winroller motorized roller/drum motor/conveyor roller manufacturer

Don't wanna be here? Send us removal request.

Text

Experience the future of logistics and automation with Winroller's gearless motor roller series! Our sorting wheels are ideal for high-speed sorting and precise item redirection. With a lightning-fast response time of 0.1 seconds and impressive sorting efficiency of up to 4,000 items per hour, our gearless technology ensures smooth, reliable performance, even with loads of up to 120kg.

Available in 50mm and 67mm diameters, the sorting wheels can be rubber-coated to increase friction, perfect for industrial automation and express logistics applications. Powered by a 48V supply, these rollers offer optimized performance and efficiency, making them a top choice for companies looking to boost operational productivity.

Ready to transform your sorting process?

Learn more at www.drum-roller.com.

We Move, You Win — Tailored to Your Needs, Focused on Your Success!

0 notes

Text

win the world

Winroller motor rollers are the ultimate solution for your conveyor system needs!

www.drum-roller.com

Our motor rollers are available with a variety of linkage options, including poly-V, sprocket, O groove, and more. These linkages offer precise power transmission and reliable performance, ensuring that your products move smoothly and efficiently along the conveyor line.

Poly-V belt wheel is widely used in industrial transmission, with 9 groove standard and PJ belt, max dragging 200kg.

The sprocket wheel is most used in heavy pallet transmission, which can drag 3000KG max.

With Winroller motor rollers, you can trust that your material handling needs are in good hands.

Contact us today to learn more!

Whatapp:+86 18168399322

Email:[email protected]

1 note

·

View note

Text

Halloween supernatural event

As the full moon rises on Halloween night, the motorized roller in the WINROLLER factory begins to stir. Its metallic frame creaks and groans as it comes to life, its powerful motor humming with energy. The roller's smooth, cylindrical surface starts to spin, faster and faster, until it's a blur of motion. Suddenly, a ghostly figure appears beside it, hovering in the air. The ghostly figure cackles with glee as it rides the motorized roller like a witch on her broomstick. The roller speeds up even more, hurtling through the factory with the ghostly figure clinging on tight. As the roller spins out of control, sparks fly and machinery rattles. But the ghostly figure just laughs and laughs, enjoying the wild ride through the factory on this spooky Halloween night. Finally, as the clock strikes midnight, the motorized roller comes to a stop. The ghostly figure disappears into thin air, leaving the roller silent and still once more. But those who work in the factory know that on #Halloween night, the motorized roller comes alive, ready to take anyone brave enough to ride it on a hair-raising adventure. ^^

1 note

·

View note

Text

SPS invitation

Dear everyone,

We are excited to announce that we will be taking part in the upcoming Smart Production Solutions (#sps ) exhibition in #nuremberg, #germany in 2023. Our booth number is 3-465.

We would like to invite you to visit our booth and discover our latest products and solutions. Our team will be available to answer any questions and provide you with more information about our company.

The SPS exhibition is an excellent opportunity to network with #industry professionals and learn about the latest developments in electric automation systems and components.

We hope to see you there!

Click www.drum-roller.com for more product information.

Contact Simon by WhatsApp at 181 6839 9322

1 note

·

View note

Text

Happy Mid-Autumn Festival!#中秋节

The Mid-Autumn #Festival, a traditional Chinese festival, is coming. It is a time of reunion and harvest.

As a global enterprise, we are increasingly in sync with the world in the field of production #automation. On this holiday, we wish all Chinese people in the world a happy holiday and wish the mainland compatriots, overseas Chinese, Hong Kong, Macao and Taiwan compatriots reunion and well-being. We wish the international friends who have cared and helped us for a long time the same happiness, happiness and success in their careers.

In the future, we will continue to develop and promote new #motorized rollers to meet the needs of the international production automation field, help automation #solutions, and provide continuous #intelligent motor drive roller technical support in industrial automation, express #transportation and #sorting, food processing, #warehousing and #logistics, #airport security and other fields. At the same time, welcome the majority of overseas businesses to negotiate cooperation, we will provide our technology and experience free of charge, through the strong union, to seek the localized development of the winning brand roller.

