diligently campaigning to promote increased awareness related to the seafarers’ wellbeing and health. This year, continuing in the same vein, the theme for Day of the Seafarer 2019 is gender equality which is expected to have a strong and far-reaching resonance.

Here, on the occasion of the upcoming Day of the Seafarer 2019, we discuss the state of affairs related to women in the industry, the way their paths have been forged and the various obstacles they have had to overcome to create a place for themselves in the maritime world. The theme for this event corresponds to the theme of women empowerment, which is chosen for World Maritime Day.

Women Seafarers in the Industry – Past, Present, and Future

There are over 1.5 lac active seafarers today in India, employed, engaged, or working on a ship, out of which 4700 are women seafarers. This last decade has seen radical developments in bringing women seafarers to the forefront and overcoming a lot of stigmas usually attached to having them onboard.

The maritime community is moving away from a regressive mentality and accepting women as an important and integral part of the shipping world. Here is a look at how the work of women has progressed in shipping, over the years.

Shipping has predominantly been a male-dominant industry. The first hint of change came when some maritime educational institutes opened their doors to female students in 1988. The IMO forged an ambitious global program called Integration of Women in the Maritime Sector and the first framework to ensure their access to training and employment opportunities was born.

This led to the inclusion of some brave young girls into the maritime institutes, who went on to create many landmarks by becoming the first Lady Chief Engineers, Lady Captains, and Lady Marine Pilots of the country. They had to overcome many challenges along the way, as they were just one or two in their classes, facing oppression and narrow-minded mentality at every step of the way. Despite many setbacks, these strong women fought for their places and earned them through sheer will and determination.

To pave the way for future generations of women seafarers, Capt. Radhika Menon, the first woman in the world to receive the International Award for Exceptional Bravery at Sea, Ms. Suneeti Bala, India’s first Lady Chief Engineer, and Ms. Sharvani Mishra came together in 2017 and established the International Women Seafarers Foundation – a platform to connect the seafaring women across the globe and share experiences to help the women in the industry.

In addition, there are several Women in Maritime Associations (WIMAs) across the world, even in developing countries such as Africa, Latin and South America, and Egypt that addresses the problems of gender discrimination and ensures that women in the maritime world are treated with honour and respect.

Due to these ceaseless efforts, the future of women in the shipping industry looks quite bright. There is greater awareness about the opportunities in maritime, encouragement for women to actively participate in the community, and support to help them grow and prove themselves. It would not be amiss to say that in another decade or so, women will be active leaders in the maritime industry, standing shoulder to shoulder with their male counterparts!

Challenges for Women Seafarers

Keeping the need for gender equality in mind, the IMO has aptly chosen the theme for this World Maritime Day as Empowering Women in the Maritime Industry and that for Day of the Seafarer as Being On Board with Gender Equality. However, although the journey towards this goal has begun, there are still quite a few challenges that women seafarers have to face.

Conservative mentality of society

There is an inherent bias in society that sailing is still a ‘man’s’ job. As a result, families are reluctant to let their daughters pursue a career in maritime, preferring a conventional path for them. The first step to creating gender equality amongst the maritime community is to overcome this strong prejudice and understand that women are as capable as men when it comes to performing any duties on board the ships.

Mental and sexual harassment

This is a by-product of the conservative mentality we have seen above. The non-acceptance of women turns to outright bullying and harassment under extreme situations, where women are treated poorly and insensitively.

Changing the mindset, making people aware of the fact that women can possess the same skillset as men are the primary requirements. In addition, governments across the world need to create and implement laws for maritime that ensure the safety and protection of women on the seas.

Harsh working conditions

Living on board a ship for long periods, from months to years, is physically and mentally taxing. The hours are long and often, in less-developed nations, even the basic amenities, such as sanitary disposal methods are not available. This creates a lot of difficulty for women on the ship, posing a major hurdle towards incorporating more women in the industry.Difficulty in maintaining work-life balance

As seafarers, women have to stay away from home for long stretches of time, which makes it very hard to maintain a proper work-life balance. In India, there is still the perception that a woman is expected to handle all the responsibilities of her home and family, in addition to the demands of her career. While this is somewhat manageable for other professions, seafaring is an exception. This deters a lot of young women from taking up a career in shipping.

Limited access to education

Maritime institutes have opened their doors to female cadets but the number is still small. Not all marine colleges are as accepting, nor do they ensure company placements that are equally broad-minded.

