Text

How to Make Money with CNC Routers?

Stone projects. If you are engaged in the stone industry, then the stone engraving machine will be your best choice. The stone engraving machine is a professional CNC Router for stone processing. This kind of CNC machine is mainly used in the stone industry, stone tablet processing industry, art relief, advertising, decoration industry, ceramic, inscriptions, garden engineering, large-scale sculptures, handicraft carvings, home improvement, film, and other industries. Over the past few years, CNC router machines have been an absolute necessity in the manufacturing sector. They successfully replaced manual machines across various industrial sectors. CNC routers help manufacturers save labor and improve work efficiency, so they have been the most popular machines all over the world, and widely used to cut and carve wood, metal, plastic, stone, foam, and so on.

As you can see, CNC Router has a broad market and development prospects, as long as you develop appropriate strategies and make full use of existing resources, you will definitely be able to reap a lot. Here are some suggestions on how to make money with CNC router machines, I hope it can help you!

article address: https://forsuncnc.com/make-money-with-cnc-routers/

1. To be a CNC Router Agent or Distributor

You find that there is a great demand for CNC engraving machines and maybe it‘s time to sell CNC routers to make money. Fine, then why don’t you become an agent or distributor of some famous CNC Router brands?

You can contact some famous brands of CNC Router manufacturers to become their regional agents to make your own profits.

Some well-known brands generally have higher requirements for agents, such as business licenses and sufficient working capital. If you meet the conditions of the brand, and there is no other agent for the brand in your intended sales area, then you can successfully become an agent for the brand. Although the procedures for well-known brand agents are cumbersome and demanding, selling these relatively well-known CNC routers are easier than unknow brands. You only need to formulate a suitable sales strategy, I believe that you can make achievements.

But being an agent is not an easy task, you need to prepare for a detailed investigation in advance.

a. Learn more about the company and its products: Know the company’s development prospects and strength, product quality and customer historical reviews, after-sale services, etc. Use this to judge the commercial value of the company’s products, as well as the expected benefits of yourself. At the same time, you need to assess whether your company’s strength is sufficient to match the brand’s products. Analyze your company’s advantages and disadvantages in comparison with other companies, strive to maximize its advantages, and make up for the shortcomings. In the end, we can screen out powerful companies and cost-effective products, and strive to provide customers with the best products and services, while earning considerable profits.

b. If you want to be a good product agency, it is not enough to only have a detailed understanding of the product and the company. You also need to have a strong sales ability. There are many merchants of CNC Router. Why do others want to buy your products instead of others? At this time, your sales ability plays an important role in this course. In the process of selling products, you need to establish a good relationship with customers to promote business development, master questioning and listening skills, accurately understand customer needs, and gain customer trust.

Master negotiation and sales skills to maximize sales opportunities. Let customers fully understand the products and analyze what benefits their products can bring to the customer. For example, 4 Axis CNC Router by FORSUN is more powerful and can be applied to the processing of various shapes, with wider application range, higher safety factor, and more thoughtful service and so forth.

Develop online and offline sales channels and formulate corresponding sales strategies for different regions and different groups of people. Let customers fully trust our products and generate a strong desire to buy. At the same time provide preferential prices to target customers.

Conduct in-depth market research on the target agency area. Understand the market demand for CNC Router in this region. For example, if the demand for CNC Wood Router in this region is far more than other types, so when promoting products in this field, you can devote most or all of your time and energy to making out best sales scheme of that type. Fully understand the expectations and suggestions of consumers on CNC Router, so as to formulate a better reasonable and effective sales plan, which both satisfies customers’ needs and your own benefits.

Understand the competitive situation of the CNC Router in this targeted area. Gathering information about competitors, the more the better, as the old Chinese saying goes: “know the enemy and know yourself, and you can fight a hundred battles with no danger of defeat”. By learning the advantages of competitors, you can better find your shortcomings by comparison and further improve them.

c. After completing the basic preparations, discuss cooperation with the selected brand. Negotiate specific agency thresholds, supply discounts, product commissions, sales price limits by manufacturers, return and exchange policies, store opening financial support, and so on. Different brands have different policies and you need to decide in accordance with actual conditions.