At the same time, we would like to inform you of our holiday schedule:

9.28 Working

9.29 Holiday

9.30 Holiday

10.1 Holiday

10.2 Holiday

10.3 Holiday

10.4 Working

Holiday hotline by whatsapp 181 68399322. Email:[email protected].

Happy Mid-Autumn Festival.

#mid autumn festival#roller#automation#conveyor#conveyor roller#drum motor#motor roller#motorized roller

1 note

·

View note

Text

How many kinds of linkage types are there for WINROLLER motorized roller?

There are two main linkage types for motorized rollers: chain-driven and belt-driven. Learn from www.drum-roller.com

1. A chain-driven motorized roller is a type of motorized roller that utilizes a chain to transmit power from the motor to the roller. The chain is typically wrapped around sprockets on the motor and roller shafts, allowing the rotational motion of the motor to be transferred to the roller. This type of linkage provides a reliable and efficient means of power transmission in motorized roller systems. Chain-driven motorized rollers are commonly used in various conveyor systems and industrial applications.#chain#roller

2. A belt-driven motorized roller is a type of motorized roller that uses a belt to transmit power from the motor to the roller. The belt is typically made of rubber or other flexible materials and is wrapped around pulleys on the motor and roller shafts. As the motor rotates, the belt transfers the rotational motion to the roller, causing it to turn. Belt-driven motorized rollers are often used in conveyor systems and other industrial applications where a smooth and quiet operation is required. They are also known for their energy efficiency and low maintenance requirements.#belt

3. What are the advantages of chain-driven motorized rollers?

High durability: Chain-driven motorized rollers are known for their durability and long service life. They are designed to withstand heavy loads and harsh operating conditions.

High torque: Chain-driven rollers can handle high torque loads, making them suitable for applications that require high starting and stopping forces.

Easy maintenance: Chain-driven rollers are easy to maintain and repair. Chains can be easily replaced if they become worn or damaged.

Precise speed control: Chain-driven rollers provide precise speed control, which is important in applications where accurate positioning is required.

Cost-effective: Chain-driven rollers are often less expensive than other types of motorized rollers, making them a cost-effective choice for many applications.

4. What are the advantages of belt-driven motorized rollers?

Smooth and quiet operation: Belt-driven motorized rollers operate smoothly and quietly, making them ideal for applications where noise levels need to be kept low.

Energy-efficient: Belt-driven rollers are highly energy-efficient, as they require less power to operate compared to other types of motorized rollers.#automatic

Low maintenance: Belt-driven rollers require minimal maintenance, as there are no chains that need to be lubricated or adjusted.

High speed capability: Belt-driven rollers can achieve high speeds, making them suitable for applications that require fast conveyor speeds.#conveyor

Cost-effective: Belt-driven rollers are often less expensive than other types of motorized rollers, making them a cost-effective choice for many applications.#motorized

Learn more from Winroller Simon by Whatsapp:+86 181 6839 9322

Email:[email protected]

0 notes

Text

WINROLLER drum motor help food safety!

Food safety is extremely important for people's health and well-being. The transportation process directly affects the hygiene and safety of food during production. Therefore, it is necessary to create a food safety transportation system that can be controlled and traced from the source. www.drum-roller.com

Focusing on the pain points of food processing (food safety difficulties, pain points, and bottlenecks)

Bacterial contamination is a long-standing problem in the food processing industry. Serious consequences can occur if it is not handled properly. In spot checks of cooked meat products, pastries, ice cream, and other products, exceeding the microbiological limit is the main reason for product disqualification. Total bacterial count exceeding the standard exists in many links such as production, storage, transportation, and sales. Secondary pollution during transportation has many uncontrollable factors and has become a major threat to the healthy development of enterprises and industries.

In terms of cold chain transportation: if the cold chain link is broken, it will seriously affect the quality of products, especially dairy products. If they are not stored in a low-temperature environment, bacteria will begin to multiply in large quantities, which can easily lead to food safety accidents.

In terms of residue: food processing enterprises in the product production process, processing equipment and transportation equipment cleaning is very important. The conveying equipment will produce some sediment after use, and it must be cleaned out after the completion of the operation to reduce the risk of microbial contamination, and then cleaned and disinfected, otherwise it is easy to cause mildew.