Ms. Sharvani Mishra recollected her experience about her placement days, where she was denied the opportunity of an interview by the recruiting company, despite the fact that she was among the top five cadets in her batch, just because she was a girl! This lack of liberal educational institutes and recruiting companies presents a hurdle for women seafarers.

Lack of leadership opportunities

Women on board ships have to work twice as hard as men to prove their capability and skills because they are held to much higher standards. Convincing one’s crewmates about the fact that they are equally serious about the tasks they are assigned and can take up responsibility equally well, takes twice the amount of effort for women, as compared to their male counterparts, says Chief Engineer Rupali Joshi.

To eliminate these challenges and encourage the active participation of women seafarers, the IMO has adopted the sustainable development goal of gender equality in the maritime industry. Let us see how it aligns with the theme for this Day of the Seafarer.

Sustainable Development Goals for Gender Equality and the Day of the Seafarer

The fifth Sustainable Development Goal, as mentioned by the UN, promotes gender equality. It aims to end all forms of discrimination against women and girls everywhere and nowhere is this goal more important than in a male-dominant industry like the maritime sector.

IMO is addressing the concerns of gender discrimination by implementing the Integration of Women in Maritime Sector programme along with the ILO. Leading shipping companies like WISTA International, BP Shipping, Nautilus International and more are promoting gender equality among the marine workforce. In the UK, over 110 companies and trade unions have signed a Charter to promote the inclusion of more women in the maritime workforce

The theme for this year – empowering women in the maritime industry – is especially significant here, as it captures the essence of the IMO’s efforts in bringing gender equality into the spotlight. Working in tandem with SDG 5, IMO is working on the principles of Training-Visibility-Recognition to support the participation of women in both shore- and sea-based jobs.

Some of the initiatives started by the IMO to fulfill the goals of the SDG of gender equality include:

Seven regional Maritime Associations for women in the Pacific, Caribbean, Africa, Arab States, Asia, and Latin America to develop training opportunities as per the requirements of the region

Gender-specific fellowships to encourage higher technical education for women seafarers

Participation in economic, political decision making, to address crucial maritime challenges

Leadership opportunities for all female alumni of IMO’s World Maritime University and International Maritime Law Institute to reinforce the impact of female role models while recruiting new female cadets

On a national level, the efforts of the maritime industry are no less. India is one of the top nations to have a high percentage of female senior managers in the maritime sector. The IWSF is creating awareness among the new generation of women seafarers, helping them deal with problems and issues they face in the industry.

In addition, leading boat manufacturers and shipping companies are increasing the percentage of female employees in their companies, to provide equal growth opportunities for women in the sector.

The Journey Ahead

Achieving gender equality in a sector where only 3% of the workforce is female is a Herculean task. However, with bold and forward-thinking maritime administrations, this can translate into a future where men and women work on an equal footing of merit.

Having skilled women on board ships can help solve the shortage of qualified workers and hence take the industry closer to safe, clean, secure, and sustainable shipping. It is important to remember, effective maritime transport is the key to economic infrastructure development. Empowering women in the maritime industry is sure to spur overall growth and development of the maritime community and hence prove to be an asset for the future of global shipping!

What are your thoughts on gender equality in the maritime industry? Any anecdotes you would like to share? Drop a comment to let us know!

Article source: https://www.shmgroup.com/blog/day-of-the-seafarer-2019-empowering-women-in-the-maritime-community/

0 notes

Photo

An Indian Perspective For World Maritime Day

Connecting Ships, Ports And People

We found this great article, from a while back, that shares some interesting ideas. Even though we normally stay focussed on ship suppliers Cape Town and surrounding - we found this article quite insightful. Enjoy!

One of the most important factors for smooth maritime trade and travel is adequate safety for ships, ports, and people. The theme for World maritime Day, 2017 connects these three key elements, celebrating the interrelation of the diverse aspects of the marine industry. In continuation to 2016’s line of thought, the theme continues to explore the different ways in which shipping is indispensable to the world.

Maritime safety and security is and has ever been an integral part of marine activities. However, for a long time, the shipping industry has been reactive about the safety of ships and people, learning from its failures.

In recent years, the IMO has identified all natural and manmade causes that can impede the travel of the ships, such as weather hazards, piracy, war, technological difficulties, cyber infringement, terrorism, stowaways, and smuggling as threats to smooth sea trade and is prompt in taking action against these to ensure that ship and port security is not compromised. The International Ship and Port Facility Security (ISPS) code is the IMO’s principal framework for mandatory and non-mandatory safety measures that need to be taken by all member nations for maritime security.

