The company has more than 20 years of R&D and production experience in glass cutter and glass suction cups ,Located in Shanghai, China.Looking forward to working with you.

Don't wanna be here? Send us removal request.

Photo

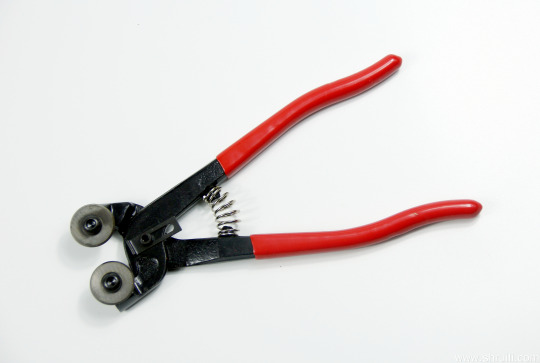

About RuiLi The high-quality choice of mosaic pliers - Shanghai Ruili manufacture Do you want to cut tiles of multiple shapes? Adding it to your cart makes it easy to achieve your goals. This tile mosaic pliers is full of iron, wear-resistant and practical, replaceable cutting wheels,don't miss it, have it, please start your cutting journey!#powertools #handtool www.shruili.com

0 notes

Photo

China International Hardware Show 2024: A great opportunity to explore unlimited business opportunities". Shanghai Ruili Diamond Tools Co., Ltd., Booth No.: E5D43。 We look forward to your visit to discuss cooperation. The China International Hardware Show (CIHS) is jointly organized by the China National Hardware Association, Koelnmesse GmbH of Germany, and the Sub - Council of Light Industry of CCPIT. It is supported by the International Hardware and Housewares Association (IHA) and the European DIY Retailers Association (EDRA), and undertaken by Beijing Headway Exhibition Co., Ltd. It is the second - largest hardware show in the world and is known as the "barometer of the hardware market and the vane of industry development". The 2024 China International Hardware Show will be held in Shanghai New International Expo Center from October 21 - 23, 2024. This time, the exhibition area is 120,000 square meters, with more than 2,600 exhibitors. The exhibits cover hand tools, electric tools, pneumatic tools, gardening and horticulture products, abrasives, small machinery, building hardware, fasteners, wire, nail and mesh products, locks and security products, etc.

0 notes

Photo

Unlock the boundless creativity and carve a new chapter of glass art with a Seiko glass cutter | RuiLi Beautiful appearance, the cutter head can be disassembled, the ergonomic handle, can cut glass and tiles more forcefully, can continuously cut more than 20,000 meters. is your powerful assistant.#diamondpaintingtools #powertools #handtool Welcome your visit and your suggestion. OEM & ODM welcomed! www.shruili.com [email protected]

0 notes

Photo

Quality 8839L Natural diamond Glass Scriber Manufacturer | RuiLi This product is the way to go when you need to engrave on glass or ceramics, and the nib is diamond, which can complete the engraving more smoothly and long-lasting, guaranteeing you an excellent experience. Our products are divided into 6 categories: diamond glass cutter, carbide glass cutter(including oil feed wheel cutter...), glass tool(including circle cutter, suction lifter, T-knife, glass plier...), diamond tool(core drill bit, diamond dresser...)and abrasive tool(grinding wheel.. ) and others. #diamondpaintingtools #powertools #handtool Welcome your visit and your suggestion. OEM & ODM welcomed! www.shruili.com

0 notes

Photo

Best Diamond grinding wheel correction pen 1.50CT Company - RuiLi The manufacturing process of the diamond pen is to use powder metallurgy method to position the diamond on the gauge handle, which is beautiful in appearance and reasonable in structure. Diamond pens are divided into single grain and multi-particle diamond pens, and different types of diamond pens correspond to the relative grinding wheel dressing. The structure of the diamond pen is generally composed of diamond and handle body, the working layer is called the nib, and the raw material is natural diamond or synthetic diamond, which is the working part of the diamond pen. It looks like a "pen", and later people like to call it "diamond pen". Characteristics: wear-resistant, high dressing efficiency. #diamondpaintingtools www.shruili.com

0 notes

Photo

Quality Diamond grinding wheel correction pen 0.50CT Manufacturer | RuiLi The manufacturing process of the diamond pen is to use powder metallurgy method to position the diamond on the gauge handle, which is beautiful in appearance and reasonable in structure. Diamond pens are divided into single grain and multi-particle diamond pens, and different types of diamond pens correspond to the relative grinding wheel dressing. The structure of the diamond pen is generally composed of diamond and handle body, the working layer is called the nib, and the raw material is natural diamond or synthetic diamond, which is the working part of the diamond pen. It looks like a "pen", and later people like to call it "diamond pen". Characteristics: wear-resistant, high dressing efficiency. #diamondpaintingtools#diamondcoretools www.shruili.com

