QINGGONG SETH MACHINERY is a world-known producer of shot blasting machines with knowledge and experience for more than 40 years, we offers a large range of shot blasting equipment. https://www.shotblastpro.com/

Don't wanna be here? Send us removal request.

Text

Overhead Rail Shot Blasting Machine

Overhead conveyor shot blasting machine make workpieces to move with constant speed through the machine. Due to this reason, the machine can be integrated into an existing production line. We can see some parts of the overhead shot blasting machine in the video. The transport system of the overhead rail shot blasting machine can be designed for different size and weights.

0 notes

Text

H Beam Shot Blasting Machine With 6 Blasting Turbines

H beams shot blasting machine plays an important role in removing all forms of rust and corrosion materials from h beams prior to painting or coating. In the blasting process, the conveyor system of roller conveyor blast machine can make oxide layer and dirt rust wore off quickly. The video shows us the daily working scene of operating the H beams shot blasting machine

0 notes

Text

Shot Blasting Machine Wiki

Shot blasting machine

Industry Cleaning, mechanical

Application Automotive industry, Construction industry, Wind power industry, Railway industry, Foundry-Forging industry, Shipyard

Inventor Benjamin Chew Tilghman

Invented October 18, 1870

The shot blasting machine is an equipment used to reinforce, clean or polish any metal surface or metal. Shot blasting, also known as abrasive blasting, more commonly known as sandblasting. Historically, shot blasting is not a relatively modern concept, the first shot blasting machine in the world was patented (US patent 108,408.) by Benjamin Chew Tilghman (1821–1901),[1] an American soldier and inventor,[2] on October 18, 1870.[3]

Shot blasting is a technique in which a selected class of abrasive particles is used to remove material from a surface at a high speed (65 -110 m/s) corrosion rate. It is the operation of forcing the abrasive stream to the surface under high pressure to smooth the rough surface, roughen the smooth surface, and shape or remove surface contaminants. A pressurized fluid (usually compressed air), or a centrifugal wheel is used to propel the blast material (commonly referred to as the medium).

Contents

1. Shot Blasting Machine Video (3D Visualization)

2. Overview

3. History

4. Methods

3.1 Mechanical blasting

3.2 Air blasting

5. Classification

4.1 Roller conveyor type shot blasting machine

4.2 Hanger type shot blasting machine

4.3 Rotary table type shot blasting machine

4.4 Tunnel type shot blasting machine

4.5 Barrel type shot blasting machine

4.6 Trolley type shot blasting machine

6. Development

7. Global market

8. References

Shot Blasting Machine Video (3D Visualization)

Overview

Shot blasting is a process that treats metals to remove rust, grease, scale, and other irregularities to create a smooth surface for applying a finishing surface. During this process, ssome abrasive material is blasted onto the surface and depending on the surface being treated, they may be sand, beads or water. It is important to create a smooth and clean surface to apply the final surface treatment, like, powder coating, to the metal surface to achieve a high-quality, beautiful and durable surface treatment. China sand blasting machine is a mechanical method that uses centrifugal wheels to propelling the abrasive to remove surface and other impurities from the surface of steel applications. In general, blasting prior to finishing serves three primary purposes:

· Cleans and descales surfaces

· Increase texture to enhance paint adhesion

· Properly reduces maintenance costs by extending coating life

History

Benjamin Tilghman was a general in the army and saw the effect of wind-blown sand on windows in the desert. This might be the basis of his shot blasting machine invention.

On October 18, 1870, Tilghman filed a patent, titled “Improvement in cutting and engraving stone, metal, glass, etc.”, in the US (US patent 108,408.), detailing many unique applications of the technology, such as sharpening files, carving bottles, cleaning boilers or turning The wood grain comes out. Later that year, a patent was issued in the UK.

Methods

Broadly, there are two methods of shot blasting machines: air blasting and mechanical blasting (also known as airless blasting, and wheel blasting).

Mechanical blasting

In this system, the abrasive is propelled by fast rotating impellers driven by power.

Air blasting

In this system, the abrasive is propelled through a nozzle by compressed air (mechanical blasting is more widely used).

Classification

According to different structures of casting metal parts, shot blasting machine can be divided into roller conveyor type, hanger type, rotary table type, tunnel type, barrel type, trolley type, and so forth.