Several new measures have been put in place with the view of meeting IMO’s goals for sustainable development. Members of the UN associated with marine trade have developed stringent strategies to ensure that there is no loss of life and property on seas or on shores.

As India is one of the key players in maritime trade, the Indian government has taken considerable efforts to maintain safe seas and safe shores. Ship manufacturers in India are expected to maintain the IMO-specified standards while manufacturing safety equipment for ships and the crew, or carrying out ship repairs and inspection.

In addition, after the terrorist attacks of 26/11, India has taken port and coastal security to the next level, making comprehensive efforts to align its ship security goals with those of the IMO and ensure integrated safety of these fundamentals. The entire coast is governed through radar surveillance and stringent identification systems are in place for unique vessel registration.

Capt. L. K. Panda, former Nautical Advisor to the Government of India speaks here about the various measures India has implemented to ensure complete safety of ships, ports, and people.

Shipping is indispensable to global trade, and when it comes to shipping, ships, ports, and people are inextricably intertwined. India’s maritime safety strategy reflects this, including dedicated focus towards combating on and offshore threats emanating from the sea, developing strong coordination mechanisms for contingencies, and creating a seamless security network for freedom of trade.

About Captain L.K. Panda :

Capt. L.K.Panda is former Nautical Advisor to the Government of India at the Directorate General of Shipping. He has joined the organization in the year 1992. He started his seafaring carrier in 1975 from T.S. Rajendra and sailed in various capacities in Merchant Ships including service as Master on various types of ships. However, after completion of his Extra Master in 1988, he joined Government of Iran as Maritime Educational Advisor for a brief period.

During his service with the Indian Maritime Administration, he has represented India in various maritime forums National & International & been a part of many committees including the committee on Modal Shift of Cargo from Rail and Road toSea. He has also served in the capacity of a consultant on behalf of International Maritime Organisation (IMO) for the Caspian States and continues to be associated with the IMO. In addition to the above, he was also nominated as an arbitrator for many marine cases.

His present assignment in the capacity of Nautical Advisor to the Govt. of India is to improve Maritime Safety Pollution Prevention, development of manpower for the Maritime Industry besides overall growth of the Industry on National and Regional basis.

Article source: https://www.shmgroup.com/blog/indian-perspective-world-maritime-day-connecting-ships-ports-people/

0 notes

Photo

As knowledgeable ship chandlers that stay in-the-know with all things shipping, maritime and other wise marine related - we thought you would find this article interesting and perhaps helpful.

Introduction

In the common usage of the term, the word container normally refers to an enclosed box of any shape which contains some substance. I know this is a very vague definition so let us refine it a bit to fit the shipping industry. Ships that carry containers or boxes measuring a specified size that contain cargo inside them are known as container carriers or container ships. This is another useful category of ships apart from the various types of ships discussed here including ROROs, Reefers, Tankers, Cruise Ships, FPSOs and DP Ships.

Container Ships

In the earlier days of the shipping industry bulk cargo was transported in ships having large cargo holds and these ships were known as bulk carriers. This is a satisfactory method for transporting large quantities of cargo such as say ore, grains etc but sometimes dry cargo needs to be segregated into smaller units each having its distinct owner and local destination.

Just imagine a hundred businessmen ordering let us say cloths from another country. Each businessman has his or her specific order and type of cloths. It would not be very easy to dump all this cargo into one cargo hold and segregate it at the receiving end.

A better choice would be to put the goods of one merchant into a container and label it as such. This would make the transportation and other related processes much easier.

This concept is what is used in container shipping and all the containers are of standard sizes and stored in an orderly fashion on the ship. Just take a look at the picture of a container ship and you will have an idea of how the container ship is designed. You will notice that unlike bulk carriers and tanker ships which carry the material inside their hatches (sometimes they can carry cargo on top as well like log carriers), the container ships carry cargo above the deck level as well apart from the containers in the hatches which may or may not be covered with hatch covers.

Another feature of these ships is that the small sized container ships usually have their own arrangement for loading/unloading of containers while the bigger ones normally depend on the shore facilities for this purpose.

TEU Explained

One term which you must understand in this regard is the Twenty Foot Equivalent or TEU. It refers to the capacity of a normal container which is 20 feet long, 8 feet wide and 8.5 feet high, though this size isn’t standardized and can vary from company to company.