0 notes

Photo

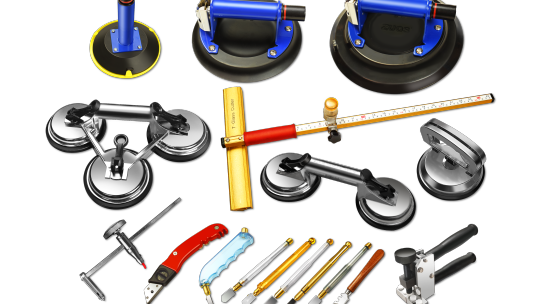

What is The status quo and development of hardware tools? | RuiLi Shanghai Ruili Diamond Tools Co.,Ltd. is leading and professional Manufacturers of glass cutting & diamond tool in China with exporting business only. Specializing in this line of business for more than 20 years. We have evolved, building a team of highly skilled workers and invested heavily in the latest technic system production facilities, which has allowed continued growth of the product range and improved the quality of the tools manufactured. Our products are divided into 6 categories: diamond glass cutter, carbide glass cutter(including oil feed wheel cutter...), glass tool(including circle cutter, suction lifter, T-knife, glass plier...), diamond tool(core drill bit, diamond dresser...)and abrasive tool(grinding wheel.. ) and others. Since exporting, we have built long business relationship with more than 50 Chinese trading companies and more than 76 big whole dealers abroad based on Price of Chinese, Service of Japan, Quality of German. Your business relationship with us gonna makes you happy and easy! Welcome your visit and your suggestion. OEM & ODM welcomed!#cutterpliers #diamondpaintingtools #powertools #handtool#rubberplant www.shruili.com

0 notes

Photo

What is The status quo and development of hardware tools? | RuiLi Shanghai Ruili Diamond Tools Co.,Ltd. is leading and professional Manufacturers of glass cutting & diamond tool in China with exporting business only. Specializing in this line of business for more than 20 years. We have evolved, building a team of highly skilled workers and invested heavily in the latest technic system production facilities, which has allowed continued growth of the product range and improved the quality of the tools manufactured. Our products are divided into 6 categories: diamond glass cutter, carbide glass cutter(including oil feed wheel cutter...), glass tool(including circle cutter, suction lifter, T-knife, glass plier...), diamond tool(core drill bit, diamond dresser...)and abrasive tool(grinding wheel.. ) and others. Since exporting, we have built long business relationship with more than 50 Chinese trading companies and more than 76 big whole dealers abroad based on Price of Chinese, Service of Japan, Quality of German. Your business relationship with us gonna makes you happy and easy! Welcome your visit and your suggestion. OEM & ODM welcomed!#diamondpaintingtools #powertools #handtool#rubberplant www.shruili.com

0 notes

Photo

Glass forceps: the beauty of modern craftsmanship and strength #plierstool #powertools #handtool In the world of modern craftsmanship, there is one tool that has won widespread praise for its unique design and powerful functions, and that is glass forceps. Not only does it have excellent performance, but it also incorporates modern aesthetics, making it an indispensable companion for craftsmen. Glass forceps, as the name suggests, are a tool that is specially used to handle glass materials. Its appearance often presents a sense of exquisite craftsmanship, with smooth lines and compact structure, which is obvious at a glance. The body of the pliers is usually made of high-strength alloy, which ensures its stability and durability when dealing with various work scenarios. At the same time, the surface of the pliers is often specially treated, which has the characteristics of non-slip and wear-resistant, making the operation more convenient. However, the real charm of glass forceps lies in their powerful features. It can easily grip a wide range of glass thicknesses, from small glass shards to heavy glass plates. This is made possible by the precision design inside the pliers and the high-quality spring system. These springs are precisely tuned to ensure that the pliers are evenly balanced when applying force and avoid unnecessary damage to the glass. In addition to this, glass pliers also have a lot of user-friendly designs. For example, the handle section is usually ergonomically designed so that the operator can maintain a comfortable feel even during long periods of use. In addition, the pliers are equipped with a safety locking device to ensure that they can be securely locked when not in use, preventing accidents. Glass forceps play an important role in modern architecture, decoration, handicraft production and other fields. Whether it's an architect building a glass curtain wall or a craftsman making glass crafts, this tool is needed to complete the work with precision and efficiency. Not only does it increase productivity, but it also makes work easier, allowing people to better use their creativity and skills. Overall, glass pliers are a tool that combines modern craftsmanship with the beauty of strength. It has won people's love and trust with its excellent performance and user-friendly design. In the future, we expect this tool to continue to innovate and improve, bringing more convenience and surprises to people's lives and work. #plierstool #powertools #handtool Welcome your visit and your suggestion. OEM & ODM welcomed! www.shruili.com