These steps are indispensable in the process of brand selection. They can help you select the right brand and cost-effective products, protect the rights of consumers, and ensure that you are profitable.

2. Outsourcing Your CNC Router Production

If you have your own brand or plan to develop your own brand, then one of the more profitable ways is to outsource the production of CNC routers, especially in the case of higher labor costs in your country. For example, you can choose to outsource non-core businesses to India, China, etc. They have excellent labor, low wages, and high-quality production. This can not only ensure product quality, but also reduce production costs, speed up capital circulation, and earn more profits for your company.

Actively develop some well-made manufacturers, and cooperate with them to add their products to our own brands and expand production channels. However, these manufacturers must undergo rigorous screening, and the quality must meet or exceed current product standards, balancing quantity, and product quality. We cannot simply pursue profitability and ignore the rights and interests of consumers. Because when running a business, customer trust is one of the important magic weapons to win.

3. Selling CNC Router Projects

Use existing CNC Router machines to develop related businesses and make finished products for sale.

For example, if you are mainly engaged in CNC Wood Router Machine, then you can use the existing machine to make the following finished products:

Furniture, such as closets, wardrobes, cabinets, and other wooden furniture. Judging from the existing market conditions, all cabinet and furniture manufacturers can benefit from CNC Wood Router Machine. The traditional woodworkers’ occasional reading in terms of processing speed and accuracy cannot meet the growing demands of the woodworking industry. CNC Wood Router machine is more efficient. At the same time, the product also has high flexibility and can be customized and produced according to the actual needs of different consumer classes.

Musical instruments. Nowadays, more and more musical instrument manufacturers combine ancient craftsmanship with modern CNC Router speed and precision to achieve the ideal visual effect. After practical tests, CNC Wood Router is undoubtedly the ideal machine for making musical instruments. It can shorten the manufacturing time, simplify the entire process, and have high processing accuracy.

Architectural woodwork. Architectural woodwork requests high precision and advanced performance. CNC machines are specially designed for machining the material for architectural use, such as aluminum composite, metal composite, wooden materials for Architectural projects. CNC Wood Router is highly efficient and ingenious in detail. It can satisfy the increasing demands of people in modern society.

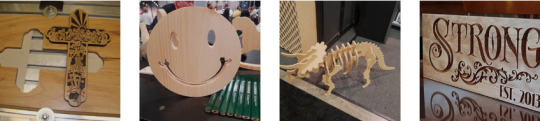

Wood Arts and Crafts

Stone projects. If you are engaged in the stone industry, then the stone engraving machine will be your best choice. The stone engraving machine is a professional CNC Router for stone processing. This kind of CNC machine is mainly used in the stone industry, stone tablet processing industry, art relief, advertising, decoration industry, ceramic, inscriptions, garden engineering, large-scale sculptures, handicraft carvings, home improvement, film, and other industries.

Our stone cutting machine possesses many advantages, such as fast speed, high precision, strong stability, low noise, and long service life, etc. It can correct the concave, convex, and uneven slope of any stone surface. The software automatically generates a new program based on the floating of the stone surface, which conforms to the surface characteristics of the stone.

Adopting a high-power drive system coordinated with the spindle’s stable engraving, it has the features of greater torque force, smoother operation, precise and powerful cutting point. And Y-axis uses the dual-motor synchronous drive, it has the features of strong power, high stability, and can realize the process of 70mm Granite thickness. It is widely used in the Stone industry, stone tablet processing industry, art relief, advertising, decoration and decoration industry, ceramic industry.

Ok, the above are a few ways that I think of how to use the CNC Router to make money.Before making a decision, be sure to make full preparations based on your own actual situation. Besides these money-making schemes, in addition, you need to continue to learn specialized knowledge of CNC Router, be familiar with changes in market conditions, keep pace with the times, and constantly adjust and optimize your strategies according to the market situation. Continuously develop CNC products with development prospects and great commercial value.

If you want to utilize CNC Router products as a career, I hope this article will help you. If anything is wrong, please correct me.

0 notes

Link

Jinan FORSUN CNC Machinery Co., Ltd., one of the best CNC Router manufacturers and suppliers in China, has been focusing on providing high quality CNC Router Machines and solutions for worldwide customers for 20 years.