Roller conveyor type shot blasting machine

This type of sand blasting machine is the most environmentally friendly and effective process angle for removing all forms of rust and corrosion materials in steel plates, pipes, steel structures, H-beams, steel pipes, profiles, and steel channel. It can not only remove rust, but also remove welding slag on structural parts, eliminate welding stress, improve fatigue strength, increase paint film adhesion, and provide ideal surface finish (SA2.5-3.0) for workpieces to ensure continuous and effective bonding between the steel surface and the coating. It is used in almost all industries that use metals, including aerospace, automotive, construction, casting, shipbuilding, railways, and many other industries.

Hanger type shot blasting machine

This type of machine is the most flexible and versatile shot blasting machine. It has two options: the single hook I type shot blasting machine and two hooks Y type shot blasting machine. It is specifically suitable for descaling of forgings, desanding of castings, removal of burrs and scales, surface treatment and deburring of welded constructions, et cetera.

Rotary table type shot blasting machine

Rotary shot blasting machine, also known as table type shot blasting machine, is suitable for various shapes and sizes, castings, forged parts, pressed parts, steel and non-ferrous metal parts and parts made of fragile materials, clean the surface, remove casting sand and debris Consolidate the surface (micro-treatment), and roughen the surface before coloring. They are divided into single rotary table shot blasting machine and swing table shot blasting machine, and the latter is more effective than the former.

Tunnel type shot blasting machine

This type of machine is a non-standard shot blasting machine designed according to the workpiece information. It is mainly used for surface treatment of large steel structures to remove rust, old paint and old putty. For large workpieces, it can use a double electric hoist to lift the workpieces through the shot blasting chamber, and the workpieces can be shot blasted. It adopts imported PLC control, with automatic/manual control mode. and has an automatic/manual control mode. The entire hook realizes automatic fault detection through the type of shot blasting machine.

Barrel type shot blasting machine

Barrel type shot blasting machine is an integral whole model, simple accessories, durable and high quality. It is mainly used for batch cleaning, deburring, descaling, decoration, deburring and shot peening treatment of various products.

Trolley type shot blasting machine

This type of machine is mainly used for cleaning and strengthening of casting surface, removal of oxides and welding slag, widely used in petroleum casting, forging, machinery, steel and other industries.

Development

Initially, the shot blasting machine was used for industrial purposes, such as removing rust or polishing metal before painting. Nowadays, the technique has decorative purposes, including sculpting and texturing. Current uses include engraving awards, such as trophies and crystal awards, production of 3D signage, glass decoration, and building refurbishment, however one of the earliest items to be sold after was Alfred Dunhill's pipes which he found sold for more money than his smooth pipes.

Nowadays, the shot blasting machine has become a mandatory industry for every industry, mainly including automotive, construction, wind power railway Industry, foundry-forging, and shipyard industry, to clean and polish surface metal preparation. The main benefit of the shot blasting machine is that it provides an effective and smooth surface to any kind of the metals.

0 notes

Text

Shot Blasting Machine

Shot blasting machine is an effective method to remove the surface contaminant, clean and roughen a smooth surface before applying a primer or coating. Shot blasting equipment is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, shipbuilding, rail, and many others. Shot blasting machine is a non-standard machine, all the detailed parameters are tailored according to customer object items detailed conditions and customer requirements. Whether wheel blasting or air blasting, our products can meet your demands. As an expert automatic shot blasting machine manufacturer from China with 45 years' experience, QingGong Machinery has sold more than 4000 sets of shot blasting equipment all over the world. Contact our engineer for competitive shot blasting machine price.

Types of Shot Blasting Machine for Sale

Shot blasting machine is an effective method to remove the surface contaminant, clean and roughen a smooth surface before applying a primer or coating.

History of Shot Blasting Machine

Industry: Cleaning, Mechanical, Metal, Metallurgy, Metal casting.

Application: Automotive industry, Construction industry, Windpower industry, Railway industry, Foundry- forging industry, Shipyard, Mould industry, Pipeline cleaning industry, Electric industry, Stone industry.