0 notes

Photo

What is Drywall compass knife: master craftsman among tools? | RuiLi Gypsum board compass knife, a seemingly ordinary but extremely valuable tool, is widely used in the decoration and construction industry. With its unique cutting function, it gives gypsum board precise lines and shapes, adding beauty to various interior and exterior decoration projects. This article will delve into the basic concept, use scenarios, working principles and possible applications of drywall compass knives, and show you the unique charm and value of this tool. First, the basic concept A drywall compass knife is a tool that is specifically used to cut drywall. It consists of three parts: the cutter head, the blade and the handle, and the cutter head part is equipped with a sharp blade to make precise cuts to drywall. Due to its unique structure and function, gypsum board compass knives are widely used in the decoration and construction industries. Second,Usage scenarios 1. Decoration project: In the decoration project, the gypsum board compass knife is mainly used to accurately cut the gypsum board to meet various decoration needs. For example, in decoration projects such as ceilings, walls, and floors, gypsum board compass knives need to be used to accurately cut gypsum board to ensure the quality and aesthetics of construction. 2. Construction industry: In the construction industry, gypsum board compass knives are also widely used. When constructing building structures such as walls, ceilings, and partitions, it is necessary to use gypsum board compass knives to accurately cut gypsum board to ensure the stability and aesthetics of the building structure. Third, the working principle The working principle of a gypsum board compass knife mainly relies on the blade of the head part. When the blade rotates or moves at high speed, its sharp edge can cut through the drywall. Since the angle and pressure of the blade can be adjusted, drywall compass knives can make precise cuts to drywall of various thicknesses and hardnesses. Fourth, the application value As an efficient and precise cutting tool, gypsum board compass knife has important application value in the decoration and construction industry. First of all, it improves work efficiency, reduces the tediousness and uncertainty of manual operation, and makes the process of cutting plasterboard faster and easier. Secondly, due to its precise cutting function, gypsum board compass knife can ensure the quality of construction and improve the aesthetics and stability of decoration and construction. Finally, its wide application has also promoted the progress and development of the industry, improving the productivity and competitiveness of the industry. Summary: Through the above introduction, we can see that gypsum board compass knife, as an efficient and precise cutting tool, has important application value in the decoration and construction industry. With its unique design and working principle, it has greatly improved the work efficiency and construction quality, and has become one of the indispensable tools in the modern decoration and construction industry. With the progress of science and technology and the improvement of application demand, it is believed that gypsum board compass knife will have more innovation and development in the future, and make greater contributions to the progress of the industry. #diamondpaintingtools #handtool #powertools Welcome your visit and your suggestion. OEM & ODM welcomed! www.shruili.com