1 note

·

View note

Text

Stone CNC Router Machine

The stone engraving machine is a professional CNC Router for stone processing. This kind of CNC machine is mainly used in the stone industry, stone tablet processing industry, art relief, advertising, decoration industry, and ceramic industry. Our CNC stone routers can do three-dimensional relief, pointed bottom engraving, flat bottom engraving, line carving, inverted edge, drilling and so on. The applicable materials include marble, granite, jade, bluestone, black stone, and other stone materials, as well as ceramics, glass, plexiglass, PVC board, aluminum-plastic board, bamboo, agate, jade, and other crafts. Main features: fast speed, high precision, strong stability, low noise, and long service life.

Other hot CNC machine collections: wood cnc machine, 4 axis cnc router, 5 axis CNC router, cnc plasma cutter, ATC CNC router, mini CNC router

Features and Advantages

The stone CNC routers have fast speed, high precision, strong stability, low noise, and long service life.

The working table of the marble engraving machine is a T-shaped steel bracket, using a full welding process and vibration aging treatment. Thus it can ensure the stable performance when the machine running at high speed, and continuous knife, keep the production processing surface is highly smooth.

The CNC router stone engraving machine uses a high-power horizontal torque spindle, with large bearings. and with high speed, a large number of chips, and the motor is not easy to damage.

Widely used in the Stone industry, stone tablet processing industry, art relief, advertising, decoration and decoration industry, ceramic industry.

Perfect for Stone lettering, stone relief, stone yang carving, stone edging, stone line carving, stone cutting, stone hollowing.

Suitable Materials:

Marble, granite, jade, bluestone, black stone, and other stone materials, as well as ceramics, glass, plexiglass, PVC board, aluminum-plastic board, bamboo and other materials.

Hardstone such as granite can be carved to 5mm in layers

Marble, bluestone, etc. can be engraved to 5mm at a time How to Buy a CNC Router Machine? Enquiry. Feel free to tell us what material you want, what is your max working size and what product you want to do. The budget is also welcome.Free Quotation provided. We will send our quotation sheet with machine configuration, photos, videos and prices to you according to your request.Launch the order. Your company will arrange the deposit, and we start the machine production from 3D design, machine body welding, machining, painting spare parts preparing, manufacture and inspection.Testing sample video and delivery. After our manufacture and inspection, we will make a final video of the machine working to you. After the confirmation, the machine will be shipped by sea through my or your agent.After-sale service. We will provide a video teaching program to tell the customer how to use or install our machine. And my service team will 7*24 hours online to answer customer questions.Feedback. We are expecting feedback from our customers. Please tell us how you feel about machine quality and service. If you have more ideas to help us improve, that will be very appreciated.

If you are interested in our products, please click here to find us. https://forsungroup.com/stone-cnc-router/

0 notes

Text

ATC CNC Router

What is ATC CNC Router? ATC CNC Router is the abbreviation of Auto Tool Changer CNC Router, also be named as Heavy Duty CNC Router. An Automatic tool changer or ATC is used in the CNC Router machine to improve the production and tool carrying capacity of the machine. ATC changes the tool very quickly, reducing the non-productive time. Generally, it is used to improve the capacity of the machine to work with a number of tools. It is also used to change worn out or broken tools. It is one more step towards complete automation.

Normally there is two types tool magazine. One is carousel type and with 8 positions or 10 positions or more positions. This ATC system is the fastest method of changing tools on a regular basis. Another is a linear type tool magazine. This tool magazine is very simple. But it is easy to operate and learn. And it is also very stable.

Other Hot CNC machine collections: wood cnc machine, 5 axis cnc router, 4 axis cnc router, small cnc router, cnc plasma cutter, stone CNC router

Features and Advantages

This ATC CNC Router adopts a new generation bus controller system Syntec controller with better stable performance, Japanese YASKAWA AC Servo motor, and driver, HSD air-cooled automatic tool change spindle from Italy, Delta inverter from Taiwan.

Automatic tool change system with 8, 12 and 16 tool magazines. Saving machining time compared with traditional machines.

Recommend automatic pusher function for this CNC Router Machine which can dock the automatic loading and unloading platform, reduce labor cost and save loading and unloading time.