Inventor: Benjamin Chew Tilghman

Invented: October 18th, 1870

Benjamin Tilghman was a general in the army and saw the effect of wind-blown sand on windows in the desert. The might be the basis of his shot blasting machine invention.

On October 18.1870, Tilghman filed a patent, titled “Improvement in cutting and engraving stone, metal, glass, etc”, in the US(US paten 108,408), detailing many unique applications of the technology, such as sharpening files, carving bottles, cleaning boilers or turning. The wood grain comes out. Later that year, a patent was issued in the UK.

Shot blasting is a technique in which a selected class of abrasive particles is used to do surface preparation, that is, remove material from a surface at a high speed (65-110m/s) corrosion rate. It is the operation of forcing the abrasive stream to the surface under high pressure to smooth the rough surface, roughen the smooth surface, and shape or remove surface contaminants. A pressurized fluid (usually compressed air), or a centrifugal wheel is used to propel the blast material (commonly referred to as the medium).

How Shot Blasting Machine Works?

During the working process of the shot blasting machine, the electrically controlled transport system conveys the object items into the shot blasting chamber, and its surfaces are hit and rubbed by powerful and dense steel shots from different coordinate directions. The oxide scale, rust layer, and dirt on the surface quickly fall off.

Used blasting media and contaminants (pill dust mixture) falling into the screw conveyor, then reclaim them into the bucket elevator and then into the air wash cleaner system, the cleaned abrasive get into the storage hopper to recycle, the residual will get out of the recycling system from the air wash cleaner system. The dust is collected to the dust collector system by the exhaust pipe, the purified air is discharged into the atmosphere, and the particulate dust is captured and collected in the dust collector, and then discharged into the atmosphere is clean and pollution-free air.

Shot Blasting Machine Parts

Blasting Chamber

Blasting cabinet body welded by steel plates and profile steel, have enough strength and rigidity.

Blasting chamber is 360° protected by high resistance manganese steel alloy liners, which is enough to deal with the shot blasting from 35HRC to more than 60HRC.

High impact toughness can make full use of the reflection kinetic energy of the shot to continue to blast cleaning the surface of the workpiece, so greatly enhance the cleaning efficiency and quality.

To avoid shot leakage, 3-6 layers of rubber sheets are fitted in the inlet and outlet, meanwhile, a high cleanness result is assured.

Blasting Chamber

Blast Wheel

Blast wheel including blast whee housing, motor, blade, control cage, distributor, and guard plate.

Guard plates in the blast wheel are designed according to abrasive shot and blades rotating track simulation. After accelerating along the round track, abrasive can reach the highest speed and cause the least self-wear.

The direct-driven motor has a low noise level, fewer spare parts, higher energy efficiency, large abrasive flow rate, and good cleaning effect, etc.

Max thickness of guard plates is up to 70 mm, the service time is greatly increased. Material for core components is high chromium wear resistance alloy, max hardness is up to HRC55-60.

Blast Wheel

Automatic Abrasive Reclaim System

Automatic abrasive reclaim system including screw conveyor, bucket elevator, separator, abrasive cleaning up system.

Screw Conveyor

Cylindrical machining process after the whole weldment to ensure high coaxiality of the whole screw, for longer surface time.

3-layer labyrinth design sealing to protect bearings from the damage of abrasive shot.

Bucket Elevator

Cage-shape belt driving wheel offers higher friction to the belt to avoid slip, decreasing the elevating belt pre tightening force

Maintenance door at bottom of the housing to maintain the bottom drive device.

Wear-resistant elevator buckets bolted onto elevator belt, tension device prevents the belt to skid.

SQP sensor can alarm and automatically power off when faults happened in bucket elevator.

Separator

A full-screen curtain air selection separator makes the abrasive more evenly dispersed, and takes the dust and other residues that may be contaminating the abrasive material to the exhaust system.

Optionally, the abrasive materials purifier can be supplied with a revolving screen.

A checking window allows workers to maintain the machine expediently.

Abrasive Cleaning Up System

An abrasive cleaning up system is used for the roller conveyor shot blasting machine and preservation line.

The abrasive cleaning up system is equipped with a wear-resistant nylon roller brush, screw conveyor, high-pressure blower, and lifting mechanism.