In terms of traditional gear motor: The traditional gear motor drive system is not only the gear motor itself, it also contains at least one shaft, multiple bearings and a frame or at least one anti-rotation device for supporting the gear motor. The traditional gear motor has obvious shortcomings such as easy rust, unsanitary, difficult to disassemble, and need maintenance, which can easily lead to dirt accumulation and cross-contamination during operation, seriously endangering food safety.

Precise force to promote high-quality production (keep the safety of the consumer's tongue)

To address these issues, WINROLLER has launched a series of all-stainless steel high-performance oil-cooled drum motors, which can achieve safe and controllable automated intelligent transportation of food and provide precise assistance to enterprises for high-quality production, safeguarding the safety of people's food.

Passed the authoritative CE safety certification

CE certification is the mandatory conformity mark of the European Union, which is used to identify whether products sold in the European Union comply with the legal directives on consumer safety, health and environmental health formulated by the European Union. Under its certification, users can rest assured that the products they choose are in compliance with health standards.

Meet cold chain transportation requirements

Different from the traditional cold chain loading and unloading operations, the investment of the electric roller has greatly improved the timeliness of each link of the cold chain logistics. In order to ensure good product performance even in the deep freeze environment, the WINROLLER is equipped with oil-cooled drum motor that can operate at minus 30 degrees Celsius. The oil-cooled drum motor has the characteristics of high strength, low temperature resistance, millisecond level dynamic response, etc., which can effectively reduce cargo damage during cold chain transportation. Let customers in the face of "cold chain logistics", can be more flexible, no longer "difficult"!

Efficient cleaning, farewell to microbial residues

Different from the traditional motor drive system, the motorized roller assemses all the external components in a cylinder body to form a simple drive unit, the integrated design makes the installation and disassembly more convenient, the pure sealed design is easier to clean, and the maintenance cost is very low. The special food-grade conveyor belt can meet the requirements of food, pharmaceutical, daily chemical and other industries. In addition to having the characteristics of high tensile strength, good bending, thin and tough, it can also meet the requirements of oil resistance, non-toxic health, easy cleaning and so on. By adopting all stainless steel electric roller food-grade belt conveyor, the whole process of food transportation from raw materials to finished products is safe and controllable.

WINROLLER motorized roller adopts high-quality materials and advanced manufacturing technology, which can ensure stable operation under various harsh working conditions, and its strong carrying capacity meets the needs of various heavy loads and high-speed operation, and has the characteristics of safety, reliability, easy maintenance, etc., which can greatly improve the production efficiency of food production line. As the core supplier of transmission equipment, we will continue to introduce more efficient, safer and smarter products to protect your food production safety.

whatsapp:86 18168399322

1 note

·

View note

Text

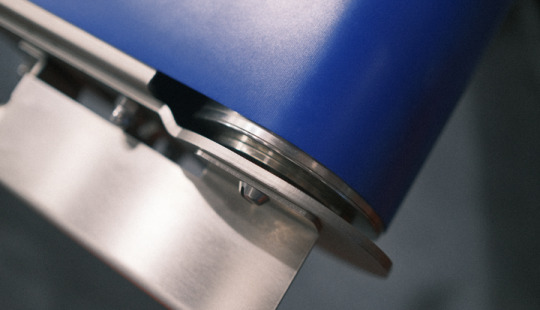

When choosing a WINROLLER cone motorized roller, there are some additional factors to consider besides Load capacity/Speed/Durability/Noise level/Ease of maintenance/Compatibility:

Cone angle: The angle of the cone should be selected based on the specific application and the characteristics of the products or materials being transported. A steeper cone angle may be better for smaller products, while a shallower angle may be better for larger products.

Surface material: The surface of the cone should be made of a material that provides sufficient friction to prevent slipping and ensure proper product movement. The material should also be durable and resistant to wear and tear.

Shaft design: The shaft of the roller should be designed to provide sufficient torque and power to move the products or materials, while also being compatible with the drive system of the conveyor.

Bearings: The bearings used in the roller should be high-quality and designed to withstand the load and speed requirements of the conveyor system.

Sealing: The roller should be properly sealed to prevent contamination and damage to internal components.