Intelligent processing of the out-of-bounds protection function prevents over-machining caused by mechanical collisions.

The ATC CNC Cutting machine can be equipped with an independent pressure roller, which effectively solves the problem of board moving when the machine is on cutting work

Applications of this ATC Wood CNC Router: sofa keel cutting, wooden doors, cabinet doors, cabinet cabinets, mold industry, advertising industry, etc.

Competitive factory direct price and one year warranty. How to Buy ATC CNC Router Machine? Enquiry. Feel free to tell us what material you want, what is your max working size and what product you want to do. The budget is also welcome.Free Quotation provided. We will send our quotation sheet with machine configuration, photos, videos and prices to you according to your request.Launch the order. Your company will arrange the deposit, and we start the machine production from 3D design, machine body welding, machining, painting spare parts preparing, manufacture and inspection.Testing sample video and delivery. After our manufacture and inspection, we will make a final video of the machine working for you. After the confirmation, the machine will be shipped by sea through my or your agent.After-sale service. We will provide a video teaching program to tell the customer how to use or install our machine. And my service team will 7*24 hours online to answer customer questions.Feedback. We are expecting feedback from our customers. Please tell us how you feel about machine quality and service. If you have more ideas to help us improve, that will be very appreciated.

If you are in need of this kind of machine, please click here to find us and get more information about it.https://forsungroup.com/atc-cnc-router/

0 notes

Text

5 Axis CNC Router

5 Axis CNC Router is a machining center with high technology content and high precision for processing complex curved surfaces. The 5 axis CNC Router has high efficiency and high precision, and the workpiece can be assembled at one time. It can adapt to the processing of modern molds such as auto parts and aircraft structural parts. Different from the pentahedron machining center, 5 Axis CNC Milling Machine has five axes of X, Y, Z, A, and C. The X, Y, Z and A, C axis form a 5 axis linkage machining. They are good at space surface machining, profile machining, hollow machining, punching, inclined holes, and beveling. The pentahedron machining center is similar to the three-axis machining center, except that it can make five faces at the same time, but it can’t be shaped, slanted, cut, etc.

5 Axis CNC Router can process complex curved surfaces of aluminum and various non-metallic materials and is suitable for training various model making and five-link processing talents. Suitable Materials: carbon fiber, fiberglass, composites, PMI foam, polyurethane foam, functional foam, resin, wood, honeycomb, plastic, clay and other non-metallic materials and aluminum alloy and other soft metals.

Other hot CNC machine collections: wood cnc machine, 4 axis cnc router, cnc plasma cutter, stone CNC router, ATC CNC router, mini CNC router

Structure of 5 Axis CNC Router

The 5-axis CNC engraving machine is mostly a 3 +2 structure, that is, three linear motion axes of X, Y, and Z plus two rotations of three rotation axes of A, B, and C rotating around the X, Y, and Z axes, respectively. Shaft composition.

Thus, from a large aspect, there are three forms: X, Y, Z, A, B; X, Y, Z, A, C; X, Y, Z, B, C;

It is divided into two combinations of rotating shafts, which are generally in the form of the double turntable, turntable plus swing head and double swing head. These three structural forms determine the size of the machine tool and the scope of the machined object for physical reasons. Among them, the five-axis linkage machine with double turntable structure is only suitable for processing small parts, such as small integral turbines, impellers, small precision molds, etc., because the workpiece needs to move in two directions of rotation when machining the workpiece. The price is relatively low. In terms of application, this is the most common type of five-link CNC machine tool.

The five-link CNC machine with the turret and the oscillating structure can be A-axis, B-axis or C-axis. The oscillating head is also the same. It can be A-axis, B-axis or C-axis, so the turret is equipped with an oscillating type. The five-joint CNC machine tool of the structure can be combined in various different ways to adapt to different machining objects, such as the blade of the turbo generator, which needs the A-axis plus the B-axis. The A-axis needs to be matched with the tip of the tailstock. If the workpiece is long and the diameter is fine, it is necessary to clamp the two ends and stretch the workpiece for processing. Of course, a necessary condition here is that the two turrets must be rotated synchronously. With the C axis plus the B axis, since the workpiece rotates only on the C axis, the workpiece can be small or large, and the diameter can range from tens of millimeters to thousands of millimeters. The diameter of the C-axis turret can also be from 100 to 200mm to 2~3 m, the specifications and quality of machine tools range from several tons to ten tons or even tens of tons. This is also a kind of five-axis CNC machine tool with a wide range of applications. Its price is middle, and the size, accuracy, and performance of the randomizer vary greatly. The five-axis CNC machine with double pendulum structure, due to its structure itself: there is usually an electric spindle with a loose broach structure in the middle of the oscillating head, so the size of the double oscillating head itself is not easy to be small, generally 400-500 mm.