After shot blasting, the lifting mechanism lowers the roller brush to the most suitable position (make the roller brush contact with the workpiece), rolling and rotating, sweeping the left abrasive on the workpiece surface into the screw conveyor. Meanwhile, the high-pressure blower continues to clean scattered pellets and dust on the surface, make the surface clear.

Nylon roll brush with high elasticity and phi 3.5mm imported composite nylon material, moderate hardness, great elasticity, and good wear resistance.

Automatic Abrasive Reclaim System

Dust Collector

3-level dust collector: settling chamber, cyclone dust collector, and cartridge filters. Cleaning efficiency is up to 99.5%.

The filters use cartridge type filters, a vertical fixed unique structure is greatly convenient for maintenance and collecting dust.

The filter adopts the Venturi principle venturi tube pulse blowback dust collecting system for clearing the dust on the filter.

How to Choose the Abrasive of Shot Blasting Machine?

Metal abrasives include steel shot, steel grit, iron shot, iron sand, stainless steel shot, stainless steel sand, steel wire cut shot, and stainless steel wire cut shot, etc.

Each type of shot blasting machine equipment requires different types of abrasives. If the final type of abrasive needs to be determined, it also depends on what kind of workpiece the shot blasting machine is blasting and the desired shot blasting effect. The size of the workpiece is different, and the abrasive used is also different, so the specific type of abrasive used depends on the situation.

The larger the abrasive diameter, the higher the surface roughness of the workpiece, but the shot blasting efficiency is also high; the abrasive diameter should be selected according to the surface roughness of the part. The shot blasting efficiency of other irregularly shaped steel shots or cut wire shots is higher than that of spherical shots, but the surface roughness is also higher.

Choose the abrasive with a moderate hardness to achieve a good application effect. Suitable abrasive hardness and excellent resilience, so that the abrasive can be projected to every part of the shot blasting machine chamber, and then reduce the blasting time.

0 notes

Text

Sandblasting room in Russia

The sand blast room is designed according to customers' workpiece size and requirements. The sandblasting room size10×4×4m, mainly blast cleaning construction machinery components. Observing windows are put on the front face of the working gate and the side door of the safety side door. so that operator can conveniently observe the blasting operation inside the house body from the outside, at the same time, it is conducive to safety production and the accident prevention. Sandblasting warning lights are set above the gate to warn outdoor operator.

The dust collector discharge reaches the national environmental protection standard, which ≤80mg/m3, capture particle size<5um, resistance <400Pa, good air permeability, low resistance, low energy consumption, and reliable filtering performance. The sandblasting system is controlled by a single-gun wireless remote control; the wireless sand blasting can reach the distance over 100 meters. Guns can be used for individually sandblast and individually blow, which can finish the dust cleaning of the workpiece surface after blasting. The wireless remote control device is simple and convenient to operation. Dust box filter cartridge cleaning is washed by the pulse tour system and the small particles remaining on the surface of the cartridge can be purged all at once. This pulse controller adopts automatic micro-computer control system and can be used simply by debugging. In the environment and safety aspects, in order to avoid harming the body of operator in the blast room both inside and outside, the control system adopts the door limit safety protection system.

0 notes

Text

SANDBLASTING EQUIPMENT

Industrial Sandblasting room equipment is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. The surface of the workpiece is cleaned by a mixture of abrasive and high pressure compressed air being directed at the workpiece by a blast operator. The operator holds a venturi nozzle tipped hose in his hands and controls the abrasive/air mixture generated at the blast machine with an "on the hose" operator switch.

0 notes

Text

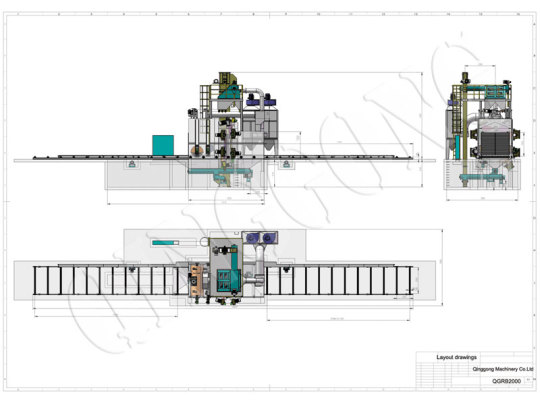

ROLLER CONVEYOR SHOT BLASTING MACHINE

Roller conveyor shot blasting machine or roller conveyor type shot blasting machine is the most environment-friendly and the most effective process to remove all forms of rust and corrosion materials from steel plate, pipes, steel structure, h beams, steel tube, profiles, steel angles and channels, etc.