The purpose of TEU is that it helps to find the equivalent when compared to other commonly available container sizes. For example if a container is 40 feet long, 8 feet wide and 8.5 feet tall it has a capacity of 2 TEU. Can you calculate the TEU of a container 48 feet long, 8 feet wide and 8.5 feet tall? (Answer is 2.4)

The chart below shows the typical TEU of container ships over the years and as you can clearly see in the picture that the TEU got nearly doubled every decade and the fifth generation of container ships have large TEU compared to their previous generations.

Article source: https://www.brighthubengineering.com/naval-architecture/11855-what-is-a-container-ship-and-its-uses/

0 notes

Photo

Upskill today’s maritime workforce to prepare for a technological future: industry report

With the shipping technological landscape changing how some areas of work in the maritime industry are carried out, it is imperative that the existing workforce is future-proofed and upskilled to ensure they can work well in an environment centred around technology.

That is the sentiment highlighted in the second Sea Asia industry insights report, ‘Technology in Maritime: Dehumanising the Industry or Creating New Job Opportunities?’ launched today (Thursday), ahead of the biennial Sea Asia conference and exhibition.

According to Esben Poulsson (pictured), Chairman of the International Chamber of Shipping and Enesel, and President of the Singapore Shipping Association (SSA), a key challenge facing the maritime industry today is that leaders need to ensure that existing staff are given the necessary training and upskilling needed to use new technologies comfortably in the industry.

“It is important that the maritime industry has the right people with the right skills to effectively harness new technologies. Initiatives like the Maritime Cluster Fund (MCF) by the Maritime and Port Authority of Singapore (MPA) are key to making sure that the current workforce has the opportunities to further enhance and improve their skills,” said Mr Poulsson.

“Industry leaders need to also work with educational institutions to ensure that our next generation of workforce is equipped with the right skills and knowledge to propel the maritime industry forward in a technological world.”

In assessing the impact of technology on jobs in the maritime industry, including ship chandlers, and whether it is being dehumanised, the report also highlights that despite current jobs being redesigned and requiring new skills from employees, a human workforce is still essential.

Kenneth Chia, Executive Director of the Singapore Maritime Foundation (SMF), pointed out that while it seems that technological innovations are making some traditional roles in the industry redundant, this does not mean all workers will be replaced.

“It is more evident that technology is altering traditional maritime jobs and changing the types of skills that are needed in the maritime industry, such as ship suppliers, as opposed to it completely removing jobs for the current workforce.

“The instinctive knowledge of an experienced industry worker is hard to replace, even with advanced technology. For example, even though we may need a lesser number of crew members working on board a vessel with smart shipping technologies, a larger group of skilled employees is also needed to work onshore so as to remotely manage what is happening out at sea,” said Mr Chia.

Chris Hayman, Chairman of Seatrade UBM EMEA, highlighted that with automation and technology is set to play a key role in the maritime industry. As such, the risk of dehumanisation and need for future-proofing will be a topic for discussion at the upcoming Sea Asia 2019 conference which would be held in Singapore.

Articles source: http://shipmanagementinternational.com/upskill-todays-maritime-workforce-to-prepare-for-a-technological-future-industry-report/

0 notes

Photo

How Do I Become A Ship Chandler?

To become a ship chandler, it is important to have a number of key skills. Ship chandlers need to have an understanding of accounting, operating a computer, problem solving, and customer service. A person in this job sells supplies and negotiates transactions directly with ship owners. Ropes and other shipping supplies can be sold, as well as food, chemicals, and cleaning supplies. Highly specialized ship chandler careers can focus on engine maintenance, for example, so the degree of education needed for the job can vary depending on what the individual intends to do.

Becoming a ship chandler requires familiarity with both local and international regulations. Ship chandlers may need to be licensed by local institutions, depending on where they live or begin their career. They also need to be familiar with the regulations of the International Ship SuppliersAssociation (ISSA), which regulates the profession and business practices. A code of ethics has been established by the association to ensure that ship chandlers follow proper behavior when it comes to advertising, pricing, and selling products.

A ship chandler plays an important role in the shipping industry, because he keeps the boats operating.

Education is also needed to become a ship chandler. To be employed by a company or start a business, at least some college work may be necessary, and technical or vocational training is often required depending on the job. At the very least, computer and customer service skills are requirements that can launch a potentially lucrative career. Since duties can vary with the specialty, such as supplying mechanical components, handling hazardous materials, or performing radar or engine maintenance, the educational requirements can vary. For someone looking work as a ship chandler, it is wise to check job listings online to see what each individual position requires.