Considering these factors will help ensure that the WINROLLER cone motorized roller is optimized for your specific application and will provide reliable performance over time.

www.drum-roller.com

Whatsapp:+86 181 6839 9322

Email:[email protected]

0 notes

Text

PTC invitation

Invitation to PTC Asia - Explore the Future of Power Transmission and Control Technology #PTC #controller

www.drum-roller.com

WINROLLER are delighted to extend our invitation to you as a valued member of the power transmission industry to join us at PTC Asia, the premier international trade fair for power transmission and control technology. As a leading motorized roller manufacturer, we believe that your presence at this esteemed event will be invaluable.#roller

Event Details:

Date: 24th~27th,OCT.

Venue: Shanghai New International Expo Centre, Shanghai, China

Booth: W3-B5-1

PTC Asia serves as a global platform for industry professionals, manufacturers, and buyers to showcase their latest innovations, exchange ideas, and explore business opportunities. By attending PTC Asia, you will have the opportunity to:

Discover Cutting-Edge Technology: Gain insights into the latest advancements in power transmission and control technology, including motorized roller solutions that can revolutionize your operations.

Expand Your Network: Connect with industry experts, potential buyers, distributors, and partners from around the world. Forge valuable relationships and explore collaborations that can drive your business forward.

Stay Ahead of Industry Trends: Attend informative seminars and conferences to stay updated on emerging trends, challenges, and opportunities in the power transmission industry.

Showcase Your Brand: Showcase your own products and technologies to a highly targeted audience. Demonstrate your expertise and establish your brand as a leader in the field of motorized rollers.#smart

WINROLLER would be honored to have you visit our booth at PTC Asia. Our team will be available to provide detailed information about our motorized roller solutions and how they can enhance your business operations.#automation

To secure your place at PTC Asia, please contact us online at www.drum-roller.com. We recommend registering early to ensure your spot and take advantage of all the event has to offer.

WINROLLER look forward to welcoming you at PTC Asia and exploring the future of power transmission and control technology together. Should you have any questions or require further information, please do not hesitate to contact us.#conveyor

Simon Liu

whatsapp:+86 181 6839 9322

email:[email protected]

0 notes

Text

What are the advantages and disadvantages of built-in and external motorized rollers?

What are the advantages and disadvantages of built-in and external motorized rollers? www.drum-roller.com

WINROLLER build-in motorized roller.

Advantages:

Space-saving design

Easy to install and maintain

High torque output

Low noise level

Disadvantages:

Limited load capacity

Higher cost compared to external motor

External Motor Roller.

Advantages:

Higher load capacity

Lower cost compared to build-in motor motorized roller

Easy to replace the motor

Disadvantages:

Requires more space for installation

More complex installation process

Higher noise level

Can the built-in motorized roller replace the external motorized roller completely in the feature?

It is possible for the built-in motorized roller to replace the external motorized roller completely in the future. However, this will depend on the specific application and the load capacity requirements. Build-in motorized rollers are generally more compact and easier to install, but they may not be suitable for heavy-duty applications that require high load capacity. Additionally, external motorized rollers may offer more flexibility in terms of motor replacement and customization.

But apparent the advantages of build-in motor motorized rollers can provide several benefits to industries, including:

Space-saving design: The compact design of built-in motor motorized rollers can help industries save valuable floor space, making it easier to optimize production lines and increase throughput.

Easy installation and maintenance: Build-in motor motorized rollers are generally easier to install and maintain than external motorized rollers. This can help industries reduce downtime and maintenance costs.

High torque output: Build-in motor motorized rollers can provide high torque output, making them suitable for a wide range of applications, including heavy-duty conveying and material handling.

Low noise level: Build-in motor motorized rollers are typically quieter than external motorized rollers, which can help improve working conditions for employees.

Overall, the advantages of build-in motor motorized rollers can help industries improve efficiency, reduce costs, and enhance the safety and comfort of their work environment.

Welcome to discuss by email: [email protected]

whatsapp:+86 181 6839 9322

1 note

·

View note

Text

What technical problems should be paid attention to when the WINROLLER motorized roller is used for the belt conveyor? www.drum-roller.com When using a motorized roller for a belt conveyor, some technical problems that should be paid attention to include:

Overloading: The motorized roller should not be overloaded beyond its capacity, as it can cause damage to the roller and the conveyor system.