Advantage of 5 Axis CNC Router

5 Axis linkage CNC machine tool system is the only means to solve the processing of impeller, blade, marine propeller, heavy-duty generator rotor, steam turbine rotor, large diesel engine crankshaft and so on. It is a high-tech, high-precision machine tool for processing complex curved surfaces. The machine tool system has a significant influence on a country’s aviation, aerospace, military, scientific research, precision instruments, high-precision medical equipment, and other industries.

The use of a 5 Axis CNC Cutting Machine makes the clamping of the workpiece easy. No special fixtures are needed during processing, which reduces the cost of the fixture, avoids multiple clamping and improves the precision of mold processing. Machining molds with 5 Axis technology can reduce the number of fixtures used. In addition, because the five-axis linkage machine saves many special tools during machining, the tool cost is reduced. The 5 Axis CNC Cutting machine can increase the effective cutting edge length of the tool during machining, reduce the cutting force, improve the tool life and reduce the cost.

Using a five-axis CNC Router processing mold can quickly complete the mold processing, fast delivery, better guarantee the processing quality of the mold, make mold processing easier, and make mold modification easier. In the traditional mold processing, the vertical machining center is generally used to complete the milling of the workpiece. With the continuous development of mold manufacturing technology, some weaknesses of the vertical machining center itself are becoming more and more obvious. Modern mold processing is generally processed by ball-end milling cutters. The benefits of ball-end milling cutters in mold processing are very obvious, but if a vertical machining center is used, the bottom line has zero line speed, so the bottom surface has a poor finish. If the four or five-axis linkage machining technology is used to process the mold, the above shortcomings can be overcome.

If you are interested in our products, please click here to find us. https://forsungroup.com/5-axis-cnc-router/

0 notes

Text

4 Axis CNC Router

What’s 4 Axis CNC Router? We install the fourth Axis on the 3 Axis CNC Router and call it A axis. These four axis can work simultaneously, that is, four-axis linkage. The four-axis linkage engraving machine is equipped with a real four-axis control system. There is special software to make a special program. Because of the work of the fourth axis, the three-dimensional machining of cylindrical, curved and circular surfaces is realized. It is suitable for more complicated machining. The working area of the rotating head (A axis ) of this 4 axis CNC Router is +/-90 degree.

The 4th axis cnc router can be widely used in casting molds, foam molds, automotive molds, train molds, aviation molds, ship molds, paraffin molds, and more applications.

Other hot CNC machine collections: wood cnc machine, 5 axis cnc router, cnc plasma cutter, stone CNC router, ATC CNC router

Features and Advantages

The Wood Router Machine body is designed with a square tube, and subjected to professional tempering and stress treatment to ensure that the router CNC machine body is strong and not deformed for a long time

Taiwan’s new generation control system; Italy imported air-cooled spindle

XYZ three-axis adopts Taiwan original PMI square rail, XY axis adopts domestic well-known high-precision helical rack, Z-axis adopts Taiwan original TBI ball screw

Automatic lubrication system, independent chassis

Vacuum table in the zone; 7.5KW large adsorption vacuum pump, can absorb materials of various shapes and sizes

The spindle can be rotated +/- 90 degrees, which can realize side milling, punching, and cutting. It is very suitable for processing all kinds of curved surfaces with high precision and fast speed, which fully meets the needs of carving

The working size of the ATC CNC Route machine can be customized according to the customer’s request. The common sizes are 1300*2500mm (4*8ft) , 1500*3000mm(5*10ft) 2000*3000mm and 2000*4000mm