0 notes

Photo

What is T-style Cutter: A line shaper with fine craftsmanship? | RuiLi T-style Cutter: A line shaper with fine craftsmanship Among the many tools, the T-shaped pusher knife has become a powerful assistant in the field of craft production with its unique design and powerful functions. The T-shaped pusher not only improves work efficiency, but also gives artists more creative space with its precision and flexibility. This article will introduce in detail the characteristics, applications and future development trends of T-type push knives, and show its important position in process production. First, the characteristics of the T-type push knife The T-Push Knife is a tool designed for precise cutting and scribing, with the following features: Stable Construction: The T-type push knife is made of a sturdy metal frame and high-quality materials for excellent stability and durability, ensuring precision and reliability for long-term use. Easy to operate: The T-type push knife has a simple design, and the user can easily master its operation skills. With a simple push action, precise line cutting or scribing tasks can be accomplished. High precision: The T-type push knife is equipped with high-precision guide rails and sliders to ensure the accuracy of cutting and scribing. This allows artists to produce more elaborate works that meet a variety of craft production needs. Versatility: The T-type pusher can be used not only for cutting and scribing, but also for engraving, grooving and other operations. By changing different blades or attachments, the T-style Cutter can be adapted to a variety of process needs. Second, the application of T-type push knife T-type push knives have a wide range of applications in the field of process manufacturing, mainly involving the following aspects: Furniture making: In the process of furniture making, T-shaped push knives are often used to cut wood, stone and other materials, mark and position, and carve various patterns and details. It helps to improve the efficiency and precision of furniture making. Model making: In the field of model making, the T-type pusher has become one of the important tools. It can quickly and accurately cut materials, draw lines, and engrave various details, making model making easier and more detailed. Artwork creation: For artists, the T-style Cutter is a powerful creative tool. It helps artists to accurately carve lines, cut images, and shape details on a variety of materials to create more beautiful works of art. Jewelry Making: In the jewelry making process, T-knives are widely used to cut, scribe, and engrave a variety of gemstones and metal materials. It helps to improve the efficiency and precision of jewelry making and meets the special requirements of the jewelry industry. Other fields: In addition to the above fields, T-type push knives are also widely used in construction, printing, packaging and other fields. With its precision and versatility, it is a must-have tool in the field of crafting. Third, the future development trend of T-type push knife With the advancement of science and technology and the development of the craft industry, the T-type push knife will usher in new opportunities and challenges in the future. The following is the future development trend of T-type push cutters: Technological innovation: In the future, the T-type pusher will continue to incorporate new technologies and innovative designs to improve its working performance and user experience. For example, intelligent control systems, high-precision sensors, etc., are adopted to improve their automation and intelligence level. Material research and development: With the application and development of new materials, the T-type push knife will face new challenges and opportunities. In the future, T-type push knives may adopt new materials that are more wear-resistant and durable to improve their service life and work efficiency. Expanded versatility: In the future, the functions of the T-type pusher will be more diversified to meet a wider range of application needs. For example, we have developed a T-type pusher with multiple functions such as engraving, drilling, and grinding to improve its adaptability and work efficiency. Personalized customization: With the continuous development of the craft production industry, the demand for personalized customization is getting higher and higher. Future T-cutters may offer more customization options to meet the individual needs and preferences of users. Welcome your visit and your suggestion. OEM & ODM welcomed! #diamondpaintingtools #powertools #handtool www.shruili.com

0 notes

Photo

What is Scriber: A precise and efficient line drawing tool? | RuiLi #diamondpaintingtools #handtool The scribe, a seemingly simple tool, plays an irreplaceable role in practical applications. With its precision and efficiency, it is widely used in various industries and fields. This article will introduce the characteristics, applications and future development trends of the line scribe in detail to show its unique value and potential in modern society. First, the characteristics of the scribe A liner is a tool used to draw a straight line or a specific trajectory. It has the following features: High accuracy: The scribe is usually designed with high-precision rails and sliders to achieve precise line positioning and drawing. This helps to ensure the quality and accuracy of the drawings, reducing the need for errors and corrections. Easy to use: The scribe has a simple structure and is easy to operate. The user only needs to adjust the line or trajectory to the appropriate position, and then gently push or pull the scribe to complete the drawing. Strong applicability: The scribe is suitable for various material surfaces, such as paper, cloth, wood board, etc. At the same time, it is also suitable for different occasions, such as drawing, making models, decorating, etc. Durable: The scribe is made of high-quality materials, which has good wear resistance and pressure resistance. After reasonable maintenance and use, it can keep it in good working condition for a long time. Second, the application of the scribe Scribers have a wide range of applications in various industries and fields, and the following are their main application scenarios: Construction & Renovation: In the field of construction and renovation, line markers are often used to draw linear, horizontal, and vertical lines, among other things. These lines are the basis for the construction of walls, floors and ceilings, and are essential to ensure the quality and aesthetics of the construction. Crafts: In the field of crafts, scribers can be used to draw patterns and lines on a variety of materials. For example, drawing cutting lines on wooden boards, drawing patterns on cloth, etc. Model Making: In the field of model making, the line scribe is one of the essential tools. It can be used to draw the shape lines of the model, cut lines, and the processing of detailed parts, etc. Office & Study: In the field of office and study, line markers can be used to make tables, draw charts, write straight lines, etc. It helps to increase productivity and focus on learning. Other fields: In addition to the above fields, line markers are also widely used in printing, packaging, advertising design, and other fields. It helps to improve production efficiency and product quality. Third, the future development trend of the scribe With the continuous progress of science and technology and the diversification of application needs, the development of line markers will also usher in new opportunities. In the future, we can expect the following development trends: Intelligent: Combine the scribe with intelligent technology to achieve automatic control and intelligent adjustment. This will greatly improve the work efficiency and accuracy, and reduce the labor intensity of users. Humanized design: Optimize the design of the scribe to make it more ergonomic and improve the comfort and convenience of use. At the same time, we develop markers suitable for different hand types to meet the needs of more users. Multi-functional: Development of line markers with various functions, such as line drawing and angle adjustment of different widths. Meet the diverse needs of users in the creative process. Environmentally-friendly materials: Use environmentally-friendly materials to manufacture line markers to reduce environmental pollution in the production process. At the same time, it advocates recycling and sustainable development, and promotes the concept of green manufacturing. #diamondpaintingtools #handtool Welcome your visit and your suggestion. OEM & ODM welcomed! www.shruili.com