The roller conveyor shot blasting machine can not only remove the rust, but can also remove the welding slag on the structural parts, eliminate welding stress and improve the fatigue strength, increase film adhesion painting, provides ideal surface finish (SA2.5-3.0) for securing a continuous and effective bond between the steel surface and coat. It is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, shipbuilding, rail, and many others.

Details about Roller Conveyor Shot Blasting Machine

The components crosses the tunnel laid on a roller conveyor, extendible outside with modular lengths. The surface treatment is done during the running through the blasting room: at one single pass it is possible to achieve the required finishing degree, according to the specification of standard ISO 8501-1 and SIS SS 055900.

Length of roller conveyor depends on customer requirements. Shot blasting machine for blasting plates and profiles can be equipped with side loading ramps, preheated chambers, scrubbers, with the chamber for painting or drying tunnel. The shot blasting machine is made of solid manganese steel plates. Blast part can be further protected by wear-resistant shields made from manganese steel. Working speed rollers during the process of blasting can be constantly updated. Innovative pressure washers provide high-quality sand cleaning abrasive. The entire device is made in accordance with the strictest European standards.

Qinggong Machinery offers a range of roller conveyor shot blasting machine from small simple machines to construction blasters, heavy duty machines and complete preservation lines. Qinggong Machinery’s extensive experience in this field caters for all component sizes as well as customer specific solutions. Working speeds from 0.5 m/min for a small roller conveyor machine to 20m/min for a heavy skew roll machine are achievable.

0 notes

Text

Shot Peening VS Shot Blasting

https://www.shotblastpro.com/shot-peening-vs-shot-blasting.html

Shot Peening VS Shot Blasting

As we all know shot blasting and shot peening are the common processes in metal surface treatment manufacture. They have the same method to spray the abrasive to the metal surface so that they are often conflated. In fact, shot peening and shot blasting are two entirely different functions. So we will explain what is shot peening and shot blasting and the difference between them in this article. Read on to learn what sets them apart.

0 notes

Text

Differences between Shot Blasting and Grit Blasting

https://www.shotblastpro.com/differences-between-shot-blasting-and-grit-blasting.htm

When the Shot blasting machine cleans up and strengthens the workpiece, there are usually two ways, that is shot blasting and Grit Blasting, shot blasting is using shot blaster throws at high speed, using the principle of centrifugal force, while Grit blasting uses the principle of air compression. They can make the surface of the work price reach a certain roughness, make the workpiece beautiful, or change the welding tensile stress of the workpiece to compressive stress, which improves the service life of the workpiece. By improving the surface roughness of the workpiece, the adhesion of the paint film of the workpiece after the painting is also improved. Shot blasting and Grit blasting are used in machinery, shipbuilding, automobile manufacturing, and aerospace. Please read on, I will explain the differences between shot blasting and grit blasting.

0 notes

Text

Surface Preparation Standard

https://www.shotblastpro.com/surface-preparation-standard.html

The surface preparation, as the name implies, is to use a shot blasting machine, sandblasting room, or other surface cleaning equipment to remove rust and oxide scale on the surface of the workpiece before the workpiece needs to be painted or sprayed to increase the adhesion of the paint on the surface of the workpiece and the service life.

1. What is Surface Preparation?

Surface preparation is a process of forming a surface layer on the surface of the basic material that is different from the body's mechanical, physical or chemical properties. The purpose of our Surface preparation of products is to make the products meet certain requirements of corrosion resistance, wear resistance, decoration, or other special functions. There are different Surface preparation methods and processes for different products. One of the most important functions that affect the performance of the coating is the quality of the Surface preparation. This can be done mechanically or chemically.

0 notes

Text

Shot Blast Media

https://www.shotblastpro.com/shot-blast-media.html

The world's first shot blasting machine was born in the United States. The shot blasting machine refers to the casting equipment that uses the high-speed abrasive thrown by the blast turbines to clean or strengthen the surface of the casting. The shot blasting machine can de-core and clean the workpiece at the same time. In the process of shot blasting, some shot blast media is needed. Let me show you today.