Competitive factory direct price and 18-month warranty. How to Buy 4 Axis CNC Routers? Enquiry. Feel free to tell us what material you want, what is your max working size and what product you want to do. The budget is also welcome.Free Quotation provided. We will send our quotation sheet with machine configuration, photos, videos and prices to you according to your request.Launch the order. Your company will arrange the deposit, and we start the machine production from 3D design, machine body welding, machining, painting spare parts preparing, manufacture and inspection.Testing sample video and delivery. After our manufacture and inspection, we will make a final video of the machine working for you. After the confirmation, the machine will be shipped by sea through my or your agent.After-sale service. We will provide a video teaching program to tell the customer how to use or install our machine. And my service team will 7*24 hours online to answer customer questions.Feedback. We are expecting feedback from our customers. Please tell us how you feel about machine quality and service. If you have more ideas to help us improve, that will be very appreciated.

If you are interested in our products, please click here to find us. https://forsungroup.com/4-axis-cnc-router/

0 notes

Text

What is a CNC Router? (Buying Guide)

What is a CNC Router Machine?

CNC router machines also known as computer numerical control router machines is computer-controlled devices used to carve out or cut through hard materials like wood, plastic, aluminum, etc.

CNC routers have varying configurations, from large industrial CNC routers to small homemade routers.

Despite the presence of a varying range of configurations, all CNC routers have specific parts which are all highly essential in the top functioning of these machines;

A dedicated CNC controller.

Servo motors or stepper motors.

A workplace bed or table.

One or more spindle motors.

Linear gears.

Servo amplifiers.

Ac inverter frequency drives.

Ball screws.

Additionally, to hold the parts in place for cutting, CNC routers may have vacuum pumps with grid table tops or t-slot holds down fixtures.

The CNC formats usually available in CNC routers are the 3-axis and 5- axis. A and B axis are usually made available by manufacturers for full 5 axis capabilities and rotary 4th axis. 4′ x 8′ and 5′ x 10.’ are the common industrial CNC router sizes.

CNC router VS. CNC machine

A CNC machine is a general word that defines all sorts of machines that are automated and controlled by a computer. These machines include CNC routers, CNC laser engravers. CNC mills and many more. As such, a CNC router is basically a CNC machine. Also, it’s important to recognize that a CNC machine is not a CNC router. It’s essentially a general term for different machines.

CNC router vs. CNC mill

CNC routers and mills differ greatly in terms of performance. Contrary to that, they all have an exceptional ability to cut through different materials. CNC routers to be specific are suited for cutting soft materials such as wood and aluminum with precision. CNC mills, on the other hand, are best suited for cutting much harder materials such as titanium.

CNC Router Projects

Advantages of CNC Router

There are so many reasons why CNC router machines have become a must-have in many industries in which the cutting through and carving of hard material is part of their procedures.

The High Efficiency

Unlike man, CNC machines can work continuously 24/7 only requiring relatively short periods of maintenance in-between. When designs are programmed in a CNC machine, they can be manufactured identically a countless number of times.

Cut Through Different Materials.

CNC routers are capable of creating programmed designs on so many different types of materials. If you need a single design to be cut through identically over about 30 different materials from wood to plastic, this device is perfect for that.

Limited Man Power Needed

When using a CNC router the only manpower needed is to program and monitor the robotics, also numerous CNC routers can be controlled by one person as the only tasks needed to be done after they begin running is occasionally changing the cutting tool.

Higher Safety Majors Enforced.

Manually controlled routers come with so many risks involving both the operator and the fabrication shops. Machitech automation CNC routers have complete safety features that go a long way to eliminate the possibility of accidents.

Precision Cuts

The best thing about CNC routers is the precision in which their cuts are being made. Unlike the manual cutters, CNC routers are capable of cutting through hard materials precisely, avoiding waste, as a result, increasing the profit margin.