0 notes

Photo

What is Mosaic pliers: the right assistant for handicrafts | RuiLi Mosaic, an artistic decorative material, requires a special tool to handle it, which is mosaic pliers. This tool not only improves work efficiency, but also provides a platform for manual artists to express their creativity. This article will introduce in detail the characteristics, applications and future development trends of mosaic pliers to demonstrate its unique value and potential in the field of handicraft art. First, Characteristics of mosaic pliers Mosaic pliers are a tool specifically designed to handle mosaic materials. It has the following characteristics: Precise operation: The jaws of the mosaic pliers are specially designed to precisely control and handle mosaic materials, whether cutting, tiling or inlaying, they can handle it with ease. High strength: The mosaic pliers are made of high-strength materials, with good durability and wear resistance, and can work stably for a long time. Comfortable Grip: The grip of the mosaic pliers is ergonomically designed, allowing craftsmen to use it comfortably for a long time and reducing hand fatigue. Strong applicability: Mosaic pliers are suitable for mosaic materials of various shapes and sizes, whether they are traditional ceramic mosaics or modern new mosaic materials, they can easily handle them. Second, Application of mosaic pliers Mosaic pliers are widely used in the field of handicraft art. The following are its main application scenarios: Home decoration: In home decoration, mosaic materials are often used for wall, floor and furniture decoration. By using mosaic pliers, artists can quickly and accurately complete mosaic cutting and tiling to create unique artistic effects. Crafts production: In crafts production, mosaic materials are favored for their unique texture and color. Using mosaic pliers, artists can cut and tile mosaics as they wish to create a variety of exquisite crafts. Church and temple decoration: In church and temple decoration, mosaic materials are widely used to make murals and decorative paintings. By using mosaic pliers, artists can precisely cut and tile mosaics to create religious works of art. Glass craft: In glass craft, mosaic materials are often used to make glass paintings and mosaic crafts. By using mosaic pliers, artists can easily manipulate glass mosaic materials to create unique works of art. Third, The future development trend of mosaic pliers With the continuous development and innovation of handicraft art, the development of mosaic pliers will also usher in new opportunities. In the future, we can expect the following development trends: Intelligent: Combining mosaic clamps with intelligent technology to achieve automatic control and intelligent adjustment. This will greatly improve work efficiency and accuracy and reduce the labor intensity of manual artists. Humanized design: Optimize the design of the mosaic pliers to make it more ergonomic and improve comfort and convenience. At the same time, mosaic pliers suitable for different hand types are developed to meet the needs of more users. Multifunctional: Develop mosaic pliers with multiple functions, such as cutting, grinding, polishing, etc., to meet the diverse needs of artists in the creative process. Environmentally friendly materials: Use environmentally friendly materials to manufacture mosaic pliers to reduce environmental pollution during the production process. At the same time, we promote recycling and sustainable development and promote the development of green art. Networking: Share mosaic art works, exchange creative experience and technical skills through the Internet platform, and promote cooperation and common progress among artists. At the same time, we use online marketing to promote mosaic art and mosaic pliers products to expand market space and business opportunities. #powertools #handtool #mosaictiles Welcome your visit and your suggestion. OEM & ODM welcomed! www.shruili.com