1. What is Shot Blasting Process?

First, let's introduce the working principle and workflow of the shot blasting machine. When the shot blasting machine starts to work, the workpiece is transported on the transportation system. Different types of shot blasting machines have different transportation methods, such as roller conveyor systems, v-wheel conveyor systems, hook conveyor systems, and others. When the workpiece into the blasting chamber, the blast turbines start to work.

0 notes

Text

Tunnel Type Shot Blasting Machine

https://www.shotblastpro.com/products/tunnel-type-shot-blasting-machine.html

Tunnel type shot blasting machine is a non-standard shot blasting machine that is according to workpieces information to design. The tunnel type shot blasting machine is mainly used for surface treatment of large steel structures to achieve the removal of rust, old patent leather, and old putty, etc.

For large workpieces, it can use a double electric hoist to lift the workpieces through the shot blasting chamber, and the workpieces can be shot blasted. The tunnel type shot blasting machine adopts imported PLC control and has automatic/manual control mode, the whole hook through the type of shot blasting machine to achieve automatic fault detection.

0 notes

Text

Tumble Belt Shot Blasting Machine

https://www.shotblastpro.com/products/tumble-belt-shot-blasting-machine.html

Tumble belt shot blasting machine or crawler shot blasting machine is the most universal among all shot blasters as their design makes them suitable for processing parts of different sizes in bulk loads. Shot blasting of casts, forged and pressed parts, remodelled cold or hot, of various complicated forms, springs, etc. (weighing up to 20 kg and manufactured in smaller and large series, the volume of a particular filling may be up to 500 L, mass up to 1,000 kg), cleaning surface, removing casting sand and filings and consolidating the surface (microhandling), roughing the surface before colouring, etc. Our company has tumble blaster for sale.

Tumble belt shot blasting machine with rubber belt

Machine Type MB150G MB300G MB400G

Productivity(t/h) 0.6-1.2 1.5-2.5 3-5

Max volume charge (dm3) 150 300 400

Max advised load (kg) 200 600 800

Drum diameter (mm) 650 1000 1000

Wheels 1 1(2) 1(2)

Wheel power (kW) 7.5(11) 11/15(2*11) 11/15(2*11)

Larger sizes are available, as are a huge range of options. Represented here are the Standard /Stock pre-engineered machines. Please contact us for further information.

Machines have a perpetual caterpillar made from perforated rubber belt. Treated objects are put by a special filling contraction to caterpillar. When caterpillar moves its special shape causes treated objects to turn and roll, which causes the whole surface of the treated object to be quality blasted in a jet of abrasive. For emptying, caterpillar is started-up in the opposite direction turning mode.

The machine's housing is protected by wear-resistant manganese steel. High efficiency of the machine is provided by the system for continued returning and cleaning of the abrasive, along with efficient turbines made from wear-resistant materials.

Standard equipment of larger machines includes: PLC Siemens, display, timer automatic or manual mode, automatic start-up of turbines, working-hours counter, etc.

The machine may be equipped with a magnetic separator, vibration conveyor and variable frequency drive for the turbines.

Tumble belt shot blasting machine with manganese steel belt

Machine Type G-150 G-250-1 G-450-1 G-750-2 G-1100-2 G-2000-2

Charging volume (l) 150 250 500 750 1100 2000

Max. recommended charging weight (kg) 300 500 1000 1500 2500 5000

Max. recommended piece weight (kg) 15 100 200 250 400 1000

Width of shotblasting chamber (mm) 850 1000 1100 1200 1700 2400

Diameter of shotblasting chamber (mm) 750 910 1200 1600 1450 1650

Total installed power (kw) 18.3 22.5 24 38 55 120

Diameter of throwing wheel (mm) 380 380 380 380 380 506

Power of abrasive throwing wheels (kW) 15 15 18.5 2*18.5 2*22 2*45

Air requirements (m3 / h) 2000 4500 5500 9600 12000 18000

Capacity of the machine (kg / h) 600 1000 2000 3000 4400 8000

Larger sizes are available, as are a huge range of options. Represented here are the Standard /Stock pre-engineered machines. Please contact us for further information.