If you are interested in our products, please click here to find us.https://forsungroup.com/what-is-a-cnc-router/

0 notes

Text

FORSUN CNC MACHINERY

CNC PRODUCTION SPECIALIST

Jinan FORSUN CNC Machinery Co., Ltd., one of the best CNC Router manufacturers and suppliers in China, has been focusing on providing high quality CNC Routers and solutions for worldwide customers for 20 years. Main computerized CNC machine types: Wood CNC machine, ATC CNC router, Basic beginner CNC router, Mini desktop CNC router, Multi-head CNC router, Rotary axis CNC router, 4/5 Axis CNC milling machine, CNC marble stone engraving machine, CNC plasma cutter, CNC foam cutter, etc.Flexible solutions. FORSUN has professional design teams to focus on different customers’ special requests. Tell us what you want, and you will get fully custom CNC routers here.Available highest quality. Each CNC router equipment from FORSUN will be tested by 13 procedures, 48 hours non-stop running, 5 layers painting and so on.Affordable price. FORSUN has its own CNC router factory in China, so the competitive factory direct price is available.

Reason for Choosing FORSUN CNC Machines

Low Operational Cost

A CNC Router machine can low down the operating cost by its fast working speed, intelligence operation, less labor use, and maximum raw material usage. Take the cabinet making as an example, it will need five workers to spend six days to finish one closet cabinet with the traditional ways, but it will only need two people to finish this closet cabinet by two days with Forsun CNC Router machines. It can save a lot of time and labor costs.

Shorten processing cycle time

A CNC Router machine can calculate the exact material processing time, which will help the owners for the better organized in product process planning, operational cost and workers arrangement in advance. And it will be easier for the whole factory run.

Smoother Edge Finish

Since CNC routers are programmed, they follow a smooth geometry when cutting material. They provide a sharp and smooth edge finish that does not necessarily require sanding.

Full utilization of material

The Forsun CNC Router machine is programmable and different parts can be nested together so as to maximize the material usage. Forsun CNC Router machine will be compatible with all the nesting software like Artcam, Alpha cam, Cabinet vision, etc where the designers can program all the products that they want to do. With this method, the raw board can be utilized by more than 95% to save a lot of materials.

To increase Material usage means cost saving. And the workers also can organize the next set of materials during the machine running, which will save a lot of time as well.

Greater Accuracy

The Forsun CNC ROUTER machine precision can be +/-0.01mm and repeat precision can reach +/-0.03mm because of its heavy-duty machine body, experienced workers, world-famous brand spare parts like SIEMENS Controller and drivers from Germany, Schneider electrical parts from France, HSD spindle from Italy and so on.

All the Forsun CNC Router machine bodies are all processed by annealing heat treatment which ensures the machine will never be deformation. And the linear guide and racks are all drilled and screwed by a five-axis machining center to make sure the precise is 100% correct.

Pretty Good Outlooking

All the Forsun CNC Router machine are with sandblasting processing, which will ensure the outlook painting can be new and beautiful more than ten years just a new car what you have. And our hot power coat thickness is more than 5mm which will never fall down. All the machines will be designed by Solid-works before production, so it will ensure the machine will be very natural and good looking

Greater Flexibility Accomplishment

Forsun Automated CNC router can handle multiple works conveniently. It is very intelligent and can work on different shapes. No matter how complex the design is or how irregular the shapes are, Forsun CNC ROUTER will be very easy to fulfill the works, which can enlarge the owner’s business channels and makes more money with more opportunities there.

Encourages Business Expansion

The Forsun CNC router machine ensures faster cycle time while at the same time allowing greater flexibility, which will apply the owners to spend more time to consider their business scope. When the CNC router owners, who only make cabinet first, find that they also can make the door, sofa, bed and other woodworking products, they will also turn to the other furniture making. And this action will help them enlarge the business scope. These are all are availed ample time to concentrate on the day to day running of the business. Large scale production = high revenue = high profitability = Happy workforce

Simplification of Business Operations

Comparing the traditional working ways, the Forsun CNC Router will make the work simple and easier. It just needs one person to draw what he wants to do first from the software. And then export G code by the software and use a disk to copy to the machine controller. Then start the machine and it will work automatically. Everything will be easy.

Creates a Fun Filling Work Atmosphere

Because the Forsun CNC router machine ensures the smooth flow of work, the workers will be less heavy work. So they will enjoy the working time and treat the CNC Router machine as a toy.

Achieve economical production and maintain a happy working environment by purchasing a Forsun CNC Router machine today. You deserve it.

Contact us online if you have any questions about our machine and service.https://forsungroup.com/

1 note

·

View note