0 notes

Photo

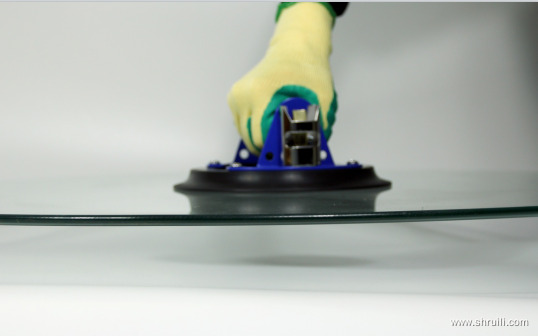

What is Vacuum Pump Glass Lifter: an exploration from principle to application? | RuiLi The vacuum suction cup, a seemingly simple tool, is actually rich in scientific principles. Its operating principle is based on vacuum technology, which achieves adsorption of various materials by creating a negative pressure environment inside the suction cup. This strong adsorption force makes vacuum suction cups have a wide range of applications in production, life and scientific experiments. First, the working principle of the vacuum suction cup The working principle of the vacuum suction cup is mainly to make use of atmospheric pressure. When the suction cup is in close contact with the adsorbed object, a negative pressure is formed inside the suction cup through a vacuum pump or vacuum generator, so that the external atmospheric pressure presses the suction cup tightly on the adsorbed object to produce adsorption force. The magnitude of this suction force depends on the size and shape of the suction cups, as well as the atmospheric and pumping pressures. Second, the application of vacuum suction cups Due to its unique adsorption capacity, vacuum suction cups have a wide range of applications in various fields. Here are some common use cases: Glass installation and maintenance: In the construction industry, vacuum suction cups are often used for the installation and maintenance of glass. By attaching the suction cups to the glass surface, they can be easily transported, positioned, and fixed, greatly improving installation efficiency. Plastic parts processing: In the plastic processing industry, because the plastic material is light and easy to deform, the use of vacuum suction cups can be easily handled and fixed, improving the processing accuracy and efficiency. Food packaging: In the field of food packaging, vacuum suction cups are often used to adsorb and move food products of various shapes, such as candy, chocolate, etc. This mode of operation is hygienic and efficient. Laboratory applications: In scientific experiments, vacuum suction cups are often used to move and fix various materials, such as glass sheets, plastic films, etc. It provides experimenters with a convenient and reliable way to manipulate experimental materials. Robotics: In the field of robotics, vacuum cups are used to perform the delicate operation and movement functions of robots. By controlling the adsorption and release of the suction cups, the robot can achieve stable grasping and precise placement of objects. Third, Advantages and disadvantages of vacuum suction cups Merit: (1) Easy operation: When using a vacuum suction cup, it only needs to be placed on the surface of the adsorbed object, and the negative pressure generated by the suction device can be adsorbed. The operation is simple and convenient. (2) Strong adaptability: The vacuum suction cup is suitable for the adsorption of various materials and surfaces, such as glass, plastic, paper, etc. It is capable of working in various environmental conditions, such as humidity, high temperatures, etc. (3) High safety: Since the adsorption force of the vacuum suction cup comes from the external atmospheric pressure, there is no risk of deformation or rupture of the object due to adsorption. Shortcoming: (1) Limiting factors: The adsorption force of the vacuum suction cup is limited by the atmospheric pressure and the size and shape of the suction cup. For some large or heavy objects, multiple suction cups or a more powerful vacuum system may be required to achieve reliable adsorption. (2) Material requirements: Some materials with rough surface or special coating may affect the adsorption effect of the vacuum suction cup. In addition, some soft materials may be deformed when adsorbed. (3) Maintenance requirements: In order to maintain good working condition, the vacuum suction cup needs to be cleaned and maintained regularly to remove surface dirt and other impurities. Conclusion As an efficient and reliable adsorption tool, vacuum suction cups play an important role in various fields. With the continuous advancement of technology and the diversification of application needs, the design and application of vacuum suction cups will be further developed and innovated. In the future, we look forward to seeing more vacuum cups with unique functions and excellent performance applied to production practices, bringing more convenience and benefits to people's lives and work. Welcome your visit and your suggestion. OEM & ODM welcomed! #handtool #powertools#bestrobotvacuum www.shruili.com