Machines have a perpetual caterpillar made from steel flaps. Treated objects are put by a special filling contraction to caterpillar. When caterpillar moves its special shape causes treated objects to turn and roll, which causes the whole surface of the treated objects to be quality blasted in a jet of abrasive. For emptying, caterpillar is started-up in the opposite direction turning mode. Tumble belt shot blasting machine with manganese steel belt, the volume of a particular filling may be up to 2,000 L, mass up to 5,000kg.

0 notes

Text

Trolley Shot Blasting Machine

https://www.shotblastpro.com/products/trolley-shot-blasting-machine.html

Shot blasting parts of different forms and dimensions, castings, forgings, pressed parts, parts and parts from fragile materials, cleaning of the surface, removing of casting sand and filings, consolidating of the surface before coloring, etc. Trolley type shot blasting machine is designed for shot blasting of large and heavy castings, complicated shapes in small series or single production. Working pieces are loaded to a rotating table on tip truck with lifting device (crane, lift truck). This rotating table is then transported in a chamber. In the entrance of this chamber are two-sided doors.

By means of handy lifts, the workpieces are loaded on the perforated rotating working table of the trolley, which then drives to the shot blasting chamber. It is recommended that the table surface is covered with the workpieces as much as possible. It normally works with the automatic switching-on, the shot blasting time is set by means of a program. During shot blasting the workpieces move on the rotating table through the jets of abrasive of throwing wheels, which are installed under different angles, enabling higher efficiency. Then the workpieces must be turned and repeat the shot-blasting process.

Application:

Shot blasting parts of different forms and dimensions, castings, forgings, pressed parts, parts and parts from fragile materials, cleaning of the surface, removing of casting sand and filings, consolidating of the surface before coloring, etc.

0 notes

Text

Transportable Container Blast Room

https://www.shotblastpro.com/products/transportable-container-blast-room.html

The movable sandblasting room or portable sandblasting room, abrasive recovery system, dust collector, sandblasting machine together, it can be transported to the site by flatbed truck. The installation time is less than 2 hours, which is the best equipment for field-flow operation.

Transportable container blast room features:

The whole blasting room adopts container installation, which can be transported from one place to another easily and convenient for sand blasting;

The transportable container blast room does not need foundation pit, can be placed on the ground directly, which reduces the investment cost of the equipment;

The transportable container blast room is suitable for a wide range of abrasive media including but not limited to: steel shot, steel grit, chilled iron, aluminium oxide, glass bead, etc.

The transportable container blast room can quickly change the type of abrasive, the abrasive can be quickly replaced according to the process requirements to realize the processing of workpieces with different materials.

The transportable container blast room adopts the filter cartridge type dust collector, which fully meets the environmental protection requirements.

Transportable container blast room fitted out with :

Main doors suitable interlocked – to prevent blasting with doors open.

Operator door – as a means of exit if main doors are stuck, also interlocked.

LED lighting.

Emergency lighting.

Steel floor with side shedders.

Cross screw conveyor at the bulkhead.

Air inlets providing ventilation for blast room and good operator visibility.

Shot-blast quality rubber lining of room.

0 notes

Text

Steel Structure Shot Blasting Machine

https://www.shotblastpro.com/products/steel-structure-shot-blasting-machine.html

Steel shot blasting machine is the most environment-friendly option for corrosion removal and surface preparation on a steel structure. Steel shot blasting equipment is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, shipbuilding, rail, and many others. Good quality steel shot blaster for sale!

Technical support:

1. The engineering team uses 3-D dynamic simulation design blast turbines layout to ensure that the steel shot ray can cover the surface of the steel structure 360 degrees.

2. The equipment adopts pneumatic control abrasive distribution system, which eliminates the blast wheel idling and injuring workers.

3. The machine adopt environment-friendly high-efficiency cartridge filter, dust collecting efficiency reach to 99.9%

4. The machine with limit switch on access door, that protect people, in any case, they open the door, the blast turbines will stop according.

5. Six layers protection curtain for protection the shot balls spatter out during blasting.

6. The machine with the sand-guide channel at the outlet of the equipment, and the steel shot on the steel structure can be poured out in the sand-guide channel, and then enter the recovery system.