In the past, it was possible to visit boats in port to become a ship chandler, to see who needed the services. Today, jobs can often be found and applied for online as well. The Internet is also the preferred medium for conducting business, and ship supply companies routinely perform transactions via computer.

The ability to communicate well is desirable in order to become a ship chandler. It is the nature of the job to discuss with the ship owners, captains, and crew the supplies and services that are needed. A ship chandler career can be based anywhere in the world there is shipping, and include any number of specialties because of the diverse needs of shipping interests.

Article source: https://www.wisegeek.com/how-do-i-become-a-ship-chandler.htm#

0 notes

Photo

Who is a Ship Chandler?

A ship chandler is a person who exclusively deals in supplying for a shipping vessel its required commodities. In other words, just like a grocer supplies food grains to households, a ship chandler supplies essentially required commodities to a ship and its crew.

The job of a ship chandler, otherwise known as ship suppliers, is very unique because it caters specifically to only one line of business therefore allowing a complete exclusivity to both parties – the seller as well as the client. Because of this exclusivity and the nature of the profession, it so happens that each and every ship chandler is held in high esteem and regard.

By approaching a ship chandler directly, it so happens that a ship’s crew can avoid the middlemen when it comes to a business transaction and thus save a lot of money which could be used in other productive areas.

When it comes to a ship’s supplies, in the absence of a ship chandler, it so happens that there are a lot of people involved. The more number of involved people means a lot of time for transit and consequentially a lot of delay in the transit process. When a ship’s crew approaches a ship chandler, because of the naturalness of a ship chandler, a ship’s crew can get the necessary commodities directly from a one-person source. This point adds to the aspect of high level of discount as since the ship chandler is the only person involved in the sale, he can afford to procure the best deals for a ship’s crew at the right prices thus allowing him to give a high return to his client in the form of rebate or discount.

This is precisely the reason why ship chandlers are held in vogue. As the shipping industry has developed and peaked over the centuries, the job responsibilities of a ship chandler have also increased. Competition has always been high in the shipping industry but in the modern times there is not just competition from within a country but also internationally.

This high level of competition makes the scope and coverage of a ship chandler very high. With the shipping industry now expanding to a great new level, it is quite possible that the profession of a ship chandler might be soon offered as a part of a university’s curriculum.

This high level of competition also ensures that a well-learnt and experienced ship chandler earns a high rate of clients and thereby a huge remuneration even after providing with the necessary discount and rebate.

The role of a ship chandler has changed over the years. In the olden days, a ship chandler mainly used to provide ropes, sail cloths and other such details to a ship’s crew. In contemporary times, a ship chandler’s role has been modified to providing maintenance requirements, food supplies, chemical compounds for the purpose of cleaning and many other modern items.

But however the role might have digressed and transformed, a ship chandler still is one of the most important necessities when one thinks about shipping and naval vessels. Without the services of a ship chandler, a ship and its crew cannot be assured of quality commodities required in a ship. In a world of changing thoughts, actions and priorities, a ship chandler’s responsibility and duty, however has managed to remain very constant and absolutely relevant.

Article source: https://www.marineinsight.com/careers-2/who-is-a-ship-chandler/

0 notes

Photo

Maritime piracy and armed robbery reaches 22-year low, says IMB report

As ship chandlers that operate across all South African ports we maintain a keen interest in all things to do with shipping, even the unpleasantries of piracy and ship robbery.

A total of 180 incidents of piracy and armed robbery against ships were reported to the International Chamber of Commerce’s (ICC) International Maritime Bureau (IMB) in 2017, according to the latest IMB report.

It is the lowest annual number of incidents since 1995, when 188 reports were received. In 2017, 136 vessels were boarded, while there were 22 attempted attacks, 16 vessels fired upon and six vessels hijacked. In 15 separate incidents, 91 crewmembers were taken hostage and 75 were kidnapped from their vessels in 13 other incidents. Three crew members were killed in 2017 and six injured.

In 2016, a total of 191 incidents were reported, with 150 vessels boarded and 151 crewmembers taken hostage.

Beyond the global figures, the report underlined several takeaways from the past year. In 2017, there were 36 reported incidents with no vessels hijacked in this area and 10 incidents of kidnapping involving 65 crewmembers in or around Nigerian waters. Globally, 16 vessels reported being fired upon—including seven in the Gulf of Guinea.