0 notes

Photo

what is Glass circle cutter: a sharp tool for cutting glass with precision? | RuiLi #handtool #diamondpaintingtools Precise cutting is essential in glass processing. As an efficient and precise glass cutting tool, glass circle cutter are widely used in many fields. This article will introduce the characteristics, applications and future development trends of glass circle cutter in detail to show their unique value and potential in the field of glass processing. First, the characteristics of glass circle cutter A glass circle cutter is a tool specifically designed for cutting glass, which combines the dual functions of a compass and a blade. The best feature of this tool is its high precision and high efficiency. The blade of the glass circle cutter is made of high-quality materials with extreme hardness and sharpness, allowing it to easily cut through glass surfaces for precise cuts. In addition, glass circle cutter have the following characteristics: Easy to operate: When using a glass circle cutter, simply place the blade against the glass surface and turn the compass section to complete the cut. The operation is simple and easy to understand, which saves a lot of time and manpower. Wide range of applications: Glass circle cutter are suitable for glass cutting of various thicknesses and materials, whether architectural glass, furniture glass or art glass. High precision: Due to the special design and material of the glass circle cutter, it is able to achieve high-precision cutting, and the cutting edge is smooth and neat, which improves the quality and aesthetics of the product. Durability: The blade of the glass circle cutter is specially treated for a long service life. In addition, proper use and care can also extend its service life. Second, the application of glass circle cutter Glass circle cutter are widely used in many fields. The following are its main application areas: Construction industry: In the construction field, glass circle cutter are mainly used for the installation and processing of architectural glass. By using glass circle cutter, architects and installers can quickly and accurately cut glass of various shapes and sizes, improving installation efficiency and aesthetics. Furniture industry: In the field of furniture manufacturing, glass circle cutter have become an indispensable tool. It is able to precisely cut glass tabletops, baffles and other components, making furniture more beautiful and functional. The field of art: For artists and craftsmen, a glass circle cutter is an ideal tool. They can use glass circle cutter to create a variety of unique works of art and decorations, showing limitless creativity and imagination. Scientific research: In scientific experiments, it is sometimes necessary to precisely cut glassware of various shapes and sizes. Glass circle cutter excel in this type of application and provide great convenience for researchers. Third, the future development trend of glass circle cutter With the progress of science and technology and the change of market demand, the development of glass circle cutter will develop in the direction of more efficient and intelligent. In the future, we can expect the following development trends: High performance: Further increase the cutting speed and efficiency of glass circle cutter by improving materials and design to meet growing production demands. Intelligent: Combine glass circle cutter with intelligent technology to achieve automatic cutting and intelligent monitoring. This will greatly improve production efficiency and cutting accuracy, and reduce human error. Versatility: Develop glass circle cutter with a variety of functions, such as adjustable size, rotatable angle, etc., to meet the cutting needs of different fields. Environmentally friendly materials: Use environmentally friendly materials to manufacture glass circle cutter to reduce environmental pollution in the production process. At the same time, it advocates recycling and sustainable development, and promotes the development of green manufacturing. Humanized design: Optimize the design of the glass circle cutter to make it more ergonomic and improve the comfort and convenience of operation. Conclusion In summary, glass compass knives, as an efficient and precise glass cutting tool, play an important role in many fields. With the continuous progress of technology and the continuous change of market demand, we believe that glass compass knives will continue to develop and innovate to bring more convenience and development opportunities to the glass processing industry. Welcome your visit and your suggestion. OEM & ODM welcomed! #handtool #diamondpaintingtools www.shruili.com