7. The steel structure shot blasting machine uses high effective abrasive recovery system. A longitudinal screw conveyor to reclaim the used blasting media and contaminants into the crosswise screw conveyor, then into the bucket elevator and abrasive residue separator, and then the cleaned abrasive get into the storage hopper to recycle, the residual will get out of the recycling system from the air wash cleaner system.

Blast wheel:

On the base of the overseas advanced technology, QINGGONG MACHINERY independently developed KT series blast wheel.

1. The blast turbine is the heart of the steel structure shot blasting machine and has a direct influence on the work efficiency, the effect of the blasted surface and the production costs.

2. KT series blast wheel can improve efficiency by up to 30%. KT blast turbines reduce the consumption of medium, cut down energy consumption, then it can improve efficiency.

3. Improve the lifetime of “Hot Parts”. The material of blades, control cage, abrasive distributor and other spare parts are high chrome wear-resistant cast iron.

0 notes

Text

Steel Profile Shot Blasting Machine

https://www.shotblastpro.com/products/steel-profit-shot-blasting-machine.html

Steel Profile shot blasting machine is the most efficient and the most effective process to remove all forms of rust and corrosion materials fromsteel profile prior to painting or coating. We are professional shot blasting machine supplier.

Type unit QGB600 QGB1000G QGB1500 QGB2000 QGB2500 QGB3000

Effective blasting width mm 600 1000 1500 2000 2500 3000

Dimension of entrance(W×H) mm 800×550 1200×550 1700×550 2200×550 2700×550 3200×550

Work speed to achieve a cleaning of Sa2.5 ISO8501 m/min 0.5~3 0.5~3 0.5~3 0.5~3 0.5~3 0.5~3

Number of wheels×power kW 4×7.5/11 4×11/15 4×11/15 6×11/15 8×11/15 8×11/15

Wheel optional kW — — — 4×15 6×15/18.5 6×15/18.5

Abrasive initial filling capacity kg 2000 4000 4000 4500 6000 6000

Processed length of work piece mm 1200~12000 1200~6000 1200~12000 3000~12000 2400~12000 3000~18000

Foundation pit required No No No Yes Yes Yes

Technical support:

1. The engineer team use 3-D dynamic simulation design blast turbines layout to ensure that the steel shot ray can cover the surface of the steel structure 360 degrees.

2. The equipment adopt pneumatic control abrasive distribution system, which eliminate the blast wheel idling and injuring workers.

3. The machine adopt environment friendly high efficiency cartridge filter, dust collecting efficiency reach to 99.9%

4. The machine with limit switch on access door, that protect people in any case they open the door, the blast turbines will stop according.

5. Six layers protection curtain for protection the shot balls spatter out during blasting.

6. The machine with sand-guide channel at the outlet of the equipment, and the steel shot on the steel structure can be poured out in the sand-guide channel, and then enter the recovery system.

7. The steel structure shot blasting machine use high effective abrasive recovery system. A longitudinal screw conveyor to reclaim the used blasting media and contaminants into the crosswise screw conveyor, then into the bucket elevator and abrasive residue separator, and then the cleaned abrasive get into the storage hopper to recycle, the residual will get out of the recycle system from the air wash cleaner system.

Abrasive residue separator

Our patented abrasive cleaner is applied for recycling shot/grit, which is to ensures high quality blasted surface and minimal abrasive shot. As the abrasive is so durable it is able to be recycled hundreds of times, resulting in an extremely low abrasive breakdown rate.

Critical to achieving this efficiency is the effectiveness of the abrasive recycling plant. Poorly designed or manufactured abrasive recycling systems will not correctly recycle the abrasive and are unable to maintain the correct abrasive working mix.

Our patented abrasive separator consists of an extended rotary separator drum that will totally remove all big clumps including big wast, scrap and paint chips etc. The abrasive is then fed through a gravity air wash separator where all dust, degraded abrasive and waste is drawn out of the good abrasive by an air current.

Only good, correctly sized abrasive is fed back to the abrasive storage hopper and blast pots for recycling.

Our patented abrasive cleaner ensures maximum recyling rates of the abrasive and high quality surface finishing is achieved.

0 notes