Belt tension: The belt tension should be properly adjusted to ensure that it is not too loose or too tight, which can cause the motorized roller to malfunction.

Alignment: The motorized roller should be properly aligned with the belt to prevent any unnecessary wear and tear on the roller and the belt.

Lubrication: Regular lubrication of the motorized roller is important to ensure smooth operation and prevent premature wear.

Electrical connections: The electrical connections to the motorized roller should be checked regularly to ensure that they are secure and functioning properly.

By paying attention to these technical issues, you can ensure that your motorized roller operates efficiently and effectively in your belt conveyor system.#roller #conveyor #belt #motor #motorized

If you want to know more, pls contact Simon Liu, Whatsapp:+86 181 6839 9322 Email:[email protected]

1 note

·

View note

Text

Current trends in the Winroller motorized roller: www.drum-roller.com Energy efficiency and sustainability: There is a growing demand for energy-efficient and sustainable solutions in the motorized roller industry. Winroller are developing more efficient motors and incorporating regenerative braking systems to reduce energy consumption and increase sustainability.

Advanced technologies: The incorporation of advanced technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI) is becoming increasingly common in the motorized roller industry. These technologies can be used to improve control and monitoring of conveyor systems, optimize performance, and reduce downtime.

Automated material handling systems: The adoption of automated material handling systems is growing rapidly in various industries, including manufacturing, logistics, and warehousing. Winroller motorized rollers are a critical component of these systems, providing efficient and reliable transportation of goods.

Modular and flexible conveyor systems: Modular and flexible conveyor systems are becoming more popular in the motorized roller industry. These systems allow for easy customization and reconfiguration of conveyor lines to meet changing production needs.

Overall, our Winroller brand focuses on developing innovative solutions that improve efficiency, sustainability, and flexibility while incorporating advanced technologies to enhance performance and control.

0 notes

Text

WINROLLER motorized roller application over the worlds

Winroller motorized rollers have a wide range of applications in various industries, particularly in automation. Winroller motorized rollers, also known as powered rollers or motor rollers, are used to facilitate movement, conveyance, and automation of materials and products. Here are some common applications of motorized rollers in automation industries:

1.Conveyor Systems: Motorized rollers are extensively used in conveyor systems for material handling and transportation within manufacturing plants, distribution centers, warehouses, and airports. They enable efficient movement of goods along the conveyor lines, allowing automation of processes like sorting, packing, and loading.#conveyor

2.Assembly Lines: In manufacturing industries, motorized rollers are employed in assembly lines to move products between workstations or stations where different components are added to create finished products. They ensure a steady and controlled movement of items along the assembly process.#automation

3.Packaging and Labeling: Motorized rollers are used in packaging lines to transport products to packaging stations, where they are wrapped, boxed, or labeled. This enhances the speed and accuracy of the packaging process.#machine

4.Automated Storage and Retrieval Systems (AS/RS): Motorized rollers are integrated into AS/RS systems to move items in and out of storage locations automatically. These systems are commonly used in high-density warehouses to optimize space and improve efficiency.#AS#FIFO

5.Sortation Systems: Motorized rollers play a crucial role in sortation systems where products need to be diverted to specific paths based on their destinations. This is commonly seen in distribution centers and e-commerce fulfillment centers.#sortation

6.Airport Baggage Handling: In airports, motorized rollers are used to move baggage and cargo efficiently between check-in, security screening, and loading areas.#airport

7.Food and Beverage Processing: Motorized rollers are utilized in food and beverage industries for processes such as bottling, canning, and packaging, ensuring products move smoothly through different stages of production. #roller

8.E-commerce Fulfillment: In the booming e-commerce sector, motorized rollers are used to automate order fulfillment, enabling faster and accurate processing of online orders.#Ecommerce

9.Automated Guided Vehicles (AGVs): Motorized rollers are integrated into AGVs, which are mobile robots used for material transport within factories and warehouses.#AGV

10. Pharmaceutical and Healthcare: Motorized rollers aid in automating processes in pharmaceutical manufacturing, allowing efficient movement of medications and products through various stages. #mediciation

The versatility of motorized rollers makes them an integral component of automation solutions, improving efficiency, reducing manual labor, and ensuring smoother material flow in various industries.

1 note

·

View note