0 notes

Photo

what is Diamond glass cutter: an epoch-making cutting tool? | RuiLi #diamondpaintingtools #handtool Diamond glass cutter: an epoch-making cutting tool In the field of glass processing, diamond glass cutter are known as epoch-making cutting tools due to their excellent cutting performance and excellent durability. Its emergence has brought revolutionary changes to the glass processing industry, greatly improving production efficiency and cutting accuracy. This article will delve into the characteristics, applications, and future development trends of diamond glass cutter. First, the characteristics of diamond glass cutter Diamond glass cutter are mainly made of a mixture of diamond particles and metal powders, which are sintered at high temperature and high pressure. Diamond is the hardest substance in nature and can easily cut through glass surfaces for high-precision cutting. Diamond glass cutter have the following advantages: High cutting accuracy: The hardness of diamond is extremely high, which can ensure the accuracy and consistency of glass cutting and reduce errors. Fast cutting speed: Due to the high hardness and sharpness of diamond, the speed of cutting glass is greatly improved, thus improving production efficiency. Durability: Diamond is extremely thermally and chemically stable, allowing it to maintain stable cutting performance in a wide range of environments. No damage to glass: Compared with traditional glass cutting tools, diamond glass cutter will not leave scratches or damage on the cutting surface, maintaining the beauty and integrity of the glass. Second, the application of diamond glass cutter Diamond glass cutter are widely used in the processing and manufacturing of various glass products, especially in the high-end market and precision manufacturing fields. The following are the main application areas of diamond glass cutter: Optical glass processing: In the manufacture of optical instruments, the cutting accuracy of optical glass is extremely high. Diamond glass cutter are the tool of choice for optical glass cutting due to their ultra-high hardness and precision. Liquid crystal display panel manufacturing: In the production process of liquid crystal display panels, high-precision cutting tools are required to complete the cutting of glass substrates. Diamond glass cutter have become an indispensable tool in the field of liquid crystal panel manufacturing due to their excellent performance. Architectural glazing: In the construction industry, the installation of glass requires precise cutting. Diamond glass cutter can quickly and accurately complete glass cutting of various shapes and sizes, improving installation efficiency and aesthetics. Artwork and decorative glass production: For some high-end artwork and decorative glass processing, a delicate cutting process is required. Diamond glass cutter meet the high demands of artists and craftsmen for cutting precision. Third, the future development trend of diamond glass cutter With the progress of science and technology and the change of market demand, the future development of diamond glass cutter will develop in the direction of more efficient, more environmentally friendly and more intelligent. First of all, the performance and life of diamond glass cutter can be further improved by improving the preparation process and technical parameters. Secondly, the development of new coatings and composites will help improve the cutting capacity and wear resistance of tools to meet changing market demands. In addition, with the popularization of intelligent and automation technology, diamond glass cutter will be combined with robot technology to achieve automatic cutting and intelligent monitoring, and improve production efficiency and precision. Conclusion As an epoch-making cutting tool, diamond glass cutter have played and will continue to play an important role in the glass processing industry. Its superior cutting performance and superior durability have brought great changes and advancements to the industry. Through continuous innovation and development, it is believed that diamond glass cutter will show more excellent performance and application prospects in the future, and create a better life and development space for human beings. Welcome your visit and your suggestion.OEM & ODM welcomed! #diamondpaintingtools #handtool www.shruili.com

0 notes

Photo

what is Tungsten carbide scoring wheels: the key to improving the cutting process? | RuiLi #sawcuttingmachine #siliconcarbideformula #powertools #handtool Tungsten carbide scoring wheels: the key to improving the cutting process In modern industry, tungsten carbide scoring wheels are a key factor in improving the cutting process due to their unique physical and mechanical properties. With its high hardness, high wear resistance and high thermal stability, it is widely used in various complex and difficult cutting operations. This article will delve into the characteristics, applications and future development trends of tungsten carbide scoring wheels. First, the characteristics of cemented carbide scoring wheel: Tungsten carbide scoring wheel is an alloy made of tungsten carbide (WC) and cobalt (Co) as the main components through powder metallurgy process. It has excellent properties such as high hardness, high wear resistance, high thermal stability and good compressive strength. These characteristics make the carbide scoring wheel maintain excellent cutting performance under the conditions of high speed, high temperature and high load, which greatly improves the cutting efficiency and accuracy. Second, the application of cemented carbide scoring wheel: Tungsten carbide scoring wheels have a wide range of applications, mainly concentrated in industries that require high precision, such as metal processing, glass processing, stone processing, etc. In the field of metal processing, tungsten carbide cutter wheels are used in milling, turning, drilling and other operations, and their high hardness and high wear resistance ensure the long-term retention of the cutting edge, improving machining efficiency and workpiece quality. In glass processing, tungsten carbide scoring wheels are used for cutting, grinding and polishing, and their high thermal stability and compressive strength prevent overheating and cracking of the scoring wheels during high-speed rotation. In the field of stone processing, tungsten carbide scoring wheels also excel and are able to complete tasks such as cutting, grinding and polishing efficiently. Third, the future development trend of cemented carbide scoring wheels: With the continuous development of science and technology, tungsten carbide scoring wheels will develop in the direction of more efficient, more durable and more environmentally friendly in the future. First of all, by optimizing the composition of the carbide material and the production process, the performance and service life of the scoring wheel can be improved. Secondly, the research and development and application of new coating technologies, such as nano coating, diamond coating, etc., can further improve the wear resistance and cutting efficiency of the scoring wheel. In addition, with the popularization of the concept of green environmental protection, environmentally friendly cemented carbide scoring wheels will also be more widely used and developed. Conclusion: As a high-performance cutting tool, tungsten carbide scoring wheels will continue to play an important role in industrial production in the future. Through continuous improvement and innovation, it is believed that tungsten carbide scoring wheels will achieve more outstanding achievements in the cutting process and provide strong support for the progress of industrial production. #sawcuttingmachine #siliconcarbideformula #powertools #handtool OEM & ODM welcomed! www.shruili.com

0 notes