“Although the number of attacks is down this year in comparison with last year, the Gulf of Guinea and the waters around Nigeria remain a threat to seafarers. The Nigerian authorities have intervened in a number of incidents helping to prevent incidents from escalating,” said Pottengal Mukundan, Director of IMB.

Nine incidents were recorded off Somalia in 2017, up from two in 2016. In November, a container ship was attacked by armed pirates approximately 280 nautical miles east of Mogadishu. The pirates, unable to board the vessel due to the ship’s evasive manoeuvring fired two RPG rockets, both of which missed, before retreating.

Six Somali pirates were subsequently detained by European Union Naval Force, transferred to the Seychelles and charged with “committing an act of piracy” where they face up to 30 years’ imprisonment if convicted.

“This dramatic incident, alongside our 2017 figures, demonstrates that Somali pirates retain the capability and intent to launch attacks against merchant vessels hundreds of miles from their coastline,” said Mr Mukundan.

Indonesia recorded 43 incidents in 2017, down from 49 in 2016. The IMB report notes that Indonesian Marine Police patrols continue to be effective in the country’s 10 designated safe anchorages.

In the Philippines, however, the number of reported incidents has more than doubled, from 10 in 2016 to 22 in 2017. According to the report, the majority of these incidents were low-level attacks on anchored vessels, mainly at the ports of Manila and Batangas. Vessels underway off the Southern Philippines were boarded and crew kidnapped in the first quarter of 2017. However, alerts broadcast by the IMB’s Piracy Reporting Centre (PRC), on behalf of the Philippine authorities, have since helped to avoid further successful attacks.

Launched in 1991, the IMB PRC is a 24-hour manned centre that provides the maritime industry, governments and response agencies with timely and transparent data on armed robbery incidents received directly from the master or owner of vessels. Reported attacks can be viewed online on the IMB Live Piracy Map.

Article source: http://shipmanagementinternational.com/maritime-piracy-and-armed-robbery-reaches-22-year-low-says-imb-report/

0 notes

Photo

How To Be A Ship Chandler

Mr. Gbenga Femi Olu is the Head, Business Development Unit of Tentropics Marine Limited, a registered marine operations company in Apapa since 2013. In this interview with MMS Plus Weekly he expatiates on ship chandelling as a profession and what it takes to succeed in the business.

Excerpts:

What is ship chandelling?

Ship chandelling simply put is a process where the chandler, that is the name of the person who undertakes ship chandelling business, supplies to a vessel products and equipment needed on board, this means: provisions, disposables, perishable items and even maintenance parts because the crew aboard a vessel sometimes do not have access to land for months so they need to feed and the chandler provides things that are very essential on board, that is what chandelling is basically about.

What role does ship chandelling play in shipping business?

I would say to a large extent, that chandelling business is very vital in the shipping business considering the fact that you cannot be on the vessel for the period of one voyage without running short of food and water, so there is no how you can disassociate chandelling from shipping.

What’s the difference between chandelling and bunkering?

The difference is that the chandler supplies provisions and food items, but bunkering is the process of loading fuel into a vessel because a lot of people misinterprets bunkering as illegal, bunkering is not illegal, as long as it done through the appropriate authorities, bunkering is just a business that involves fueling a vessel and suppling fuel to a vessel, there is also what is called water bunkering. Water bunkering is a scenario where, in as much as the vessel is on top of water people think maybe it gets water directly from the sea, you have to physically transport water in tanks to the vessel where it is loaded on board, this is what the crew use for bathing, cooking and washing.

So can a chandler function as an oil bunker or water bunker?

It depends because there are different bodies that handle each with different requirements. So, if you decide to do bunkering alongside chandelling, that means you have to belong to the two bodies and meet their individual conditions, so you would not have issues with them when you are conducting your business.

So who can be referred to as a ship chandler?

A ship chandler is someone who carries out the business of providing services to vessels in terms of supplying their necessary needs like provisions, disposables and sometimes can be extended to suppling maintenance parts of the vessel, that is, engine parts and other essential items. A ship chandler has to be someone that is trusted by the ship owner because food poisoning is something they try to guard against.

The quality of what is supplied to them is very important and that is why when a chandler is able to come on board, it is very important that he maintains a high level of hygiene and timeliness of delivery on board. The vessel does not have the luxury of time because they have to quickly disembark their cargo and go back to where they are coming from.

Is ship chandelling studied in any Nigerian university?